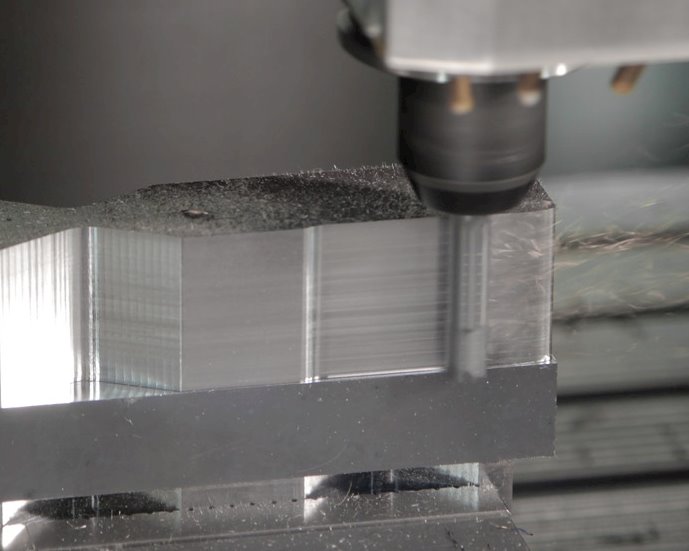

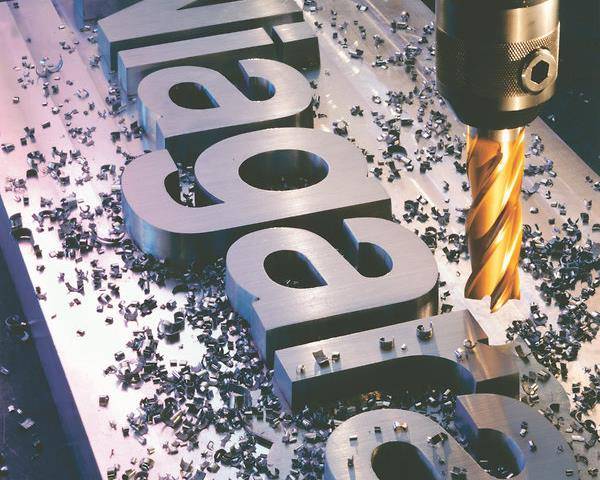

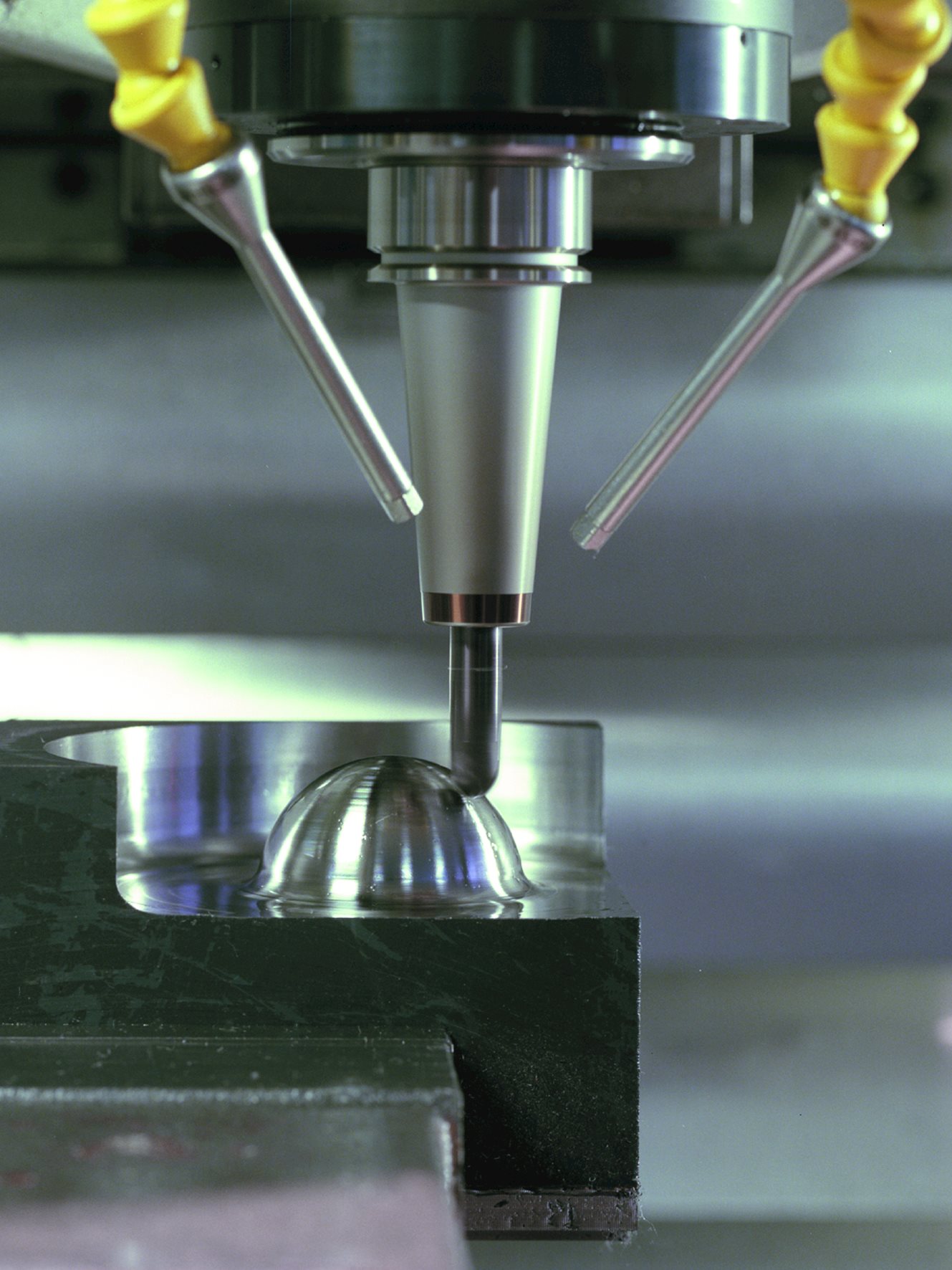

Multi flute solid carbide end mills

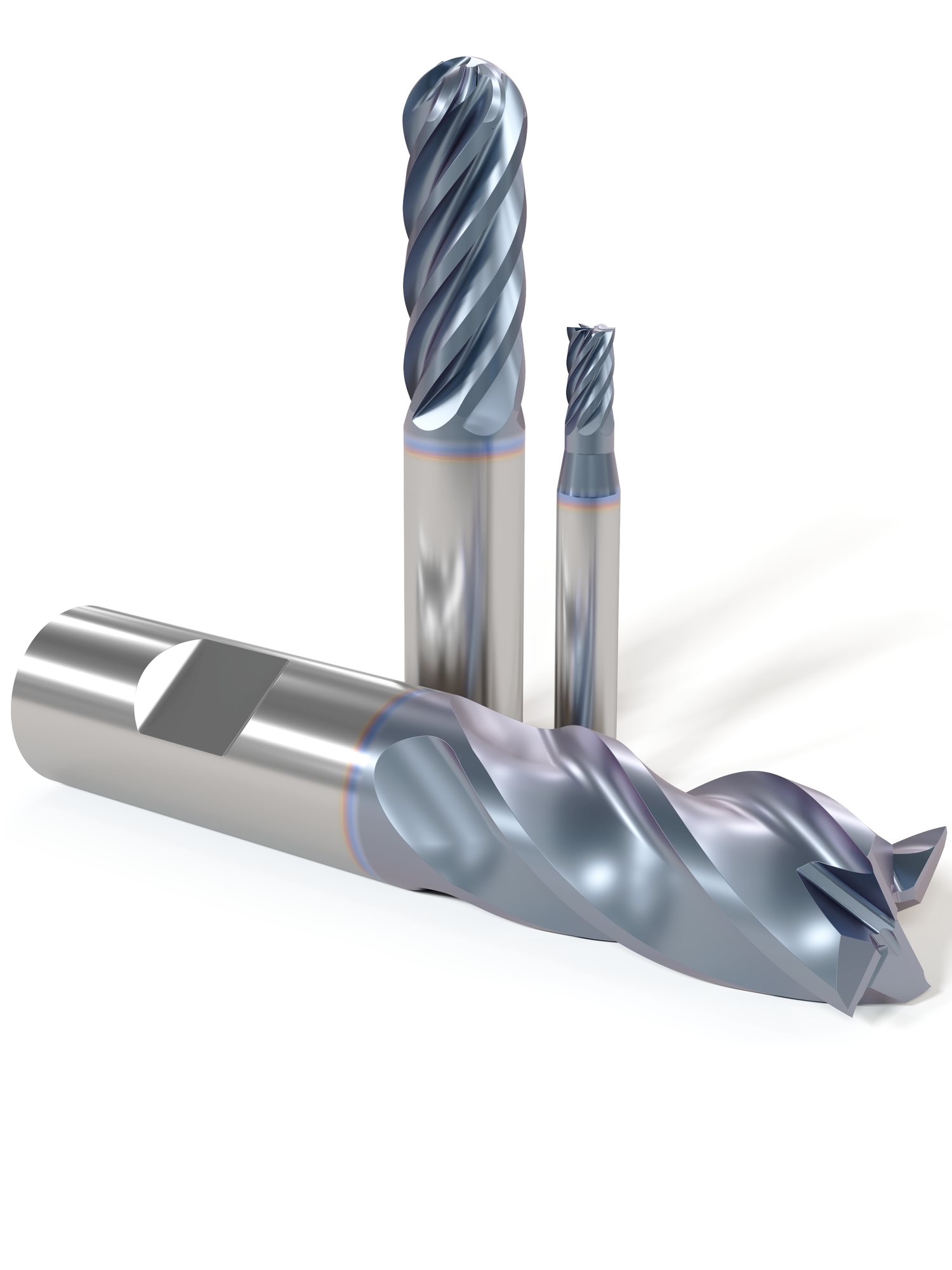

Take optimized roughing to a new level of performance with the Multi Flute family of products.This product series now offers smaller diameters down to 1/8”, necked versions with extended reaches, and even a new ball nose option for those demanding 3D applications that require optimal performance and tool life. Thanks to the introduction of over 80 new tools, this extensive product range has all you need to master the art of optimized roughing.

Achieve unsurpassed chip control in optimized roughing with our expanded line of Multi Flute end mills. Innovative engineering, such as a new, advanced chip splitter design, ensures that you can thrive even in applications requiring depths of cut up to 3 times the diameter of the tool.

