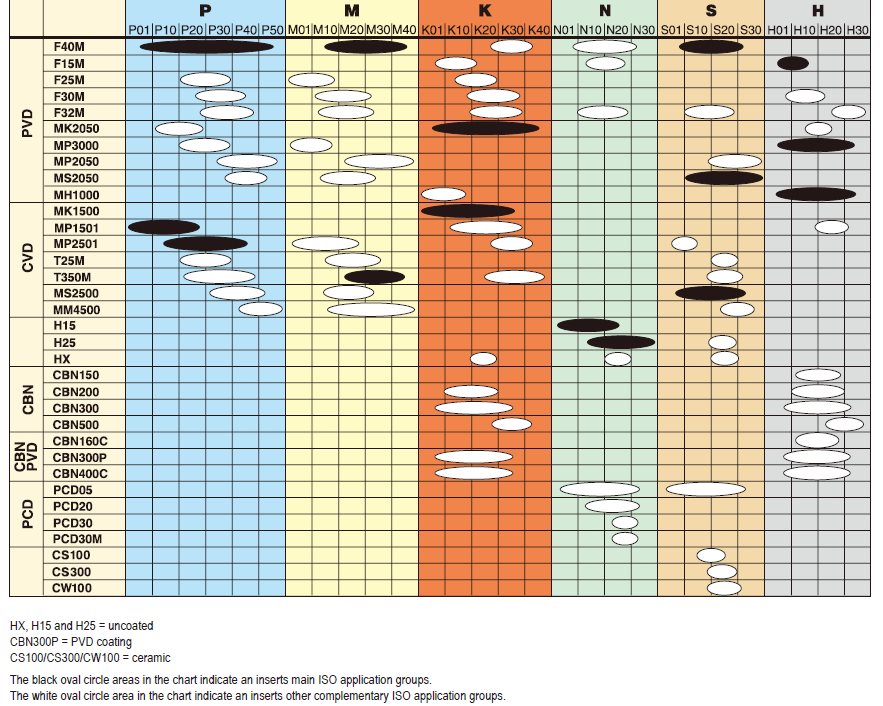

Seco Milling Insert Grades

Seco Milling Grades : F40M, F15M, F25M, F30M, F32M, MK2050, MP3000, MP2050, MS2050, MH1000, MK1500, MP1501, MP2501, T25M, T350M, MS2500, MM4500, H15, H25, HX, CBN150, CBN200, CBN300, CBN500, CBN160C, CBN300P, CBN400C, PCD05, PCD20, PCD30, PCD30M, CS100, CS300, CW100The black oval circle areas in the chart indicate an inserts main ISO application groups.

The white oval circle area in the chart indicate an inserts other complementary ISO application groups.

* You can increase your toollife by comparing grades. Lower number = Hard grades for wear resistance, Higher number = Tough grades for chipping resistance)

So P10 is harder than P20 with better wear resistance, P30 is tougher than P20 with better chipping/fracture resistance

Seco Milling Insert Grades Table

| Seco Material Groups (SMG) with Reference | General Grades (could be different by Milling Cutter Series) |

SMG P2 (S235JRG2) Low-alloy ferritic steels, C < 0.25%wt

Low-alloy weldable general structural steels | MP2501, T350M (+F40M) |

SMG P4 (C 45E) Low-alloy general structural steels, 0.25% < C < 0.67%wt

Low-alloy Quench & Temper steels | MP2501 |

SMG P5 (42 CrMo 4) Structural steels, 0.25% < C < 0.67%wt

Quench & Temper steels | MP2501 |

SMG P8 (X 40 CrMoV 5 1) Tool steels

High Speed Steels (HSS) | MP2501, T350M |

SMG P11 (X 20 Cr 13) Ferritic & martensitic stainless steels | T350M, MP2050 (+MS2500) |

SMG P12 (X 5 CrNiCuNb 16 4) Maraging and precipitationhardening stainless steels | MP3000, T350M, MP2050, MP2501 (+MS2500) |

ISO M (X 5 CrNi 18 10) Free-cutting, austenitic and duplex stainless steels | F40M, MS2050 (+MP2050, T350M) |

