How to select the right turning grade for Hard Materials?

A mapping of Hard Materials Turning grades and how to select the right one.SMG H (Hard Material) is divided in 8 sub-groups, to capture specific material characteristics and reduce the complexity of every specific material.

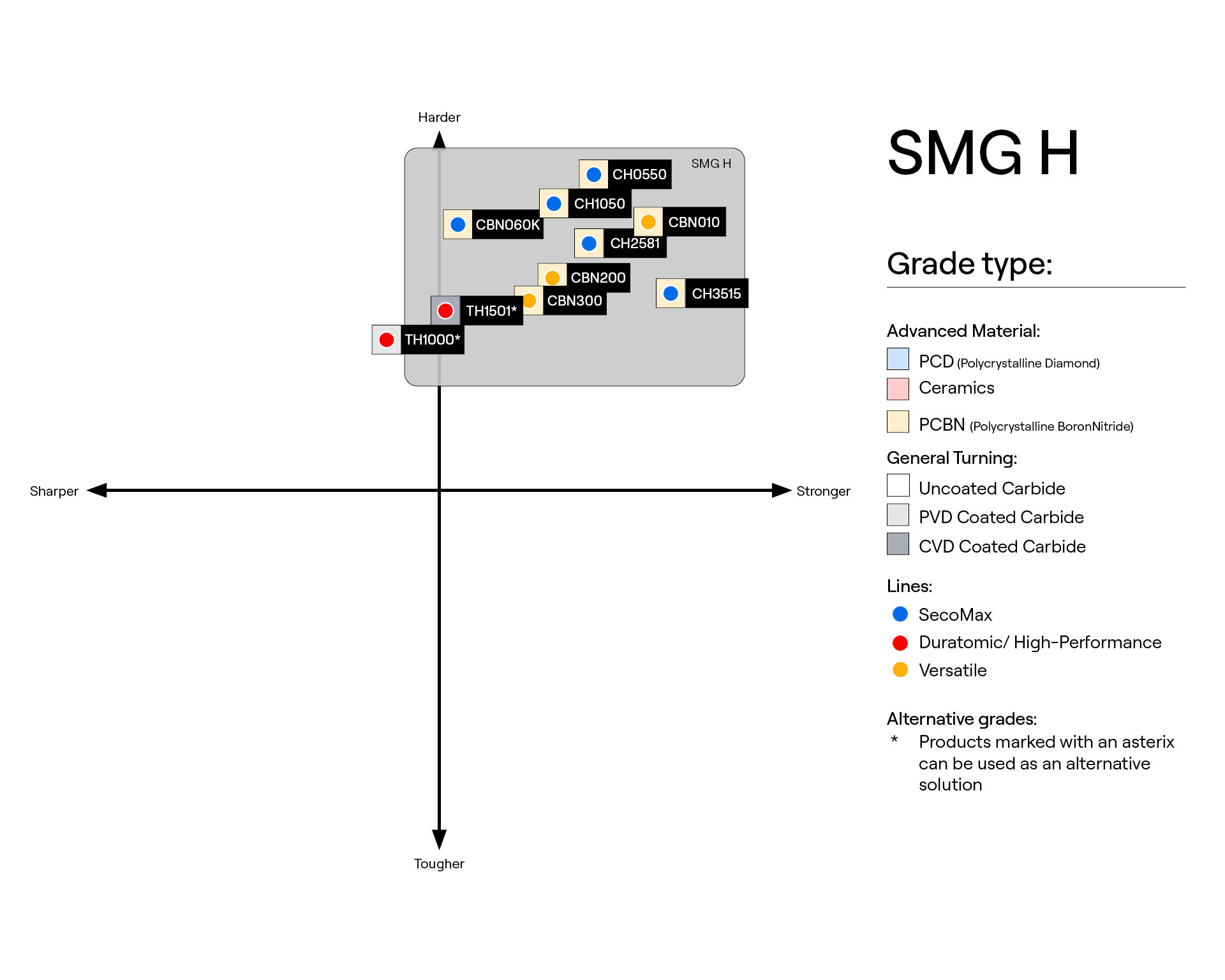

Based on grade portfolio, you can find a starting grade recommendation which can be optimized depending on the application, based on below mentioned grade mapping.

SMG | Description | Reference | Calibration |

H3 | Case-hardened steels | 16 MnCr 5 | 60 HRC |

H5 | Quenched & Tempered steels | 42 CrMo 4 | 50 HRC |

H7 | Quenched & Tempered steels, Bearing steels | 100 Cr 6 | 60 HRC |

H8 | Tools steels & High-Speed Steels (HSS) | X 40 CrMoV 5 1 | 50 HRC |

H11 | Martensitic stainless steels | X 20 Cr 13 | 45 HRC |

H12 | Maraged and precipitation-hardened stainless steels | X 5 CrNiCuNb 16 4 | 1450 N/mm² |

H21 | Austenitic nodular cast irons | X 120 Mn 12 | 50 HRC |

H31 | White cast iron | EN-GJN-HV600 (XCr11) | 55 HRC |

Discover this material in details

Discover our Product Range

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64