Shops Angle Their Way to Optimized Rough Milling

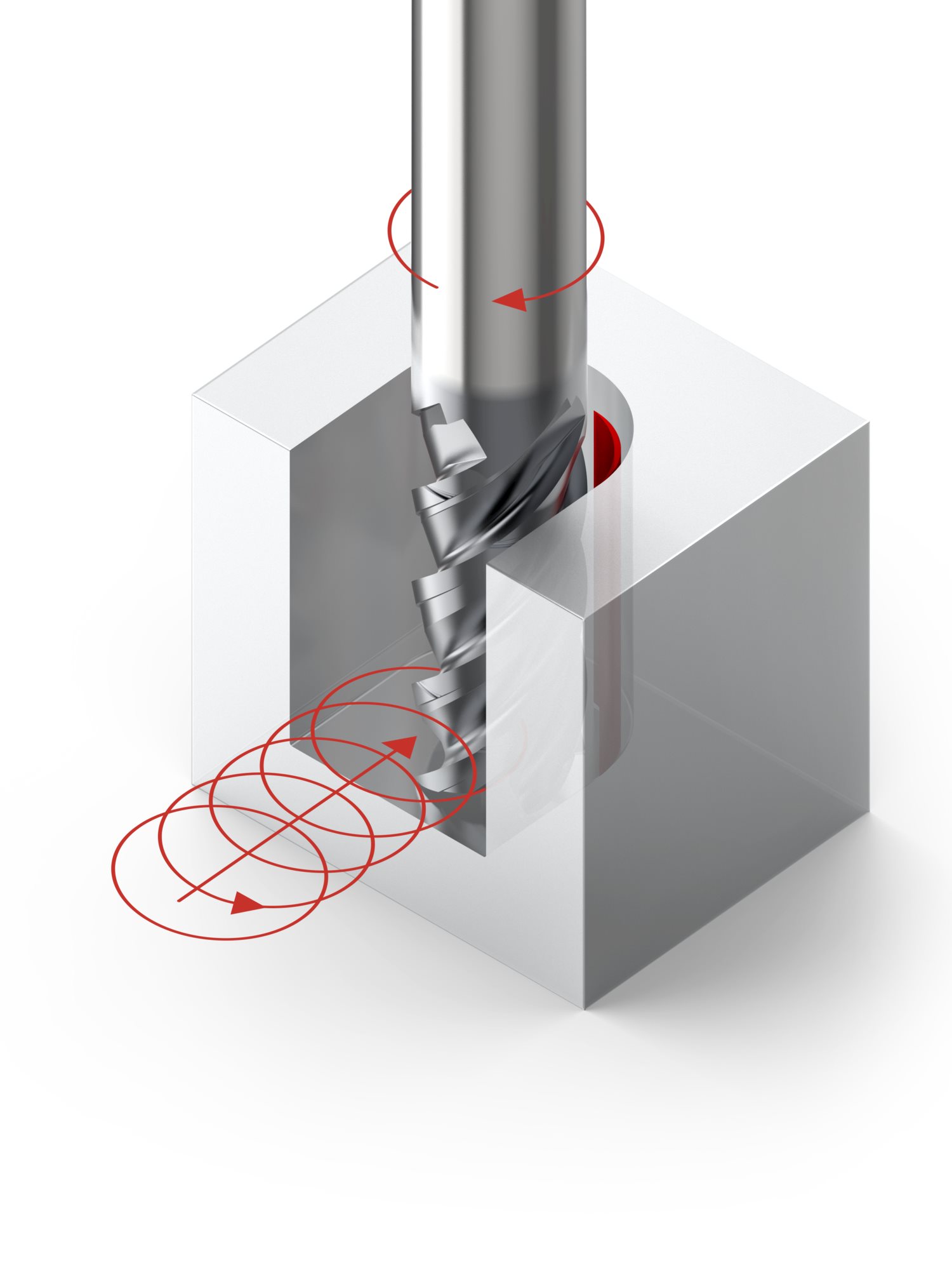

For optimizing conventional roughing, shops must opt for speeds and feeds that their machine tools and software can sustain throughout each milling path.While the goal in conventional roughing is to remove as much material as possible in one pass, Dynamic Milling, on the other hand, hinges on maintaining a constant angle of engagement (AOE) or arc of contact with the cutting tool for optimized roughing operations. Because any changes in an end mill's AOE with a workpiece affect the tool, workpiece and machine tool, a consistent AOE, along with sustainable speeds and feeds, extends tool life and generates quality parts.

