Secure your milling productivity and reduce per-meter costs

Secure your machining productivity with costefficient, versatile milling thanks to well-optimized JSE510 solid end mill geometries.Need to control production costs at the same time your shop handles an ever-increasing range of materials and applications? Achieve the lowest cost per meter in steels, stainless steels, cast iron, titanium and some aluminums with a single, welloptimized family of solid end mills: the Seco JSE510 series. Designed with four geometries and two length variants that give it well-optimized performance across virtually all milling applications, JSE510 end mills have the best-in-class tool life and stability today’s shops need.

The JSE510 series makes it easy to control vibrations and optimize milling thanks to geometric innovations like irregular tooth pitch, a progressive helix and optimized flute configurations. High-cobalt carbide and advanced SIRA coatings also contribute to long tool life and high reliability. And every tool comes with full access to the complete range of Seco Tools service and support, making it even easier for shops to achieve fast, cost-effective part production.

View all products

- 216 total tools

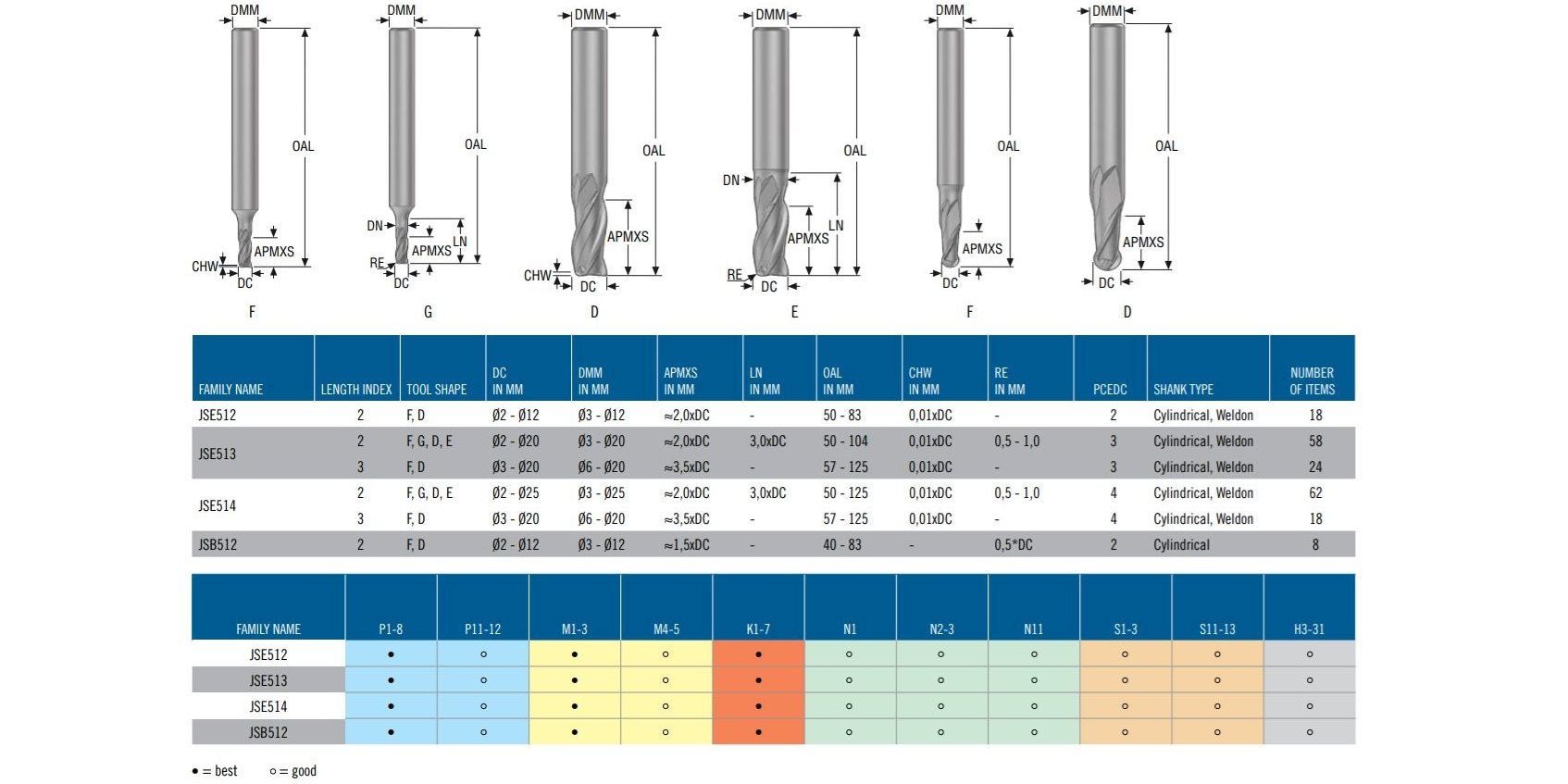

- 4 geometries (2-flute JSE512, 3-flute JSE513, 4-flute JSE514 and ball-nose JSB512)

- 2 lengths (normal/LV2 and long/LV3)

Redesigned from the ground up for stable, costeffective machining, Seco JSE510 solid end mills offer the best balance of performance and value in their class. The long tool life is matched with highrigidity geometries that can still perform even in lessstable machining platforms. An optimized grade completes the package – and ensures reliable milling applications in virtually any steel, stainless steel or titanium, as well as some aluminums and other materials.

Designed with irregular tooth pitch to allow increased speeds and feeds, a progressive helix and an optimized high-cobalt carbide with SIRA coating, JSE510 solid end mills are built for stability and reliability. In addition to high tool life, the family boasts a comprehensive application range that will allow your shop to handle any job. Two, three, and four-flute configurations and the JSB512 ball-nose geometry handle roughing and finishing for simple prismatic parts and complex 3D contours alike, including drilling, helical interpolation, ramping, full slotting and side milling. This helps your shop handle any job at the same time you cut back on the inventory required for flexible production.

Contact Us