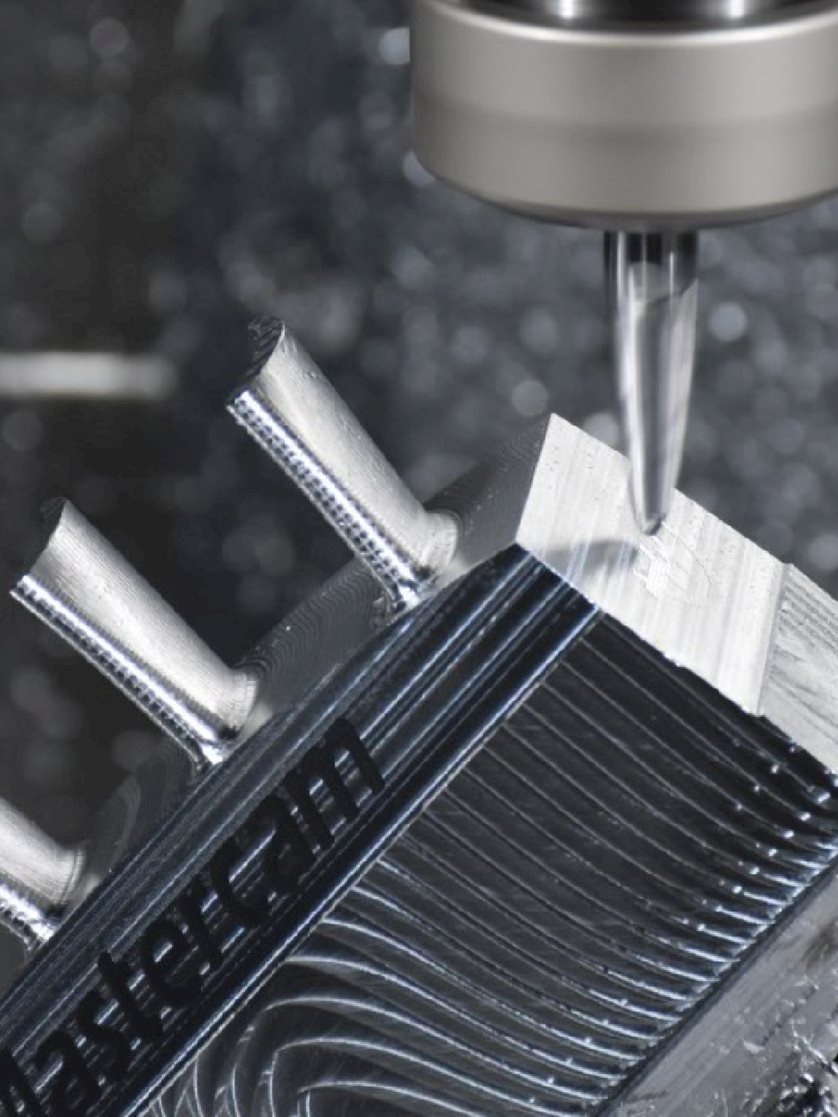

TAKE BIGGER STEPOVERS FOR FASTER FINISHING PRODUCTIVITY

For the fastest possible finishing cycles in the toughest stainless steels and superalloys, you need an innovative approach. New barrel tools from Seco utilize innovative circle-segment end mill geometries designed for use with advanced CAD/CAM programming strategies. The result: 80% faster cycle times. And with the help of Seco experts, it’s easy to apply this technique in your shop – or to find the custom barrel tool geometry that will speed up your unique finishing operations.