For optimizing conventional roughing, shops must opt for speeds and feeds that their machine tools and software can sustain throughout each milling path. Using 4 or 5-flute endmills and standard pocketing routines, shops engage 50% to 100% of the tool. Unfortunately, with this practice, problems arise when the tool enters a corner.

Because the tool stepover is not adjusted accordingly, the cutter becomes too engaged which causes it to chatter. This chatter, in turn, transfers to the part surface and causes premature tool wear as well as poor surface finishes requiring extensive secondary operations.

Dynamic Milling is well suited for 2D prismatic type parts and any part feature that allows for using the whole flute length of the cutter at 2 to 5xD radial engagement. Such potential part applications are often found in many manufacturing sectors ranging from medical to moldmaking.

In medical applications, manufacturers typically rough out knee-implant tibial trays from solid material. While four-flute cutters match well with this task, five or six-flute cutters enable those manufacturers to apply Dynamic Milling. The helix, rake, angular relief and short flute lengths of these cutters combine to produce a strong roughing tool that handles side roughing as well as Dynamic Milling techniques for shorter cycle times and longer tool life.

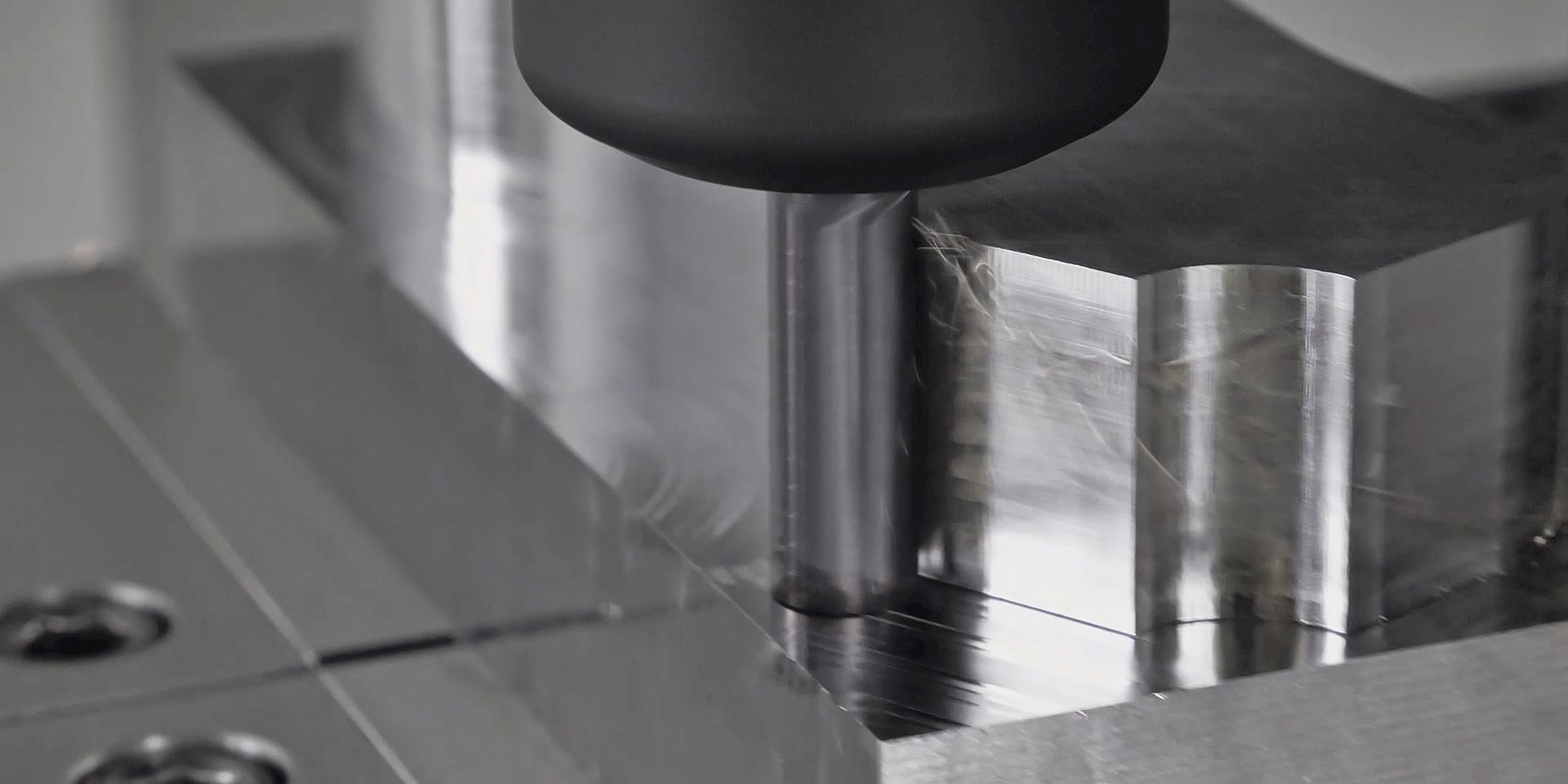

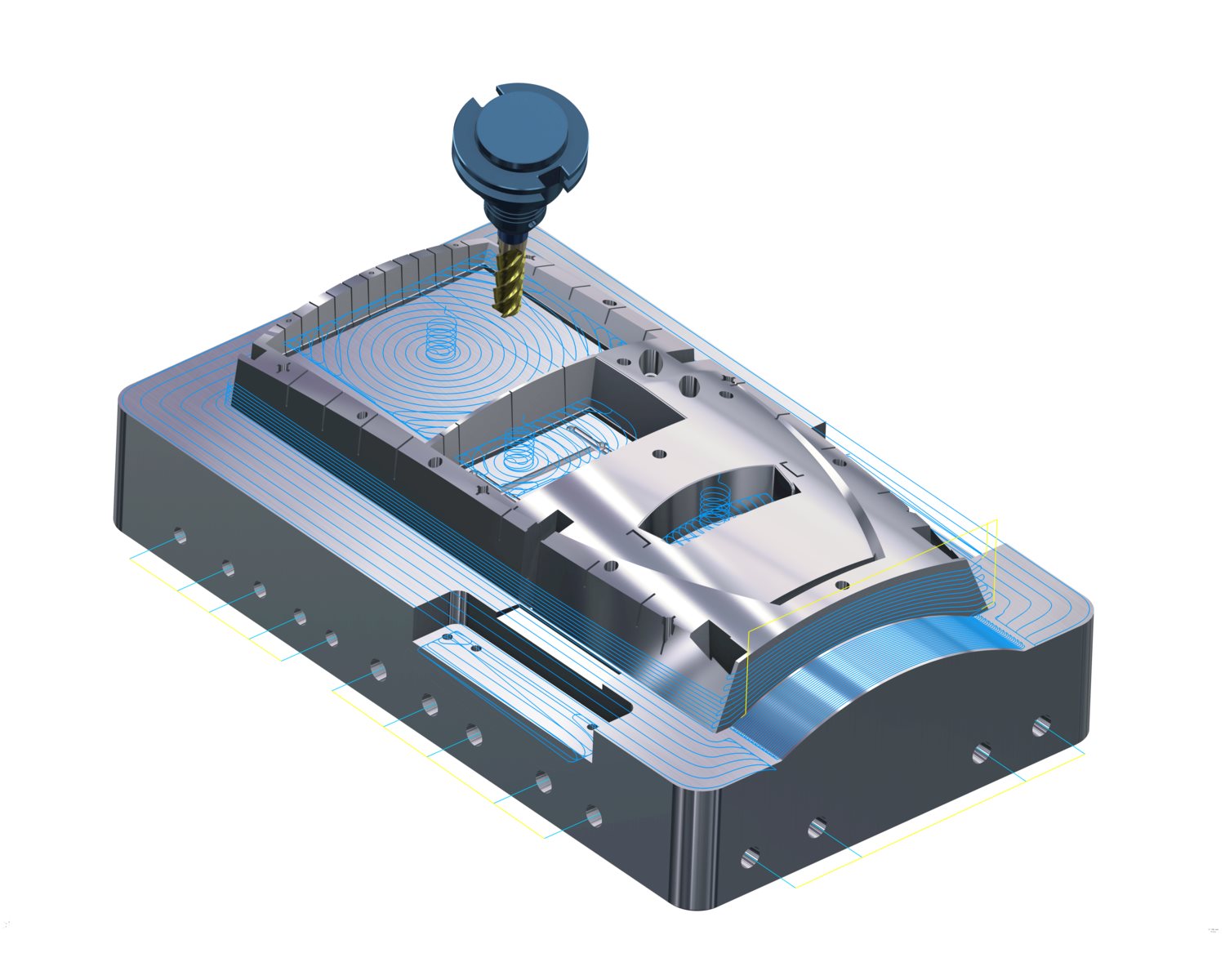

Because Dynamic Milling dramatically shortens roughing operations and thus cycle times, its use has grown in all segments of the industry. Take for example moldmaking. When roughing out molds, moldmakers seek to produce a near-net shape in the shortest amount of time possible. Dynamic Milling helps achieve that by ensuring a constant AOE that allows for faster material removal.

