ACHIEVE LONGER TOOL LIFE FOR EVEN MORE CFRP PRODUCTIVITY

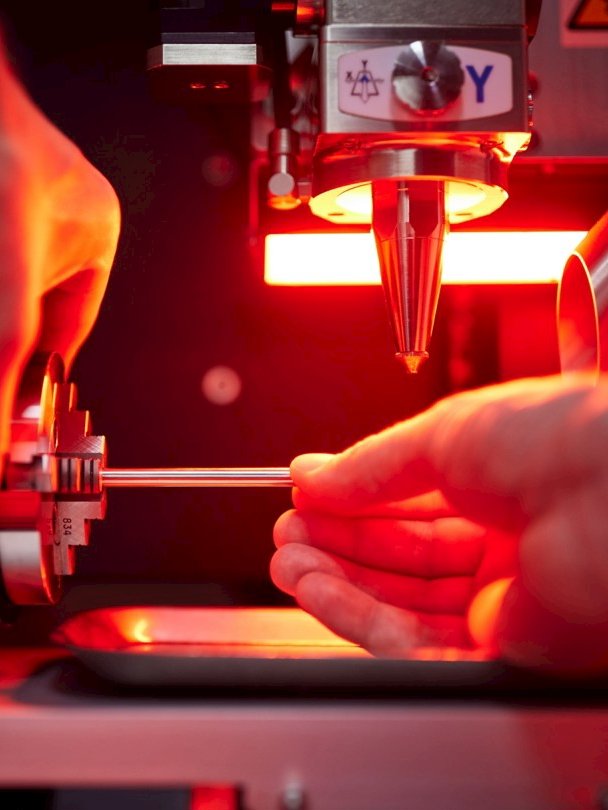

Machining carbon fiber has always been tough and carbon-fiber reinforced plastic (CFRP) has abrasive properties that can be hard on tools. Overcome any CFRP challenge and achieve 30-50% greater tool life with the newly upgraded range of tools from Seco. Our comprehensive kit of CFRP tools now comes with an optimized grade, extending tool life. Plus, with the help of Seco experts, you can easily receive the custom solutions you need to handle any CFRP composite material properties at the greatest possible machining efficiency.ACHIEVE LONGER TOOL LIFE FOR EVEN MORE CFRP PRODUCTIVITY

With its abrasive properties and wide range of composite configurations, carbon-fiber reinforced plastic (CFRP) is one of the most challenging materials to cut in a way that’s efficient in both cost and time. Accomplish both goals at once with the newly improved range of CFRP machining solid end mills from Seco. Our ten innovative geometries have been made even more capable with an optimized carbide and DURA coating combination designed to be the best possible grade for the material – and offer 30-50% better tool life for cost-effective, reliable CFRP processes.

MAKE TOUGH CFRP CHALLENGES EASY WITH A COMPLETE KIT OF OPTIMIZED TOOLS

There are few things in machining that are more complicated than handling CFRP materials. Fiber placement and density, the resin material, and unique built composites make carbon-fiber machining difficult at the best of times. Overcome these challenges with the help of Seco. We offer a comprehensive range of 10 geometries for CFRP machining, each designed for the highest level of reliability for a specific application area.

SOLVE MACHINING CHALLENGES FOR ANY CFRP COMPOSITION WITH SECO EXPERTISE

When dealing with CFRPs, issues such as poor workpiece quality, unreliable manufacturing processes, delamination, glazing and fiber pull-out are common – and for every new CFRP combination, new solutions need to be found. Instead, rely on the expertise of your partners at Seco Tools. Our wide-ranging experience with all CFRP materials allows us to help you find the optimal combination of geometry, carbide grade and coating thickness for your unique application needs.

Discover the Product Range

RANGE OVERVIEW

JC8 series: 10 total CFRP geometries (2 uncoated). 95 items in total

YOUR BENEFITS:

Better tool life

Complete range of CFRP solutions

Exceptional process reliability

Easily altered coating/geometry combinations

Purchasing and processes unchanged thanks to same GPNs for new grades

Easy access to Seco CFRP expertise

YOUR CHALLENGES:

- Inconsistent and low tool life when machining carbon-fiber reinforced plastics (CFRP).

- The huge range of CFRP combinations and sometimes complex shapes make it difficult to optimize applications.

OUR SOLUTIONS:

- Achieve 30-50% better tool life compared to the existing product line thanks to a carbide upgrade designed for improved bonding with the DURA coating.

- Solve your application challenges with the help of Seco CFRP experts, who can help you with machining virtually any type of CFRP composite.

Discover the Product Range

or

Contact us for more information

Related content

JC845 - Compression - Composite - 3-5 Flutes

Composite - Modern Tools for Machining Carbonfibre, Glassfibre & Stacked Composites

The Rise of Composite Materials in Aerospace Manufacturing

New End Mills from Seco offer fast, efficient composite machining

Seco JC800 series - CFRP machining

The cutting edge of precision: Innovations in laser machining

Laser-assisted thermal machining: the solution for manufacturing with MMCs?

The rise of MMCs: Advantages, challenges, and solutions in using Metal Matrix Composites

Composite: Advances in Composite material machinability

Composite Materials: Flying High!

The lighter side of heavy transport