Expand production with collaborative uses of Additive Manufacturing

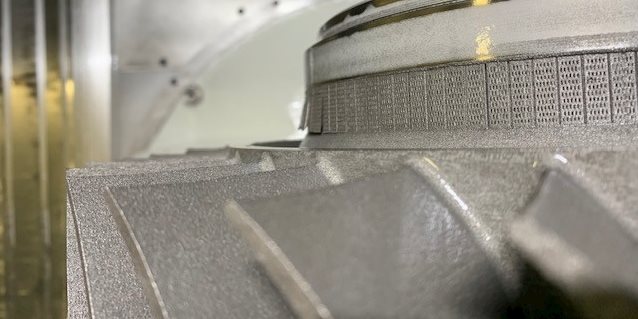

The aerospace solution centered around a blisk for a jet engine, 3D printed as a near net shape in titanium. Seco machined this geometrically complex part – made from one of aerospace's long list of truly difficult metals – to demonstrate the potential for enormous savings of time, material and tools.Virtual visitors to the seventh annual Seco Inspiration Through Innovation (ITI) event saw numerous breakthroughs, including one in aerospace manufacturing and another with an impact beyond individual industries. The aerospace solution centered around a blisk for a jet engine, 3D printed as a near net shape in titanium. Seco machined this geometrically complex part – made from one of aerospace's long list of truly difficult metals – to demonstrate the potential for enormous savings of time, material and tools.

Just as importantly, the entire blisk project demonstrated the power of collaboration. A group of industry pioneers worked together to achieve new solutions and enhance approaches to manufacturing tasks through combined resources, expertise and capabilities.

Out of necessity, aerospace applications deal with some of manufacturing's most-challenging materials. Lightweight, heat resistant, strong and reliable, these metals revolutionize aircraft performance and stability – and complicate the machining process with tough-to-cut metals. Blisks themselves represent a revolutionary development that fuses disks with blades into a many-sided part with multiple angles. Furthermore, to pass stringent quality validation testing and earn airworthiness certification, the industry uses tightly specified processes with no margin for error.

As Seco Tools AB Global Business Development Manager Anna Malycheva observed, "The aerospace industry is very conservative, with extreme requirements for validation and quality control. Nonetheless, AM is an attractive opportunity for many original equipment manufacturers (OEMs) because of the savings that it entails. Some of the largest industry players are looking into this together with us to transform manufacturing methods. It's very difficult to transform this industry quickly, but manufacturers do have an incentive to do so because the savings are so substantial."

Substantial, indeed: For the ITI demonstration, finishing an AM-created near net shape blisk reduced machining time by 80% from 40 hours to 8. Those time savings also brought 80% savings in cutting tool costs. That's partially because unlike blisks machined from solid blocks of titanium, the 3D printed shape included mere millimeters of material and a few support structures to remove.

Although commercial and military airframe manufacturers don't yet use fully additive manufactured (AM) blisks, service personnel use AM solutions to replace blades that wear or sustain damage in use. However, given the production of some 40,000 blisks in 2019 and every anticipation that post-pandemic orders will reach previous levels, AM technology offers enormous promise. Seco Tools UK Global Business Development Manager Jon Shipley pointed out that "We now can enable end-to-end solutions for customers from their raw materials, developing the process suitability of that, right through to the end of finishing. We don't just go to customers and sell products in isolation. We need to look way beyond what we sold even just 5 or 10 years ago. Collaborating with partners who specialize in other aspects of the process enables us to magnify expertise to a level that's greater than the sum of our individual capabilities."

Within the Seco approach to customers and their needs, collaboration and innovation pair up to provide unparalleled solutions. On the blisk project, Seco's new barrel tools – up to 80% faster than conventional ball-nose end mills – took a leading role in transforming an AM shape into a finished part. These tools enable shops to achieve high-quality surfaces with bigger stepovers but without reducing cutting speeds, dramatically lowering cycle times.

Along with Seco, the blisk project brought together seven other collaborative partners to achieve a joint solution. Their knowledge, insights and technology in additive and subtractive processes made this part a reality.

- Sandvik Additive Manufacturing provided the titanium powder and engineering know-how. The Beam-It facility in Italy – a recent acquisition – printed the near net shape.

- GOM UK provided the ATOS system that measured and scanned the 3D printed part to create a 3D point cloud and digital twin.

- Open Mind Hypermill CAM programming created the tool paths to machine the blisk.

- Jemtech provided the coolant that helped optimize tool life.

- Schunk tool holding ramped up precision with stability.

- GROB simultaneous 5-axis CNC machining centers performed the production tasks.

This diverse list of collaborators quickly approached the problem, applied expertise and innovation to solving it, and formulated an actionable plan. A multi-disciplinary team brought everyone to the table for a two-month project that might take one company two years to accomplish on its own.

This fruitful collaboration produced a successful part – and even more importantly, an ideal demonstration of the value of partnerships across the company. The results also demonstrate, as Malycheva pointed out, that "This is not something to dive into without planning and expertise." Increased part complexity requires equally specialized manufacturing resources. When customers enlist their own R&D departments on issues such as these, the effort may require more time and resources than they can devote to it. Through strategic choices of partners or even partner networks, customers can gain support for these initiatives – and save time and effort.

Along with the technological advances that collaboration produces, Seco also emphasizes the sustainability that these approaches provide. Besides the tangible benefits to industry and environmental goals, collaboration also builds relationships that endure beyond the schedule of any individual project. Every partner benefits from these collaborations, and each relationship can scale to solve new problems and meet new challenges.

In addition to the partners who collaborated on this specific project, Seco also can work with many additional machine tool OEMs and other suppliers to customize individualized solutions. Through its Innovation Hub, Seco created a collaborative environment that can bring in industry partners to design and develop best-in-class machining processes and tooling innovations. At the same time, Seco continues its full commitment to technical training and education, both for employees and for customers.

Customers all look for improvements in efficiency and productivity, but when they describe their real goals, they ask for solutions beyond what new and better tools can deliver. That's why – as a customer-centered company – Seco places so much emphasis on responding to customers with holistic solutions.

When customers provide a clear scope of work, especially in prototyping and quality validation, Seco can apply creativity and collaborative resources to respond to each unique challenge. That includes situations in which a customer stipulates a particular brand or partner that it brings to the table itself.

Disruptive technologies take on additional importance when companies seek to innovate to meet customer challenges. Those technologies include a focus on expanding the use of 3D metal printing into tool production. As Seco rethinks its approaches to many problems, it applies AM technologies to improve the ways in which it delivers coolant to the cut.

Traditional tool production techniques involve series of connected, straight-line coolant delivery channels. This approach lacks the efficiency of the veins in a leaf or other natural structures that deliver liquids from one point to another. With additive manufacturing, Seco can create coolant channels that take exactly the right paths, achieving leaps in efficiency that other approaches cannot reach.

Seco is willing to question the status quo in the quest for better results for its customers, to help them achieve better results in less time and with greater profitability. Collaborative resources only enrich the company and its ability to deliver results that enhance manufacturing with greater performance and flexibility.

Contact us here