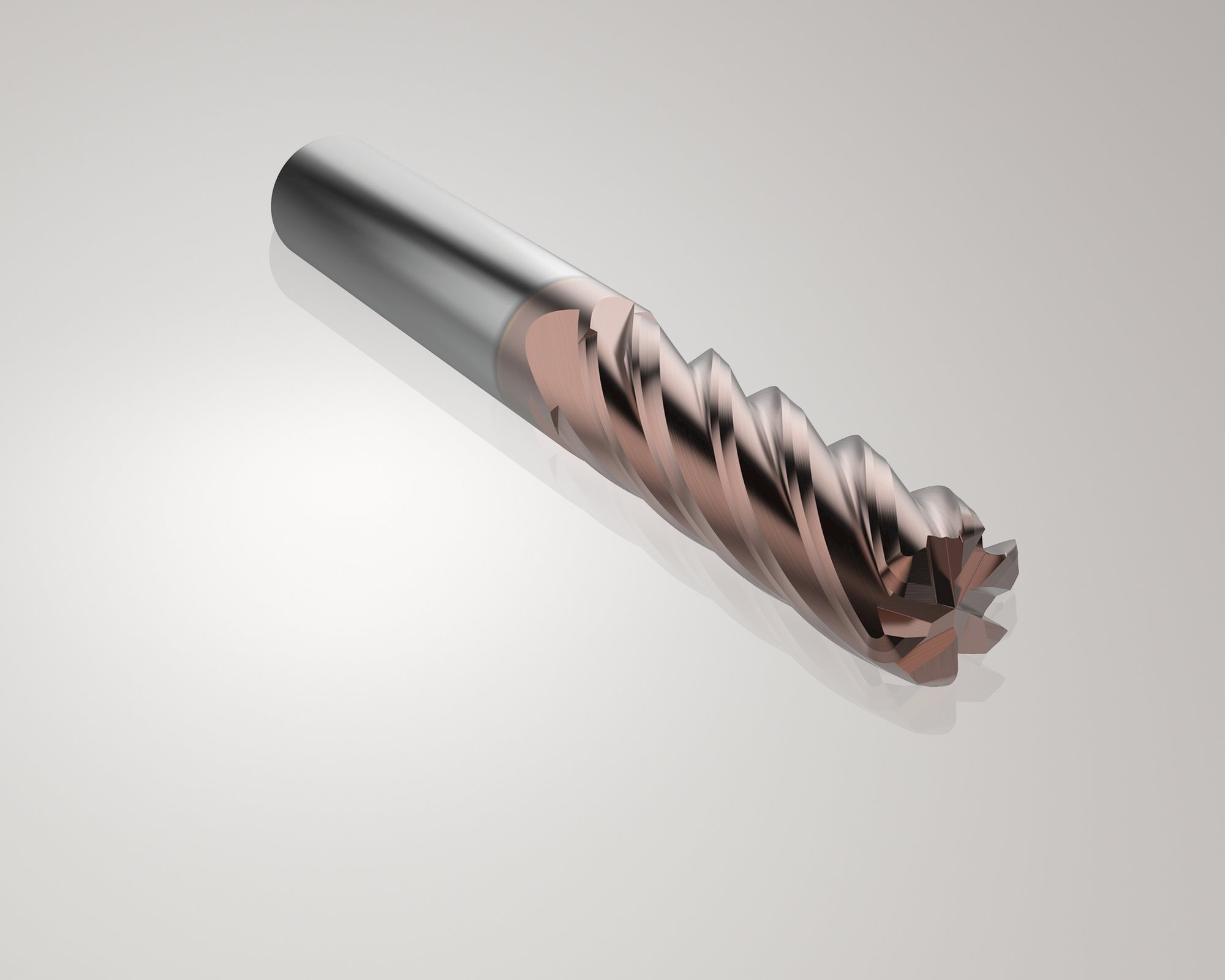

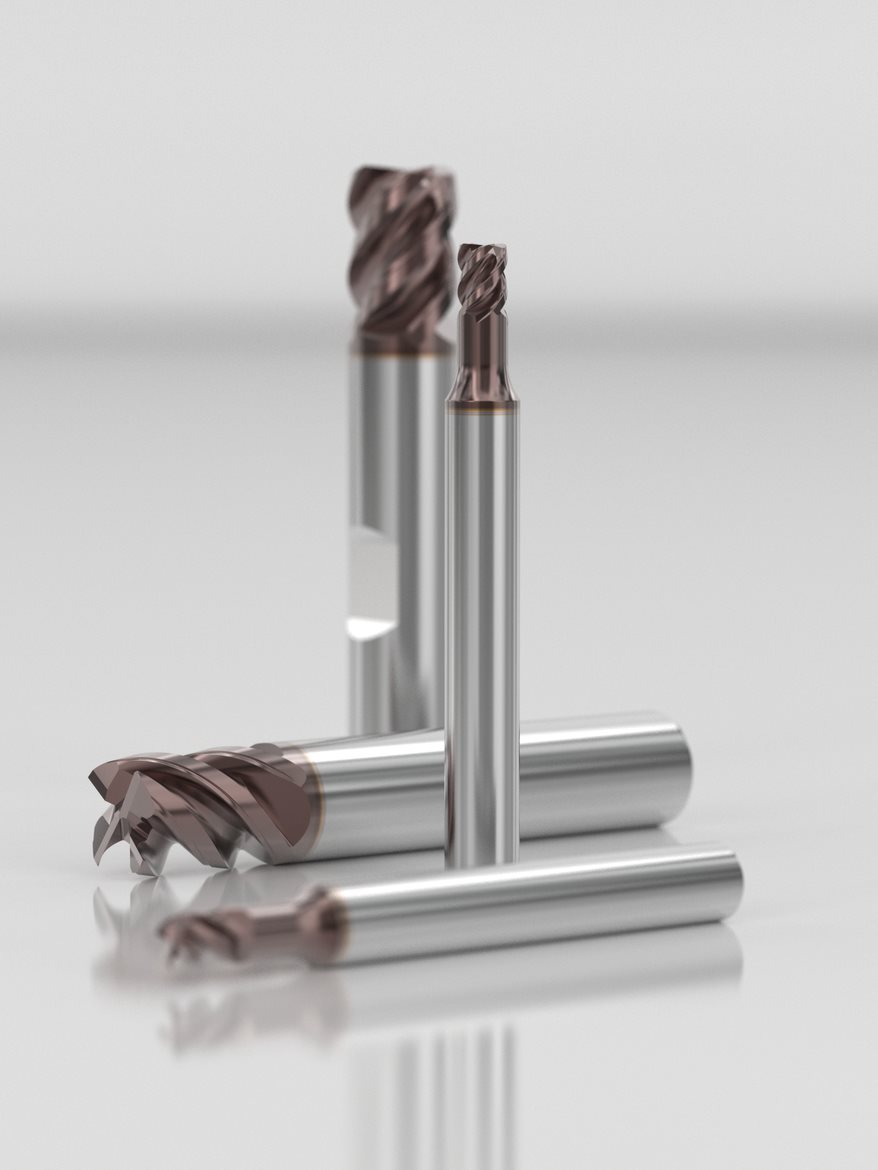

Efficiently mill titanium and cobalt chrome implants with Seco JH724-JH726 End Mills

Learn how Seco JH724-JH726 medical barrel solid end mills provide access to machine condyle surfaces on titanium femoral knee implants.Discover the product range