Access our free Online Course on Barrel Tooling

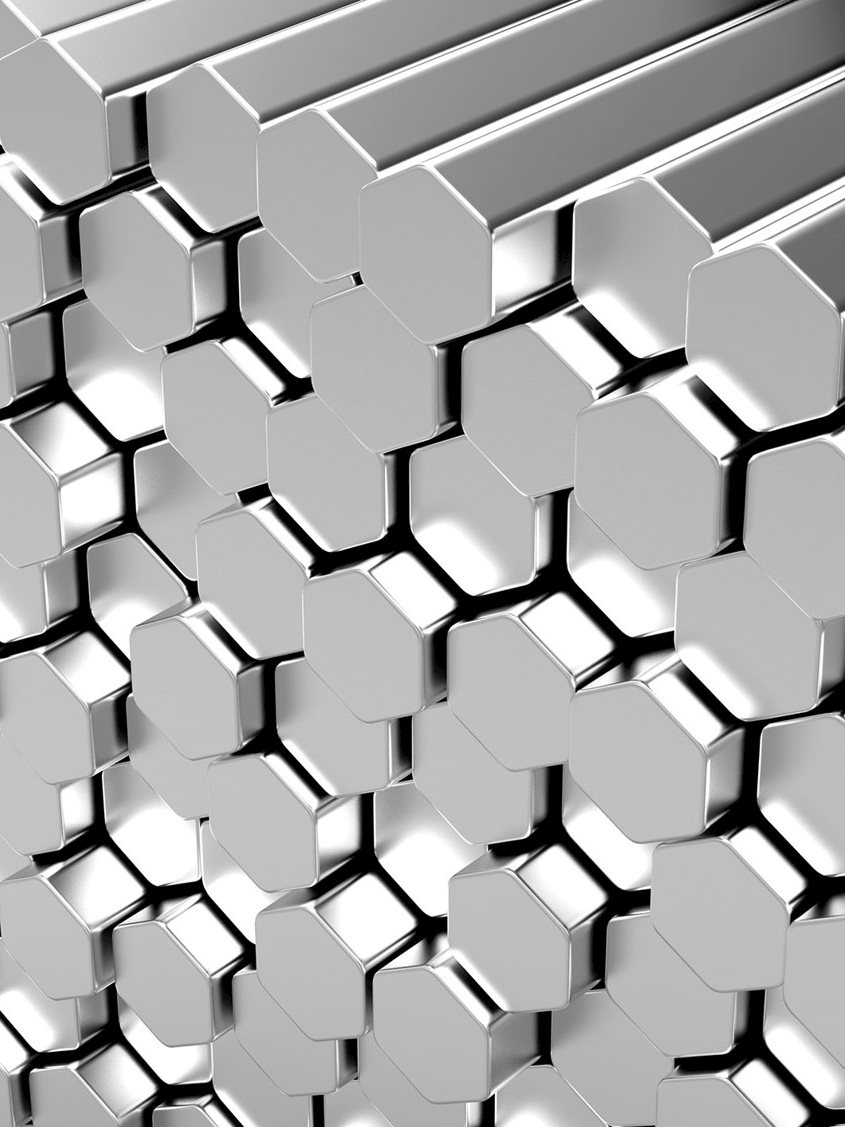

Finishing tough materials such as titanium, precipitation-hardened steels and stainless steel can require slow cutting speeds and multiple tool geometry variations that lead to long cycle times. Speed up these time-consuming processes without speeding up the spindle using new barrel solid end mills from Seco Tools. With a 5-axis machine, these innovative, circle-segment end mill geometries allow for big stepovers to finish the same parts up to 80% faster than conventional ball-nose end mills.

