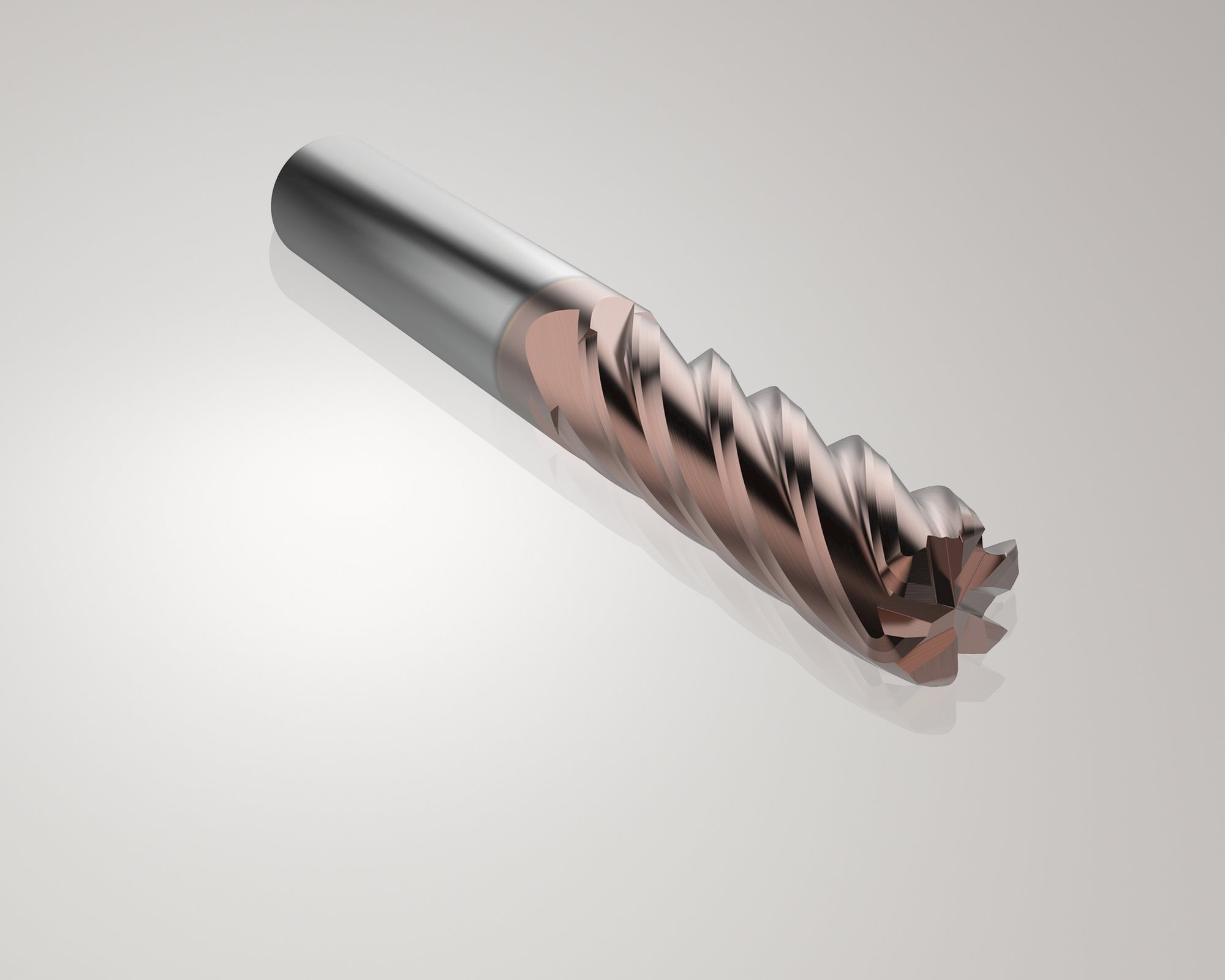

Extend Tool Life And Secure Your Processes With HTA Coating

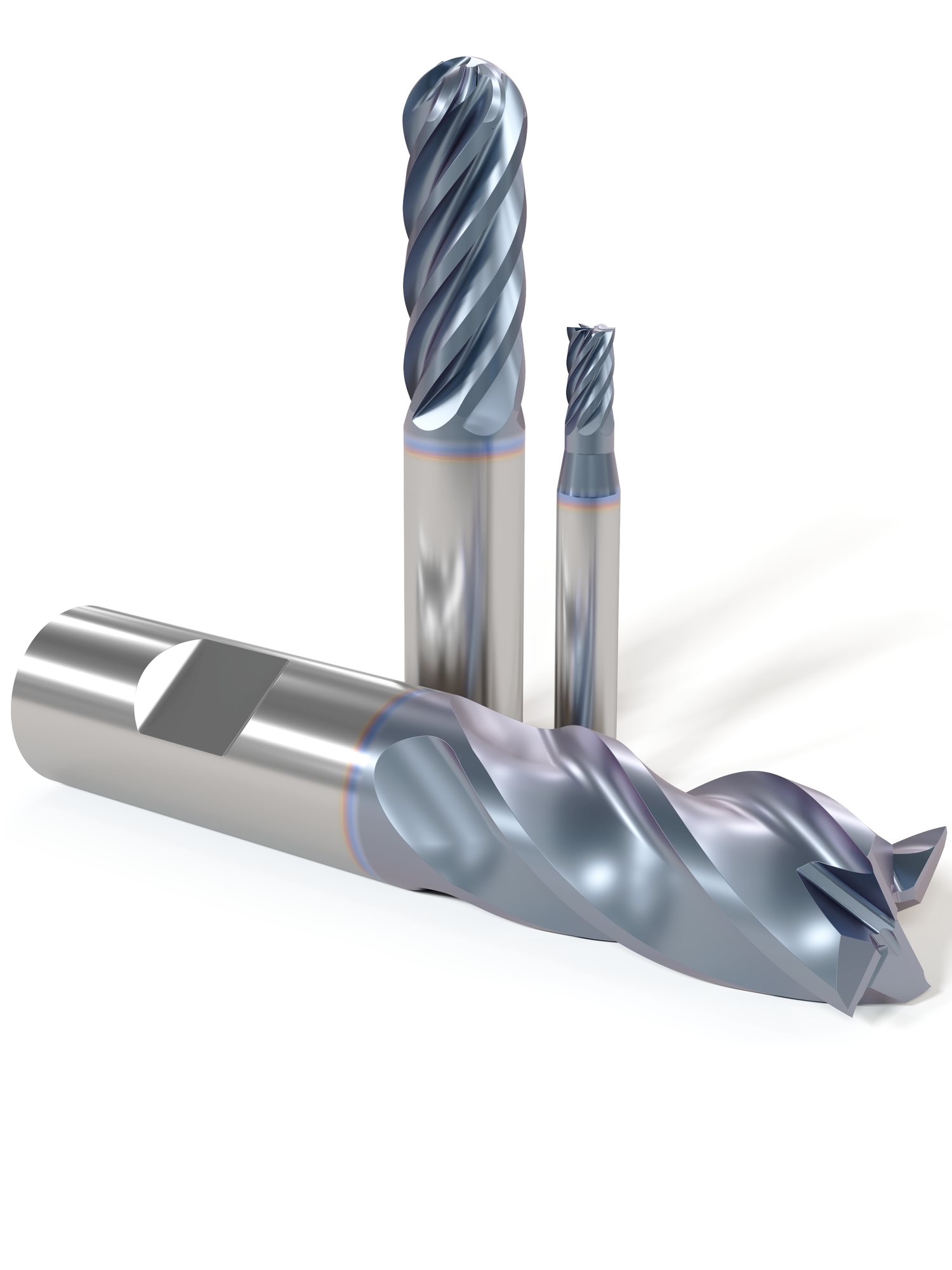

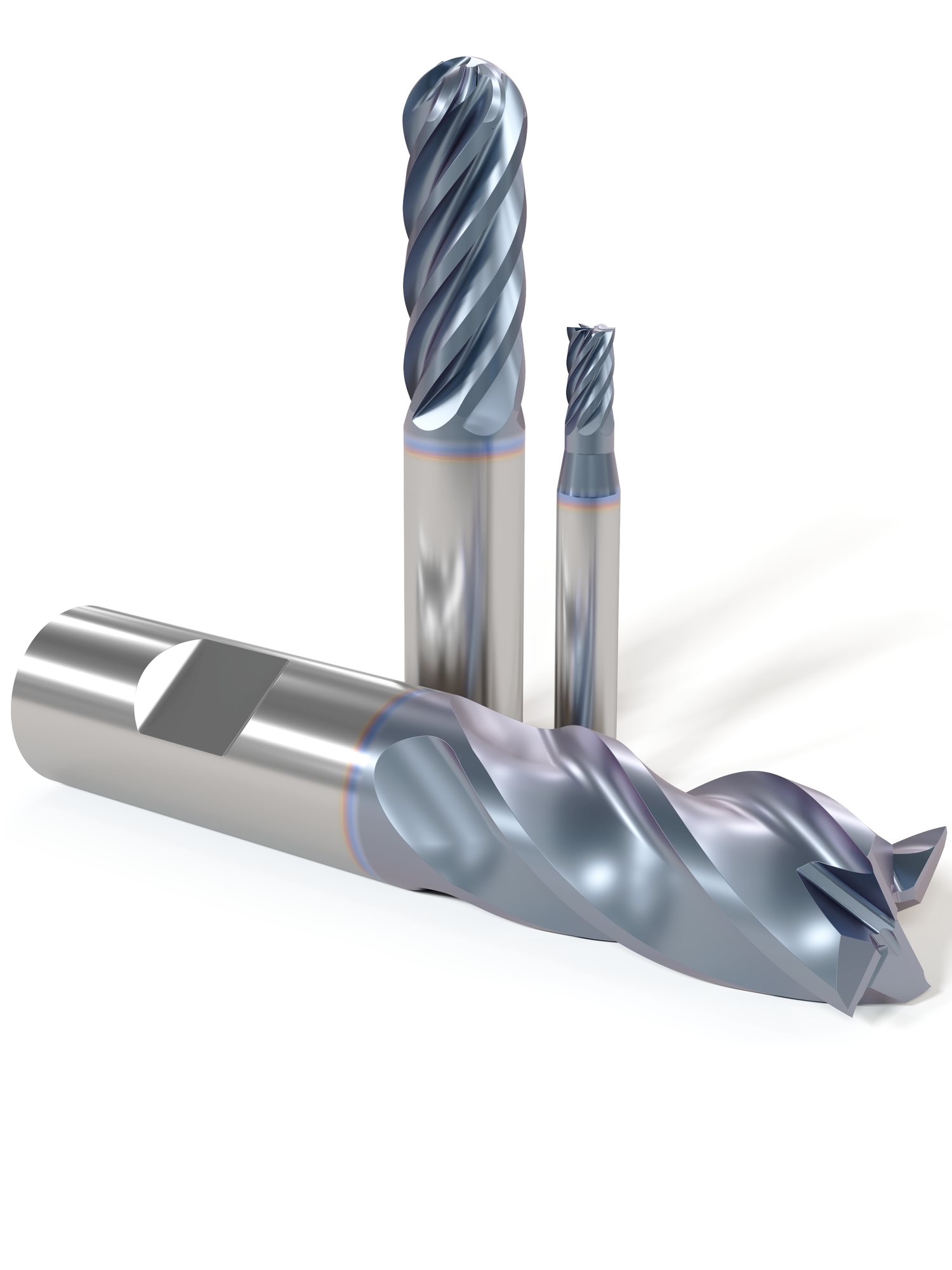

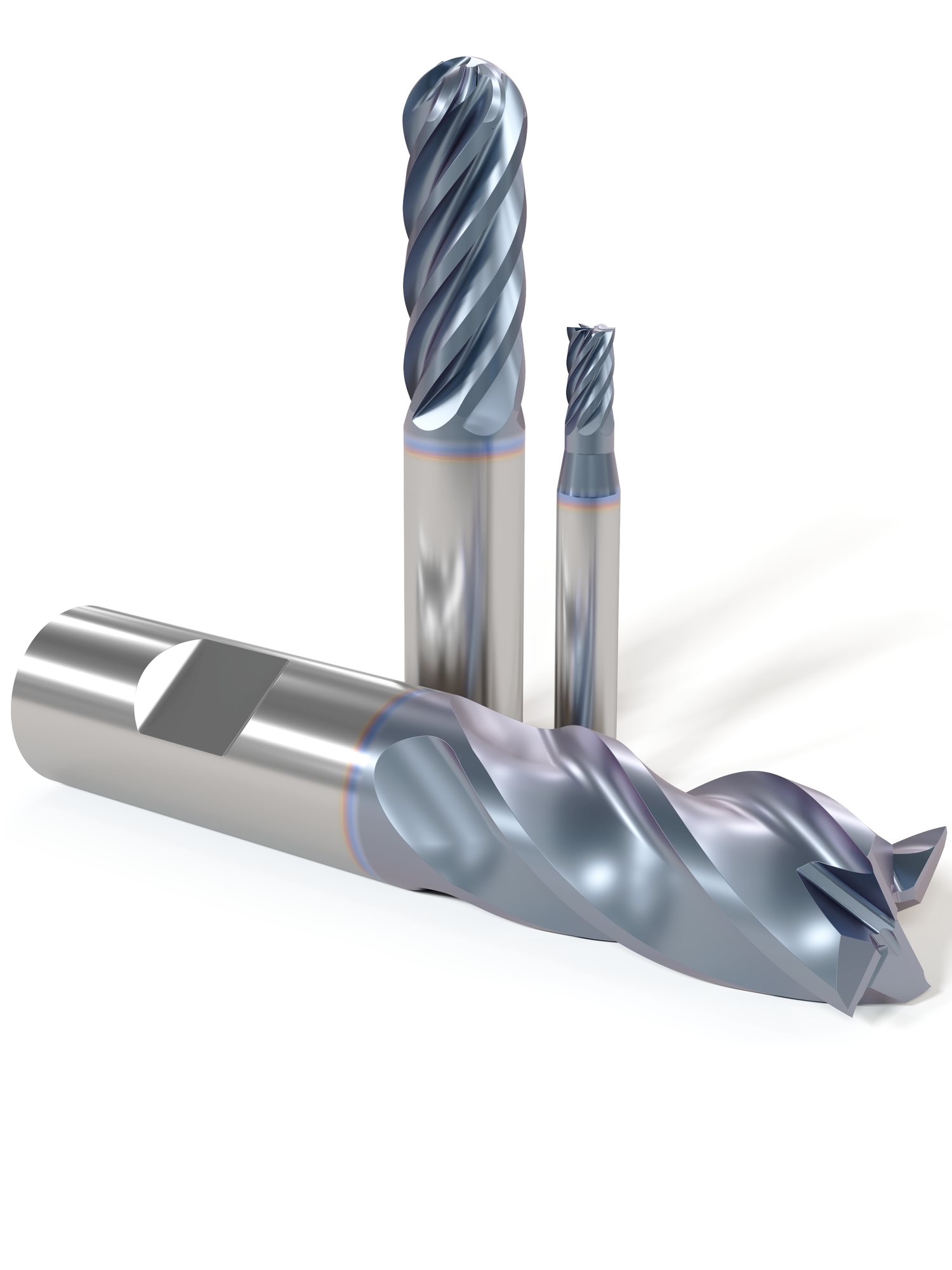

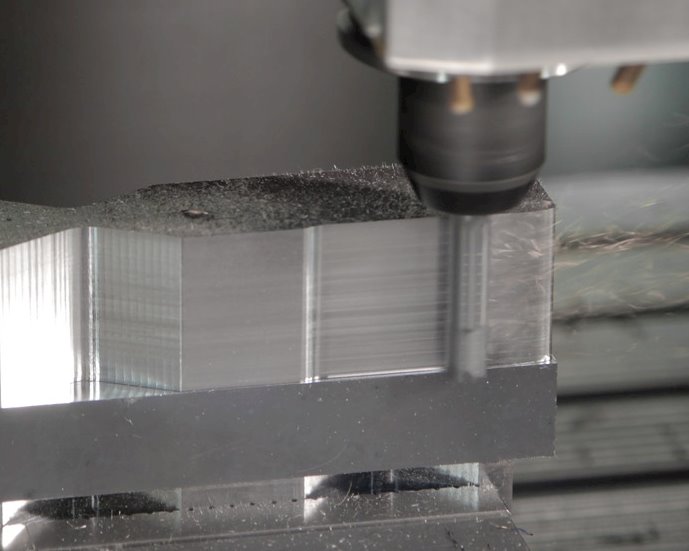

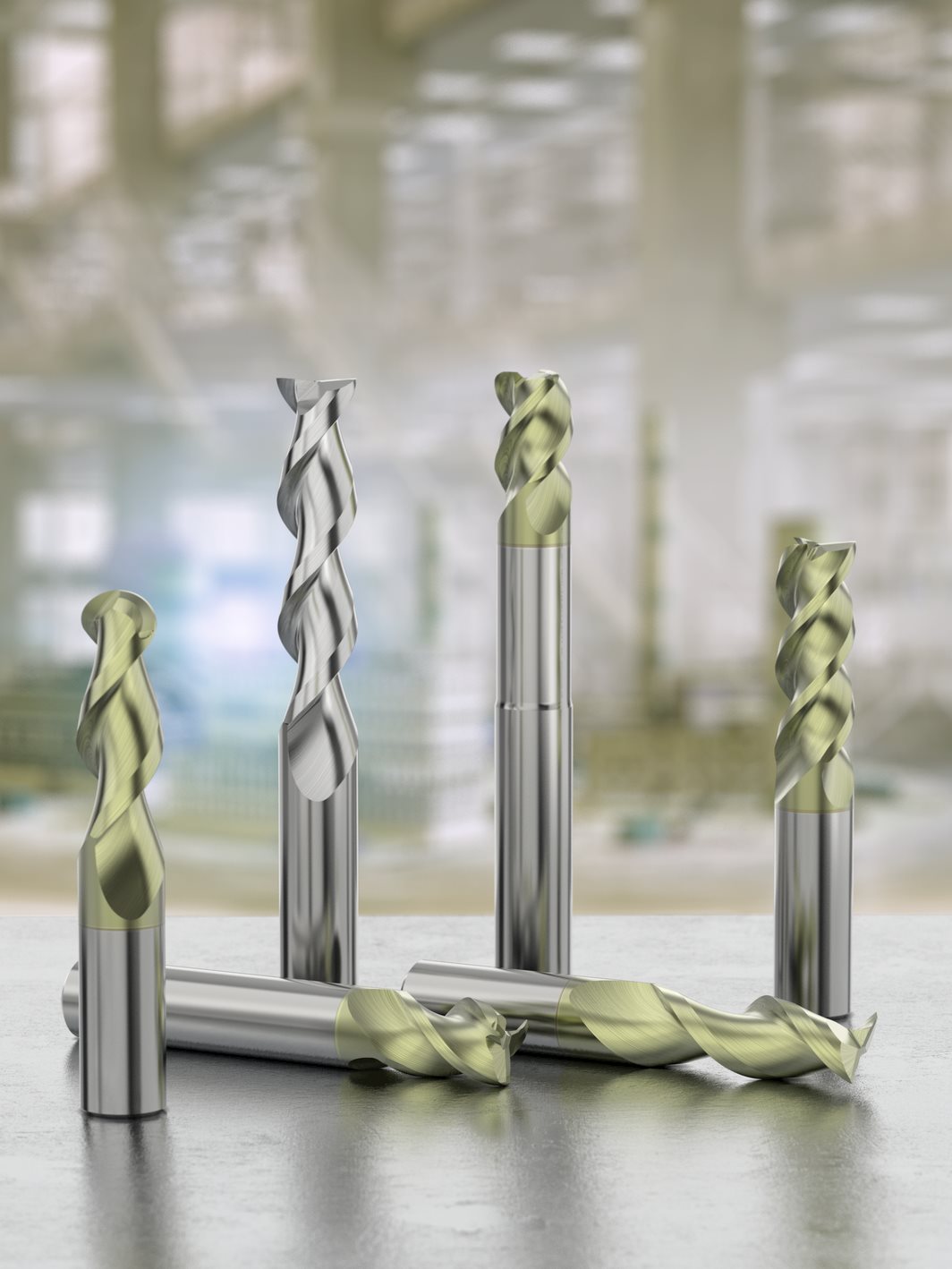

