Consume less power for more aggressive Aluminum / ISO-N machining with upgraded solid carbide end mills

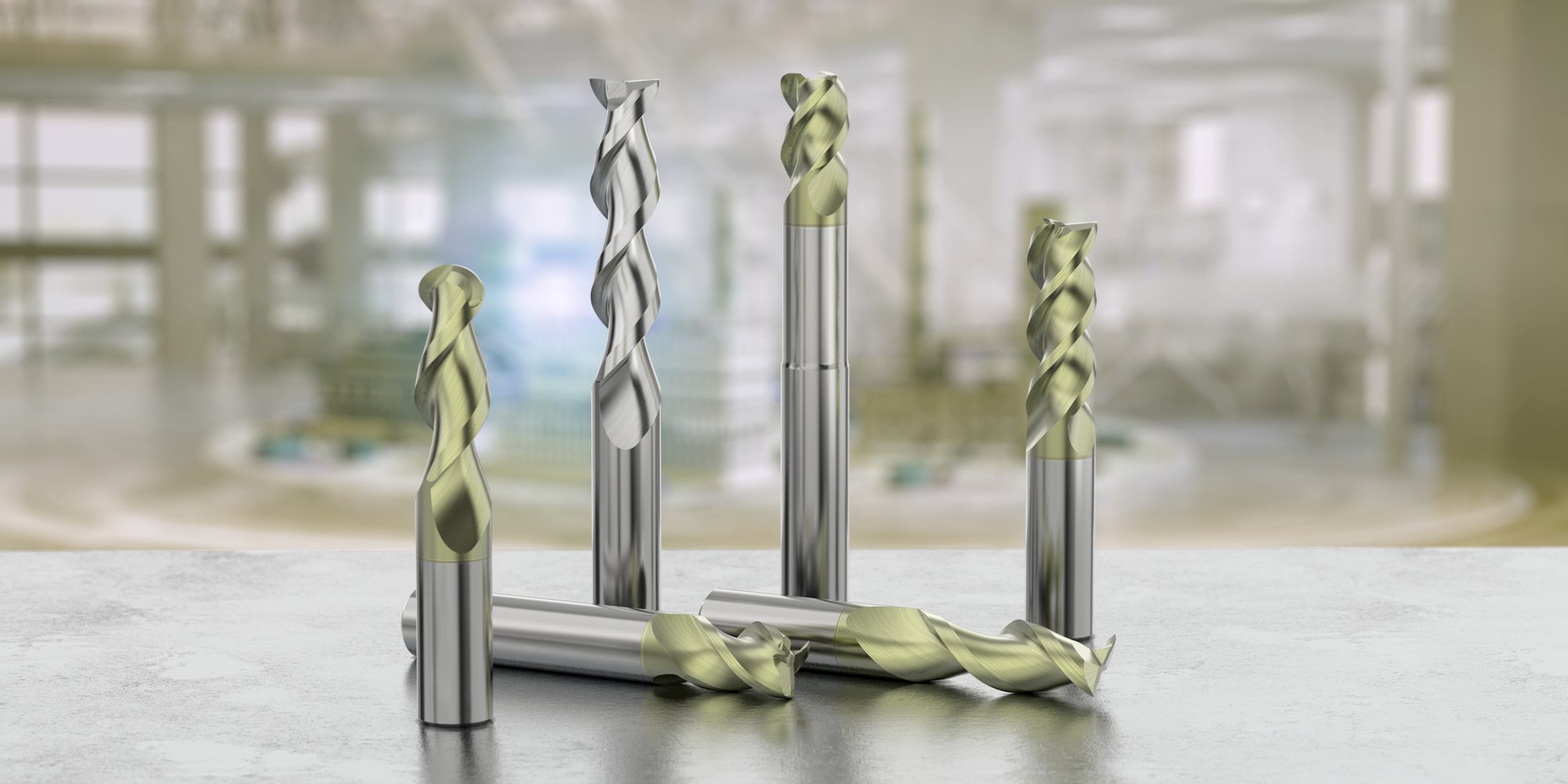

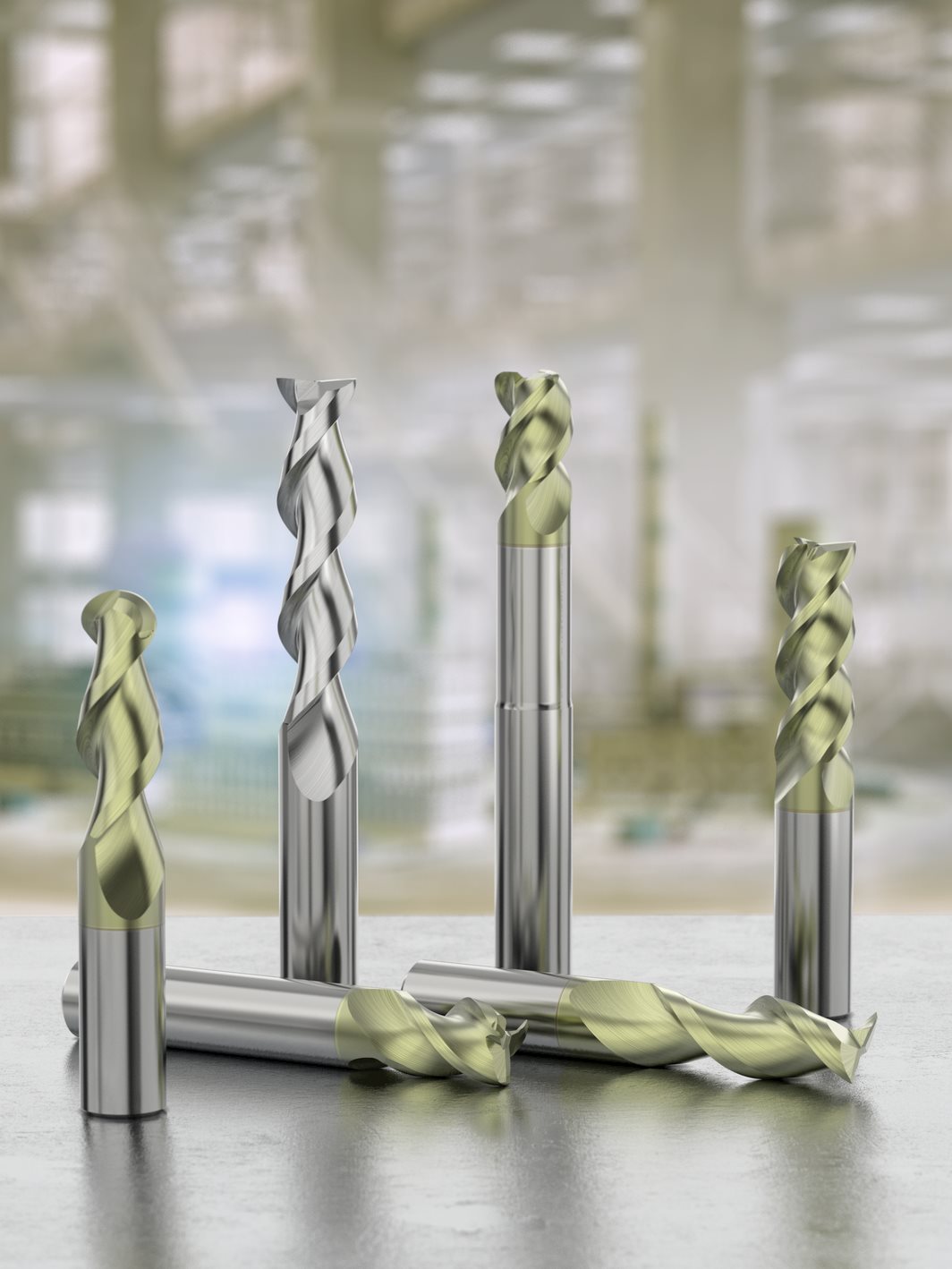

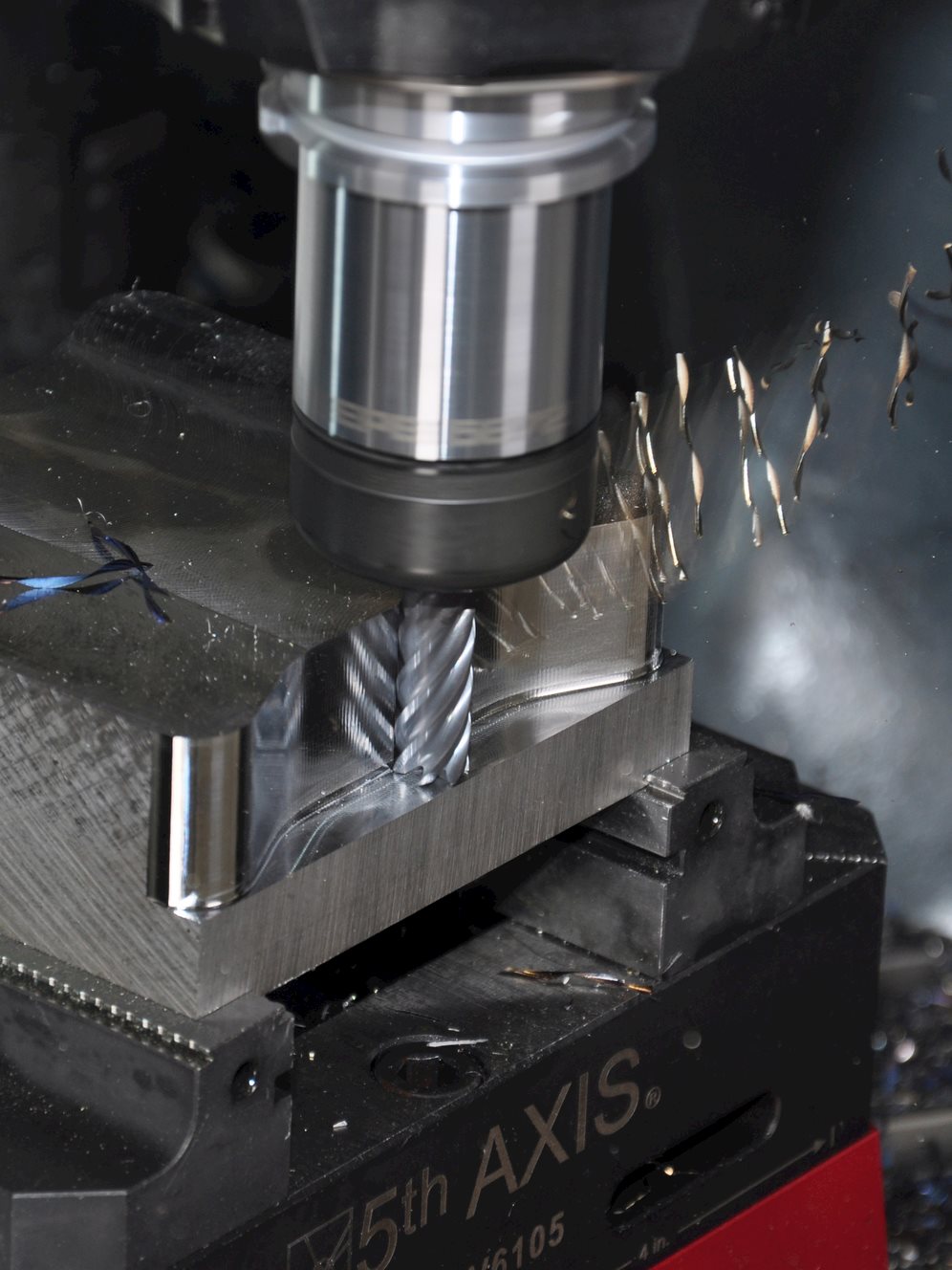

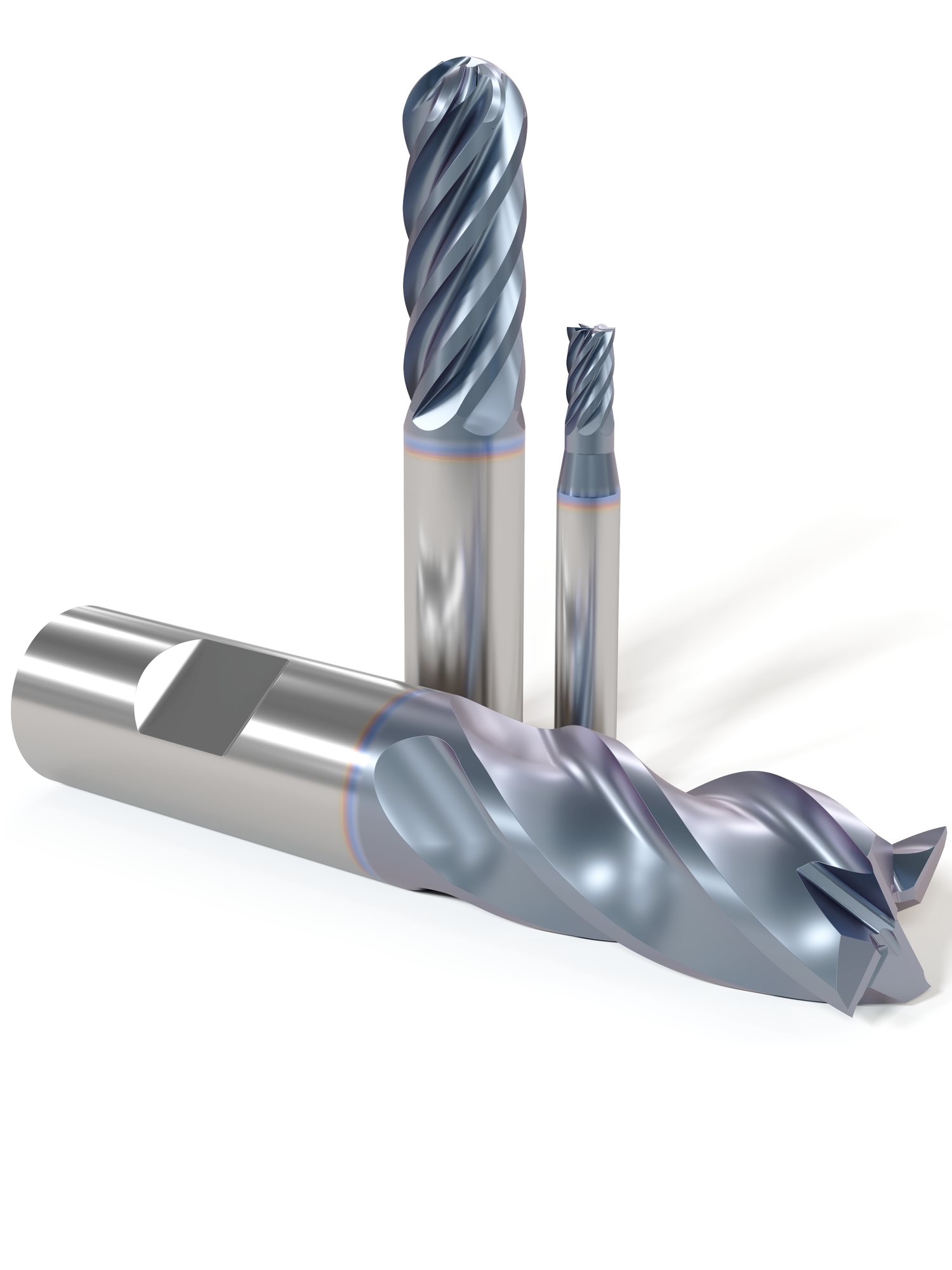

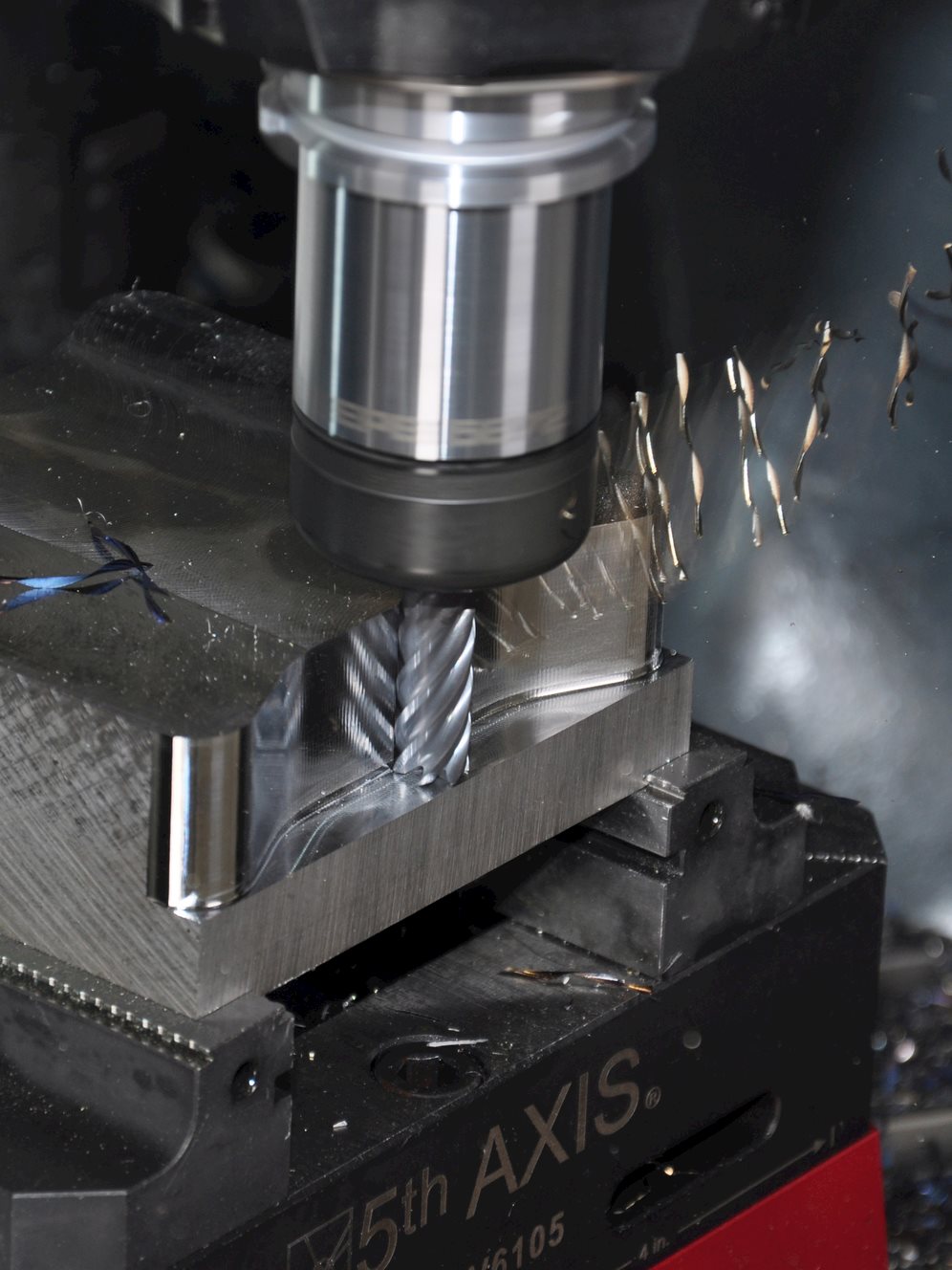

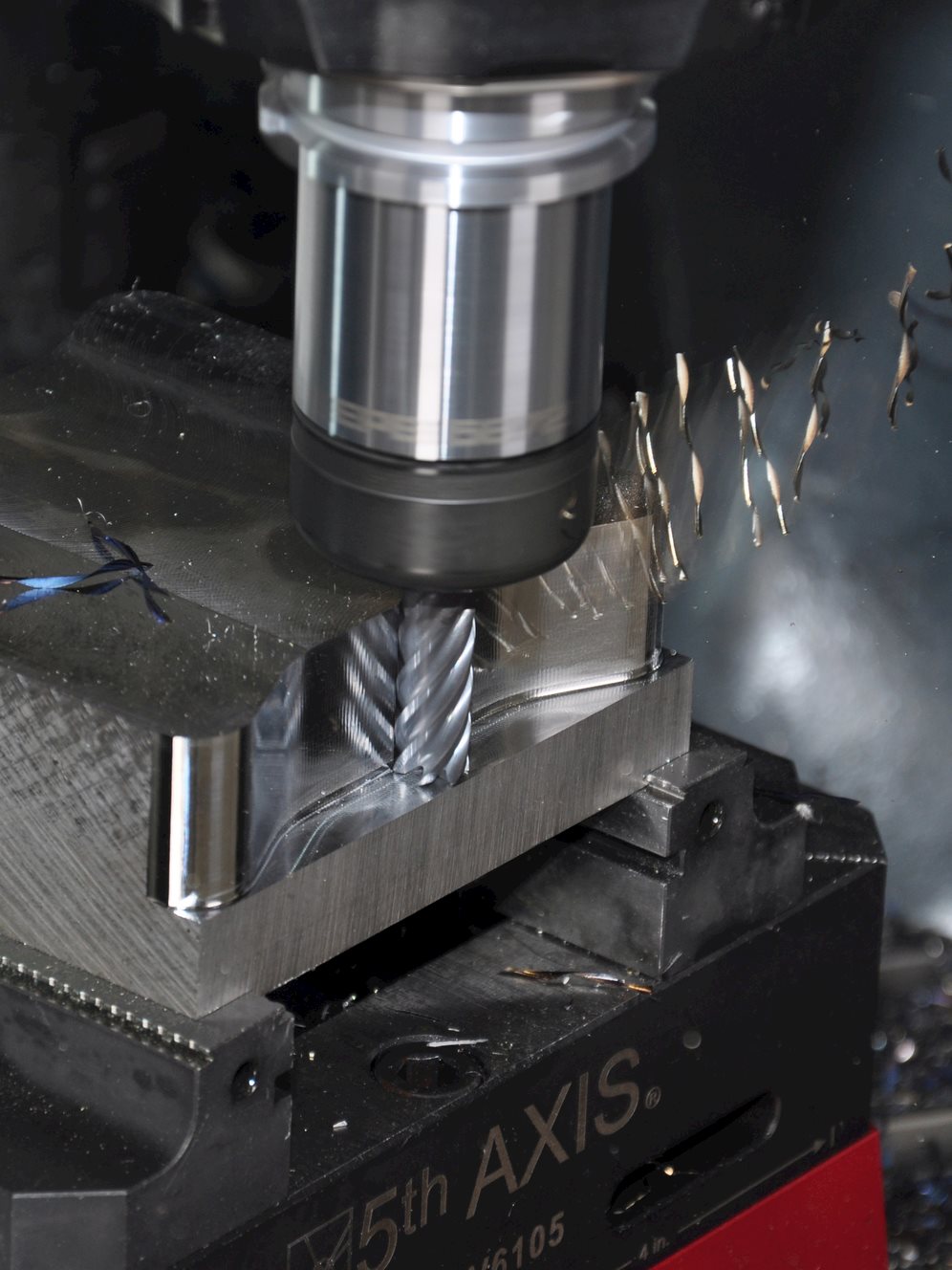

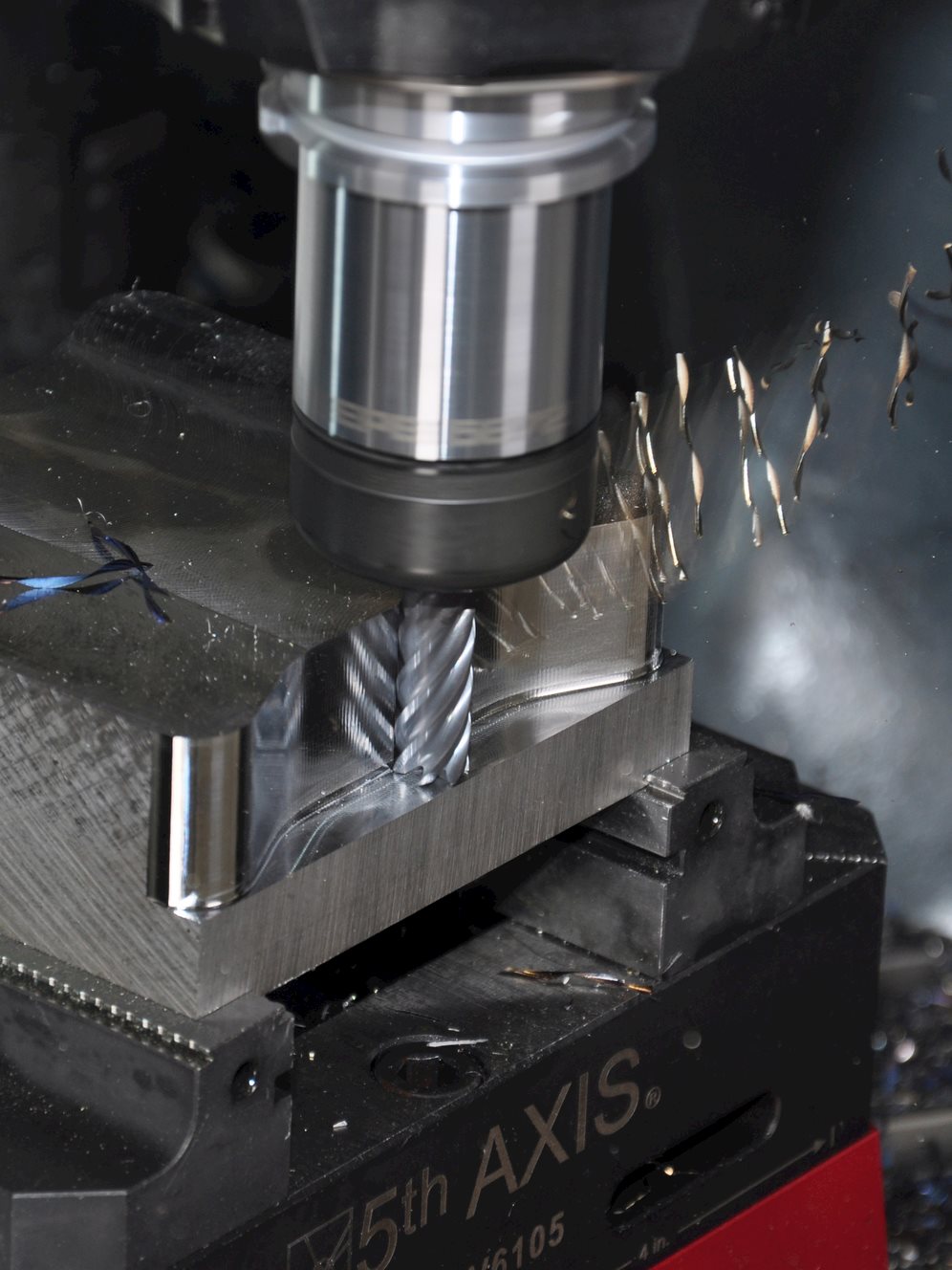

