How to optimize machining processes for stainless steel

Machining stainless steel can be difficult and make you face unexpected challenges. Swemachinist guides you through some considerations to take.

You can get stainless steel that is amazing to work with, amazing to cut in, amazing to mill in and drill in…and then you have the other side where it's horrible to work with and everything is against you.

The material’s hardness can significantly shorten tool life, result in work hardening that affects the quality of cuts, cause overheating leading to warping, and create vibrations during machining.

Here are my key strategies for optimizing the machining process:

The first thing is to take a step back and understand what kind of job it is. Is it a long shaft? What kind of stainless steel is it? - there are so many different types that behave in different ways.

Then how will you lay out the roughing and finishing? Do you have to do several turns? It all depends on the work piece.

Other questions I ask myself include: Is it milling? Is it turning? Is it going to be drilled?

What will be the next machining operation? All this preparation is vital. You can even have a preparation list to make this process as smooth as possible.

Considering all these aspects then leads to the next step – What tooling is needed for the job?

Tool life or built-up edge is hands-down the main issue when we discuss machining stainless steel. I’ve thrown this question out there on my Instagram account and I would say 99% of people answered saying this was the main issue.

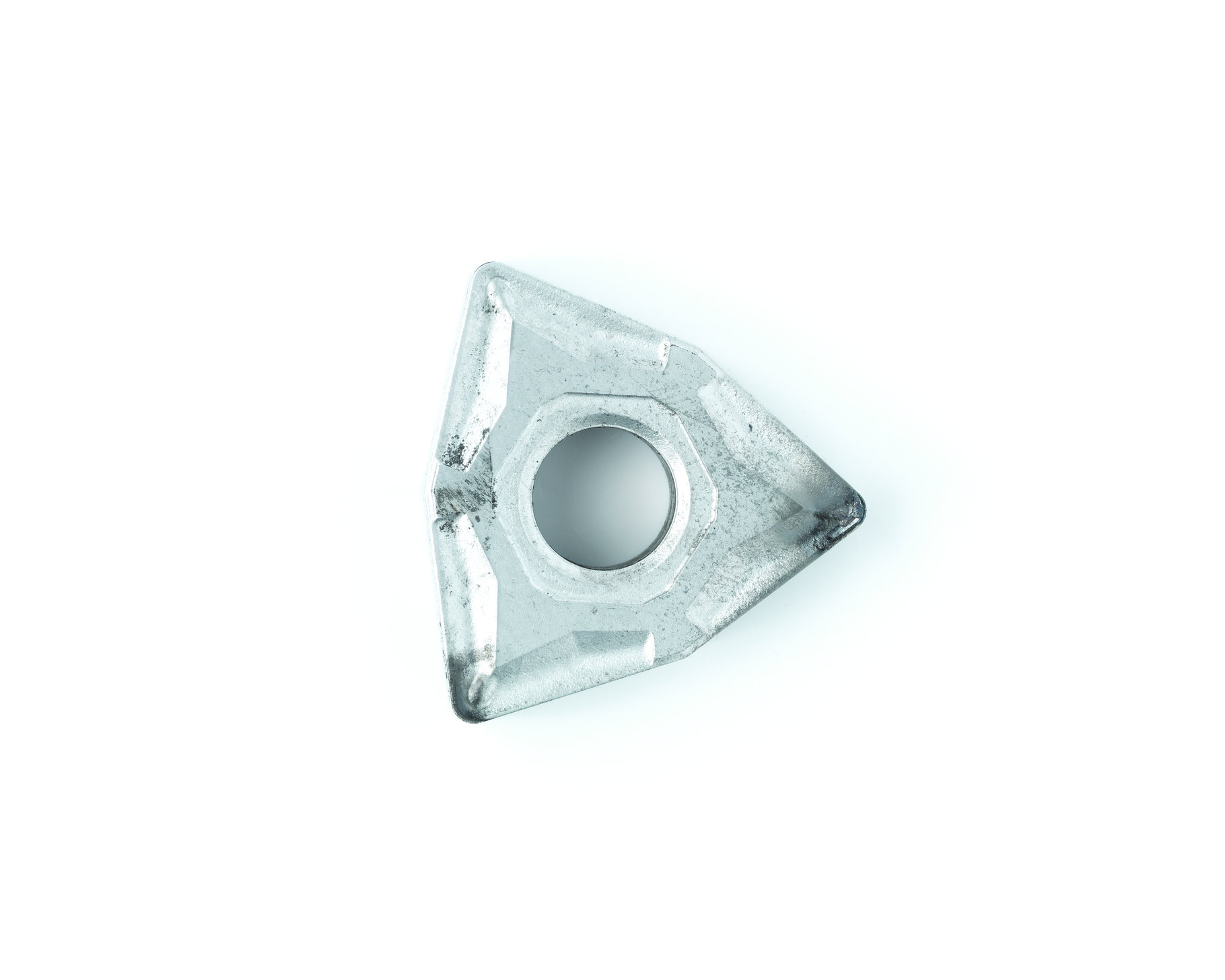

Once you’ve established the parameters of the assignment it’s easier to choose the tooling. But when starting you need to consider if you have special coatings on the insert to help you maximize tool life.

Seco has developed a functional chrome-colored layer on the full insert that lets you see where there has been tool wear, so you can avoid using the same part of the edge for too long.

If you have four corners it makes easy to see what you have left, especially if you are working with two people at one machine.

Maybe tougher inserts are better, too. There’s usually a whole list of inserts you can go through here, and if you're lucky enough, you have several already, so you can switch inserts.

But if you don’t, it’s helpful to ask someone, like an experienced colleague or even the supplier. Or you can get help from digital tools, such as the Seco Assistant with its compare feature. With that, you can use the insert you have as a reference to find a better-fitting one.

In stainless steel you need to look at the speeds and feeds a bit more to get the proper ones with proper cooling. For example, if you're turning it or it’s an interrupted cut, this will be a huge issue. So, you need to find the right inserts for the specific application. But the speeds and feeds will really help you. You can use them for the specific insert in the specific material.

It’s important not to go too low on the speeds and feeds - especially the feed - because then it can start work-hardening the stainless steel. You always need to check the speeds and feeds, so they work with the proper inserts and material. And if tools wear out quickly, consider adjusting the cutting speed, as well as using different tool coatings or increasing coolant flow.

How do we set this up so we can get the finished part? Is the surface going to be as good as we want? Can we hit the tolerance? What happens when we release it from the chuck maybe - does it move if it's a bigger part?

Steady set-up is crucial here. You can achieve that by using shorter tooling if possible and by also adjusting the speeds and feeds to minimize vibrations during the job. If the parts warp, you may also want to consider your clamping strategies to maintain flatness.

Generally, my colleagues and I say that stainless steel will always be this problem child material: everyone loves it and it’s great but there can always be some issues.

At some time or other I have experienced all the issues that I’ve described above and I’m looking for answers too! It’s such a fine process that it's not something you can kind of land on absolutely consistently 100 percent of the time. Be prepared to have to adjust as you often need to respond to situations as they arise.

Having a pragmatic and calm approach will help you, and you will learn from the experience because each type of stainless steel can behave differently. Good luck!

Discover and download the Machining Optimization Checklist here

Inline Content - Survey

Current code - 5fce8e61489f3034e74adc64