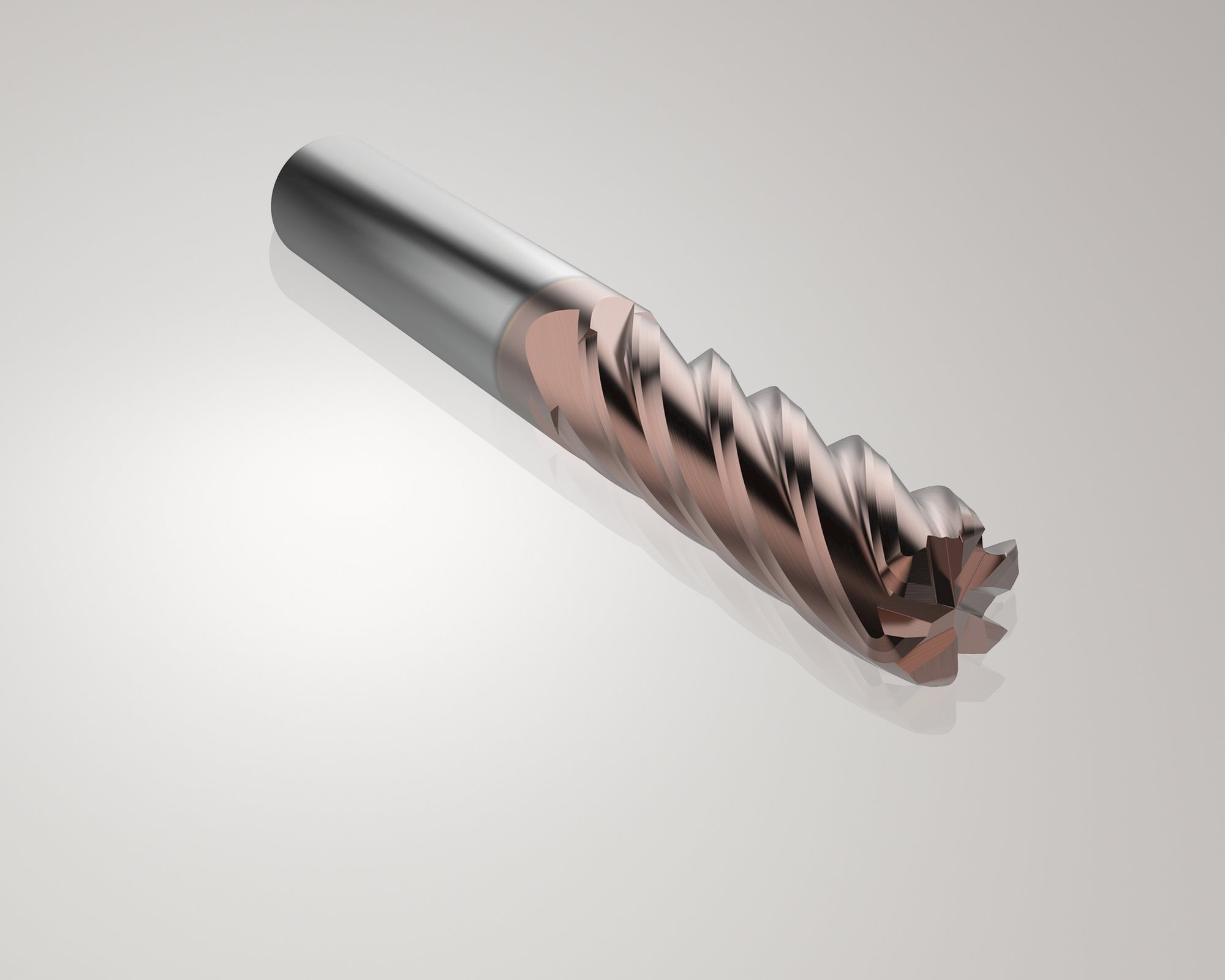

For modern manufacturers, keeping up with the competition requires integrating new tool styles and the advanced part-programming strategies that allow them to work. For the fastest, most reliable finishing operations, new barrel-shaped tools use an innovative “taper” or “drop” geometry with a 10° rake and 20° helix angle to enable large increases in stepover. This is possible through the use of advanced CAD/CAM systems or new plugins built for the uses of these tools. Using 5-axis machine movement, the tool’s cutting profile can remain engaged with the surface of the part at the proper angle at all times.