Achieve optimal removal rates and tool life for Aluminium / ISO-N machining Milling non-ferrous materials like aluminum, brass, copper and other ISO-N materials allows manufacturers to push their machines to the limit and achieve the highest metal removal rates (MRR). Push past those limits and achieve higher MRR in ISO-N materials – even with older and less rigid machines – with the upgraded family of A245/A345 solid carbide end mills from For increased tool life and the best workpiece finishes, has developed a proprietary ANF (aluminum non-ferrous) PVD coating designed to minimize built-up edge associated with gummy ISO-N materials. Meanwhile, geometry enhancements such as a polished K-land and optimized flute shape improves chip evacuation and minimizes cutting forces to reduce the power consumed during milling by a minimum of 20%.Machining non-ferrous materials like aluminum, brass, copper and other ISO-N materials allows manufacturers to push their machines to the limit and achieve high metal removal rates (MRR). Push past those limits for increased MRR in ISO-N materials – even with older and less rigid machines – with the upgraded family of A245/A345 solid carbide end mills. Improved tool geometry and a new PVD coating result in a minimum of 20% less power consumption, yielding improved cutting efficiency, superior surface finishes and exceptional tool life.

Your challenge:

Machine horsepower and torque limitations cause poor metal removal rates in ISO-N materials.

Our solution:

Reduce cutting forces and power consumption with the A245/A345 product families’ newly developed ANF PVD coating and improved geometry.

