WHAT DOES IT TAKE TO ENGINEER FOR TOMORROW?

The rapidly changing pace of the medical device industry puts increased market pressure on cost efficiency and sustainability. Managing market needs requires planning and working smarter already from the beginning. Collaboration with forefront partners and engineers optimises expertise and innovation to develop solutions for the future.

According to a recent market analysis report from Grand View Research, the size of the global orthopaedic market continues to grow at an impressive pace, with an estimated value of USD 53.8 billion in 2026. At the same time, healthcare systems are recovering from post-pandemic care, resuming elective surgeries and managing backlog. Factors including an ageing population, obesity, and road and sports injuries contribute to the need for innovative devices and implants. Most of these devices are manufactured via machining.

In addition, the sophistication of tools and technology, ranging from a "smart knee" implant with an embedded chip to more durable and pliant materials to more efficient and sustainable machining strategies, impact Seco's approach to engineering cutting tools.

“We build our solutions by being at the forefront, leading the industry and developing collaboration and partnerships with market leaders. At Seco, we have a global team of dedicated professionals and Engineers. By collectively combining our top in-house engineering skills with partners, we are in a stronger position to deliver innovative solutions to meet demanding customer needs,” says Andrew Fielding, Business Development Manager, Medical, at Seco Tools.

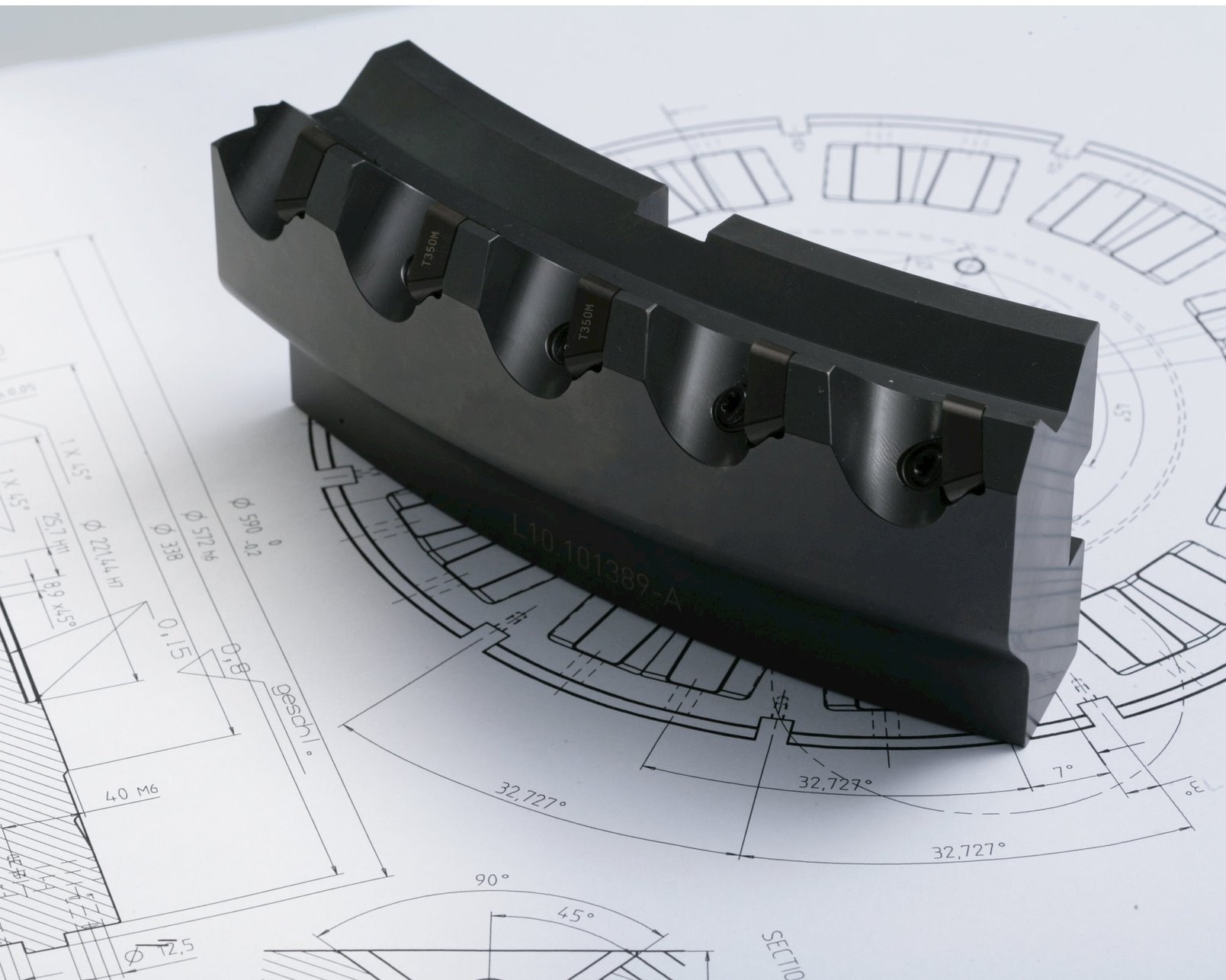

“In developing cutting tools and full machining strategies for medical devices and components such as femoral implants, manufacturers have needs and expectations regarding tolerance, surface finish, and the high quality of the component. We rely on computer aided design and manufacturing (CAD/CAM) software to engineer, design, and produce precision cutting tools to optimise component needs. Working with our CAM partner, OPEN MIND, is an example of collaborative engineering.

“In developing cutting tools and full machining strategies for medical devices and components such as femoral implants, manufacturers have needs and expectations regarding tolerance, surface finish, and the high quality of the component. We rely on computer aided design and manufacturing (CAD/CAM) software to engineer, design, and produce precision cutting tools to optimise component needs. Working with our CAM partner, OPEN MIND, is an example of collaborative engineering.

OPEN MIND is a worldwide leading developer of innovative CAD/CAM solutions.

Therefore, we view OPEN MIND, with their CAD/CAM solution hyperMILL, as a market leader in this area: their solution is an essential complement to our portfolio to lead, not follow the industry. To master the challenges of the medical device industry, hyperMILL offers innovative CAD/CAM technologies to safely machine the entire range of components and the most demanding materials”.

“Together with OPEN MIND, we share expertise and knowledge. So hyperMILL and our tooling go hand in hand. Partnerships and collaborations such as Seco and OPEN MIND are not about promoting each other’s products. It is to challenge one another to develop better processes through tooling and software,” says Guy Savage, Project Engineer at Seco Tools.

Medical device manufacturers are the primary beneficiaries of collaborative engineering. By combining leading solutions within CAM and cutting tools, we can better optimize machining strategies and processes for manufacturers. With hyperMILL, users safely generate, optimize and simulate NC code. hyperMILL VIRTUAL Machining closes the gap between the CAM system and the actual machine environment. By programming the CAM with relevant data about a machine or tool, a digital twin gets as close as possible to real-world output.

The machine simulation is carried out on a digital twin model, taking into account the workpiece, blank, and tool, as well as the tool holder, fixtures, and clamps. This does not affect production or require a massive investment because it is simulated digitally first.

“By collaborating, we can often calculate the cost per component, understand how to work more efficiently with the machine, and identify where you can reduce costs. Furthermore, you save time, improve device quality and enhance manufacturing safety. Virtual machining models can also contribute to more sustainable machining and strategies to reduce energy use,” explains Andrew.

“Collaboration with partners in the industry is how we drive innovation,” concludes Andrew.

Discover the e-book from OPEN MIND