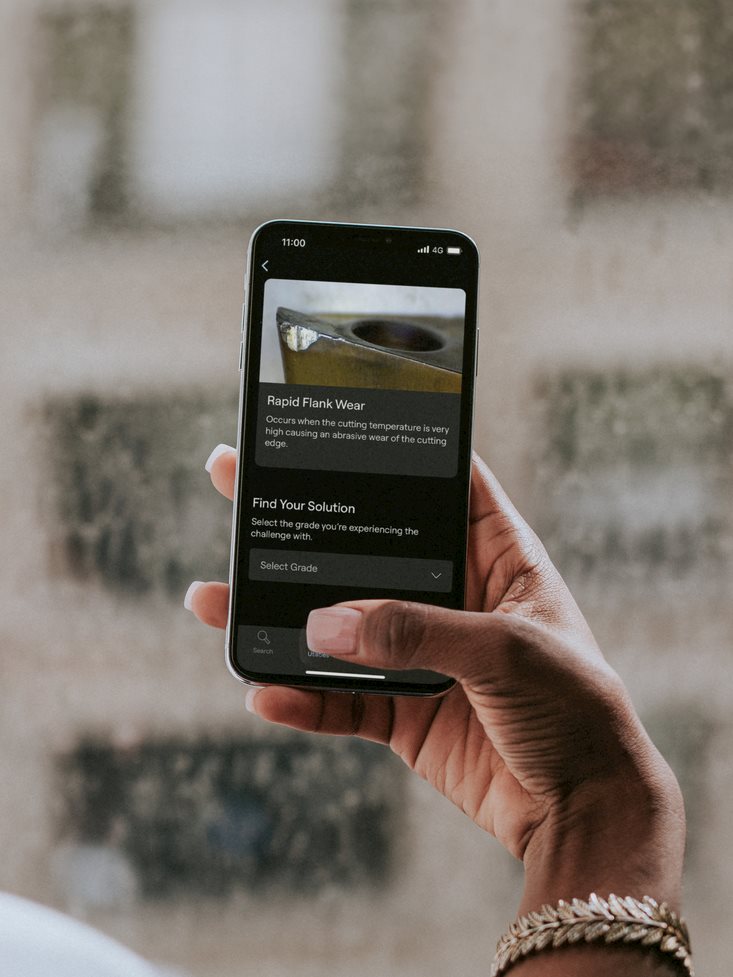

Applying new technology can be challenging for any shop – especially when it lacks the in-house expertise necessary to even get started. Seco Tools can help. By partnering with Seco, you can gain access to the CAD/CAM programming expertise required to begin using barrel tools to cut down on finishing time. In addition to our standard barrel-style shapes, Seco can also offer all styles of barrel geometry’s as custom products, such as lens shapes, ensuring you always have access to the ideal tools for your part-production needs.

Four cutting geometries, 24 new standard items.

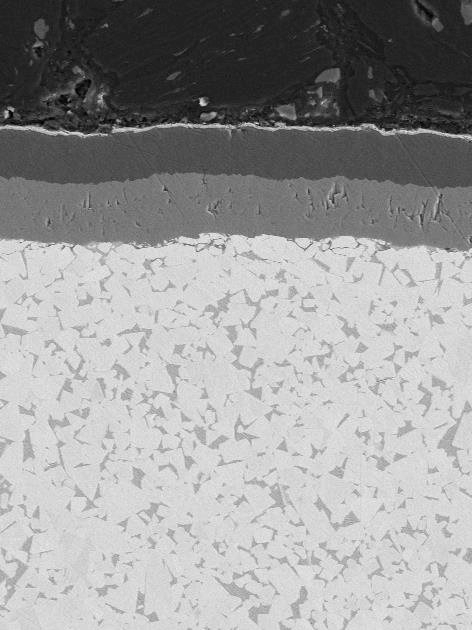

“Drop” Shape: JH734 and JH736, available in diameters from 6-16 mm.