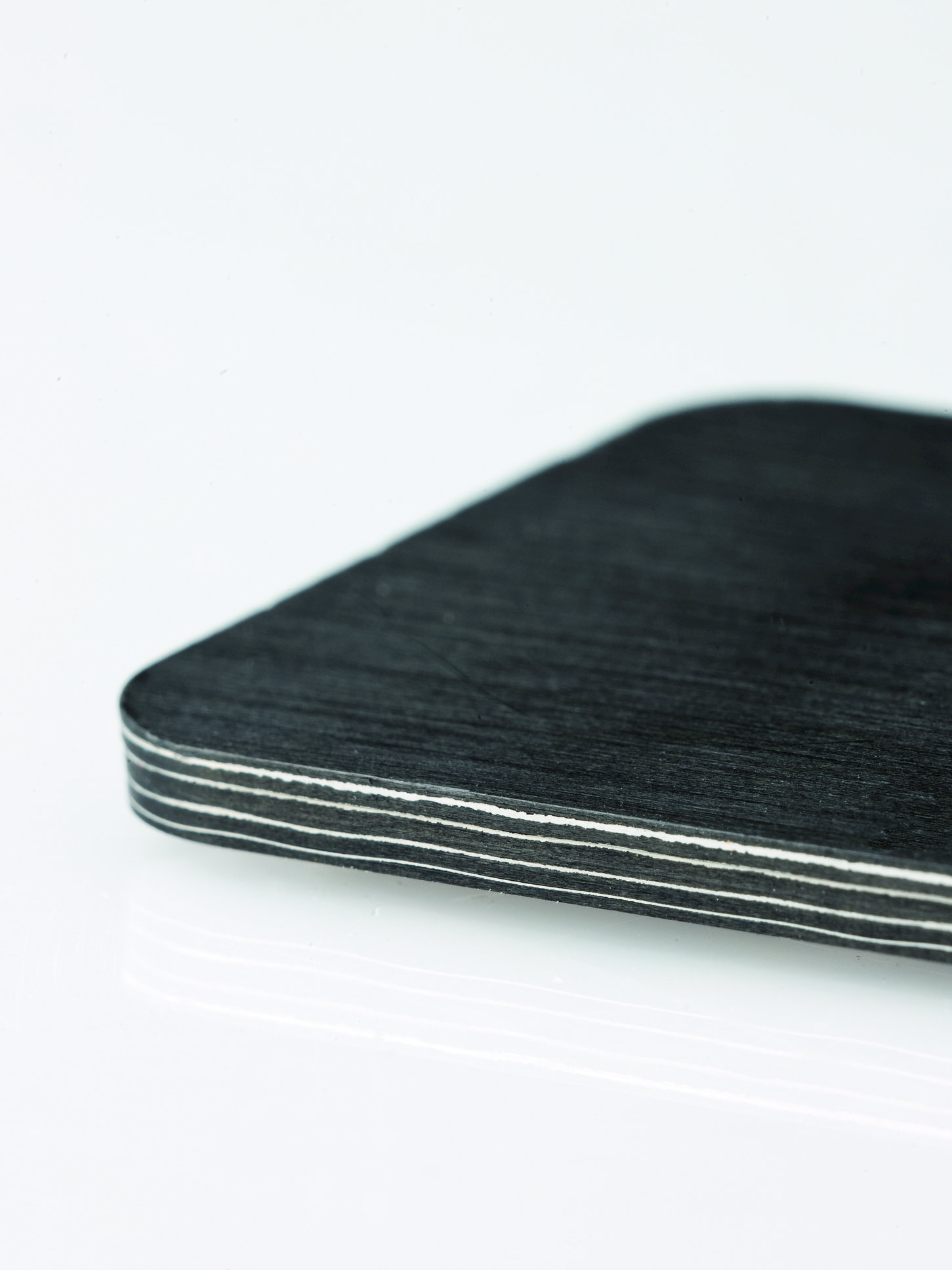

Machining aluminum and other ISO-N materials efficiently requires tools that can handle aggressive speeds and feeds, even in less stable machining conditions. The existing A245/A345 product line addresses these issues with a cylindrical margin that minimizes chatter and vibration for superior surface finishes. Now, these products also feature a polished K-land that minimizes chip contact for superior chip formation. The helix, radial rake angle and flute shape have all been optimized. These advancements in technology allow for increased chip loads and sheer potential, resulting in a reduction in cutting forces and power requirements for truly exceptional MRR.

Your challenge:

Chatter, vibration and poor chip control lead to unstable processes and inconsistent performance.

Our solution:

Increase milling efficiency with a fully optimized geometry, including a newly engineered flute shape and K-land that minimizes chip contact during the chip formation process.

