By reconditioning your tools, you can take advantage of a longer tool life and benefit from cost reduction

How to save money by reconditioning your toolsIn many companies, used solid carbide tools are scrapped as soon as they become worn or damaged.

Still, this isn't the only option available.

Today you can extend the life of your tools by reconditioning them and this helps you to reduce their initial cost. Have you ever considered the possibility of regrinding and refurbishing your tools before?

Reconditioning is a process of “rejuvenating” existing solid carbide tools, such as drills, reamers and cutters.

Good quality cutting tools are not cheap and tend to wear out over time. The cost of replacing them is often high, especially for smaller mechanical workshops with limited budgets.

The budget you invest in new tools is often an economic investment that should not be underestimated.

For this it is essential to find a way to offset the initial purchase cost. A good tool reconditioning program enables companies to meet rigorous standards and compete in the market while delivering quality and cost-effective products.

Some of the benefits you can get by reconditioning your tools are:

- reduce inventory costs

- increase your competitiveness on the market

- avoid wasting material

- increase corporate sustainability

So, to summarize, it is possible to give new life to worn tools, allowing companies to increase their productivity and save money by avoiding unnecessary purchases.

In addition to the obvious signs of blunt and rounded cutting edges, there are some details that machine operators should be able to recognize, in order to understand whether a tool needs to be refurbished or not. Here are some examples:

- Decrease in cutting capacity

- Higher machine and spindle loads

- Worst surface finishes

- Chip shape and size

If the cutting edges of the tool are heavily worn and damaged, it is not always possible to reconstruct the correct geometry and respect the dimensional tolerances.

Therefore, it is essential for the user to pay attention to the wear levels and define the correct cutting screws, in order to then be able to take advantage of the advantages of reconditioning seen above.

Seco Tools has created a tool reconditioning program, which helps you recover partially used solid carbide cutters and drills, reducing your costs and limiting the need to purchase new tools.

Thanks to the processes of reconstruction and re-sharpening of the cutting edges and reapplication of the coating, we restore the geometry of the tool and the coating to the original characteristics.

Some benefits of the Seco Tools reconditioning program are therefore:

- Seco original geometry and coating

- Significant savings on tool costs

- Guaranteed quality. All processes are ISO 9001 and ISO14001 certified

- Tools capable of still guaranteeing high performance

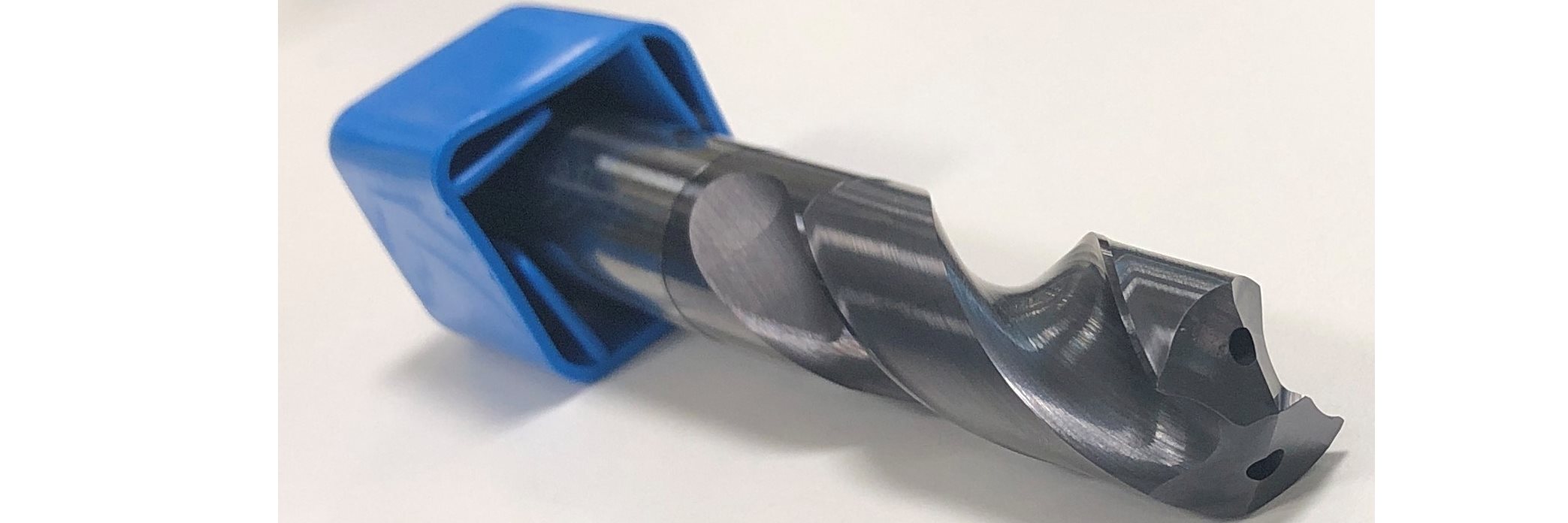

Before and after refurbishing a drill through our refurbishing service:

Before you recondition the tip After you have reconditioned the tip

Important: We mainly recondition Seco Tools tools and not other brands.

If you have purchased Seco Tools tools and would like to give them new life, you can contact us and we will provide you with all the necessary information.

You can contact our sales department closest to you and/or your officer to find out more about the program and how to participate.

Inline Content - Gridded Links

Tags: 'contact'

Max links: 1

Do you prefer us to contact you? Fill out the form and we will contact you as soon as possible!

Inline Content - Sugar Form

Sugar Form url - https://info.secotools.com/acton/fs/blocks/showLandingPage/a/45194/p/p-001a/t/page/fm/0

Frame height - 550 px