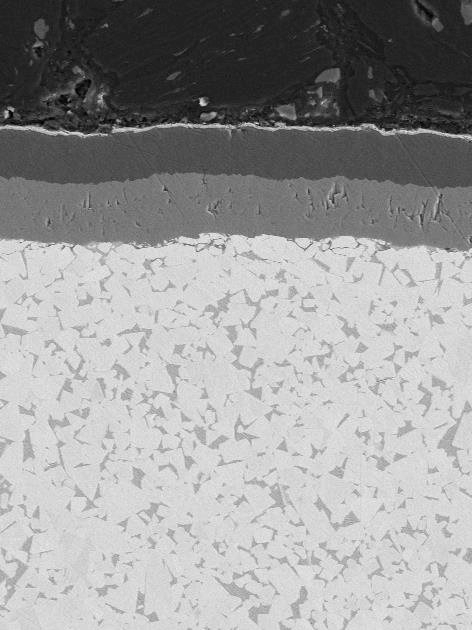

“Taper” Shape: JH744 and JH746, available in diameters from 4-16 mm.

All barrel-type shapes can be produced as custom tools.

Discover the new Barrels tools product range

JH734 / JH736 - Drop shape - 4-6 flutes

JH744 / JH746 - Taper shape - 4-6 flutes

Faster finishing cycle times

Fewer required tool changes

Higher post-processing reliability

Easy access to Seco expertise

- 3+2 or full 5-axis semi-finishing and finishing operations in ISO-M and S materials take too long, with too many tools required to complete the part.

- Applying new advanced cutting strategies requires expertise that can’t be found in-house.

- Barrel-style solid end mills allow for bigger stepovers using the same cutting speeds for high-quality surface finishes – in a fraction of the time required when finishing with several ball-nose end mills.

- Seco experts have the CAD/CAM knowledge necessary to take full advantage of these tools and can help any shop integrate the technology into its operations.

Discover the new Barrels tools product range:

JH734 / JH736 - Drop shape - 4-6 flutes

JH744 / JH746 - Taper shape - 4-6 flutes

or

Contact us for more information

Related content

Barrel Tooling - Online Course

JH734/736 - High Speed – Drop Shape – ISO-M and ISO-S – 4-6 Flutes

JH744/746 - High Speed – Taper Shape - ISO-M and ISO-S – 4-6 Flutes

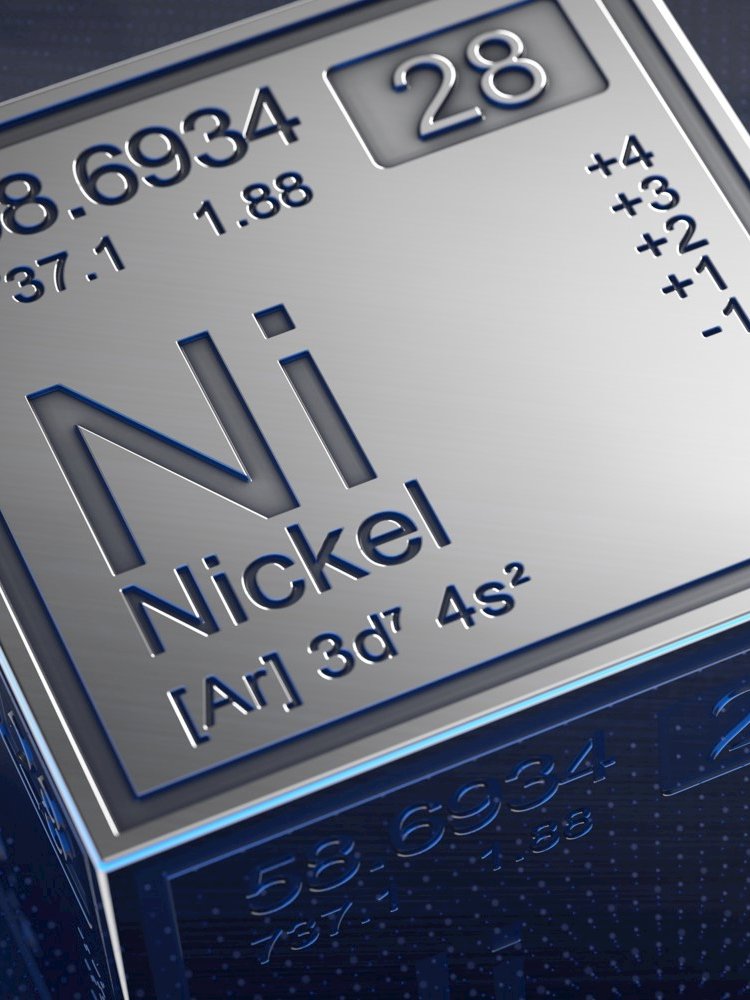

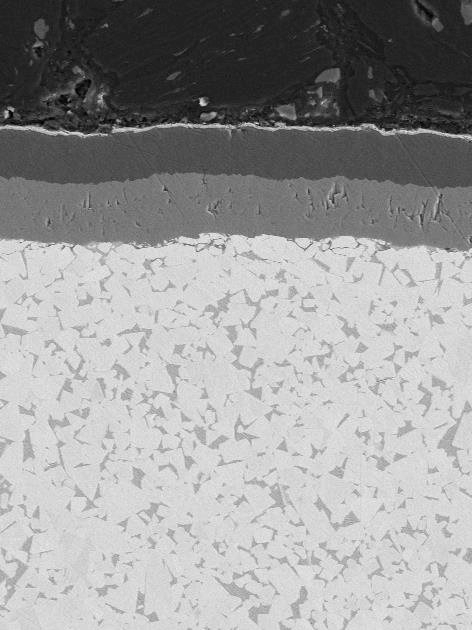

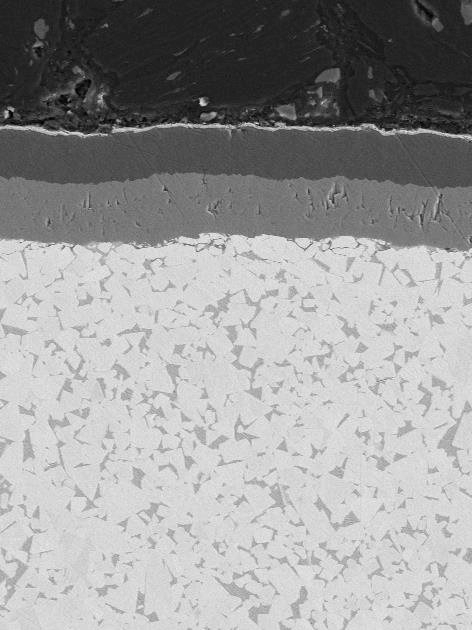

Challenges in stainless steel

Challenges in titanium

Seco Barrel Machining Tools - JH734/JH736 & JH744/JH746

Seco JH724-JH726 Medical barrel Solid End Mills

Advances in superalloy machinability

8 tips to machine titanium alloys

Factsheet - JH730 Solid End Mills addition

JH730 Solid End Mills addition

Seco JS754 Stub Series Brings Versatility and Value When Milling Tough Materials

FEEDMAX -MS DRILL

Manage Tool Wear with Stainless Steel

Overcome stainless steel supply challenges

The Rise of Composite Materials in Aerospace Manufacturing

ActOn’s ‘secret weapon’ is transforming medical implants

Balancing key factors in stainless steel machining

Superalloys and Titanium / ISO S

Stainless Steel / ISO M

Industry-specific solutions and strategies for machining ISO-S materials

New strategies and solutions take on ISO S materials

Fact Sheet JH724 JH726 Medical Barrel Solid End Mills

Seco and Mastercam: How Accelerated Finishing Tools Enhance Surface Finishes and Save Time

Aerospace Pintle Plate

JS720 Solid End Mills addition

Superalloys and Titanium / ISO S

Stainless Steel / ISO M

Finish Stock Allowance with Solid End Mills

Video: Aerospace Machining: Aircraft Pintle Plate in Titanium | Seco Tools

Getting Technical - Machining Stainless Steel

Getting Technical - Machining Titanium and Super Alloys

Tips on how to machine Nickel-based Alloys | Seco tools

JH724/JH726 - High Speed - Taper Shape Medical - CoCr/Titanium - 4-6 Flutes

PRODUCT PRESENTATION - JH724 JH726 MEDICAL BARREL

THREADMASTER™ ISO-S THREADING TAPS