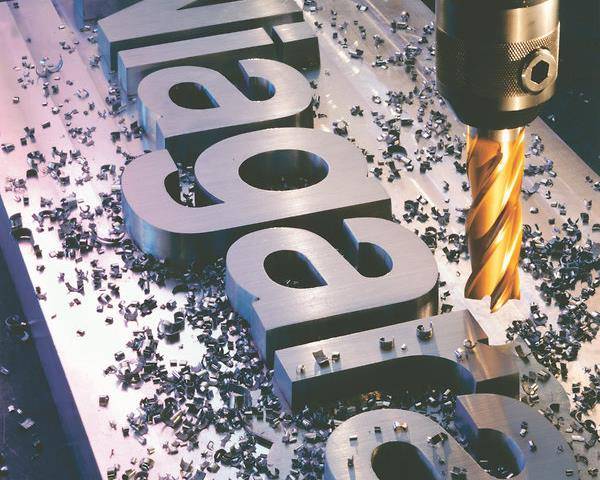

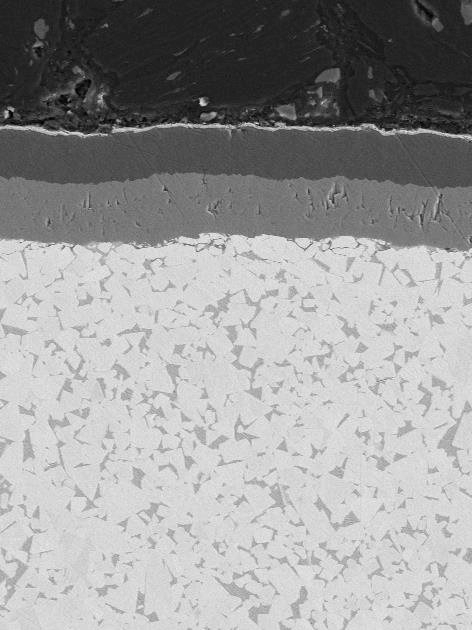

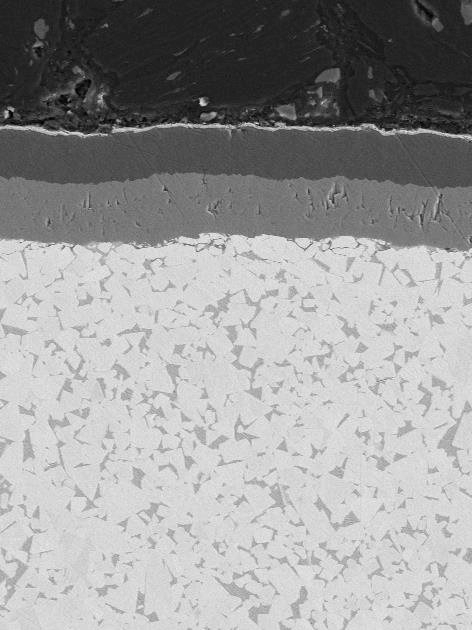

ISO-N materials can be gummy, building up on the cutting edge of tools in a way that negatively impacts tool life, surface finish and process stability. To address this, the new ANF PVD coating developed by Niagara Cutter® creates a smoother and homogenous surface that minimizes friction and built-up edge. A substantial improvement over TiCN coating on the previous generation of A245/A345 end mills, the new ANF coating minimizes built-up edge for better surface finishes and longer tool life.

Your challenge:

Gummy ISO-N materials create built-up edge, resulting in reduced tool life and workpiece surface quality.

Our solution:

Maximize tool life and improve workpiece surface finish with the proprietary ANF PVD coating developed in-house by Niagara Cutter® to reduce built-up edge.

