Getting Technical: Smart tool selection for sustainable machining

How sure are you that you use the correct tooling for your applications? What can you do to check this in a reasonable period? In this live event, we will define some first steps, draw the first big lines, some big axes, along which a company should start to build its own tool selection strategy and methodologyJOIN US ON LINKEDIN

JOIN US ON YOUTUBE

We will also stream on Facebook and Twitter if you prefer these channels.

Tool Holder

Tool Holder

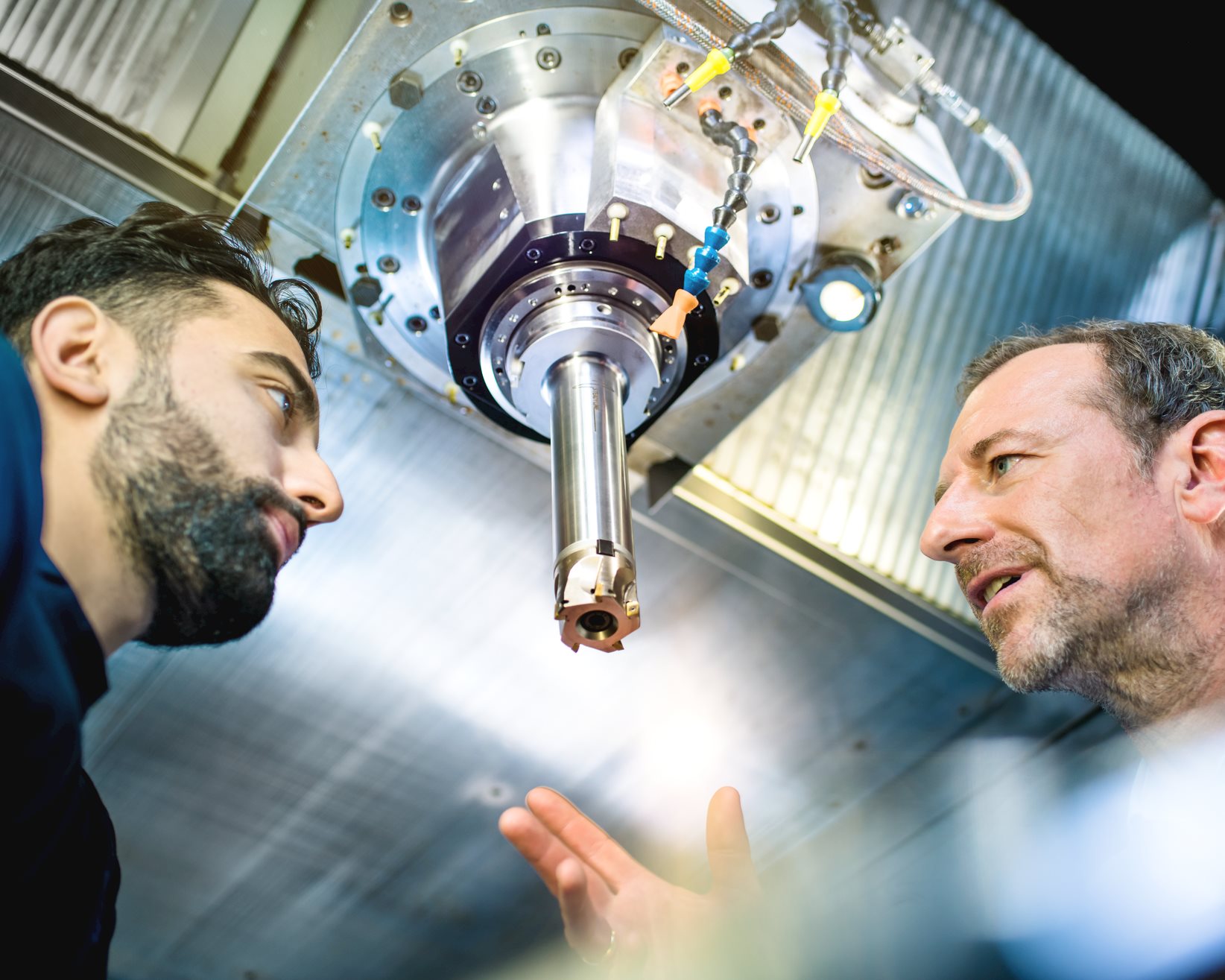

If a machinist consults Seco Machining Navigator catalogues or uses one of several software tools or Apps Seco offers to select cutting tools and cutting conditions, and he combines different cutting edges (geometries, cutting materials, dimensions …) with different cutting edge carriers (toolholder, milling cutters, solid …) to create unique cutting tools; and takes those cutting tools and applies them in the different geometrical applications and the different machining strategies in which they could be used (a square shoulder milling cutter can be used for square shoulder milling but also for face milling, slot milling, …, 2D milling as well as copy plunge milling, …); there are approximately 41.000.000 possible combinations geometrical application - workpiece material – machining strategy - cutting edge carrier - cutting edge that make sense. Forty-one million! Truly a solution for everything and everyone! And I can only talk for Seco Tools, and we are only one out of many suppliers!

How sure are you that you use the correct tooling for your applications? What can you do to check this in a reasonable period? You could of course test each and every of those combinations, couldn’t you? Why is that important? Or isn’t it important at all?

Smart tool selection

Obvious we need a strategy, a methodology to find our way in this jungle. And a well defined one! Guessing, supposing, hoping for the best … will not do!

Tool selection is a key step in the creation and maintaining of a sustainable company operation in general and a sustainable machining process in particular. And tool selection goes far beyond pure technical considerations like which cutting material or which cutting geometries.

Tool selection is a chaired task for company management, production management, engineering, and workshop. And all must take their role in it. Company management must define the expectations on the general tooling concepts related to the overall company targets and KPI’s.

Production management must define the global technical expectation on tooling within the production system and organisation. Engineering must work on individual application level and make sure the individual selected tools suit objectives and expectations.

The workshop co-workers will apply the selected tools and their role is to observe, correct or modify when needed, and feedback their observations and proposals for improvement corrections. They are the gate keepers for the gate between theory and practice or reality.

The workshop co-workers will apply the selected tools and their role is to observe, correct or modify when needed, and feedback their observations and proposals for improvement corrections. They are the gate keepers for the gate between theory and practice or reality.

In this live event we will define some first steps, draw the first big lines, some big axes along which a company should start to build its own tool selection strategy and methodology. The rewards when having a companywide sustainable tool selection strategy? Well, the punishment for not having that … big spending’s on not needed or wrong tooling gathering dust somewhere in the tool crib, not running machine spindles because ‘’there is something with the tool’’ or operators are out in the workshop jungle on a safari to hunt down the tool they need, scraped workpieces, low OEE, long set-up times, long and non-planned problem solving meetings, not kept promises to customers and angry customers on the phone, frustrated workshop people and management...

JOIN US ON LINKEDIN

JOIN US ON YOUTUBE

We will also stream on Facebook and Twitter if you prefer these channels.