ISO K (EN-GJL-250, EN-GJV-400...) Cast irons | MK2050, MK1500 (+MP1501) |

ISO N (Aluminium) Non-ferrous metals | H15, H25, HX (+F40M) |

SMG S3 (Inconel 718) Nickel-based superalloys | MS2500, T350M (+F40M) |

SMG S12 (TiAl6V4) Titanium, medium alloyed, (a+β) | MS2050 (+F40M) |

ISO H (42 CrMo 4 HRC 50) Hard materials | MP1501, MP3000 |

* For more correct grades and chipbreakers, please refer to Product pages in Milling Catalog

* For cutting data such as Cutting speed, Feed, and Depth of cut, please find insert in search box and click the cutting data menu

Detailed Information

Basic Milling Grades

| Grade | Detail | Main application | Complimentary application |

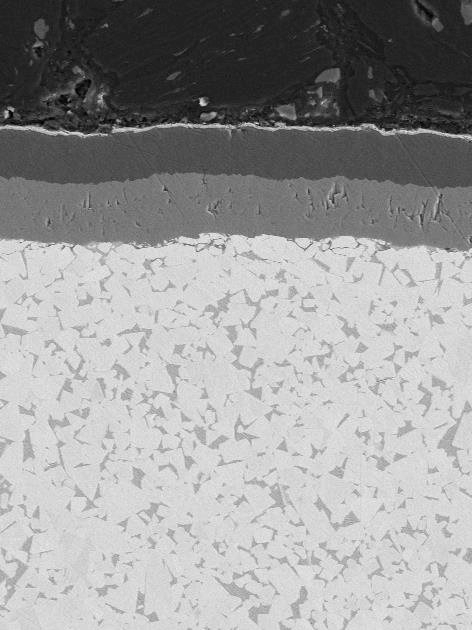

MP2501 (MP2500) | First choice in steel for maximizing manufacturing output under most varying productivity. CVD-coated grade based on Duratomic™ coating First choice in steel for maximizing manufacturing output under most varying productivity. Alternative choice stainless steel applications under stable condition.

Ti(C, N)-Al2O3 | P10-P40 | M01-M20 K20-K40 S01-S10 |

| F40M | | | for Low cutting speed on Austenitic stainless steels Excellent versatility, the best safety proven for a long time PVD-coated grade for fine to medium rough milling. First choice for milling with small feeds and/or low cutting speeds. Excellent for milling when there is a risk of vibrations and when coolant is used. Recommended for machining superalloys.

(Ti, Al) N – TiN |

| P01-P50 M10-M40 S05-S25 | K25-K35 N05-N25 |

| T350M | Basic recommendation on Ferritic & martensitic, or difficult-to-cut stainless steels CVD-coated grade as basic choice for difficult stainless steel and an alternative in difficult operations in steel.

Ti (C, N) – Al2O3 | M20-M40 | P15-P45 K20-K40 S15-S25 |

| MK2050 | First choice in all cast iron materials. PVD-coated grade for cast iron, Improved edge integrity.

First choice in all cast iron materials. Excellent for milling with and without coolant.

(Ti,Si)N/(Ti,Al)N | K01-K40 | P05-P25 H10-H20 |

| MS2500 | First choice in Nickel based alloys (Inconel) Optimization grade for superalloy materials, also suitable for rough milling in tool steel.

Ti (C, N) – Al2O3 | S01-S30 | P25-P45 M10-M30 |

| MS2050 | First choice for machining titanium alloys. PVD-coated grade first choice for machining titanium alloys. Can also be used as a complementary grade for milling stainless steels when increased toughness is needed.

(Ti;Al) N – NbN | S05-S30 | P35-P45 M10-M30 |

Alternative Milling Grades - CVD

| 재종 | Detail | Main application | Complimentary application |

MP1501 (MP1500) | When harder grade than MP2501 is needed for wear resistance CVD-coated grade based on Duratomic™ coating. Grade for high performance and productivity in steel material under stable conditions and for milliing hardened steel. Excellent grade for grey and nodular cast iron.

Ti (C, N) – Al2O3 | P01-P25 | K05-K35 H15-H25 |

| MK1500 | Basic grade for milling cast iron and nodular cast iron, with or without coolant. CVD-coated grade based on Duratomic™ coating.