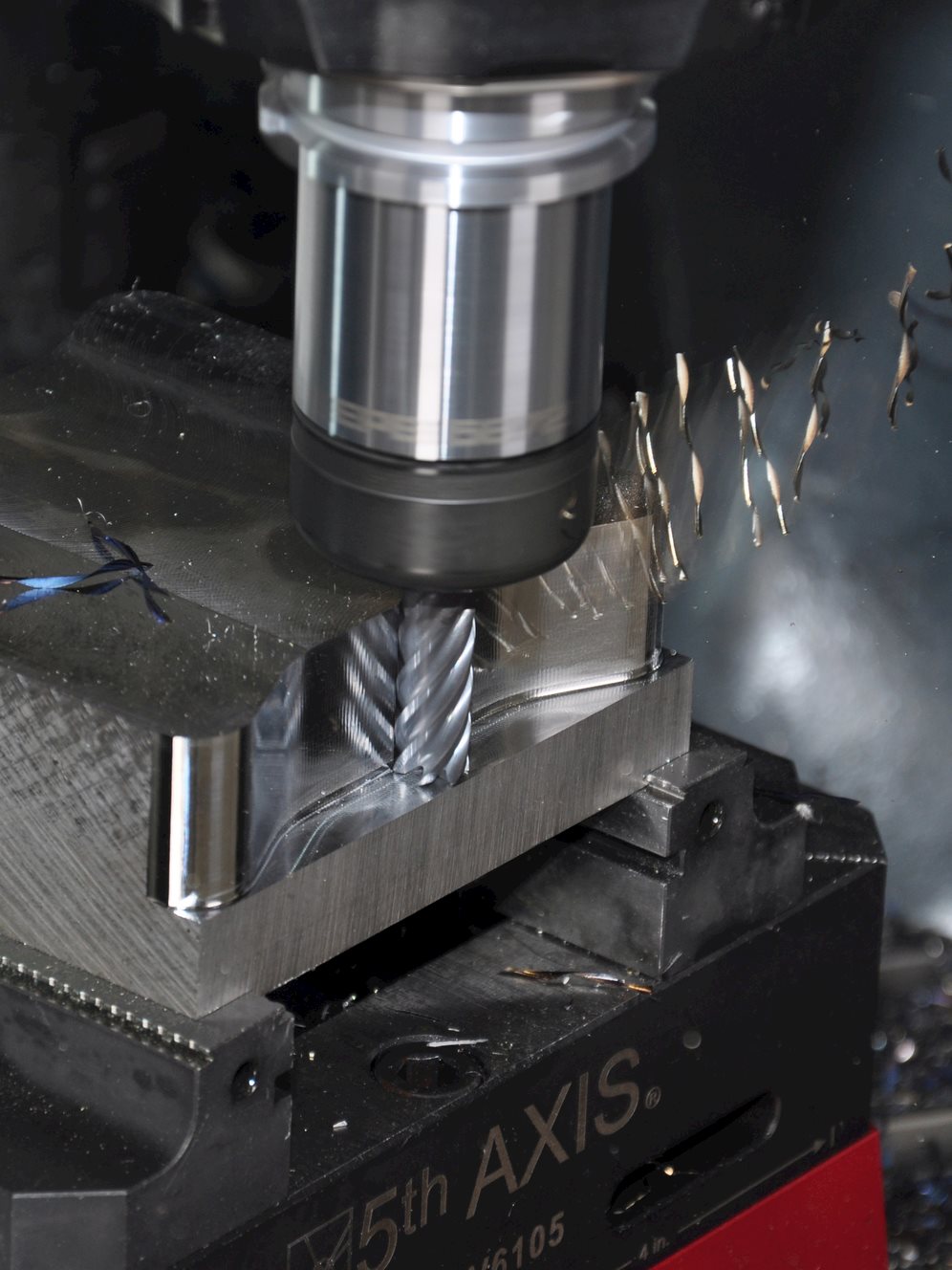

Optimized roughing can be highly effective for machining part features such as pockets with challenging corners as well as any straight walls two times the diameter of your end mill and require long axial depths of cuts. This strategy enables you to machine pockets three to four times faster than conventional methods while also dramatically extending the life of your tools.

