Composite Materials: Flying High!

Saving weight is currently a huge challenge for the aerospace industry. Enhanced performance, reduced fuel consumption and lower emissions can offer manufacturers major advantages in a competitive market and the use of composite materials offers opportunities in all these areas.The weight and balance of an aircraft is critical to flight safety and a significant challenge for the aerospace industry. Enhanced performance, reduced fuel consumption, and lower emissions offer manufacturers major advantages in a competitive market, and the use of advanced composite materials provides opportunities in all these areas.

After experiencing a slump for many years following 9/11 and the global recession, the global airline industry has seen strong growth in the last 3—4 years. However, rising fuel prices, dull economic conditions, and increasing competition are realities that are impacting the revenue-generating potential of the global airlines business today.

One way for manufacturers to address these issues is through weight saving, which reduces both fuel consumption in aircraft and environmental impact. This has led to a 50 percent increase in the use of composite materials in the latest generation of commercial aircraft.

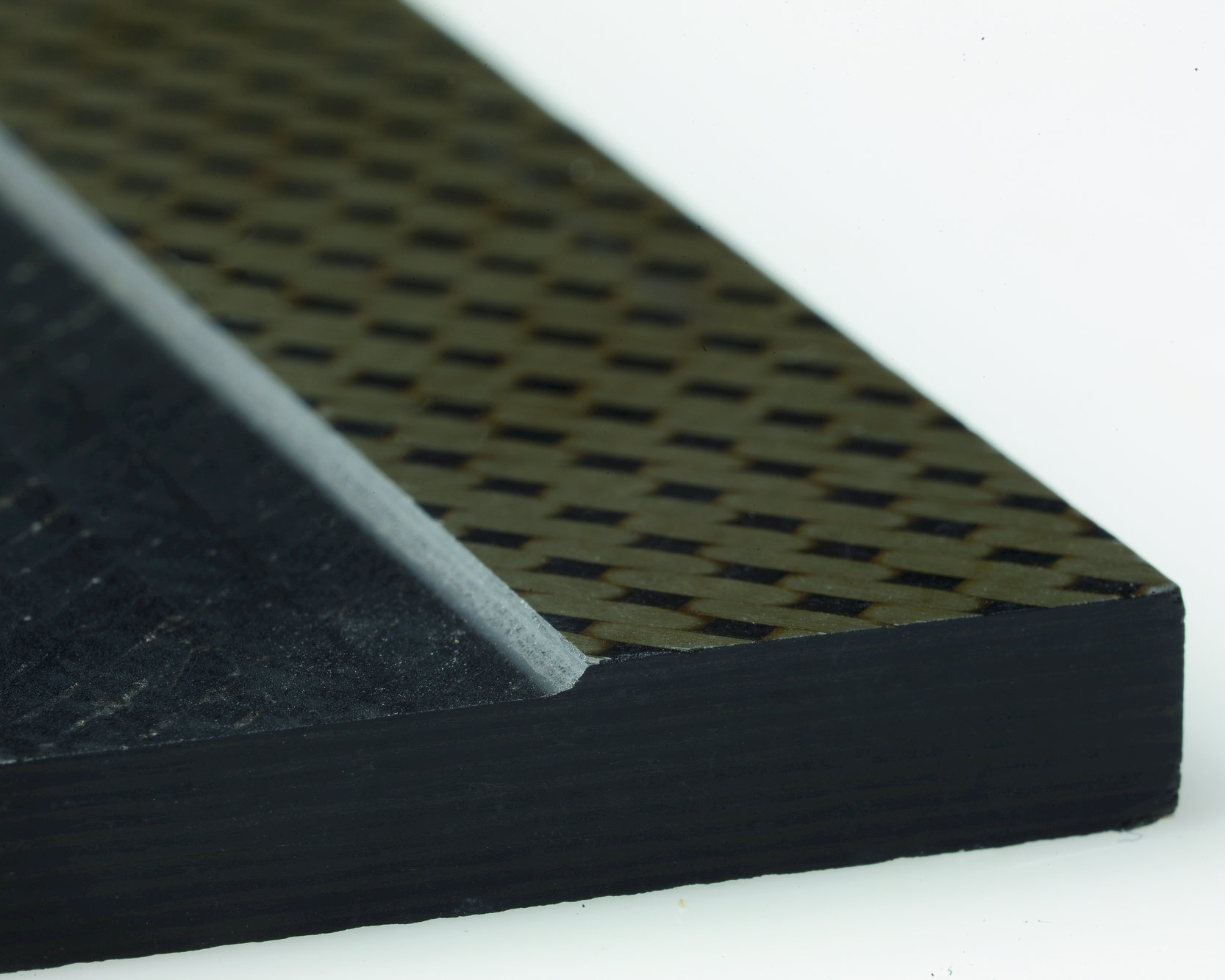

Composite materials are essentially a combination of two or more dissimilar materials used together to combine the best properties or impart a new set of characteristics that neither of the constituent materials could achieve on their own. These technologies address a wide range of issues, such as reducing the weight of existing metallic parts, avoiding corrosion, and designing out noise and vibration.

Composite materials are essentially a combination of two or more dissimilar materials used together to combine the best properties or impart a new set of characteristics that neither of the constituent materials could achieve on their own. These technologies address a wide range of issues, such as reducing the weight of existing metallic parts, avoiding corrosion, and designing out noise and vibration.

Composite materials are crucial to the aerospace industry because they provide equal or greater structural strength compared to metal components, with a lesser need for replacement. These lighter weight components allow increased fuel efficiency and reduced repair costs, offering the same or higher strength components with reduced weight. Typically found in aircraft are carbon fiber, glass fiber, and Kevlar (aramid) fiber in structural components, along with ceramic matrix composites used in brake, combustion, and exhaust components.

