The ISO Application standardization

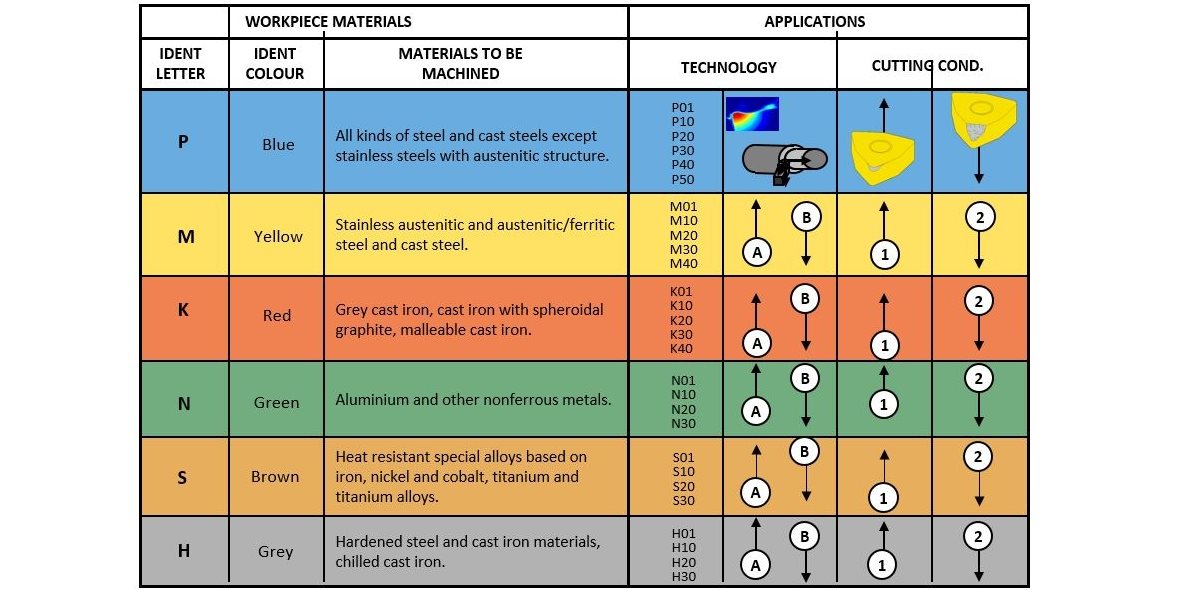

There is a wide variety of workpiece materials being machined in the machining industry. Within the ISO system, all these materials are grouped in six different groups named ISO-P, ISO-K, ISO-M, ISO-N, ISO-S and ISO-H.There is a wide variety of workpiece materials being machined in the metal cutting industry. Within the ISO system, all these materials are categorized into six different groups named ISO-P, ISO-K, ISO-M, ISO-N, ISO-S and ISO-H.

The grouping is based on the relative machinability of the different workpiece materials. Each group is characterized by a letter (P, K, M, N, S, H) and visualized by a color. The letter has no meaning, and the color is the theoretical color a chip has the moment it is formed when machining that material.

The second dimension in the ISO machining application system is the type of machining process. The type of machining is defined in terms of typical loads that will act on the cutting edge, mainly mechanical loads or thermal loads or different combinations between the two. The machining types are labelled 01, 10, 20, 30, 40, 50, and 60 (the figures have no meaning, no dimension). The type 01 stands for high thermal loads combined with low mechanical loads (which is typically found in finishing operations) whereas 60 stands for low thermal loads combined with high mechanical loads (typically found in roughing applications). All figures in between represent different combinations. The system for machining type ranking is rather subjective.

ISO application standardisation

1. Increasing wear resistance of cutting material (high cutting speeds).

2. Increasing toughness of cutting material (high feeds and DOC).

A. Increasing heat generation and higher temperature.

B. Increasing cutting forces.

The denomination P10 refers to a finishing operation in steel materials, whereas M40 is a rather heavy roughing operation in stainless steels.

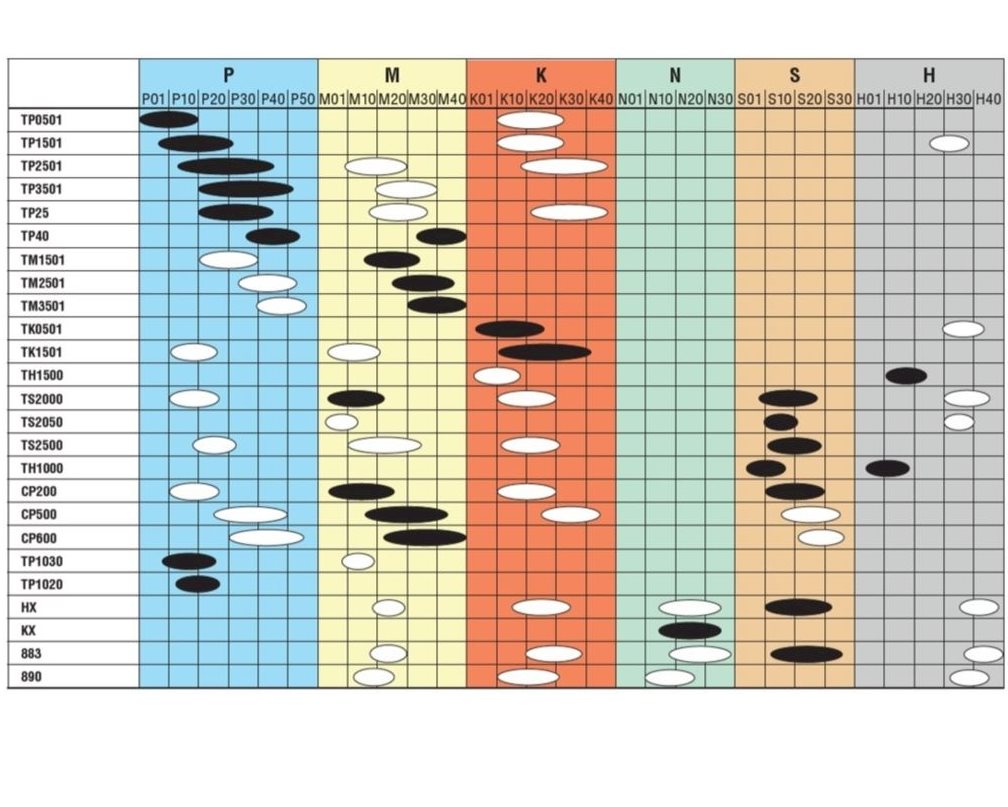

Carbide producers use this ISO system to show an overview and a ranking of the different carbide qualities and cutting geometries in their range. It is important to remember that the ISO machining application system is a systematic approach to classify different types of machining operations in different workpiece materials and NOT a standardization system for carbide grades and cutting geometries.

Below, you'll find an example for turning. For more information, you can refer to our Machining Navigator catalogs.

For more information on ISO material groups, you can also visit our:

ISO material groups page

Do you want to know more?

Contact Us

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64