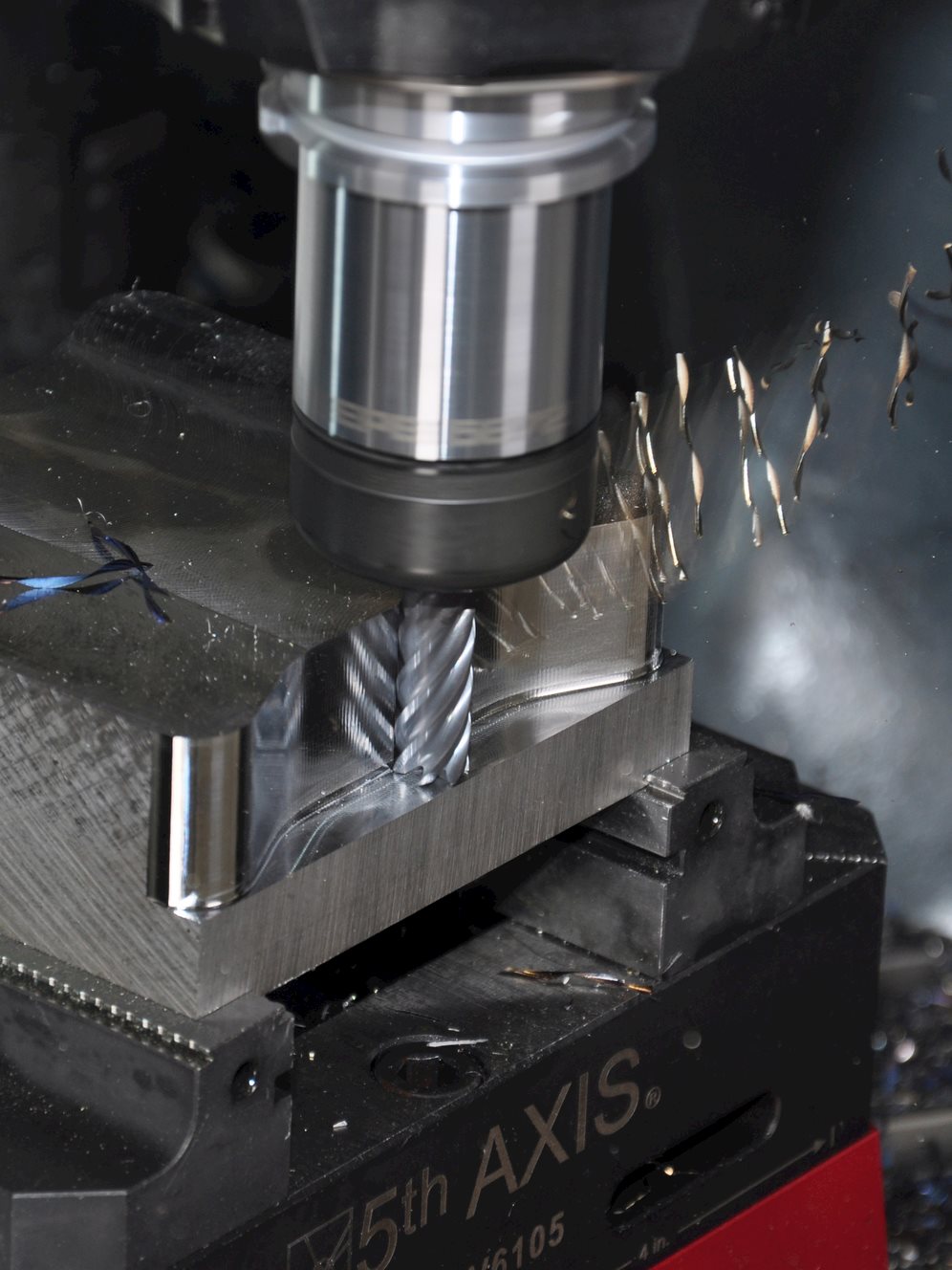

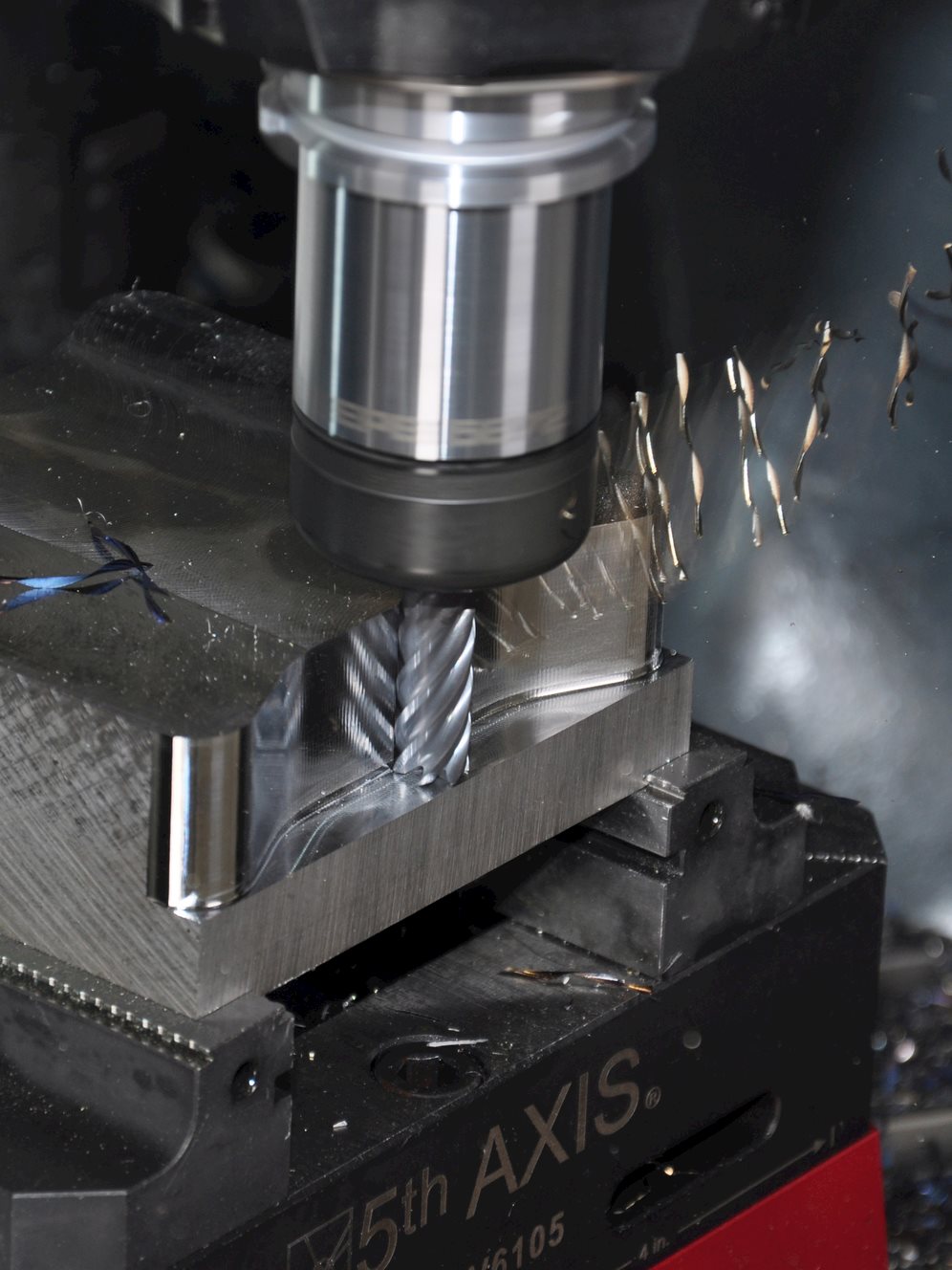

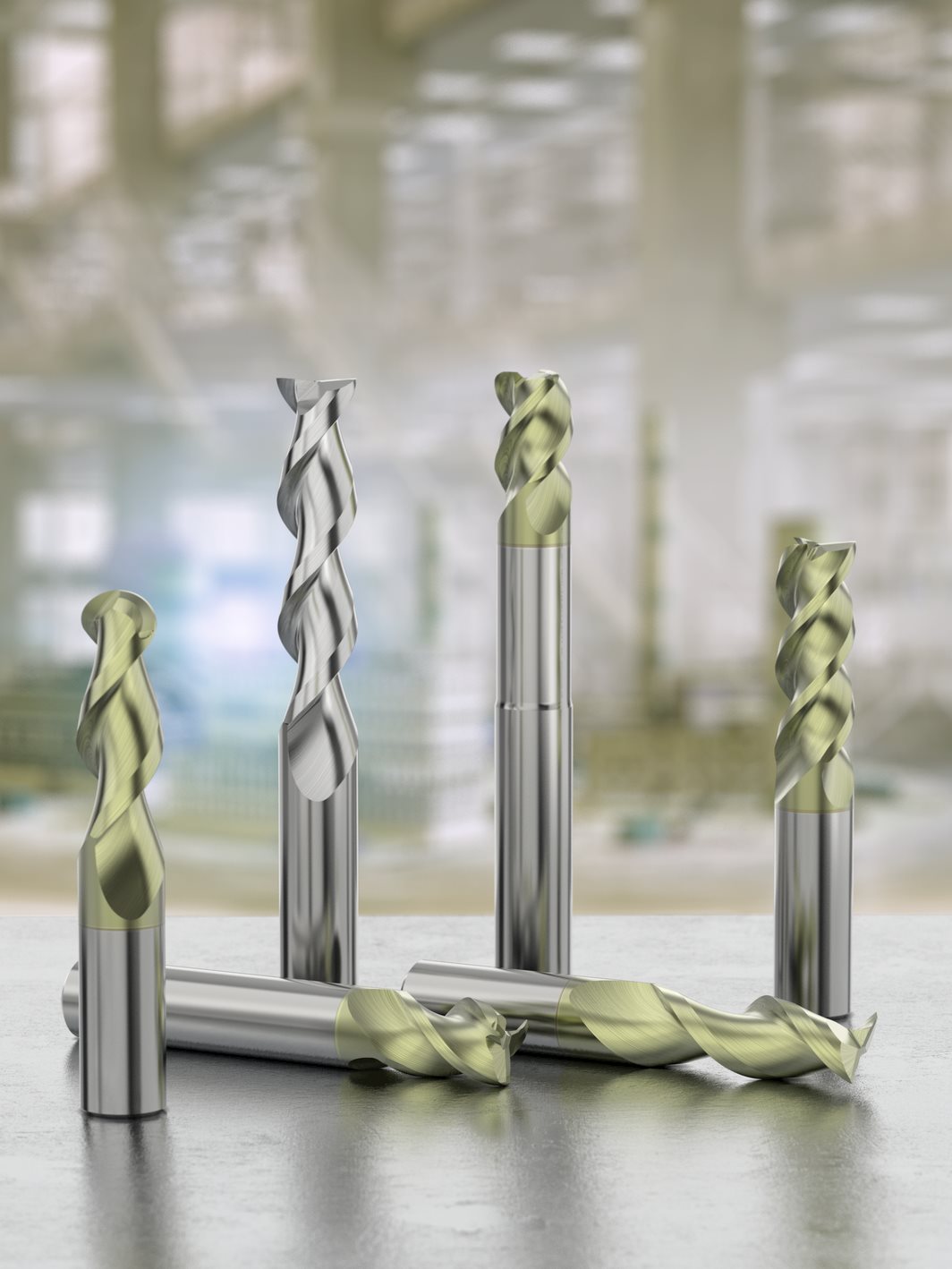

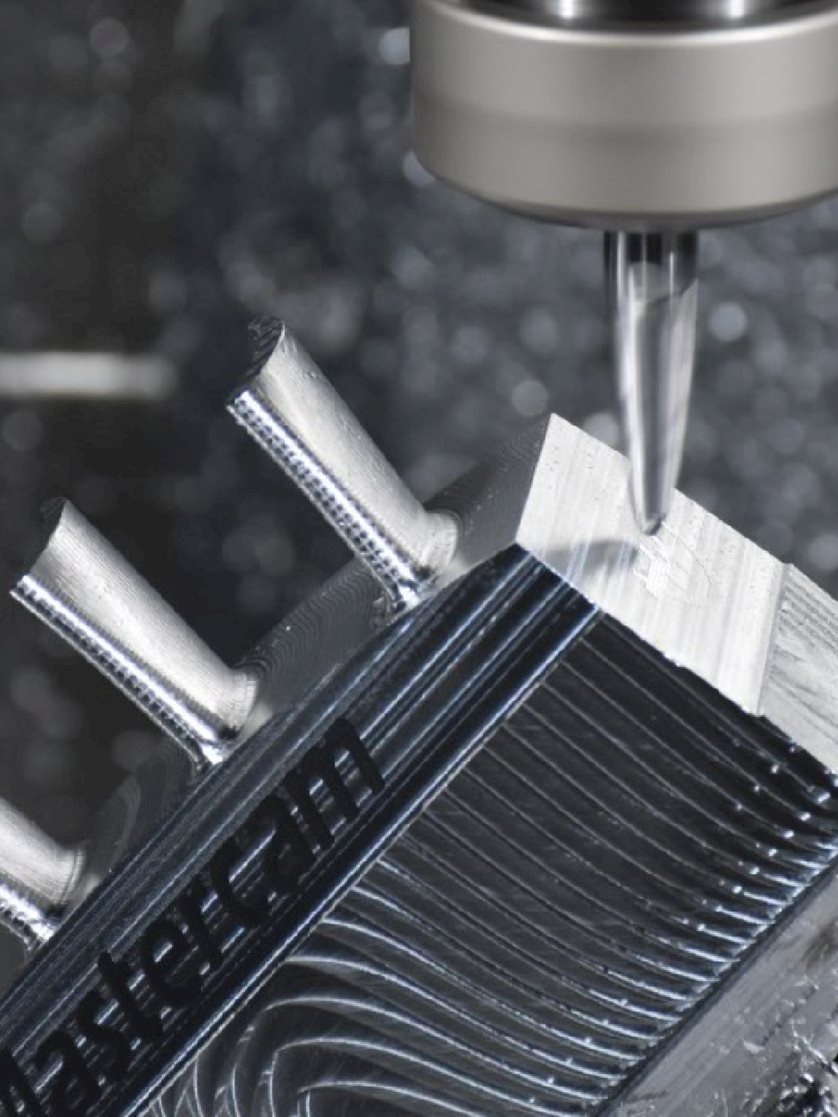

Keep gummy, abrasive ISO-S & ISO-M materials under control and maximize tool life with the new HTA coating, available on select Niagara Cutter® products.Gummy, abrasive superalloys and stainless steels are extremely tough on tools, and that means they’re tough on your processes and your bottom line. Secure your applications and ensure consistent, high performance with the new High-Temp Alloy (HTA) coating from Niagara Cutter®. Designed specifically for ISO-S and ISO-M materials, the HTA coating significantly improves tool life and reliability by preventing chipping, thermal and abrasive wear, and built-up edge.

Your challenge:

Unpredictable tool life in ISO-S and ISO-M material groups.

The Seco solution:

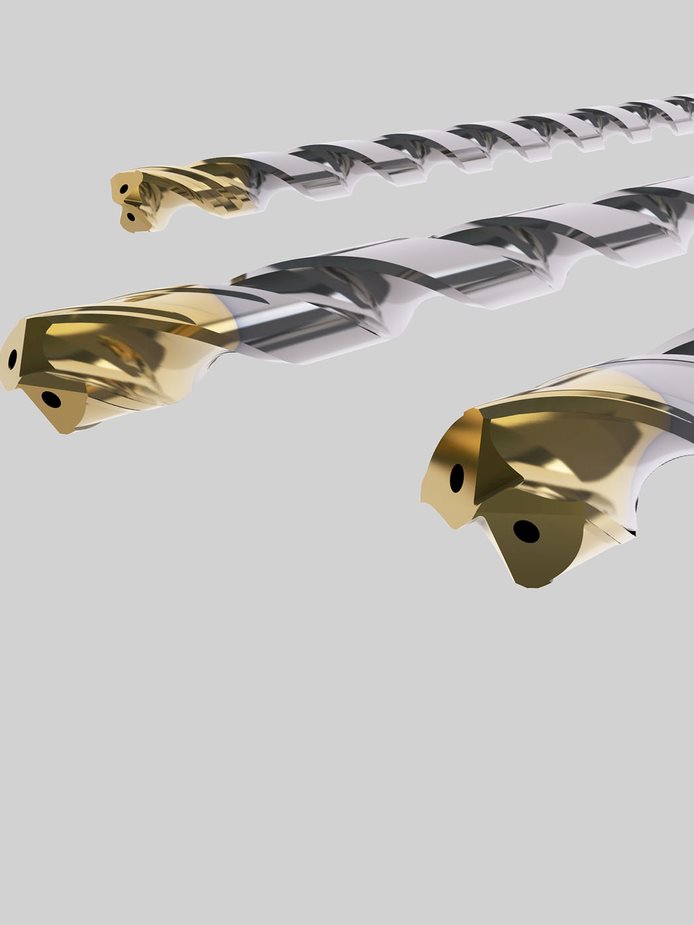

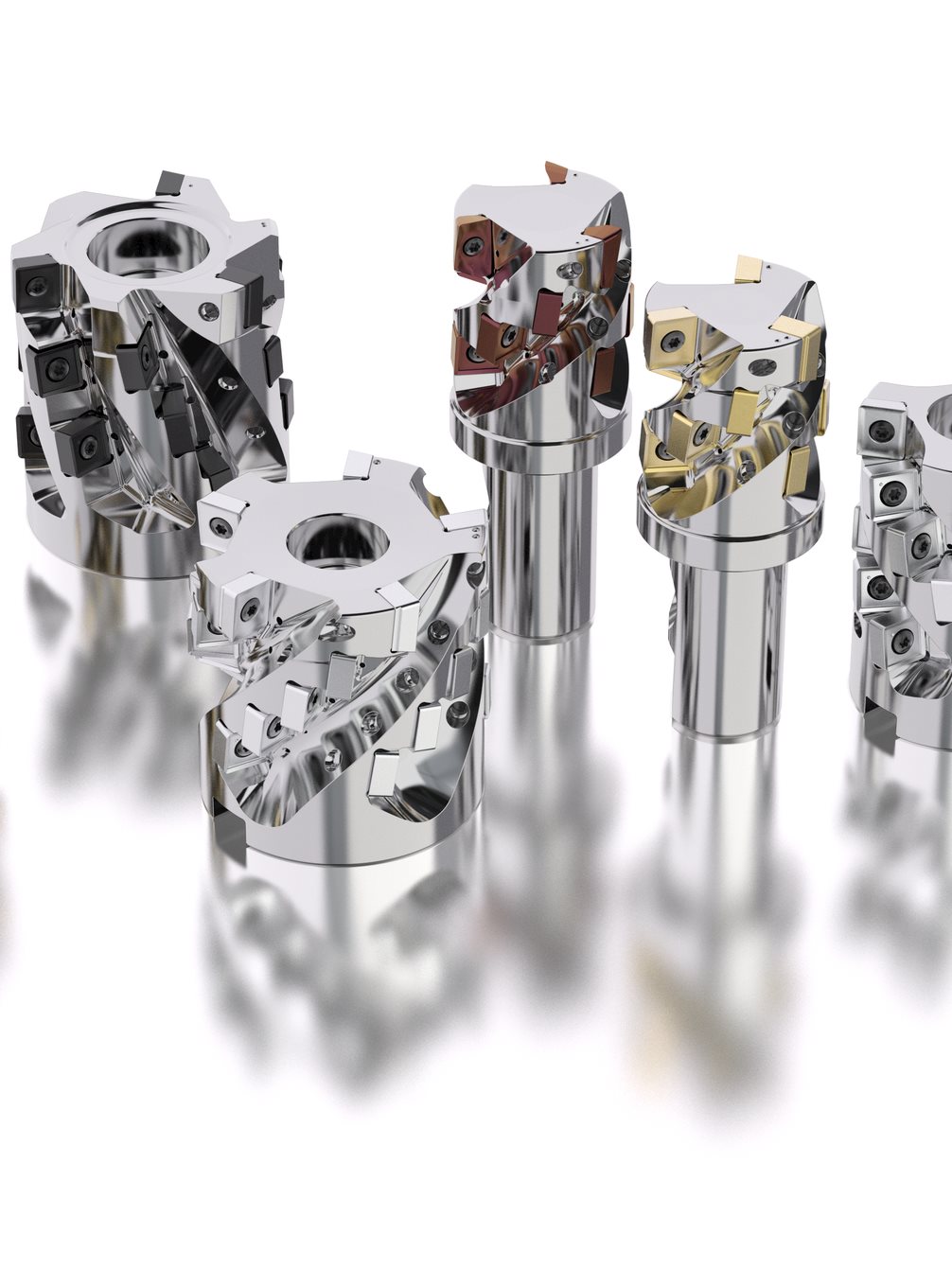

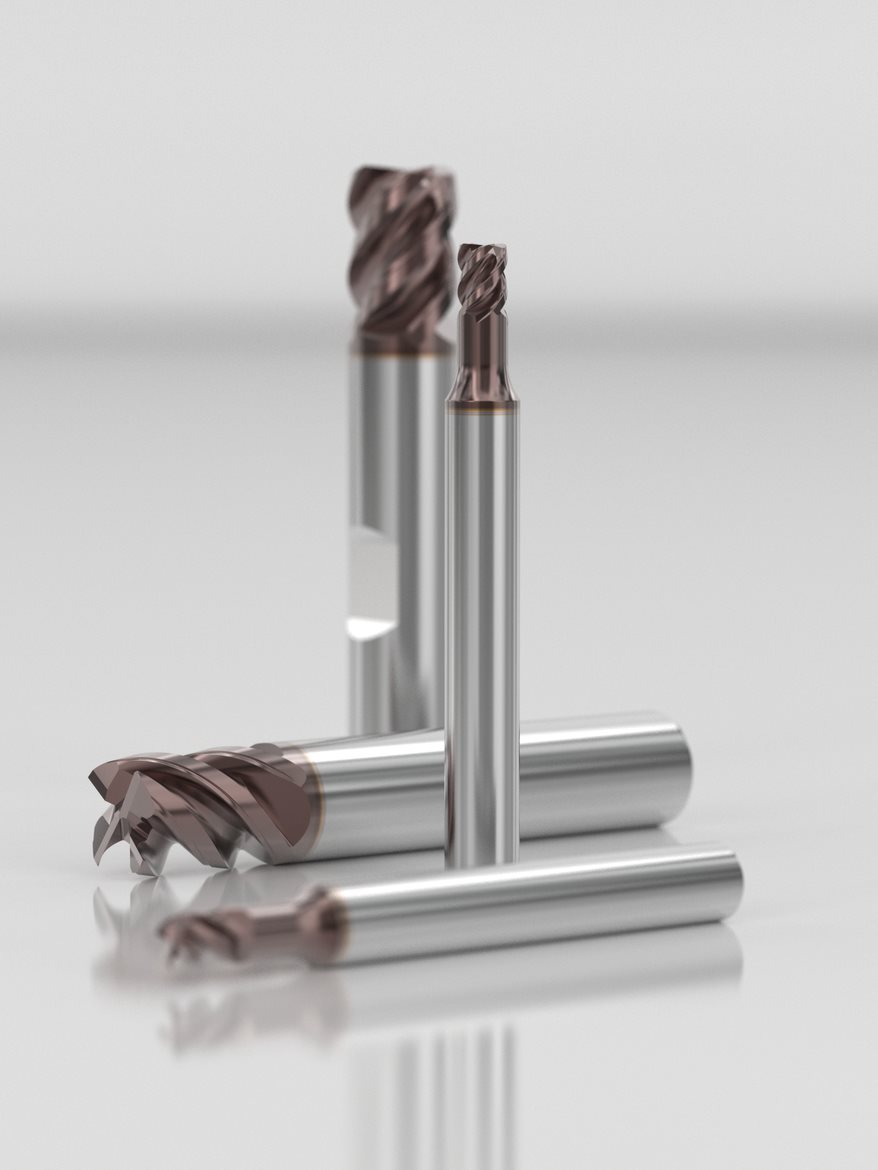

HTA-coated solid end mills specifically engineered for overcoming challenges in ISO-S and ISO-M solid milling applications.

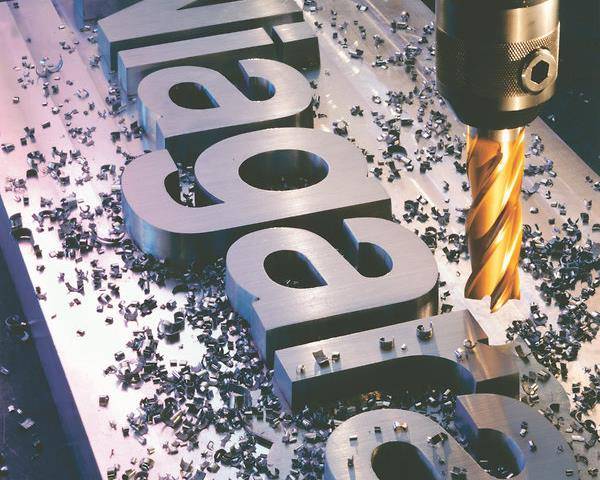

Versatility and performance are considered incompatible, especially when it comes to milling materials like stainless steels and superalloys. These difficult-to-machine materials cause considerable tool wear, and the reduced tool life requires frequent machine stoppage for tool replacement, delaying deliveries and reducing the time available for production. Handle these challenging materials easily with the new HTA coating, now available on a select range of Niagara Cutter® solid end mills for stability and high performance for everything from optimized roughing to finish machining.