Composites can typically reduce the overall structural weight by 20—50 percent, improving fuel efficiency. They also provide lower costs for assembling components because they require very few fasteners, bolts, etc., and in some cases, consolidate multiple metal components into one composite component.

However, the use of composite materials presents several challenges for aircraft manufacturers. Like metal machining, composites have unique manufacturing requirements that must be maintained to ensure part compliance. This, along with advanced automation processes to help reduce manufacturing costs, is ever-evolving. In most cases, only dedicated manufacturers can fabricate composites as they can invest in advanced technology specifically for these materials and support ever-growing aircraft build rates.

Seco’s offering consists primarily of diamond-coated carbide end mills. These tools create a very good surface quality while maintaining a very high speed and feed. Seco also offers PCD (Poly-Crystalline-Diamond) brazed cutting edges, optimized for difficult cutting conditions on challenging workpiece materials.

Seco’s offering consists primarily of diamond-coated carbide end mills. These tools create a very good surface quality while maintaining a very high speed and feed. Seco also offers PCD (Poly-Crystalline-Diamond) brazed cutting edges, optimized for difficult cutting conditions on challenging workpiece materials.

Common problems when drilling composite materials include delamination, splintering, and poor surface finish. By applying optimized point geometries, the quality of the hole is improved and secured, while the diamond coating or PCD achieves competitive cutting data and extended tool life. Seco has recently launched two new standardized machine tools for hybrid stack materials: JC898 and JC899.

The rougher, JC898, is a high-feed tool with a through-coolant channel for removing excess material with compressed air. The finishing tool, JC899, has a patented double geometry design and machines a circular side milling cycle to finish the components.

Looking into the future, it is clear the aerospace industry will continue to demand lighter, more efficient aircraft.

Eventually, we may see aircraft constructed entirely of composites rather than metal, but for now, aircraft are still part metal, part composite. In the short term, we will likely see the development of processes and applications for the use of recycled materials and ongoing material optimization to reduce manufacturing costs, as composite materials are still expensive to fabricate.