Ideal part materials for Dynamic Milling are those that tend to work harden due to heat generated during conventional roughing applications. Those include tool steels, Duplex stainless steels, PH stainless, InconelÒ, Titanium and other high-temperature alloys. Dynamic Milling on the other hand, generates lower levels of heat in the cutting zone. This, in turn, lessens the chance of part deformation and helps extend tool life.

Regardless of part application, chip control is mandatory for successful Dynamic Milling, which is why the cutters developed for the strategy will feature advanced chip splitter designs. These splitters provide effective chip control even in applications requiring depths of cut up to five times the diameter of the tool. Such chip splitter technology is used on cutters like those in the line of Seco Solid Milling Multi Flute end mills.

This extensive range of cutters spans over 740 tools, all of which were developed specifically for Dynamic Milling. Within that range are 6, 7 and 9-flute series of cutters, all of which feature eccentric OD reliefs that make for stronger cutting edges and variable indexing to reduce harmonics and provide smooth cutting and better surface finishes.

Key variables of Dynamic Milling include the machine tool, CAM software, cutter and tool holder, each of which has an impact on the success of the process and on the tool’s performance. On the machine tool side, high acceleration/deceleration capabilities are needed for Dynamic Milling. Machines must also have controls with advanced lookahead (a couple thousand lines) functionality, glass scales and good overall rigidity to keep up with the relatively complex cutter paths involved with Dynamic Milling.

Dynamic milling continues to evolve, however. For instance, Seco is taking dynamic milling to higher levels by applying tools with more flutes – anywhere from 6 to 9 flutes – and reducing the radial depths of cut. This means the stepovers are reduced, but feed per tooth is increased to further boost material removal rates, process security and tool life. While 2 and 3xD flute lengths are the norm, Seco has advanced to 4 and 5xD, meaning that shops can take advantage of a tool’s full cutting length to enhance cost effectiveness.

