Skiving

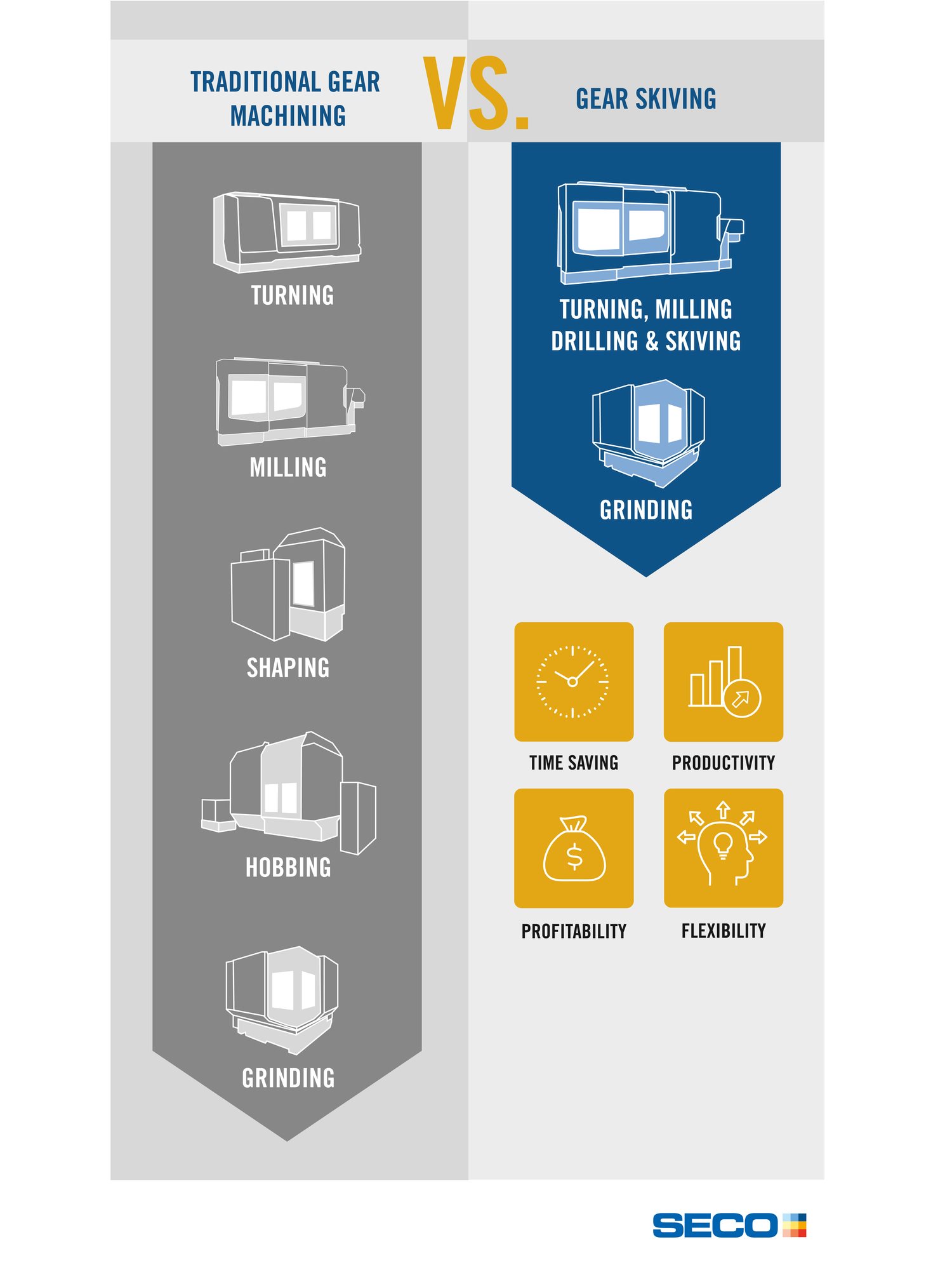

This article explains the gear machining process of skiving, how it works, why it should be used and which advantages skiving offers. Seco Tools offers advanced indexable solutions for skiving.It is a gear manufacturing process, which with a dedicated solution is applicable both on internal and external gearing. Skiving - especially as regards the solution with an interchangeable solid carbide head - allows the finishing of the tooth profile, and today it can be performed not only with the latest generation CNC gear cutting machines but also with multi-tasking machines or modern machining centres .

It cannot be regarded as a new manufacturing method, given that the first patent on skiving was filed in Germany in 1910. For almost a century, however, it did not spread due to technological limitations both in terms of software and hardware, which didn’t ensure reliability, precision and speed to make it convenient and productive.

To get a rough idea of the operating principle, you can imagine combining the gear hobbing with gear shaping. The skiving cutter can be associated to a process with a multi thread gear hob; by extremizing the number of threads of the gear hob, so that each principle corresponds to a cutting tooth, you will obtain a skiving tool.

Unlike gear hobbing, the skiving process however creates an irregular distribution of the chips with a negative rake angle at the exit of the tool tip; for this reason, a multi-pass approach is required in skiving.

Thanks to the recent technological evolution of machine tools, software and tooling itself, today skiving is a fast, efficient and flexible option to manufacture gears.

This technology allows to work the component in all its phases on a single multi-tasking machine or machining centre with a single setup. It therefore eliminates the need to have more dedicated machines, avoiding setup errors deriving from the transfer from one machine to the next, eliminating radial run-out errors almost completely. This approach allows to significantly reduce the total machining time compared to those processes that include broaching, profiling or hobbing operations, ensuring reliable and repeatable machining of the components.

The precision in the synchronization between workpiece spindle and tool spindle, now possible even at high cutting speeds, guarantees high performance while maintaining quality.

In skiving each cutting edge of the tool will work a tooth of the component in a continuous cutting process, thus representing a very efficient alternative to gear shaping, even with respect to broaching.

The productivity and versatility of this method make it suitable to produce both single pieces and medium-sized lots.

Skiving is essential especially when dealing with small geared components or with short exit space that would prevent the use of grinding wheels. In these cases, the tool exit space would be excessive, and this would damage the shoulders or parts that should not be touched according to the drawing. On the contrary, thanks to the reduced required exit space of the skiving tools, many of the common drawbacks present in other manufacturing processes are avoided.

The innovative solution with carbide inserts will eliminate the need to sharpen tools, which is unavoidable when using traditional solid tools. This means that the workshop will no longer be forced to keep twin tools in stock, optimizing the tool warehouse.

The novelty of the solution with interchangeable carbide heads allows, in addition to the possibility of sharpening them up to 4x, to keep the shank and only change the head at the end of its life.

- Machining of a complete component with a single setup

- Reduction of the processing phases

- Reduction of machine stops

- Reduction of production time

- Increase in performance and productivity

- Better quality and predictability

- Cost reduction

- Duration and convenience

- Elimination of regrinding with the insert solution

- Ability to work in the presence of shoulders