Discover the Aluminium Finisher brochure

Inch & metric range expansion encompassing select existing Niagara Cutter® geometries with and without ANF PVD coating:

- 2-flute configurations

- A245 square corner end mill

- AB245 ball end mil

- 3-flute configurations

- A345 square corner end mill

- A345R corner radius end mill

- A345M metric square corner end mill (ANF coated only)

- AN345 reduced neck square corner end mill

- AN345R reduced neck corner radius end mill (ANF coated only)

Related content

Seco Helical Turbo 16 milling cutters

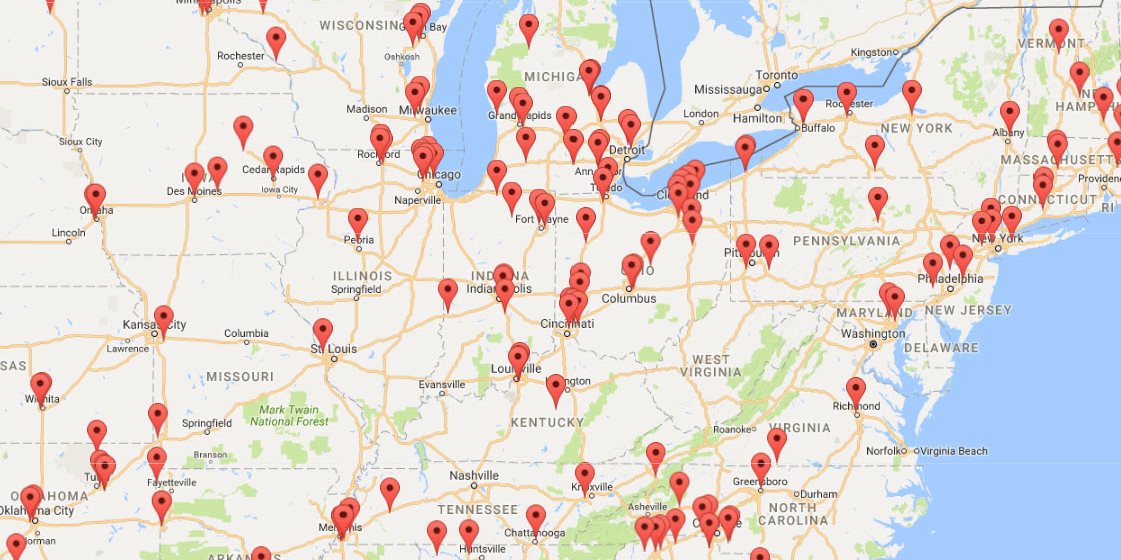

Distributor locator

A245 - High Performance - Square and Ball - Aluminum - 2 Flutes

MAXIMIZE YOUR PRODUCTIVITY IN ALUMINIUM APPLICATIONS

NIAGARA CUTTER® A245/A345 UPGRADE

Tackle Aluminum Milling with Ease Using the Niagara Cutter A Series

A345 - High Performance - Square - Aluminum - 3 Flutes

A245 A345 2022_1 Product Presentation

4 TIPS FOR NEXT LEVEL PERFORMANCE IN ALUMINUM MACHINING

New and Improved Solutions from Niagara Cutter for Aluminium Machining

High Performance Optimized Roughing in 17 4 PH Stainless Steel Dry

Niagara Cutter High Feed Machining Product Introduction

Challenges in non-ferrous materials

ABOUT NIAGARA CUTTER

Niagara Cutter Multi Flute - Elite Series

Optimized Roughing 17-4 PH Stainless Steel Dry

Niagara Cutter's SN200R, SN400R and SN500R

High Performance Optimized Roughing with Stabilizer 2.0

Mold & Die End Mill Expansion Introduction

Niagara Cutter to Be Fully Integrated to Seco Brand

Niagara Cutter Brand Integration Distributor Resources

Video: High Performance Optimized Roughing with Stabilizer 2.0

Video: Niagara Cutter Stabilizer 2.0 Product Introduction

ACS540 / ACS540R End Mills

Multi flute solid carbide end mills

Niagara Cutter® HTA Coating Product Expansion

Machining Navigator / Catalog NIAGARA

Machining Navigator / Catalog Solid End Mills

6 Essential Tips for High Performance Roughing with the Stabilizer 2.0 | SECO TOOLS

High Performance Optimized Roughing in 17 4 PH Stainless Steel Dry | SECO TOOLS

Niagara Cutter High Feed Machining Product Introduction

Niagara Cutter Stabilizer 2.0 Product Introduction

New Seco Niagara cutter™ 5-flute End Mill delivers extreme versatility

Non-Ferrous / ISO N

Video: Machining Demo shown at Mazak Technical days | Seco Tools

Optimized Roughing

High performance Machining

Optimize Your Machining Processes with these 7 Tips

What Do Coatings Do?

Aluminum A-Frame

The new materials set to shape the future of the aerospace industry

The Rise of Composite Materials in Aerospace Manufacturing

The rise of MMCs: Advantages, challenges, and solutions in using Metal Matrix Composites

Factsheet - Seco Solid End Mills for Aluminum

Seco S43/S45/S46 Solid End Mills for Aluminum

Non-Ferrous / ISO N

Brochure - Niagara Cutter - Solid End Mills for ISO-N Machining

Product Range Presentation - ACS540 / ACS540R

Versatile Tools cut costs and scrap for HMLV production

Video: Niagara Cutter AN230 & AN335 High-Velocity Solid End Mill for Aluminum

Video: Multi Flute Range Addition

Niagara Cutter Universal Drill Product Introduction

Video: Niagara Cutter NTM100 Threadmill

Video: Optimized Roughing 17 4 PH Stainless Steel Dry

Video: Optimized Roughing 17 4 PH Stainless Steel Dry

Video: Niagara Cutter ELITE Series Multi Flute S638

Video: Niagara Cutter's SN200R, SN400R and SN500R

Video: Niagara Cutter NTM100 Threadmill

Video: Niagara Cutter Universal Drill Demonstration | SECO TOOLS

Giving Detroit an Edge Since 1928