Access our free Online Course on Barrel Tooling

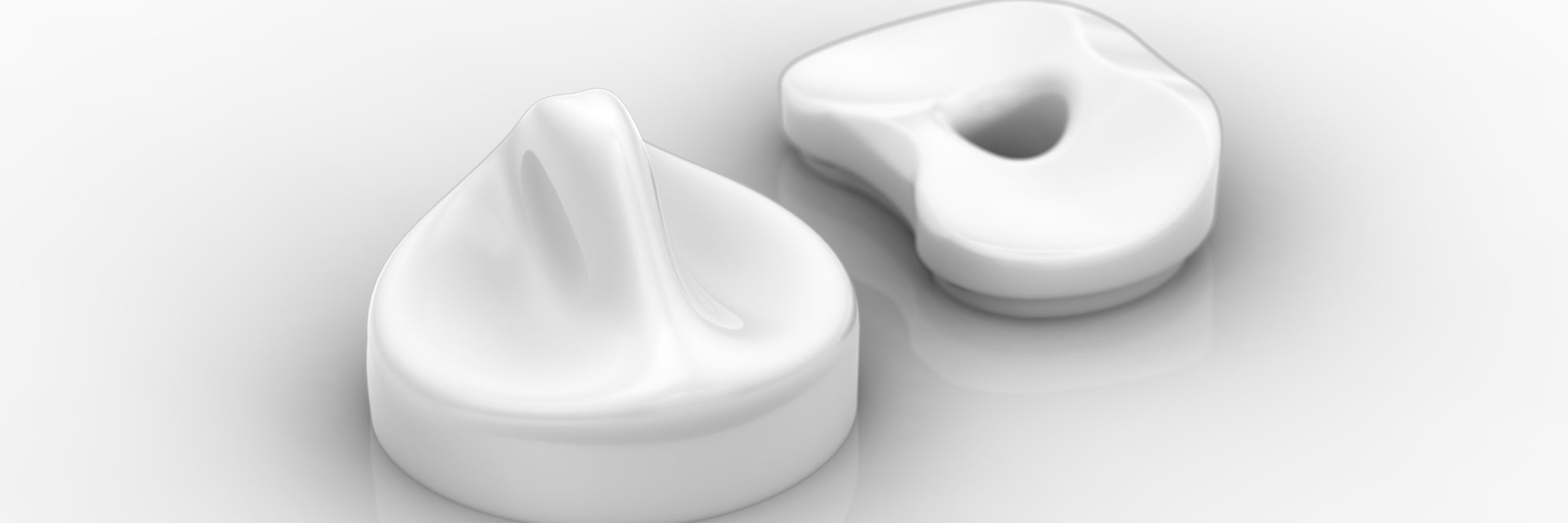

Major medical OEMs are quickly transitioning from cobalt chrome to titanium for femoral knee implants, and those must be milled because the material cannot be ground. Manufacturers like you are now under pressure to implement machining strategies to overcome specific titanium femoral knee implant milling challenges. A cost-effective approach is the use of Seco JH724-JH726 medical barrel solid end mills with profile radii design that allow you to both finish condyle surfaces and blend surfaces with the same tool to reduce tooling costs and inventory. With large profile radii, these cutters allow for bigger stepovers while cutting at the same speeds as ball-nose end mills for shorter part cycle times and superior medical-grade surface finishes. Smaller tool tip radii provide reach into tight implant cavities.

Your challenge:

Cost-effectively mill femoral knee implants made from titanium that is impossible to grind.

The Seco solution:

Semi-finish and finish femoral condyle knee implant surfaces with one JH724-JH726 medical barrel solid end mill.

Your challenge:

Access and machine hard-to-reach patellar grooves on femoral implants.

The Seco solution:

Smaller than regular barrel tools, Seco JH724-JH726 medical barrel solid end mills are larger than ball nose end mills.

Medical implants must have perfect surface finishes. Until now, grinding has been the only way to achieve them – but titanium implants do not allow for grinding. To achieve flawless milled condyle femoral knee implant surfaces, Seco JH724-JH726 medical barrel solid end mills with multiple profile radii geometry allow you to machine main condyle surface for improved productivity, and then finish the blend radii with the same tool to eliminate any surface height deviations from tool changes and any visual transitions/imperfections on the part surface.

Your challenge:

Prevent visual imperfections on femoral surfaces from tool changes.

The Seco solution:

JH724-726 medical barrel solid end mills eliminate the need for multiple tool changes between semi-finishing and finishing operations to ensure consistently smooth part surfaces.

Your challenge:

Increase milling stepover width to shorten machining cycle times.

The Seco solution:

Special multiple radii geometries on JH724-JH726 cutting profiles allow for larger milling stepovers to prevent any visual transition marks on part surfaces.

Single-use tools have shorter overall working lives, which translates into less parts per tool and greater tooling costs that can shrink your profit margins, especially when milling titanium or cobalt chrome knee implants. With medical specific substrates, multi-radii geometries and HXT tool coatings, the reconditionable Seco JH724-JH726 medical barrel solid end mills enable you not only to reduce tooling costs and inventories, but also to lower cost per part while ensuring peak tool condition for both semi-finishing and finishing condyle surfaces on knee implants with the same tool.

Your challenge:

Amortize tooling costs as quickly as possible.

The Seco solution:

Reconditionable Seco JH724-JH726 medical barrel solid end mills allow you to machine more medical implants with less tooling inventory.

Your challenge:

Reduce scrap caused by worn tools.