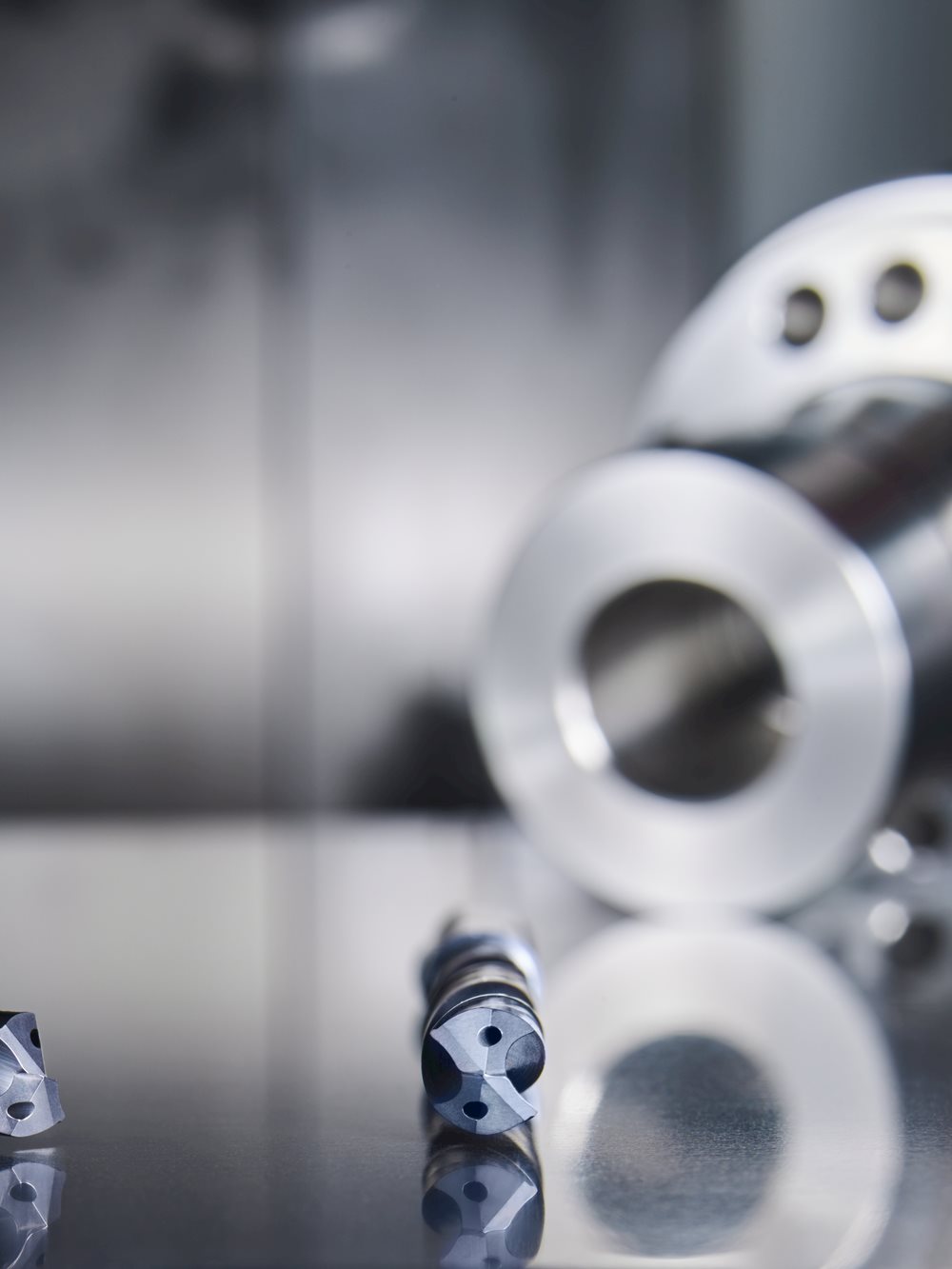

Titanium, Inconel®, stainless steels and other tough, hard-to-machine materials are critical for state-of-the-art knee implants, turbine blades, jet engines and more. These types of components are extremely challenging in terms of surface finish, quality and tolerances – and due to the high material costs, manufacturers can’t afford scrapped workpieces. Niagara Cutter® HTA coating provides a unique blend of reliable toughness and increased heat and abrasive wear resistance. This ensures stable, reliable processes across a wide range of applications.

Your challenge:

Built-up edge, heat resistance, and chipping

The Seco solution:

Increased process performance and stability with HTA coating, premium carbide substrate, and proven high-performance geometries.