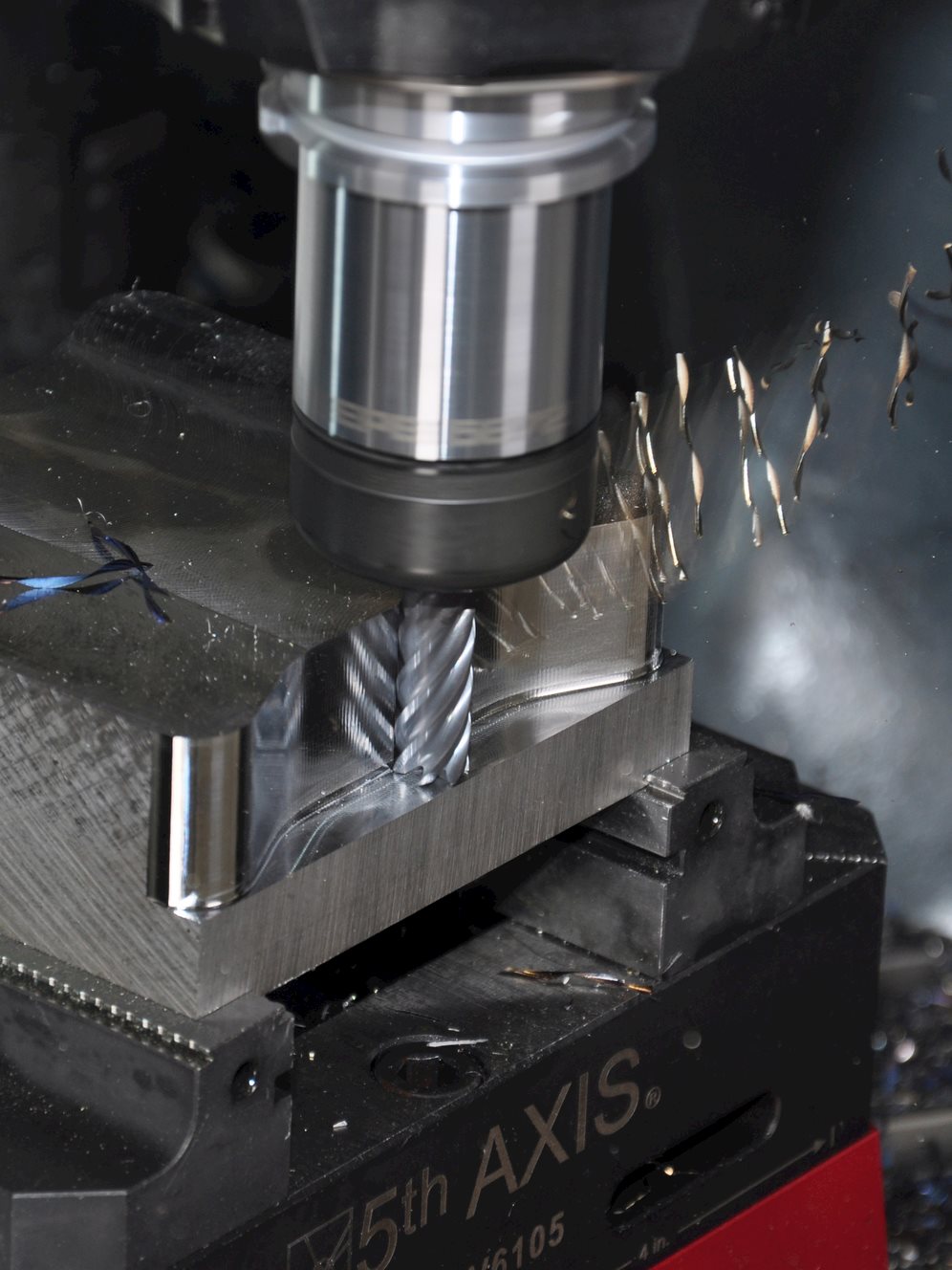

- Increased chip evacuation in deep pocket applications

- TiAIN coating increases tool life

- Smoother cutting for an improved surface finish

- High heat abrasion resistance

- Stronger cutting edge

- Designed for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloys

- Eccentric O.D. relief creating a stronger cutting edge

- Variable indexing to reduce harmonics providing smoother cutting and improved surface finish

- Increased radial depths as compared to the S738 & S938

View High-Performance Range

View Advanced Roughing Range

- Designed for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloys

- Variable indexing to reduce harmonics providing smoother cutting and improved surface finish

- Eccentric O.D. relief creating a stronger cutting edge

- Increased feed rates as compared to the S638

View High-Performance Range

View Advanced Roughing Range

- Designed for Optimized and Peripheral Roughing and Finishing applications in Stainless Steel, Titanium and high-temperature alloys

- Eccentric O.D. relief creating a stronger cutting edge

- Variable indexing to reduce harmonics providing smoother cutting and improved surface finish

- Maximum feed rates

View High-Performance Range

View Advanced Roughing Range

Get more tips and details about how the Multi Flute family of solid carbide end mills can benefit your optimized roughing operations