Ti (C, N) – Al2O3 | K01-K30 | |

| MM4500 | Extremly tough grade for duplex stainless steel. Can also be used for a wide range of materials when cutting conditions are unstable.

Ti(C, N)-Al2O3 | | P40-P50 M10-M40 S20-S30 |

Alternative Milling Grades - PVD

| Grade | Detail | Main application | Complimentary application |

| MH1000 | Extremely hard grade for milling hard steel but also favourable in finishing operations in cast iron.

(Ti;Al)N | H01-H30 | K01-K15 |

| MP3000 | Highly wear resistant optimized grade for milling in steel.

(Ti;Al)N | H01-H30 | P15-P35 M01-M10 |

| F15M | Hard and wear resistant grade for milling in aluminium and non-ferrous alloys.

Excellent grade, in combination with protected cutting edges, for high speed machining in hardened steel.

(Ti, Al) N – TiN | H01-H10 | K01-K15 N10-N20 |

| F25M | Alloyed steel, Cast iron, Hardened steel Tough grade for rough milling in tool steel.

(Ti, Al) N – TiN | | P15-P35 M01-M15 K10-K25 |

| F30M | Basic grade for Minimaster inserts and thread milling inserts.

Also suitable for milling stainless steel, hardened steel and superalloys.

(Ti, Al) N – TiN | | P20-P40 M05-M25 K15-K35 H05-H15 |

| MP2050 | PVD-coated grade for tough machining conditions and high temperatures in martensitic and austenitic stainless steels, dry and wet machining possible.

Alternative in super alloys in unstable conditions. (Ti,Si)N/(Ti,Al)N | | P30-P50 M20-M40 S15-S30 |

| F32M | Universal grade for R335.14 replaceable head offering an excellent combination of strength and toughness.

The F32M shows an exceptionally broad application range and is applicable in all type of material with this type of tool.

(Ti, Al) N – TiN | | P25-P45 M05-M35 K15-K35 N05-N25 S05-S25 H20-H30 |

Uncoated Grades

| Grade | Detail | Main application | Complimentary application |

| HX | Wear resistant grade for milling in cast iron and non-ferrous alloys such as Aluminium. | | K15-K25 N15-N25 S15-S25 |

| H15 | Hard, wear resistant grade for milling in aluminium. | N01-N20 | |

| H25 | Tough micro-grain carbide grade for milling in superalloys and aluminium. | N10-N30 | S15-S25 |

Related content

Inspiration through Innovation 2020 – Aerospace Manufacturing Best-Practice Virtual Event

Truck And Bus Applications

Thank You!

