Škoda Auto and Seco Tools collaborate to eliminate a production bottleneck

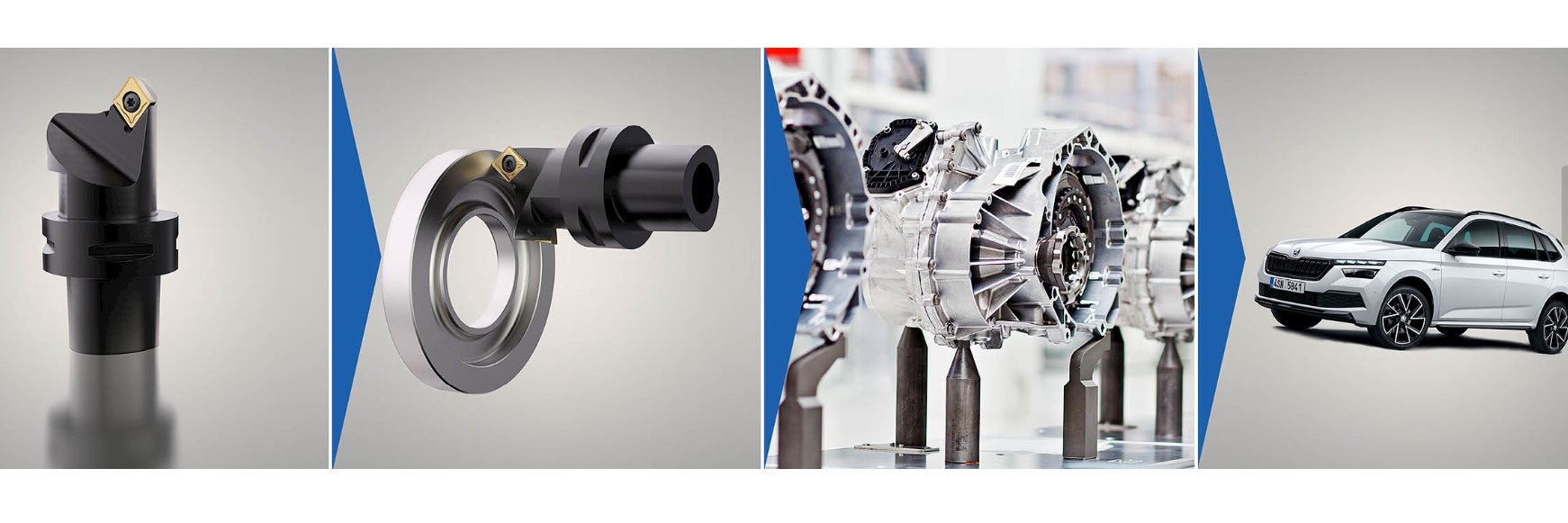

Even in an operation as modern as the Škoda Auto production plant in the Czech Republic, opportunities for improvement exist. For more efficient machining of a complex gearbox component, Škoda and Seco Tools collaborated to develop and evaluate a combined cutting tool. Seco technical specialists used a 3D printed model and an innovative tool design to streamline and shorten production for rapid creation of a non-traditional solution.Founded in 1864, the Škoda Auto production plant in Vrchlabí, Czech Republic, upholds a long, proud tradition of manufacturing excellence. Škoda has produced cars there since 1946, including the 1203, 105 and 120 vehicles, and, more recently, the Favorit, Octavia and Roomster models. In 2012, Škoda transformed the plant into a fully up-to-date manufacturer of car components. The company produces direct-shift automatic gearboxes used in Škoda cars and other brands of Škoda’s parent Volkswagen Group.

Approximately 1,000 Škoda employees work two shifts a day to produce up to 2,300 two-clutch, seven-speed DQ200 automatic gearboxes with advanced DSG direct shifting system technology. The Vrchlabí production plant is one of the region's most important industrial employers and among the most advanced facilities within VW Group. The production process uses leading-edge technologies that support Industry 4.0, including collaborative robots, autonomous transporting systems and the digital twins approach to manufacturing design and documentation.

Seco and Skoda partnership

Škoda recognizes that every facility – however advanced – offers opportunities for further optimization projects. One such project targeted removal of a bottleneck from production of a unique gearbox part. A turning operation used three different ISO cutting tools and consumed nearly 51 seconds of cycle time. The second spindle of the CNC turning center set idle, wasting production time while the trio of tools machined part features.

Škoda sought to reduce machining time on the turning center and increase production capacity. Various cutting tool suppliers suggested changing inserts and cutting speeds, which did not produce the desired efficiencies. The proposals generated minimal machine time savings and increased cutting tool costs.

Then Škoda decided to accept an innovative approach suggested by Seco Tools. Seco originated a project to develop and evaluate a combined cutting tool for precise, efficient machining of the gearbox component. In only four days, Seco technical specialists developed a non-traditional solution and presented plastic models of two new tools generated on a 3D printer. Work on the details of Seco's first suggestion revealed a unique solution: a single multi-purpose cutting tool that could perform all the desired operations. In just two more weeks, a production test of the tool proved its overall functionality and ability to meet the required part parameters. Škoda put this solution into regular production approximately eight weeks after the project began.

With one tool instead of three, Škoda eliminated tool changes among operations and shortened production time. Analysis of the operation sequence also enabled technicians to optimize the tool paths further and save more time.

The innovative Seco tool reduced final machining time to 40.2 seconds, a savings of 10.7 seconds, or more than 20% of the operation's original cycle time. This outstanding result saved Škoda more than 10,000 € in tooling costs within a single year.

Application engineer Milan Kudrnáč and key-account manager Petr Zeman represented Seco on the supplier side in this Škoda project. Additive manufacturing supported their efforts and enabled fast, inexpensive generation of tooling models. The models quickly and easily validated the new solution and helped uncover potential production problems. The models also provided a perfect way to present a solution to a manufacturing partner.

The custom tool

Škoda and Seco collaborated closely to support the project. Seco employees appreciated Škoda’s active approach to the project, the auto manufacturer’s interest in the development process and the opportunity to cooperate directly in the workshop. Good communication offered the key to this successful collaboration.

Mr. Vladimir Flandera, specialist for mechanical machining at the Škoda Auto Vrchlabí plant, managed his company’s participation in this project. He also appreciated the importance of the active approach, speed and flexibility on Seco's part, as well as continuous and complete communication.

By reaching its main goal on this project, Škoda saved 10,650 € in direct yearly tool costs alone. Further savings resulted from use of a single specialized cutting tool that costs less than the three ISO tools it replaced. The biggest impact, however, comes from elimination of the production bottleneck. The specially designed tool smoothed overall workflow and greatly reduced the wait before the second spindle of the CNC turning center could perform subsequent operations on the workpiece. The shorter processing time also reduced use of compressed air to cool and remove chips from the cutting zone.

Through 3D printing technology, Škoda has developed real-world models of tooling concepts. Based on its excellent experience with this effort, the company went on to use the approach on other projects. Škoda’s internal innovation contest recognized this success, and the Vrchlabí plant now uses this solution globally in other VW production plants.

Dipl.-Ing. Ivan Slimák, PhD., managing director of Škoda Auto’s Vrchlabí plant, provided a highly positive review of the tool development project, noting the effective collaboration between Škoda and Seco Tools – and not only in cost savings. The biggest benefit, in his eyes, was the opportunity for shared experience, as well as the professional and personal development of the people involved. “It is very important to show that the Czech industry is able to keep up with the changing world through the latest technologies, and has skilled people who can lead it further on,” he said.

To learn more about our solutions and how we can support your project, contact us.

Contact us