Stabilizer 2.0

S545

S638

S738

S938

Contact Us

Related content

CONTACT US

Product Range Presentation - HTA Coating Product Family

Brochure - HTA Coating Product Family

ACS540 / ACS540R End Mills

Niagara Cutter Multi Flute - Elite Series

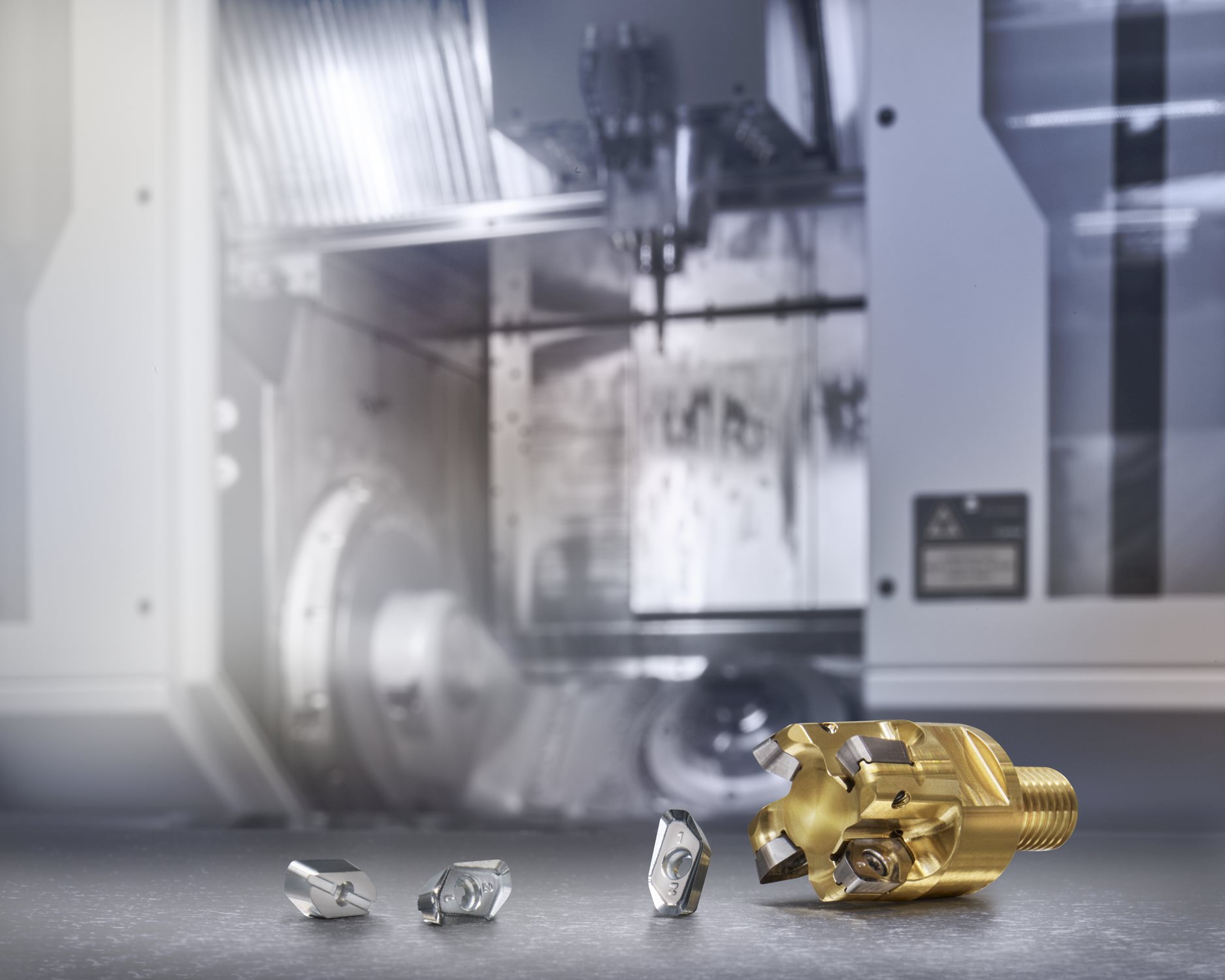

Niagara Cutter High Feed Machining Product Introduction

JS720 Solid End Mills addition

Challenges in titanium

Overcome Challenges Milling Superalloys and Stainless Steel

JH730 Solid End Mills addition

Challenges in stainless steel

8 tips to machine titanium alloys

Video: Niagara Cutter ELITE Series Multi Flute S638

SCS638R - Advanced Roughing - Square - Universal - 6 Flutes

SCS938R - Advanced Roughing - Square - Universal - 9 Flutes

SCS738R - Advanced Roughing - Square - Universal - 7 Flutes

S938R - High Performance - Square - Universal - 9 Flutes

S738R - High Performance - Square - Universal - 7 Flutes

S638R - High Performance - Square - Universal - 6 Flutes

S545 - High Performance - Square - Universal - 5 Flutes

ABOUT NIAGARA CUTTER

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

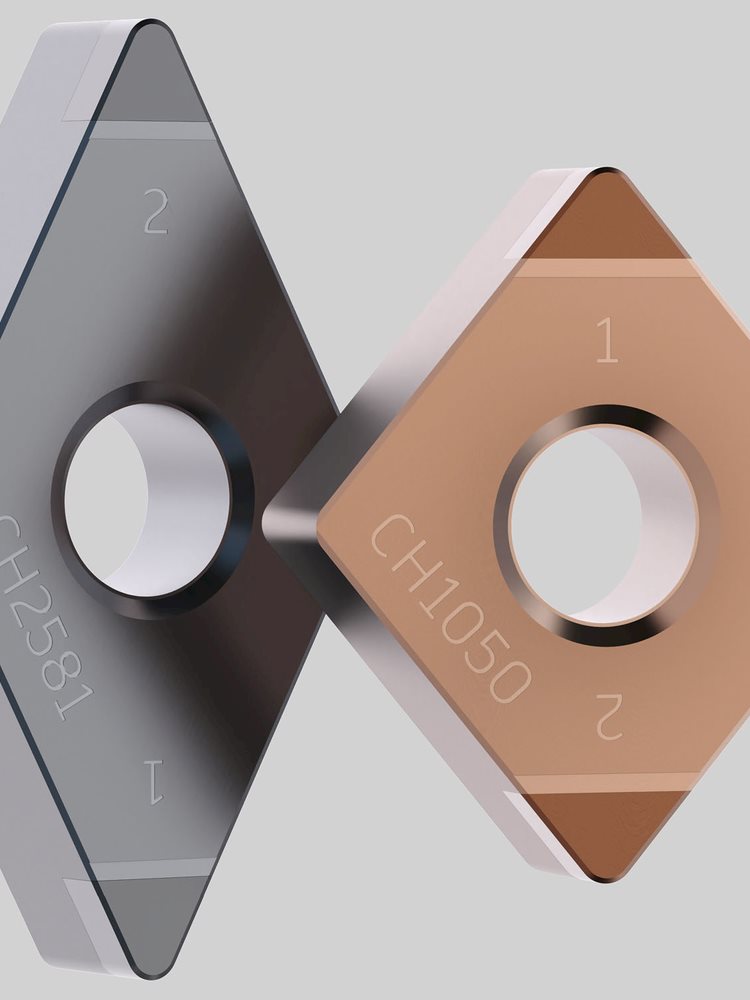

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

Seco Digital Tool Assembly: quick, accurate data

Square T4-12 Upgrades

Universal Drills

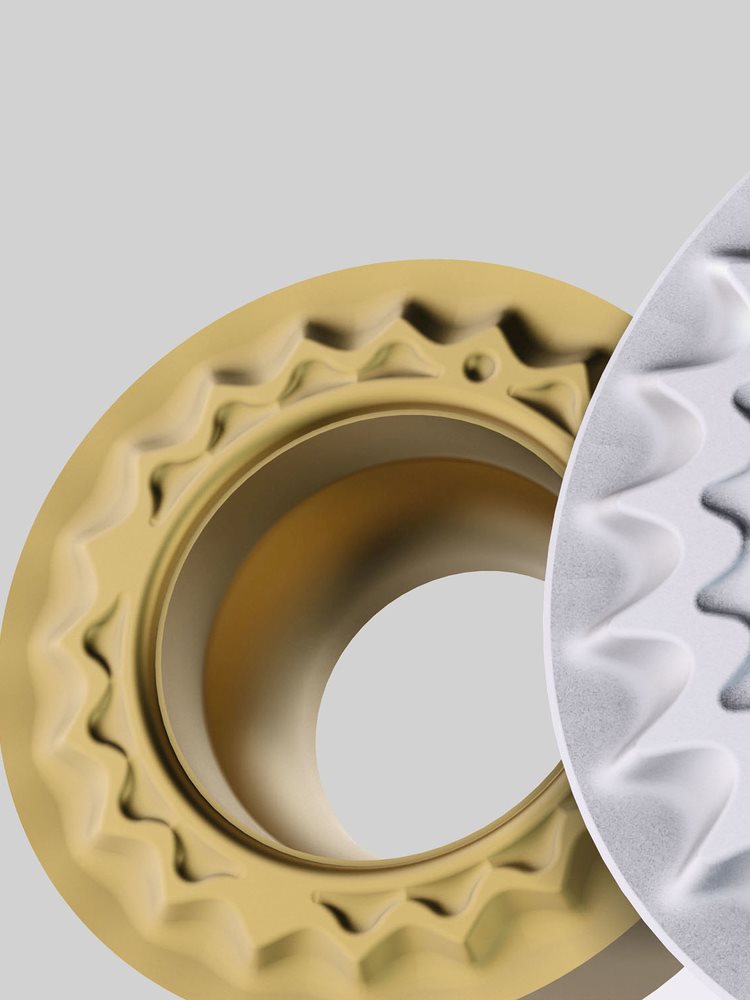

MF2 Chipbreaker on Round RCMT/RCGT Inserts

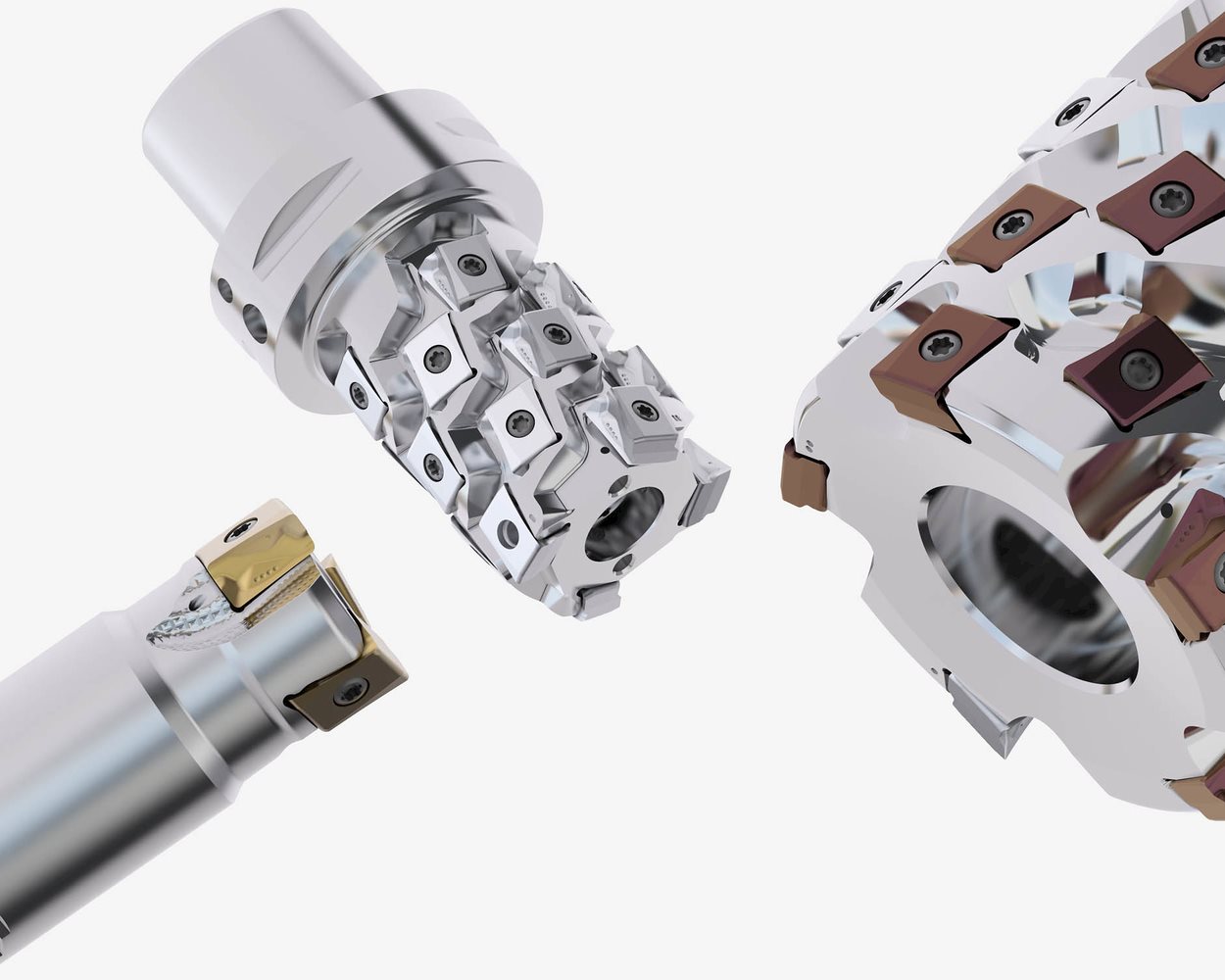

SECO HELICAL TURBO 16 MILLING CUTTERS

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Titanium: Advances in Titanium alloy machinability