About Seco Tools

Standard Diamond Coated Drilling Solutions

Seco Profile Milling Solutions

Jetstream Tooling® with MDT

Threadmaster™ Thread Mills

Jetstream Tooling® with MDT

Seco Milling Solutions

Seco Feedmax™ Solid Carbide Drills

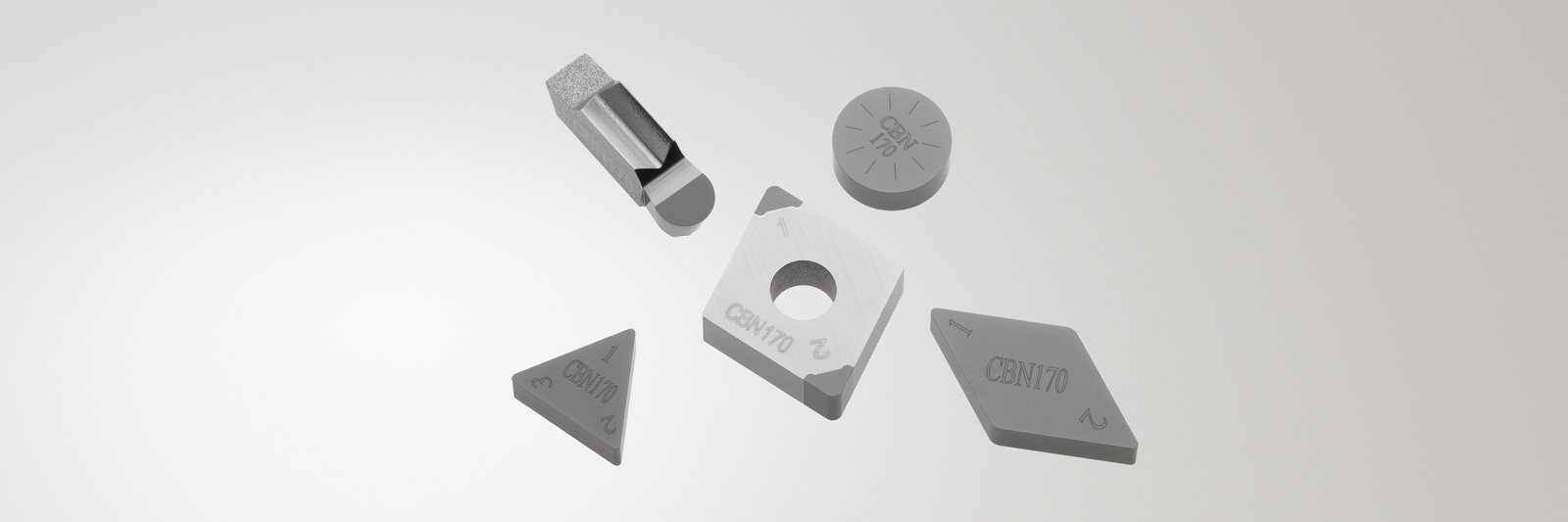

Secomax™ CBN170

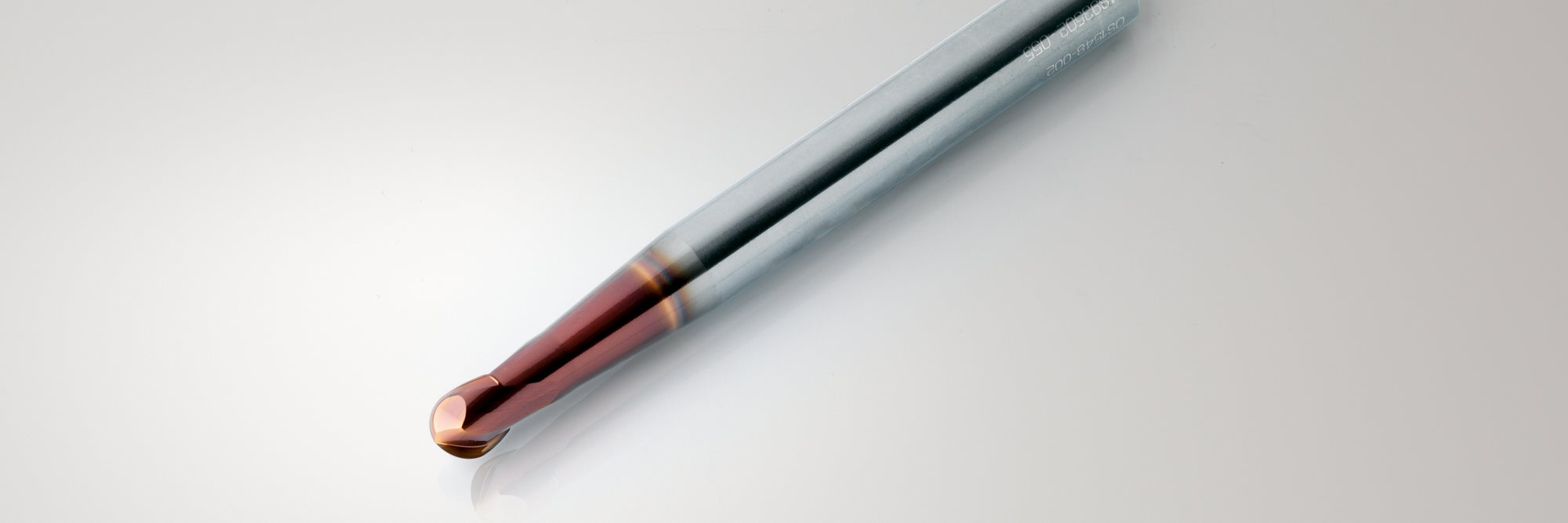

Seco Jabro Solid Carbide

Seco Copy Milling Solutions

Plunge Milling Cutters

Seco Graflex Boring Tools

Seco Graflex Boring Tools

Seco Holemaking Solutions

Seco Holemaking Solutions

Ball Bearing Location