Download Brochure

Descargar Folleto

Related content

High Performance Optimized Roughing in 17 4 PH Stainless Steel Dry

Niagara Cutter High Feed Machining Product Introduction

Optimized Roughing 17-4 PH Stainless Steel Dry

ABOUT NIAGARA CUTTER

Niagara Cutter Multi Flute - Elite Series

Niagara Cutter's SN200R, SN400R and SN500R

High Performance Optimized Roughing with Stabilizer 2.0

Mold & Die End Mill Expansion Introduction

Niagara Cutter to Be Fully Integrated to Seco Brand

Niagara Cutter Brand Integration Distributor Resources

Video: High Performance Optimized Roughing with Stabilizer 2.0

Video: Niagara Cutter Stabilizer 2.0 Product Introduction

ACS540 / ACS540R End Mills

A245/A345 family of end mills

Niagara Cutter® HTA Coating Product Expansion

Machining Navigator / Catalog NIAGARA

A245 A345 2022_1 Product Presentation

NIAGARA CUTTER® A245/A345 UPGRADE

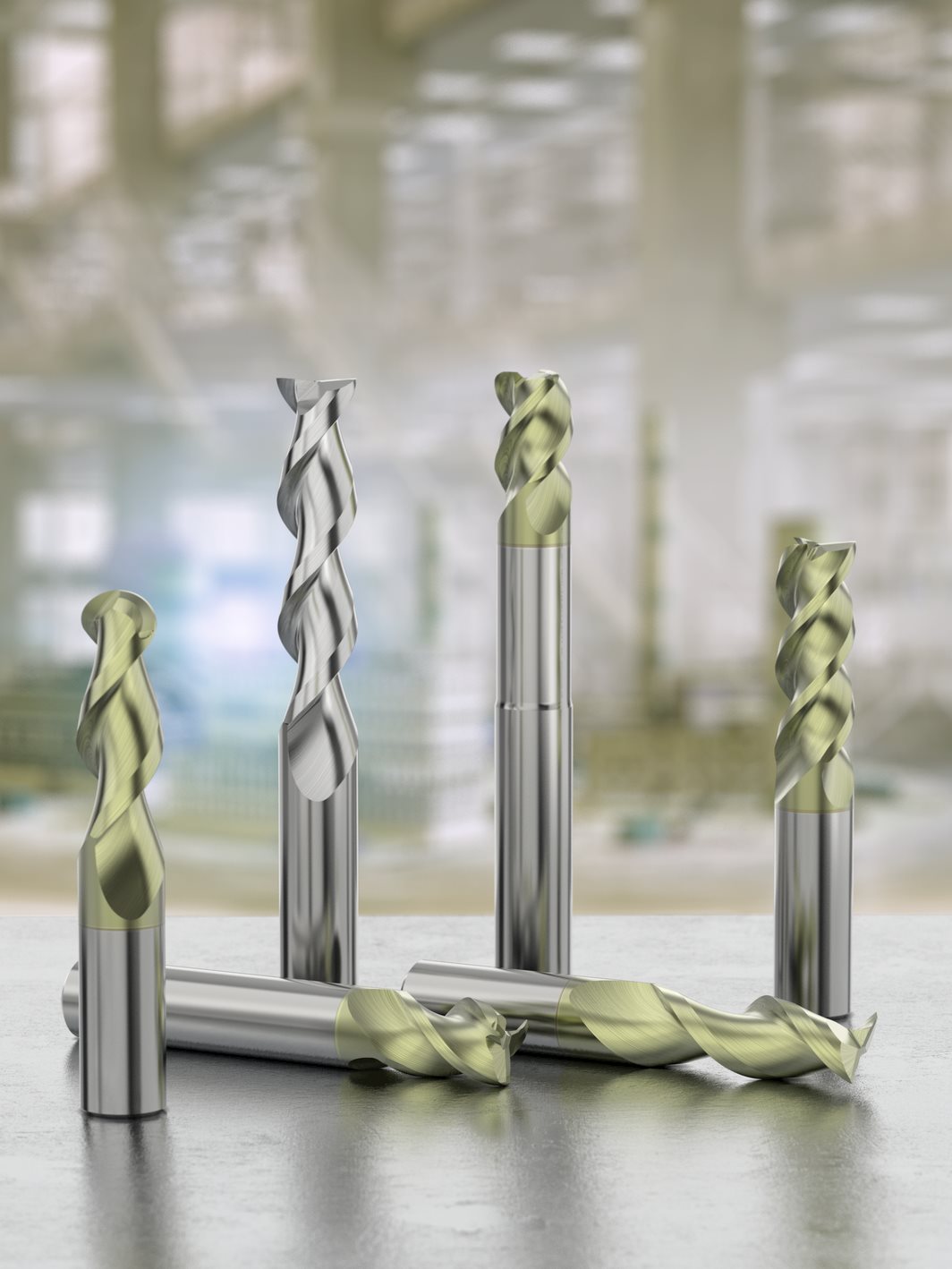

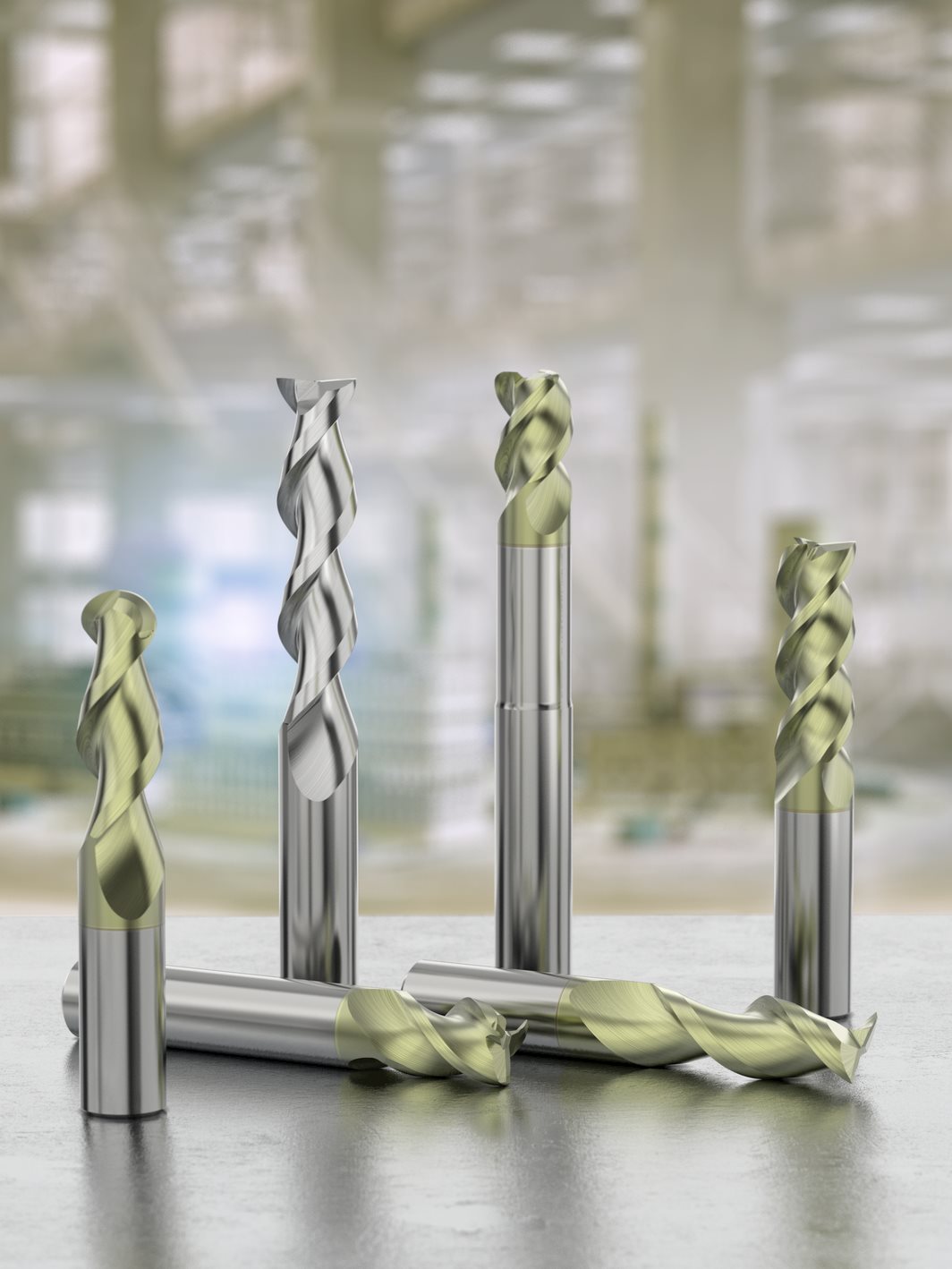

MAXIMIZE YOUR PRODUCTIVITY IN ALUMINIUM APPLICATIONS

Tackle Aluminum Milling with Ease Using the Niagara Cutter A Series