Discover your free guide to Dynamic Milling

To further increase tool life in Dynamic Milling, shops are trending toward even further reductions in stepovers. For instance, a 6-flute tool that would typically require a 10% to 12% stepover, but shops are now reducing that amount by half – 5% to 6% percent – then doubling the feedrate. Doing so cuts the AOE by half as well. All of which reduces the heat affected zone and increases tool life by 50%.

Another trend is applying the Dynamic Milling to 4-flute endmills. These tools provide more chip evacuation room, and when run on a high horsepower, heavy duty machines such as those with a CAT 50 taper spindles, stepovers of 75% are possible while still applying the Dynamic Milling strategy. This results in metal removal rates beyond those achievable with indexable cutters and significant reductions in cycle times.

Additionally, as CAM system algorithms become more sophisticated, operators grow more confident in their Dynamic Milling operations.

The process has become so stable, many shops are comfortable letting a machine perform Dynamic Milling unattended.

Despite the many benefits of Dynamic Milling, shops continue to neglect the effective machining strategy – either because they don’t know how to implement it or don't understand how it works. Instead, these shops stick with outdated speed and feed parameters that fail to produce optimal results.

With Dynamic Milling, shops can shorten milling cycle times by 40% to 70%. In addition, it often doubles and triples tool life while improving workpiece surface finishes. Further, the milling strategy boosts material removal rates and helps control heat generation. All of which ensures process security, especially when it comes to unmanned operations.

Discover our product range:

Inline Content - Gridded Links

Tags: 'advanced roughing solid carbide end mills'

Max links: 1

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64