The Seco solution:

Reconditioning keeps your Seco JH724-JH726 medical barrel solid end mills in top condition to generate superior milled surface finishes.

Discover the product range

Contact Us

Are you interested in Medical solutions?

Discover all our solutions and content around it

Related content

Barrel Tooling - Online Course

PRODUCT PRESENTATION - JH724 JH726 MEDICAL BARREL

Knee Replacement Components

JH724/JH726 - High Speed - Taper Shape Medical - CoCr/Titanium - 4-6 Flutes

Fact Sheet JH724 JH726 Medical Barrel Solid End Mills

Learn more about Seco Medical Solutions

Is this the future of orthopaedics?

Factsheet - JH730 Solid End Mills addition

JH730 Solid End Mills addition

Medical

Femoral Insert

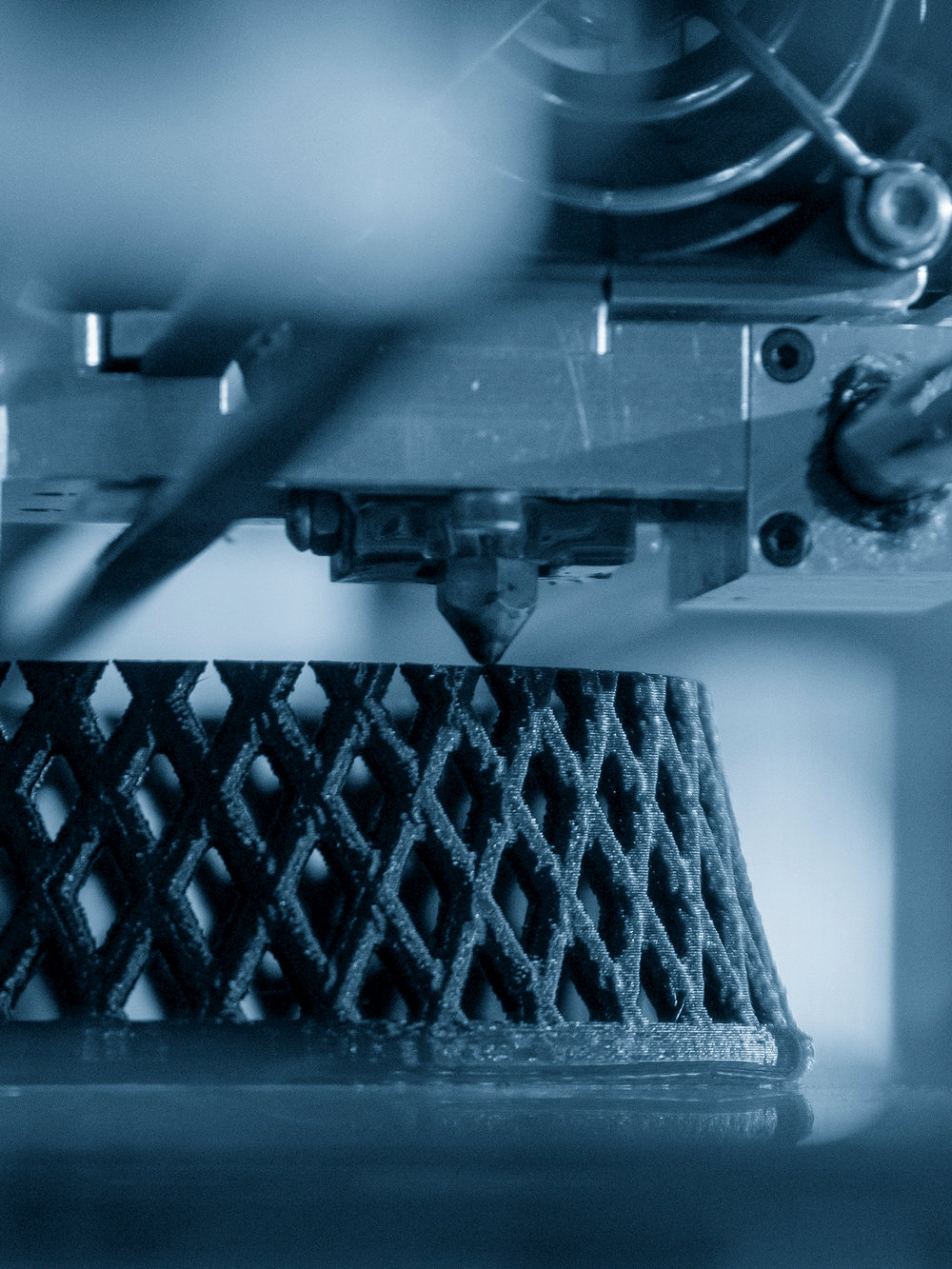

Challenges and benefits of Additive Manufacturing in the medical segment

ActOn’s ‘secret weapon’ is transforming medical implants

Lingering effects from the Covid-19 pandemic in the knee implant surgeries market

Finish Stock Allowance with Solid End Mills

New Seco Solid-carbide cutting tools boost knee implant machining speeds

8 tips to machine titanium alloys

Industry-specific solutions and strategies for machining ISO-S materials

Medical Brochure

Femoral Knee Implants – a new manufacturing paradigm

New strategies for orthopedic machining

Milling tooling developments increase quality and productivity in the machining of orthopedic replacement components

Solid Support for Additive Manufacturing

Inspiration Through Innovation 2024 Aerospace and Medical

Why a Strategic Partnership is the Perfect Medicine for Permedica

Tibial Tray

Bearing Inserts

Dental Implant Components

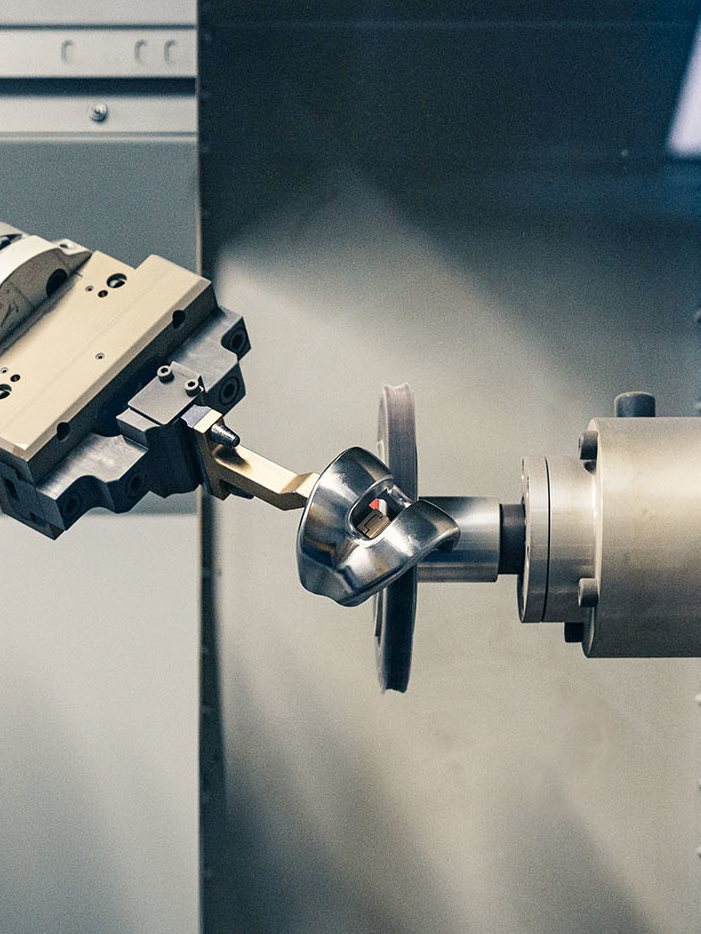

Knee replacement component machining demonstration

Seco End Mills for Plug-and-Play Dental Milling

Seco Barrel Machining Tools - JH734/JH736 & JH744/JH746

FINISH 3D PARTS FASTER WITH NEW BARREL FINISHING TOOLS DEDICATED TO ISO M AND S MATERIALS

Inspiration Through Innovation

5 Additive Manufacturing Trends Enhancing Production and Tooling

What does it take to engineer for tomorrow?

How 3D Printing is Making its Mark in Medical

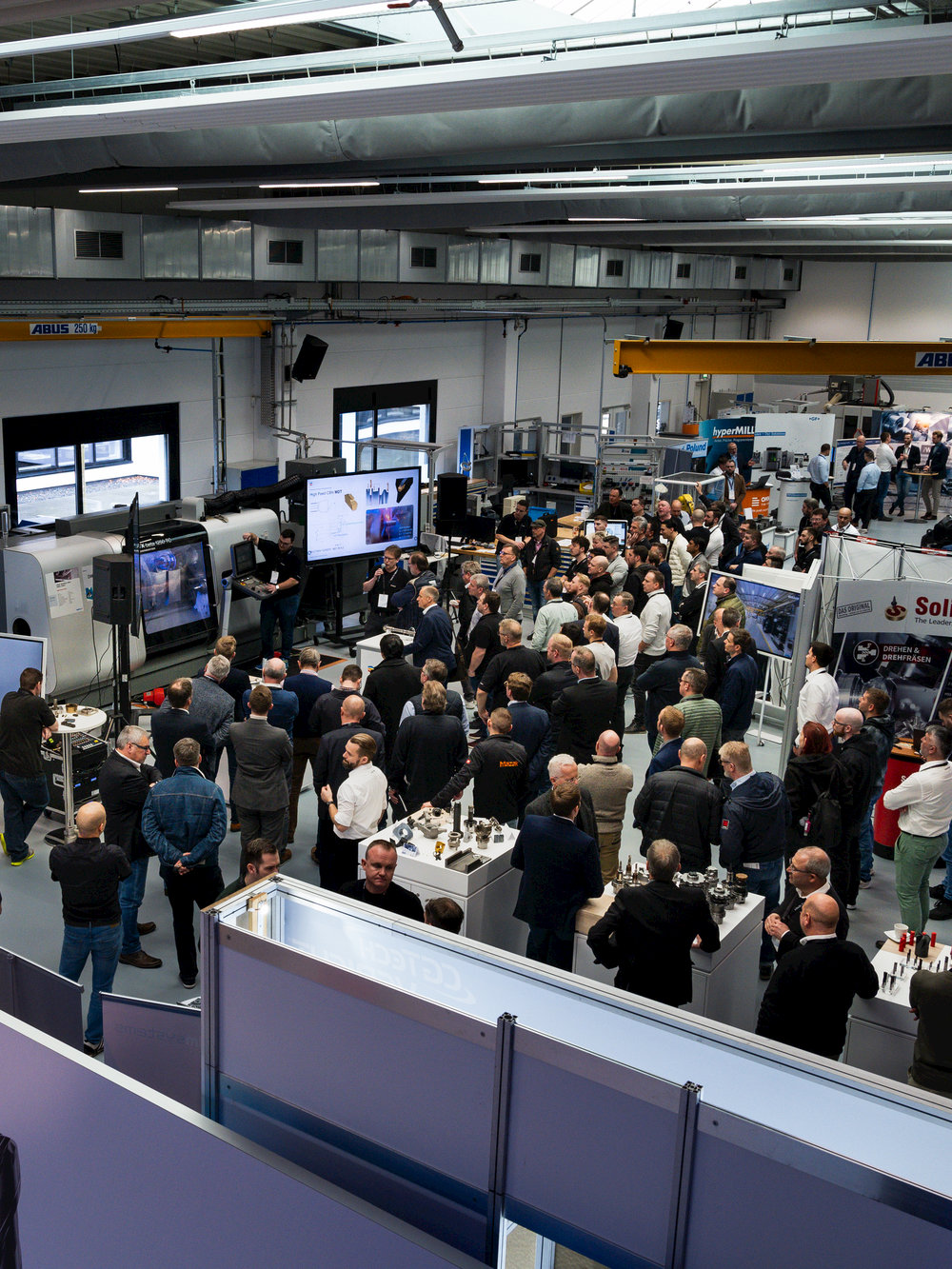

Inspiration Through Innovation 2024: Championing collaboration in the pursuit of manufacturing excellence

Expert Tips and Insights on Precision Medical Manufacturing | ITI Event

ITI 2024 | Medical Shoulder component machining demo

Hip Replacement Components

Spinal and Trauma Components

Titanium: Mastering Today’s Challenges, Shaping Tomorrow’s Trends

Contact our medical experts

Meet the Mini Mills

Seco collaborates with GF on machining specific medical components | Seco Tools

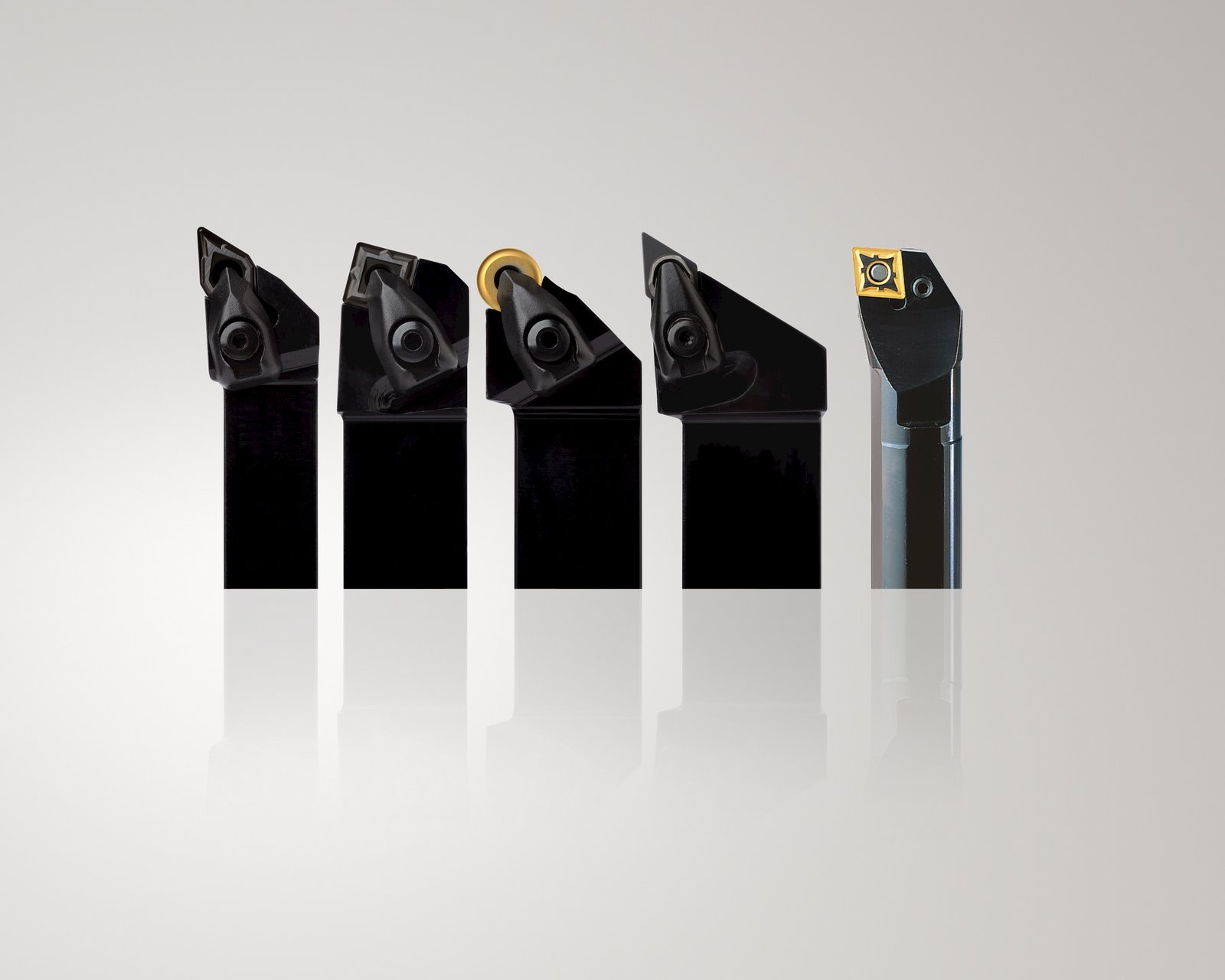

Shank Toolholders and Boring bars

Medical ITI - A Precision medical manufacturing event | Seco Tools

Seco supports Medical innovation with virtual event and exclusive content

Industries

Seco JM500 delivers visible improvements for micromachining

Intelligent future

Front-Runners

Seco Taps T32 - T33 - T34

Seco Hydraulic Chucks

Seco Helical SN8-13

JCO710 - High Performance - Square - Titanium - 4-6 flutes

Seco High Feed SP

High Performance HSS-Co End Mills

Seco News Summary 2022.2

Good news from Cobalt study

HSS-Co End Mills

Seco JS754 Stub Series End Mills

Brochure - Product Highlights

JETSTREAM TOOLING® SECO CAPTO™ GENERAL ISO TURNING