Titanium: Mastering Today’s Challenges, Shaping Tomorrow’s Trends

Optimized Roughing 17-4 PH Stainless Steel Dry

Niagara Cutter's SN200R, SN400R and SN500R

High Performance Optimized Roughing with Stabilizer 2.0

Mold & Die End Mill Expansion Introduction

Seco Stabilizer Series: Unmatched Metal Removal

Seco Stabilizer Series: Unmatched Metal Removal

Seco C-Series General Purpose End Mills

NIAGARA CUTTER™ AN230R/AN335R

How to be more successful in stainless steel turning

Seco Taps T32 - T33 - T34

Seco JH724-JH726 Medical barrel Solid End Mills

Seco Hydraulic Chucks

Seco End Mills for Plug-and-Play Dental Milling

Seco Helical SN8-13

Seco High Feed SP

Seco News Summary 2022.2

Seco JS754 Stub Series End Mills

Brochure - Product Highlights

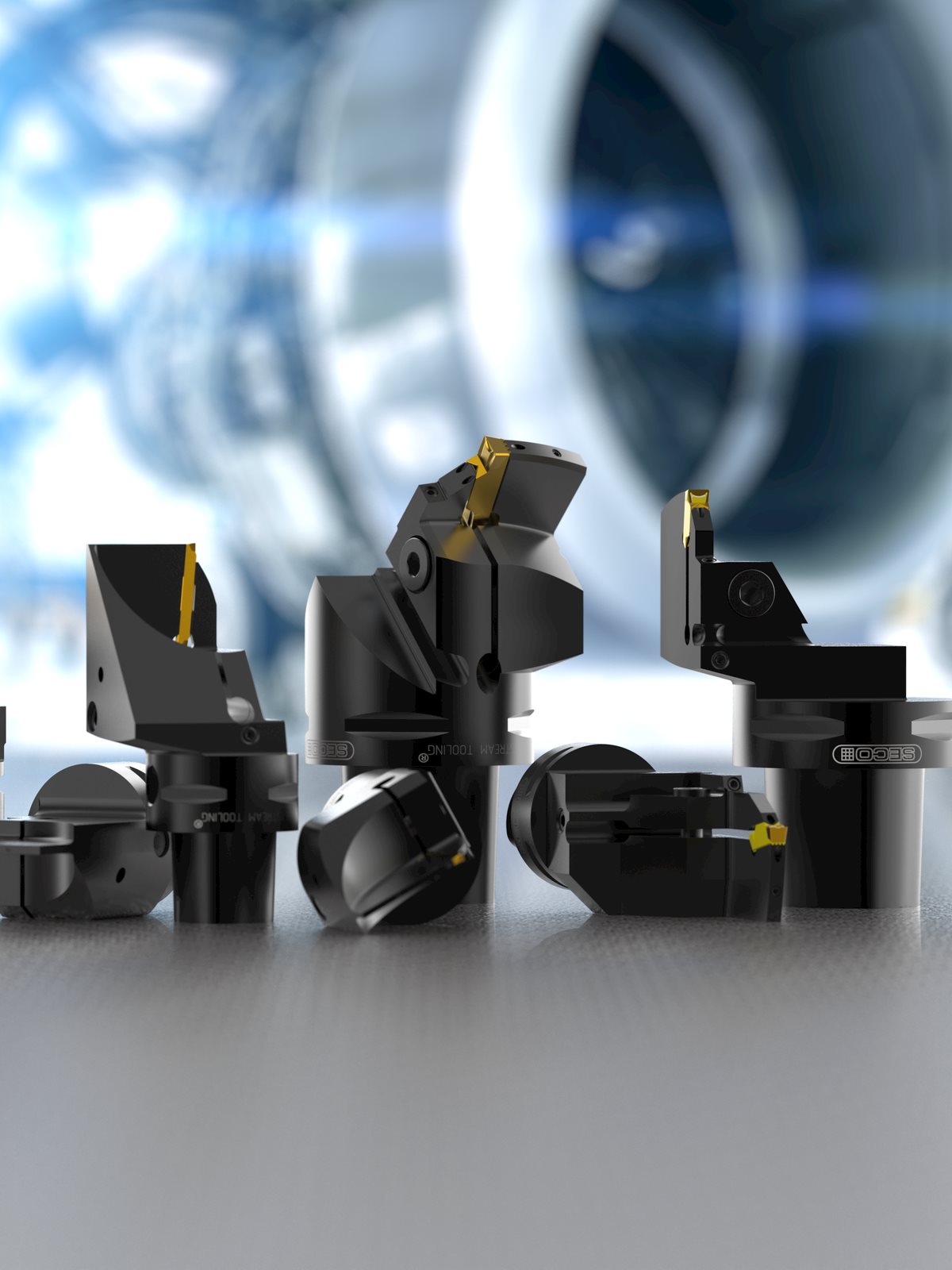

JETSTREAM TOOLING® SECO CAPTO™ GENERAL ISO TURNING

Niagara Cutter to Be Fully Integrated to Seco Brand

Niagara Cutter Brand Integration Distributor Resources

Video: High Performance Optimized Roughing with Stabilizer 2.0

Video: Niagara Cutter Stabilizer 2.0 Product Introduction

Manage Tool Wear with Stainless Steel

A245/A345 family of end mills

Multi flute solid carbide end mills

Machining Navigator / Catalog NIAGARA

A245 A345 2022_1 Product Presentation

NIAGARA CUTTER® A245/A345 UPGRADE

MAXIMIZE YOUR PRODUCTIVITY IN ALUMINIUM APPLICATIONS

Tackle Aluminum Milling with Ease Using the Niagara Cutter A Series

Niagara Cutter A245/A345 End Mills in Aluminum Application Video

Machining Navigator / Catalog Solid End Mills

Video: Multi Flute Range Addition

6 Essential Tips for High Performance Roughing with the Stabilizer 2.0 | SECO TOOLS

High Performance Optimized Roughing in 17 4 PH Stainless Steel Dry | SECO TOOLS

Niagara Cutter High Feed Machining Product Introduction

Niagara Cutter Stabilizer 2.0 Product Introduction

Advances in superalloy machinability

Webinar: Efficient chip control in stainless steel turning

How to optimize machining processes for stainless steel

Seco and Mastercam: How Accelerated Finishing Tools Enhance Surface Finishes and Save Time

Seco Octomill™ 06: Flexible, Robust Tooling

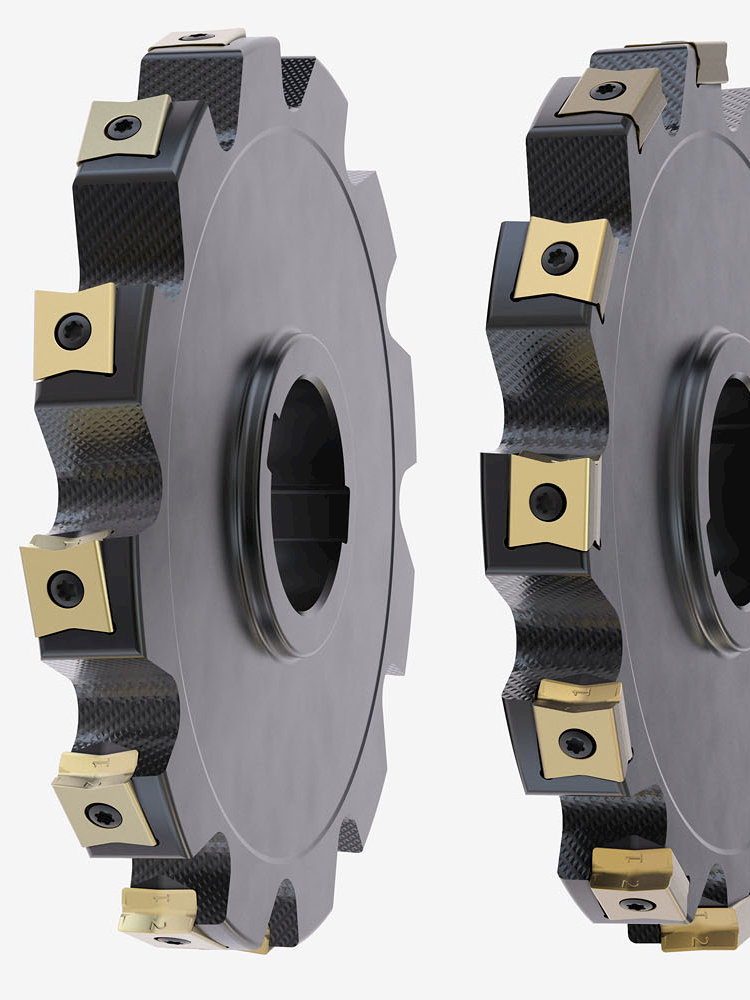

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Seco Component Guidance

Seco T35 Taps: match Tooling to Materials

Versatile Round 20 Inserts Increase Tool Life

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Steadyline® ø25mm (1”) series

New MP Milling Grades

Unleash your drilling potential

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

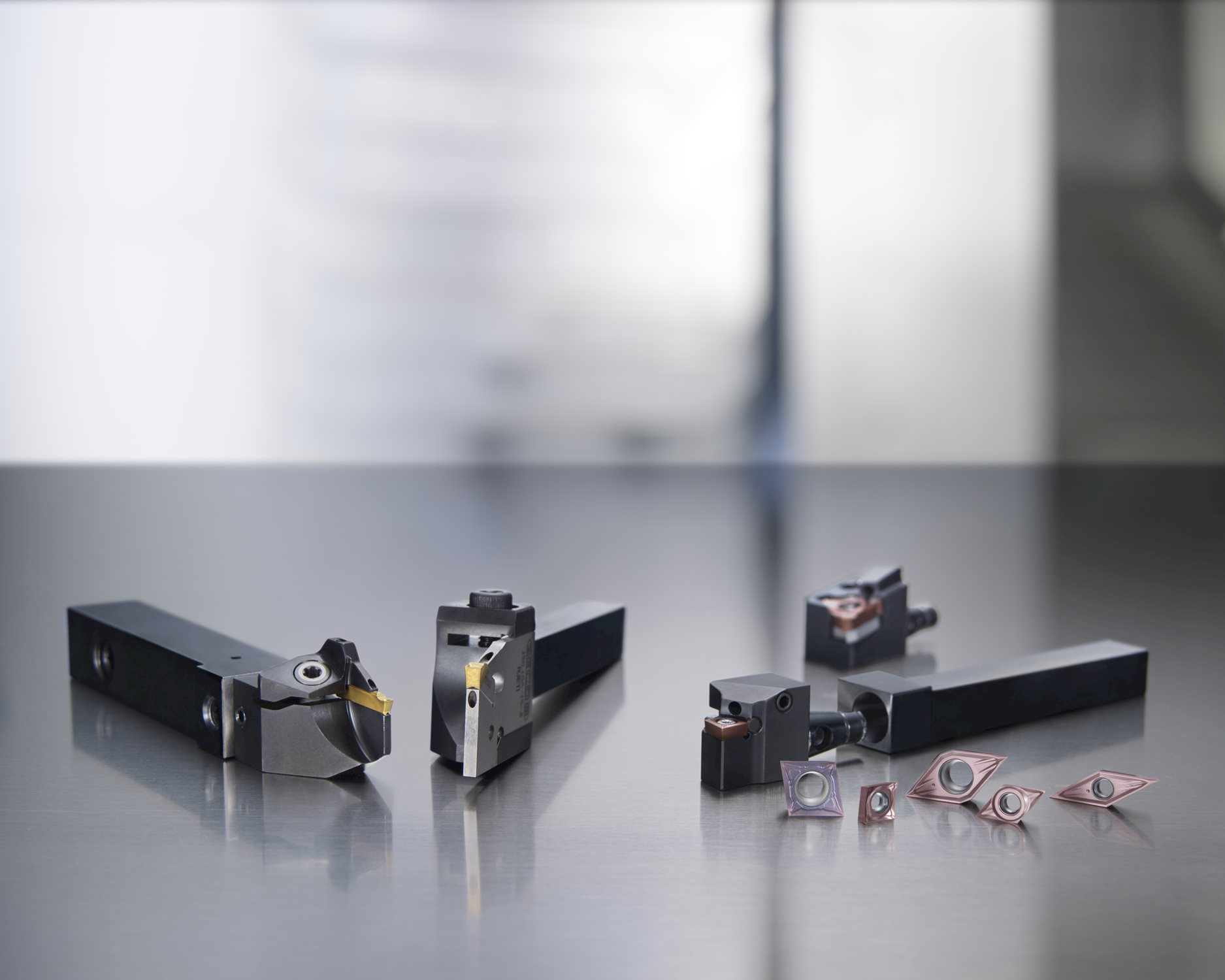

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER