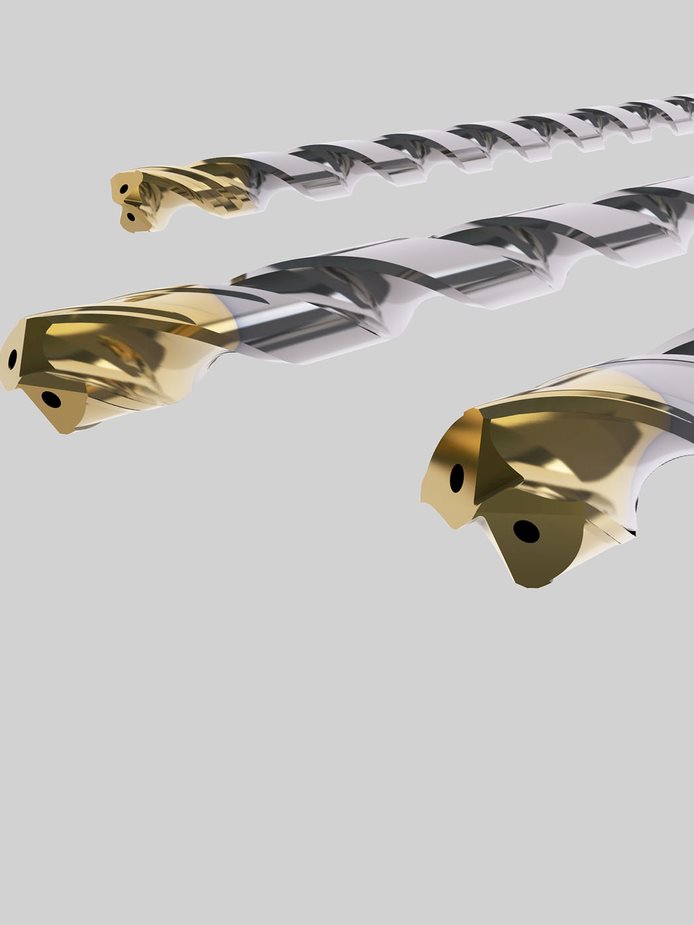

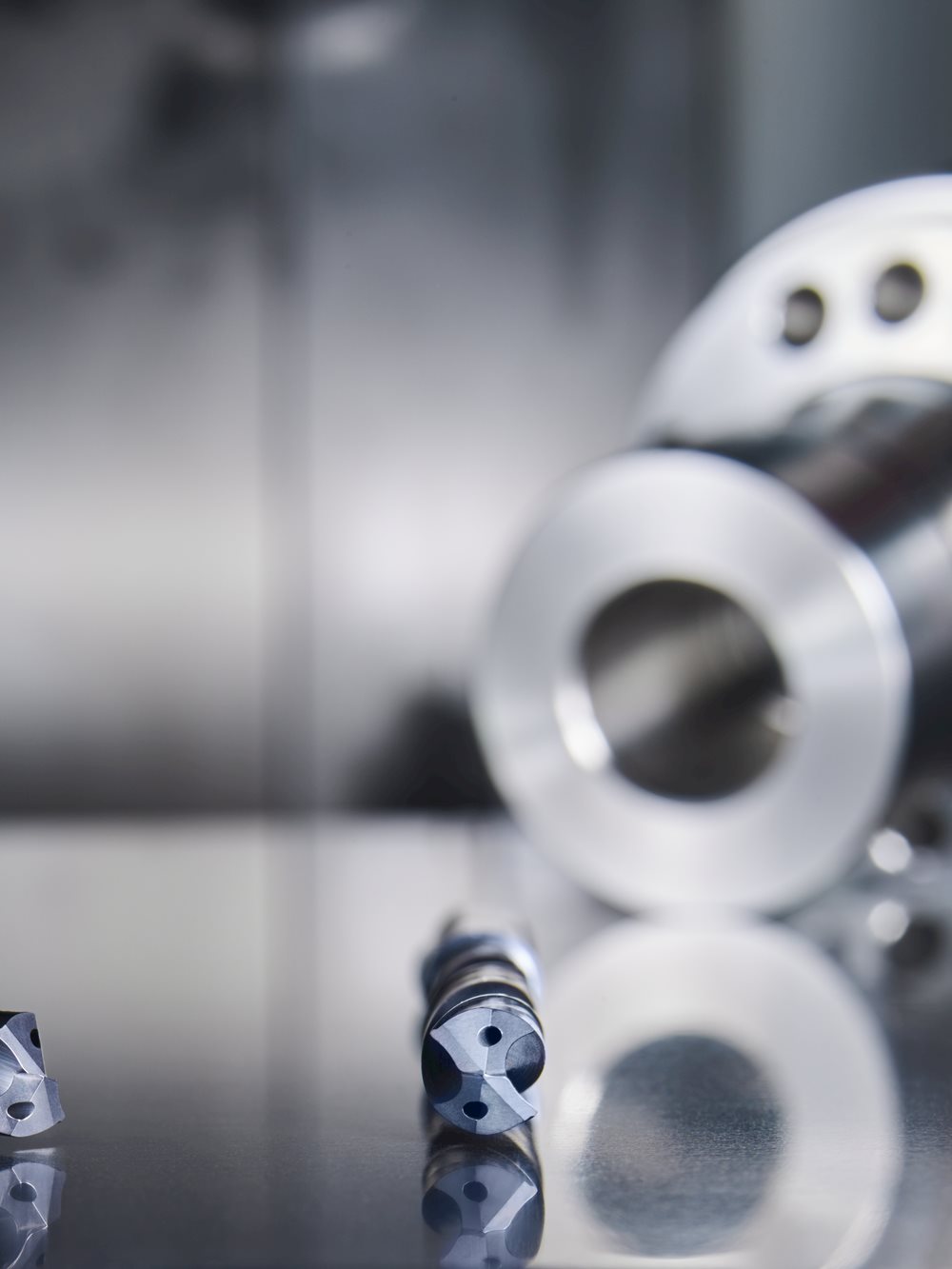

JS720 Solid End Mills addition

Overcome your challenges in Titanium alloy machiningDiscover the product range

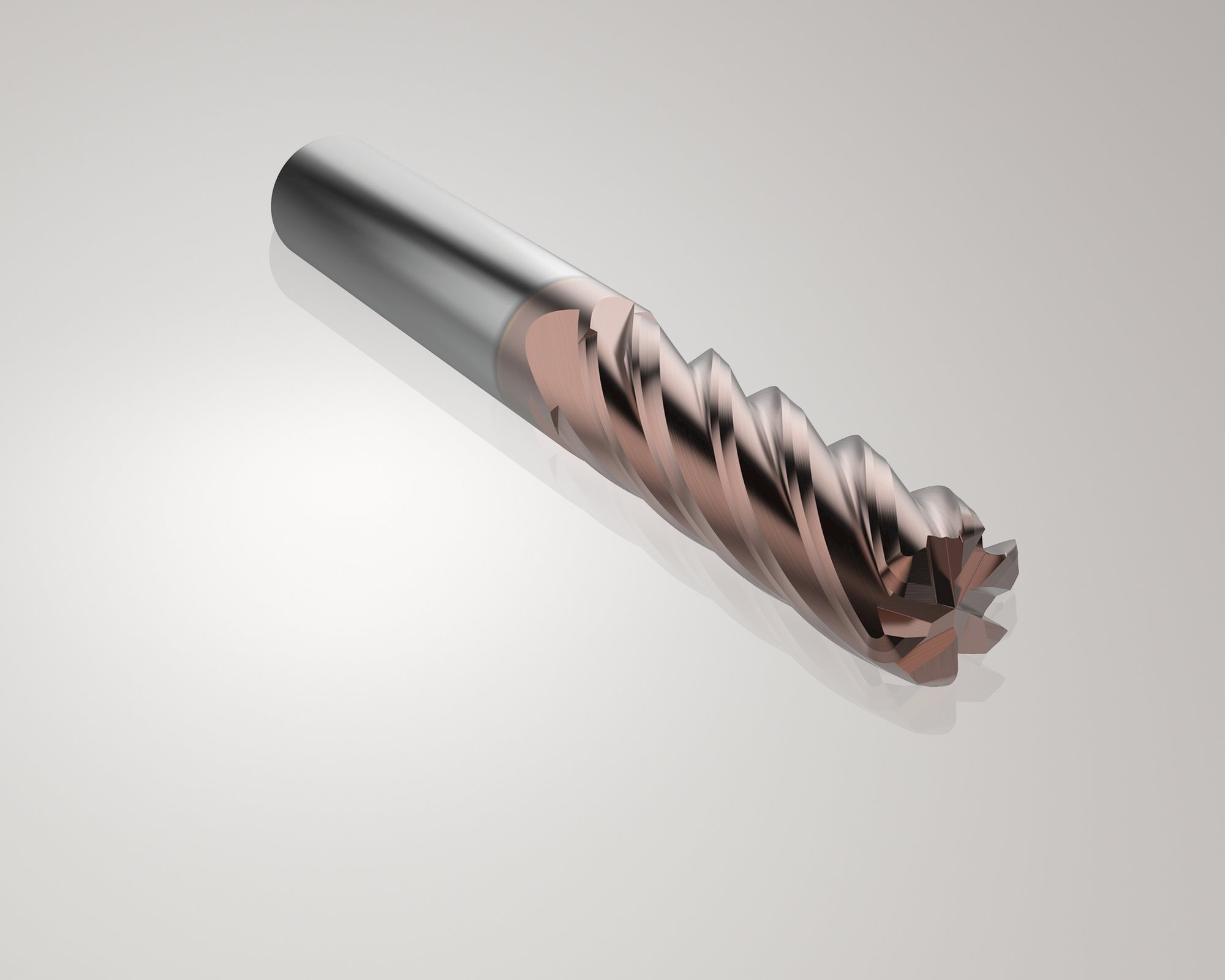

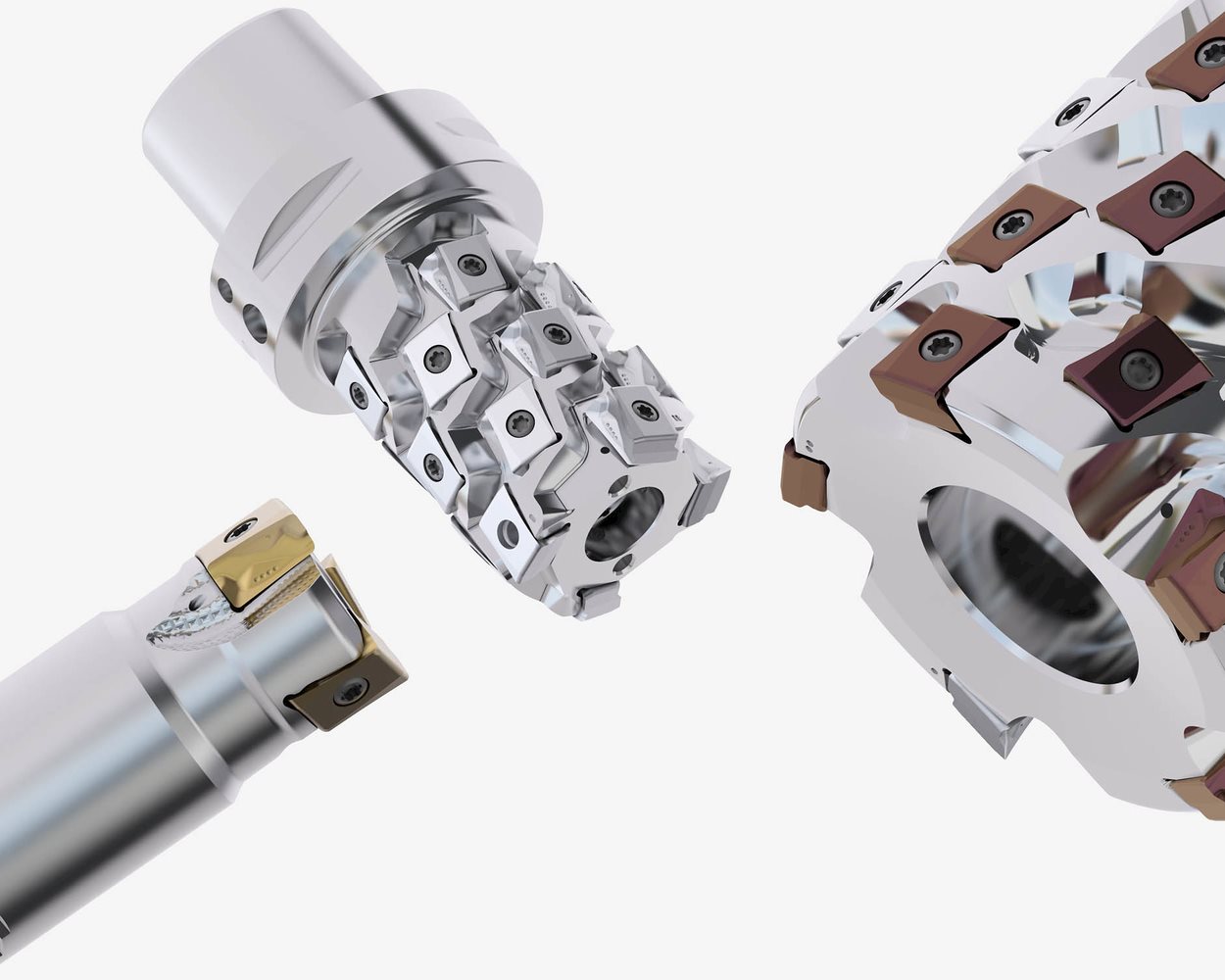

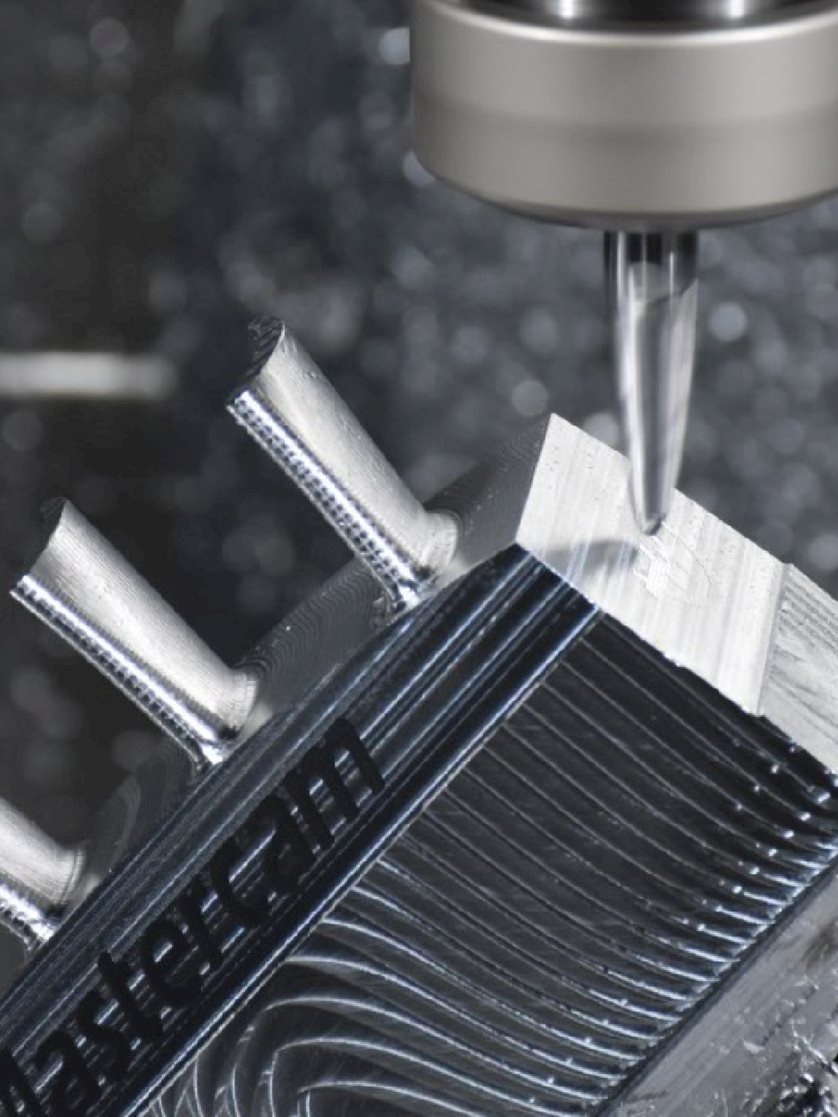

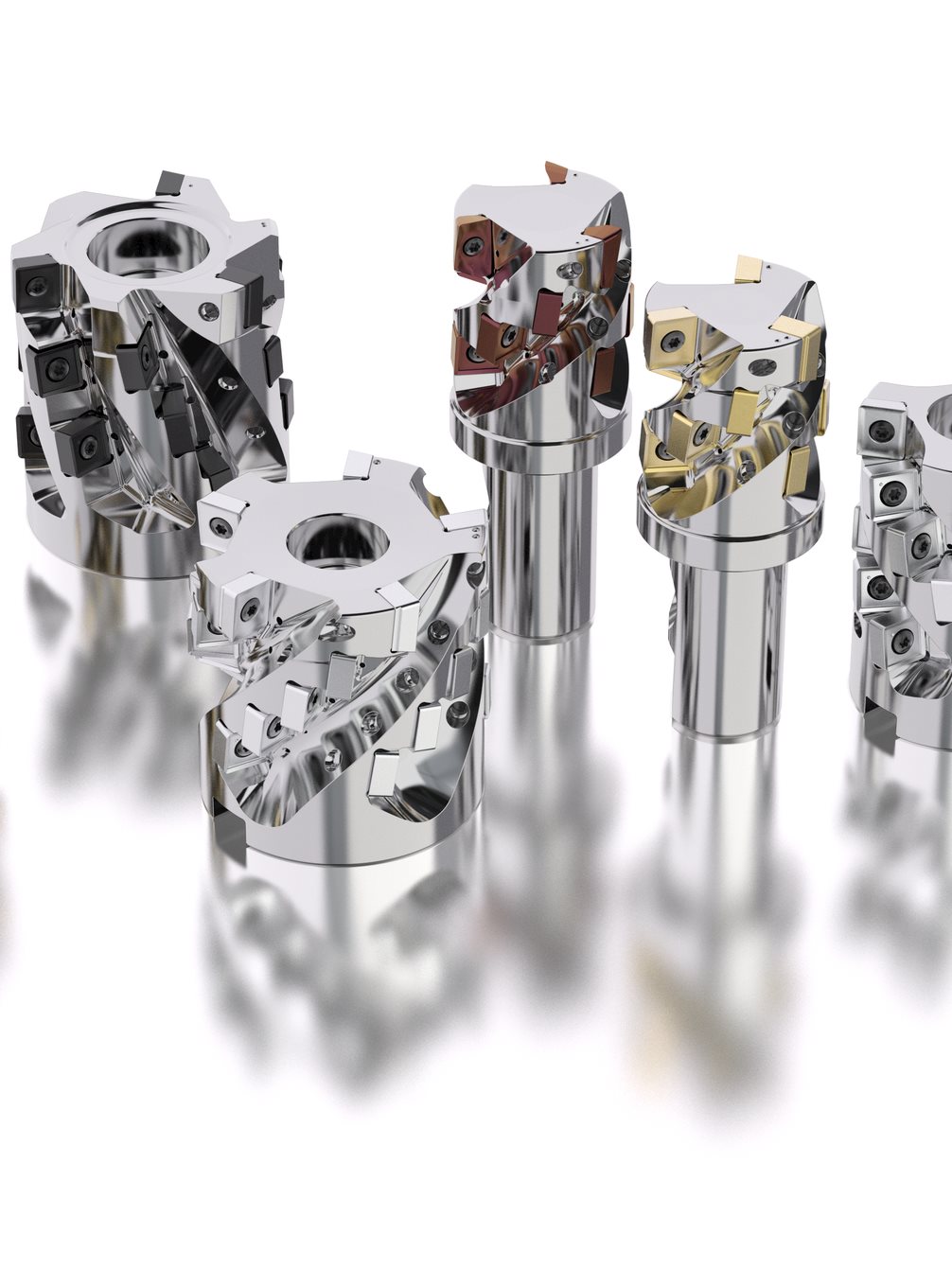

The JS720 end mills are excellent choices for machining ISO S & M materials, offering high performance in semi-finish operations and advanced roughing strategies. When it comes to advanced roughing titanium, these end mills can run at an ae that is 7 to 15% of the Dc.

These end mills feature many notable characteristics. An irregular pitch prevents chatter. The tapered core design increases stability while allowing for a high radial width of cut.

A new polished HXT coating with superior bonding ensures longer tool life. A 38-degree helix angle provides reliable cutting action in less stable conditions, while a 9-degree radial eccentric relief contributes to strong cutting edges.

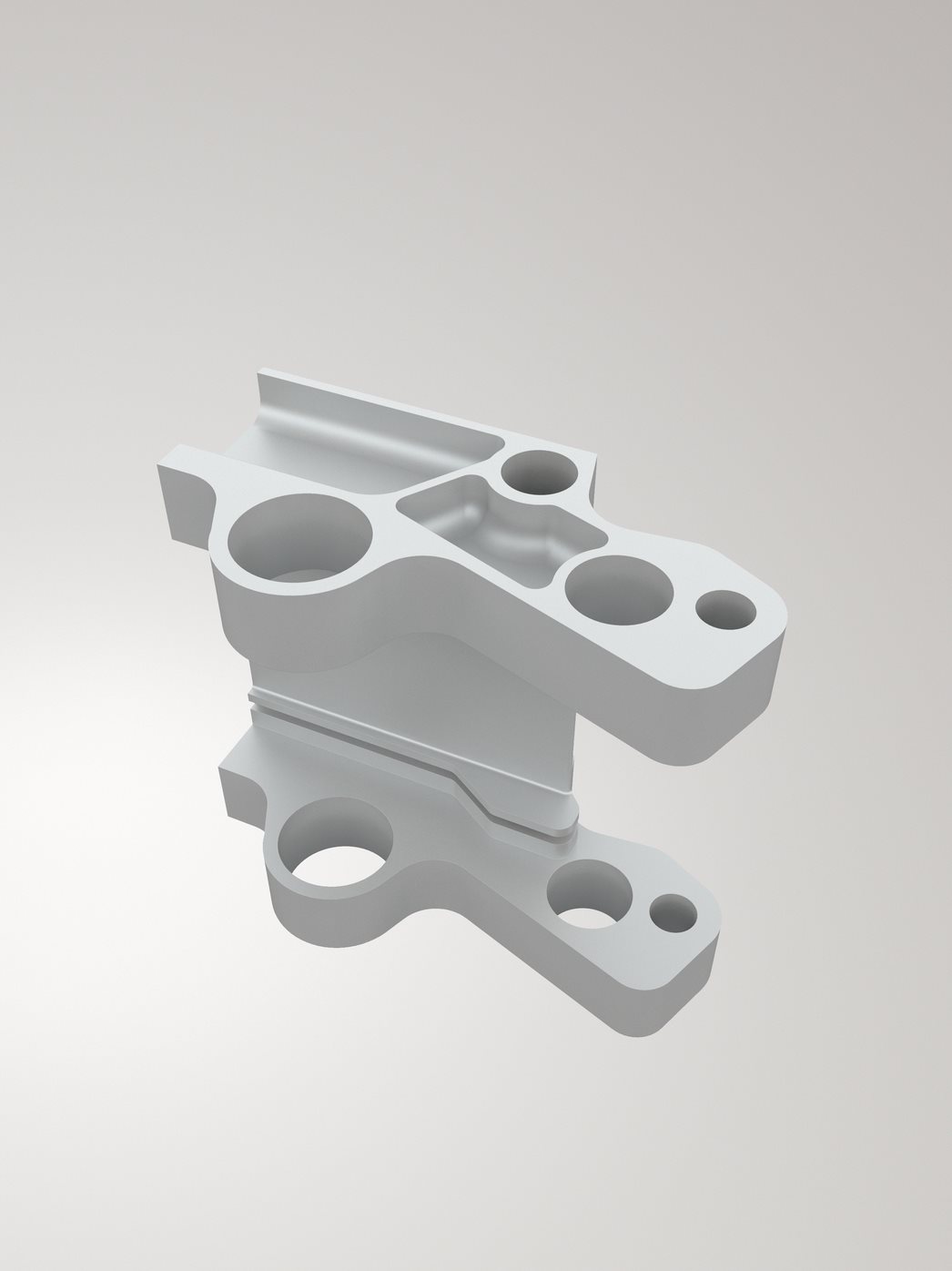

Additionally, the JS720 features radii optimized for aerospace structural part machining.

Overall, our innovative approach to edge preparation, coating and polishing gives our JS720 series the ability to achieve up to 30% more tool life than similar cutters. These cutters also prove to be 70% more productive than conventional 4 flute end mills in comparable situations.

Your challenge:

Optimize cycle time in advanced roughing operations whilst maintaining your tool life.

Our solution:

9 flutes increase metal removal rate whilst maintaining the same Feed per Tooth and a tapered core reduces tool deflection.

Your challenge:

Machining deep pockets in aerospace structural parts.

Our solution:

38° helix angle provides reliable cutting action in less stable conditions, while optimized chip splitters reduce tool breakage and workpiece scrap.

Your challenge:

Extended tool life.

Our solution:

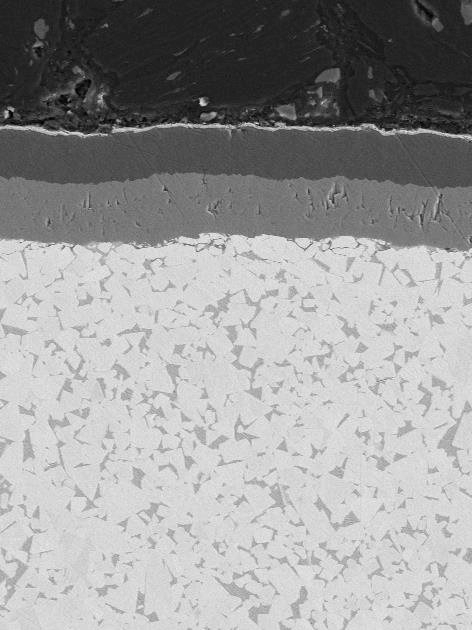

Our HXT coating is pattented and provides superior bonding and a hard top layer.

- Optimized tool design

- Cutting diameter range from Ø6 to Ø25mm

- 6 and 9 flute

- Corner radii from 0.5mm to 6mm

- Cutting lengths from 2.5x to 3xDc

- With and without Chip splitters

- Standard Cylindrical shanks, with Weldon and Safe-Lock™ shank options

Discover the product range

Contact Us

Related content

JS720_C Advanced Roughing - Square - Titanium - 6-9 Flutes

Factsheet - JS720 Solid End Mills addition

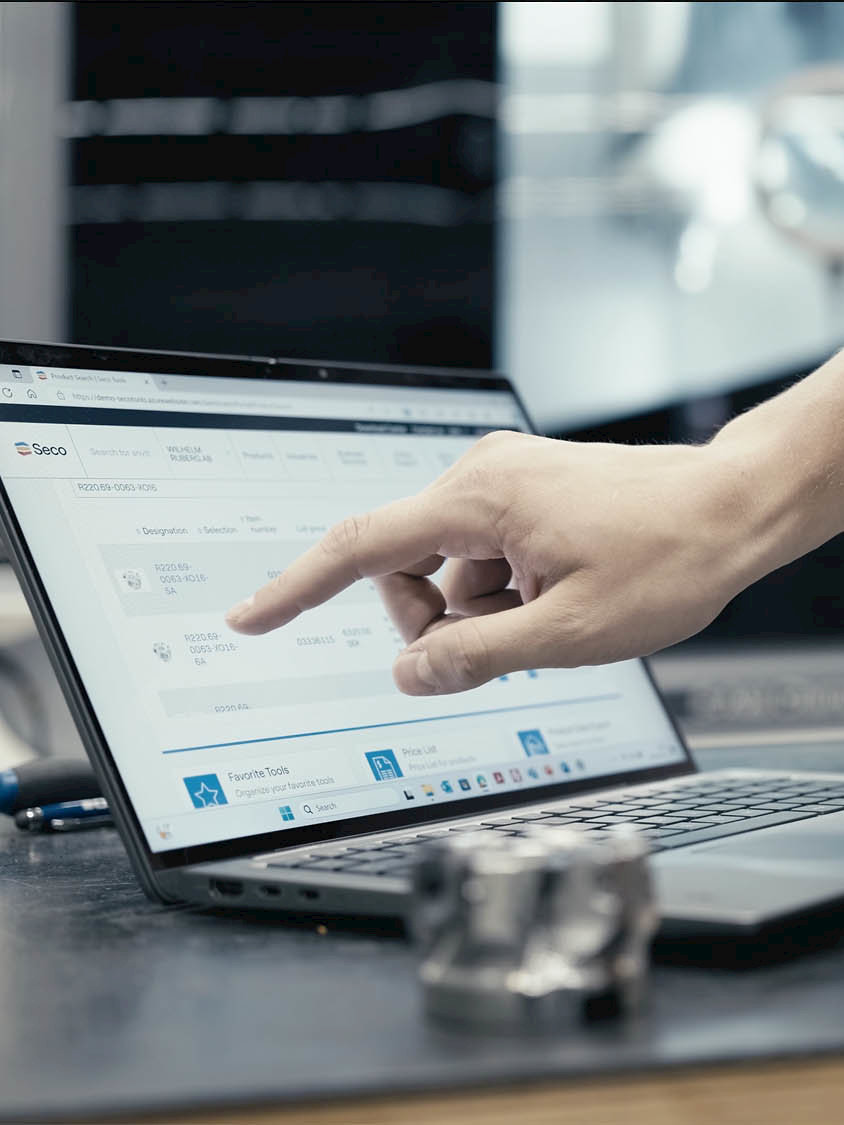

Seco Digital Tool Assembly: quick, accurate data

8 tips to machine titanium alloys

Seco Nanojet Reamers: reliable precision

Easy setup with Seco Digital Axial Boring Heads

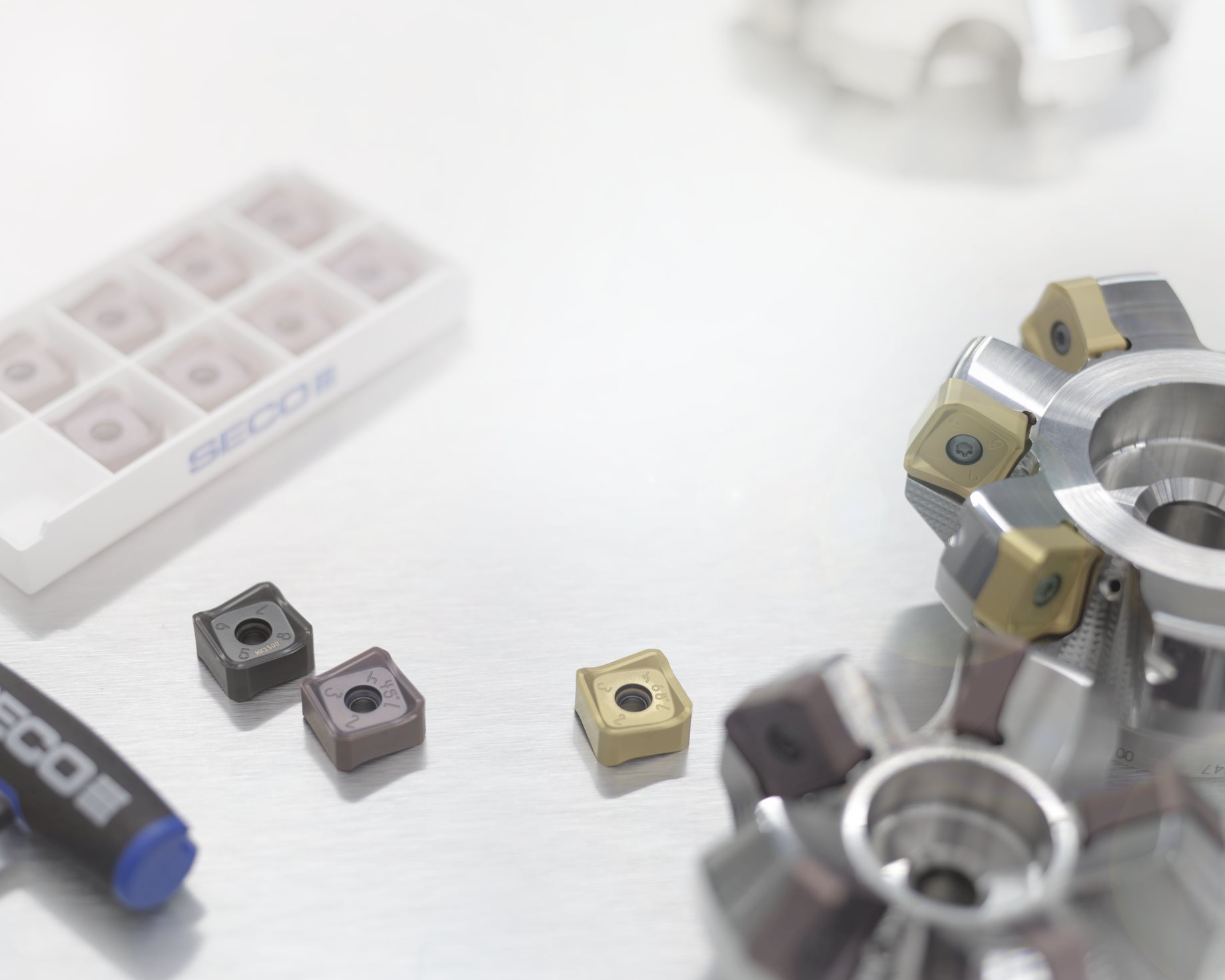

New MP Milling Grades

JH730 Solid End Mills addition

Challenges in titanium

Square T4-12 Upgrades

Aerospace

JS720/730 High Performance - Square and Ball - Titanium - 6-9 Flutes

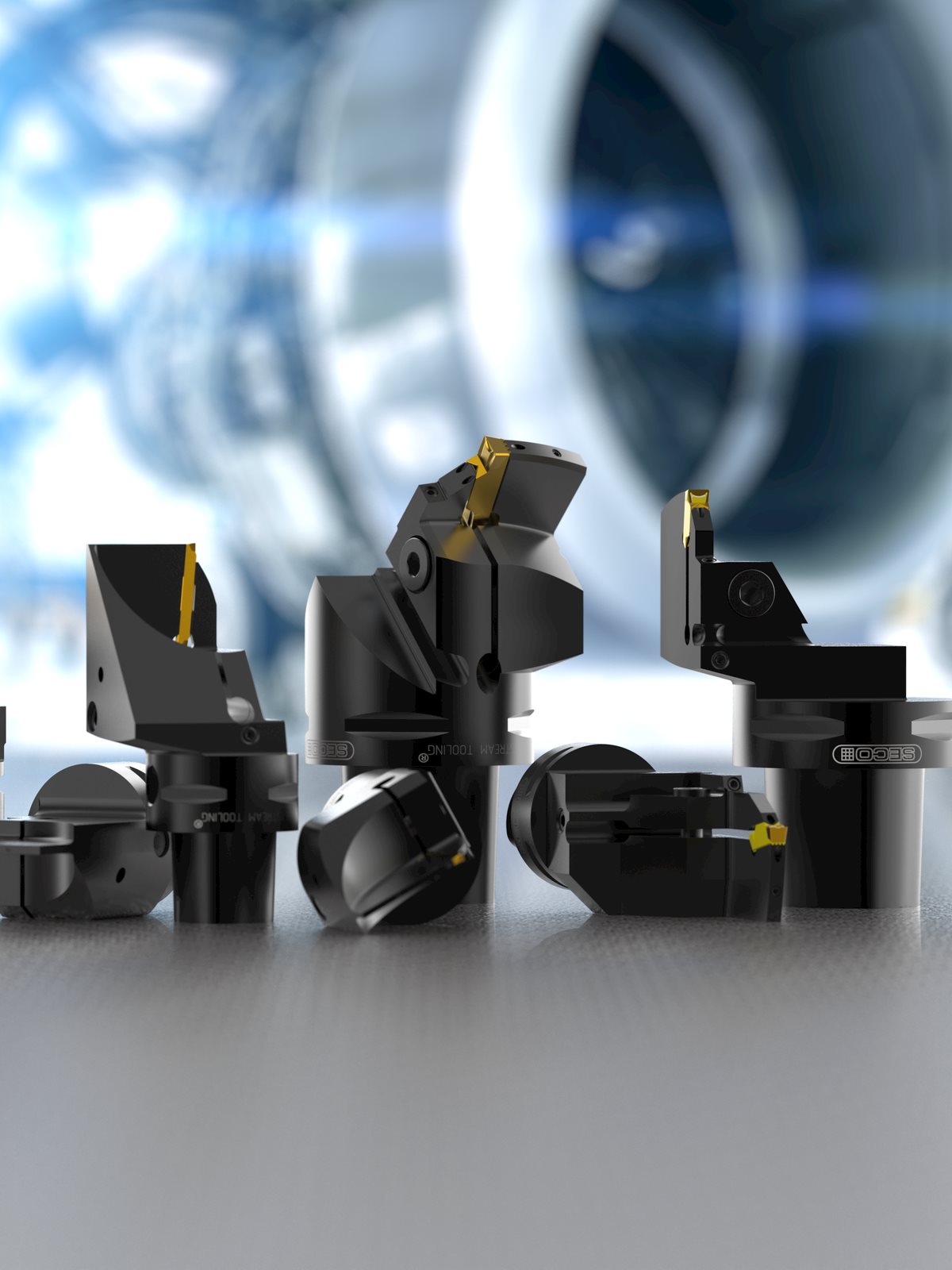

Optimize Multi-Task Machining Coolant And Results

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

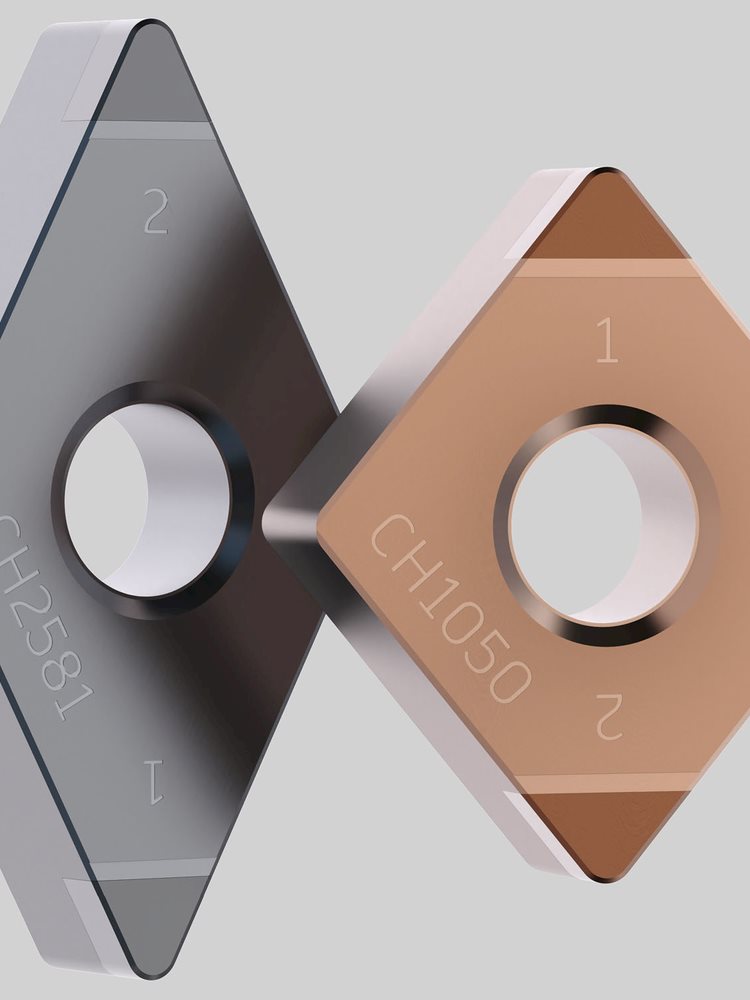

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

Universal Drills

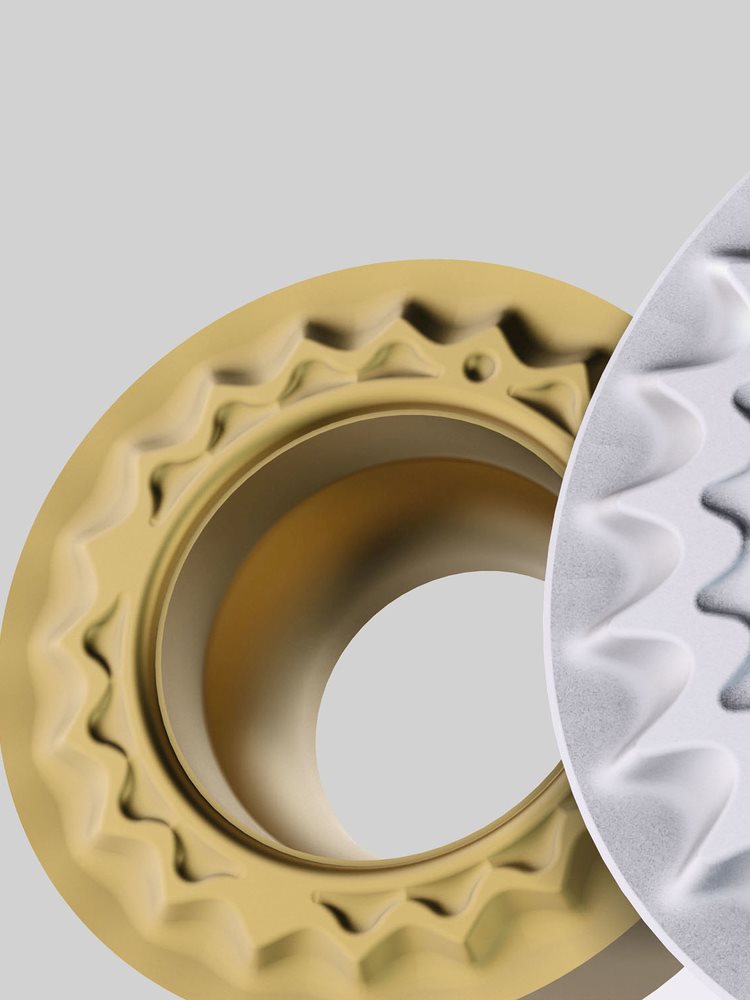

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Titanium: Mastering Today’s Challenges, Shaping Tomorrow’s Trends

Titanium: Advances in Titanium alloy machinability

Seco X-Head Exchangeable End Mill System

Aerospace Pintle Plate

Advances in superalloy machinability

The new materials set to shape the future of the aerospace industry

The Rise of Composite Materials in Aerospace Manufacturing

Composite Materials: Flying High!

Seco and Mastercam: How Accelerated Finishing Tools Enhance Surface Finishes and Save Time

Reducing the carbon footprint in structural aerospace components

Towards a leaner and greener aviation industry

Why making an aeroplane pylon is a true collaborative process

Addressing the Aerospace Machining industries skills gap, one customer at a time

Video: Why is Wire-Arc Additive Manufacturing important when machining a Blisk?

Additive and Subtractive Manufacturing of a Titanium Blisk

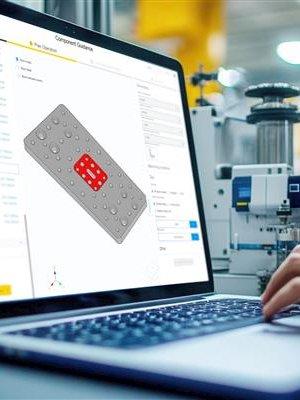

Seco Component Guidance

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

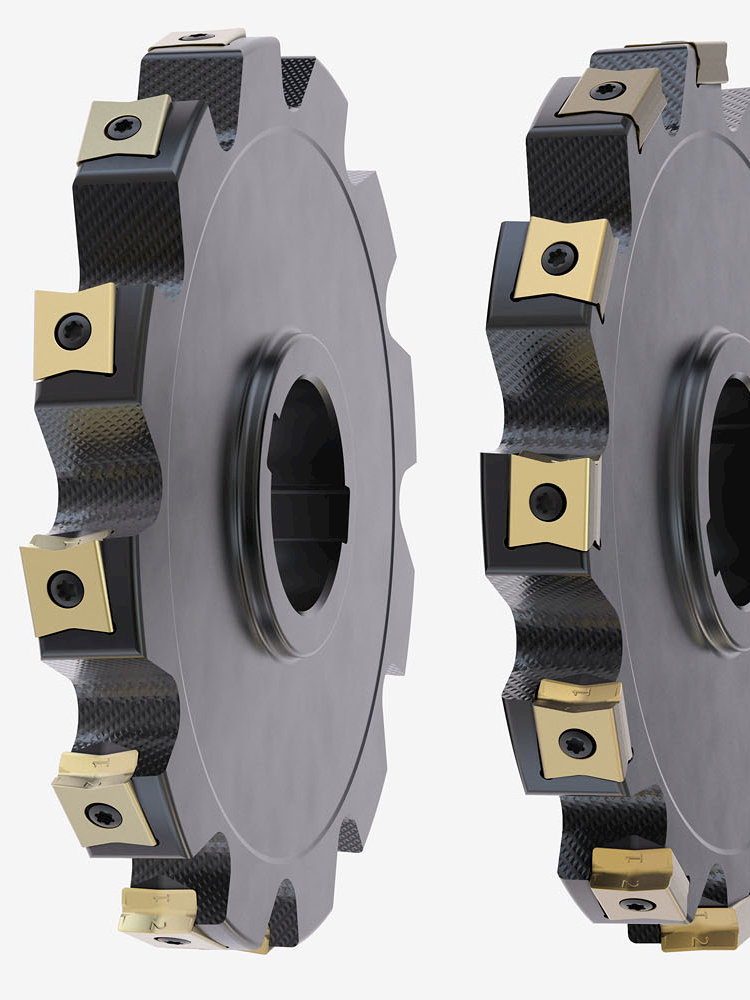

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Seco T35 Taps: match Tooling to Materials

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

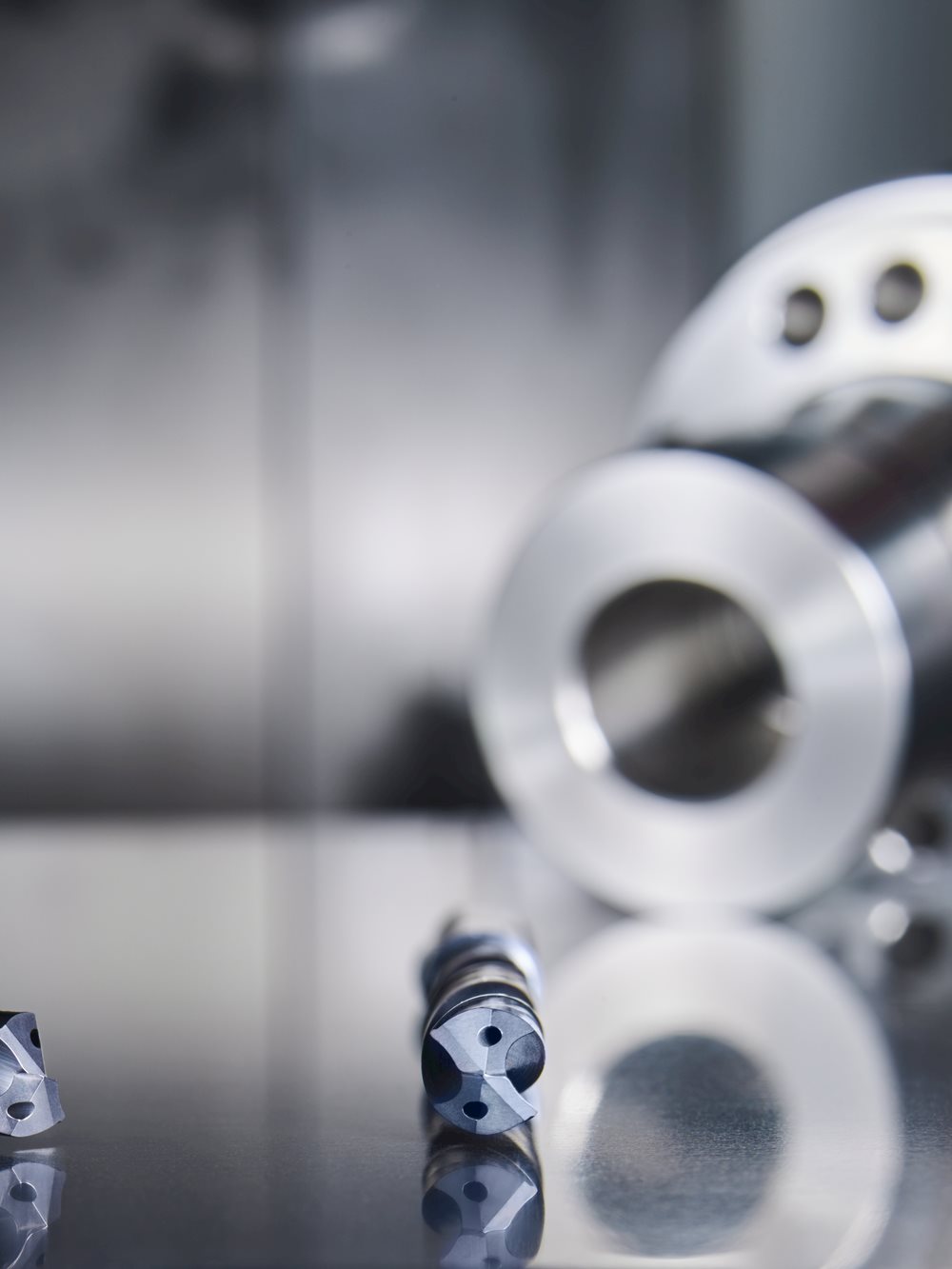

Unleash your drilling potential

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22

The rise of MMCs: Advantages, challenges, and solutions in using Metal Matrix Composites

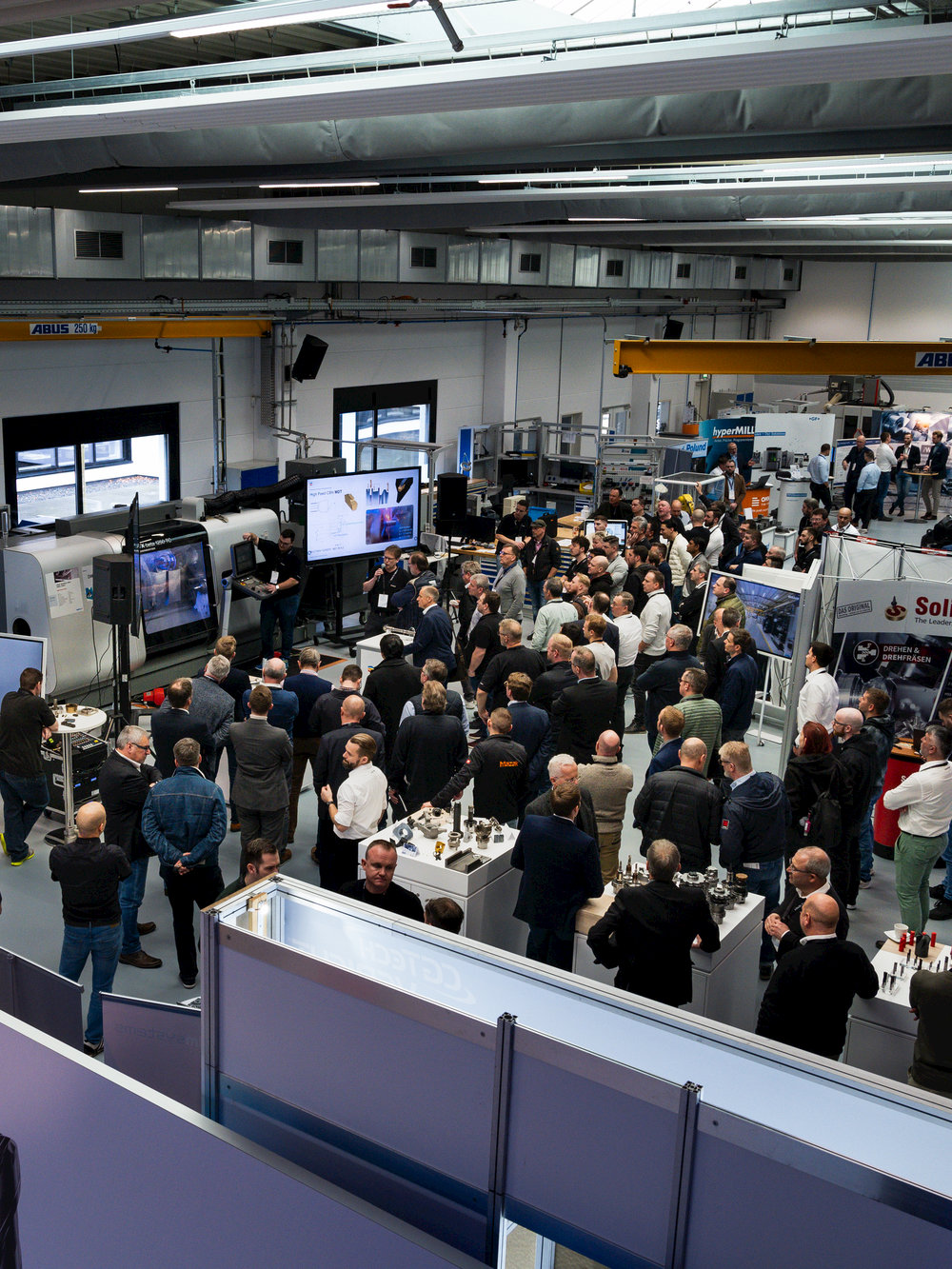

Inspiration Through Innovation 2024 Aerospace and Medical

Advances in Titanium Alloy machinability

Industry-specific solutions and strategies for machining ISO-S materials

Expand production with collaborative uses of Additive Manufacturing

Lift-off for Mettis Group

Video: Aerospace Machining: Aircraft Pintle Plate in Titanium | Seco Tools

Seco JS754 Stub Series Brings Versatility and Value When Milling Tough Materials

Video: Advanced Tooling for Aerospace Disc Manufacturing

Getting Technical - Machining Titanium and Super Alloys

Navigating the complexities of aerospace supply chains

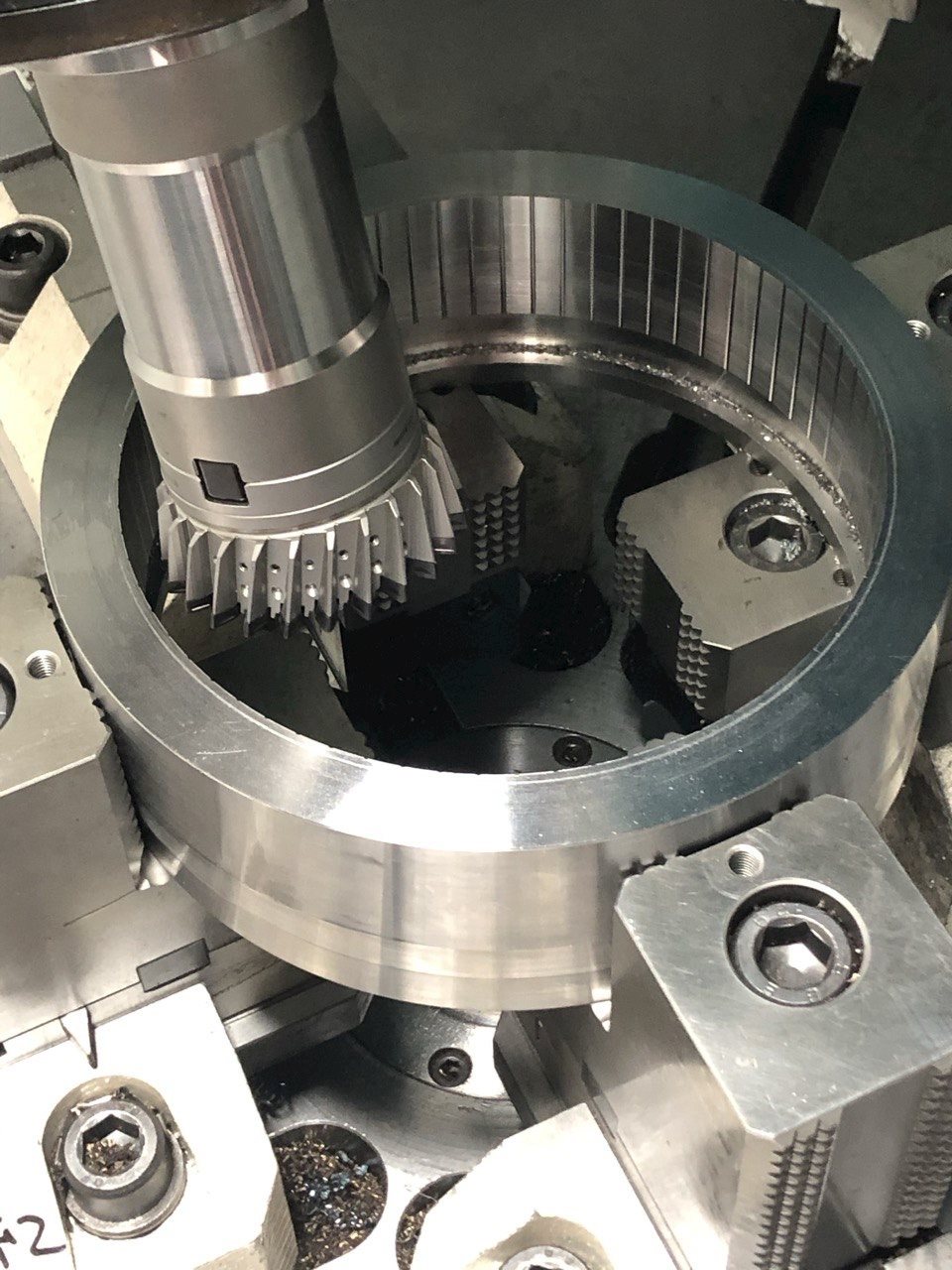

Aerospace Jet Turbine Discs

Inspiration Through Innovation

Laser-assisted thermal machining: the solution for manufacturing with MMCs?

5 Additive Manufacturing Trends Enhancing Production and Tooling

ActOn’s ‘secret weapon’ is transforming medical implants

MEP takes the edge off aerospace part manufacturing

Superalloys and Titanium / ISO S

Why gear skiving can be good news for jet turbine disc manufacturers

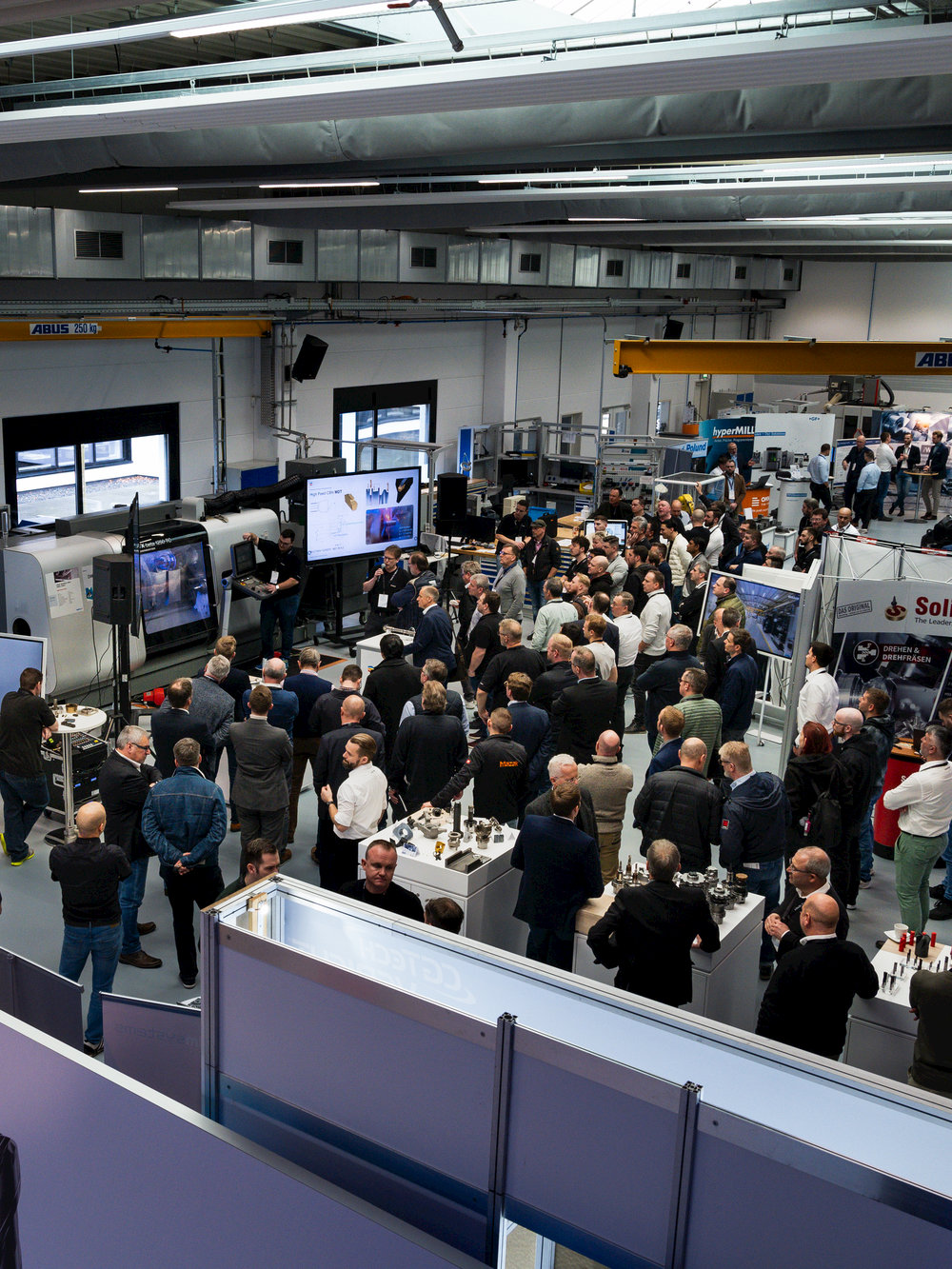

Inspiration Through Innovation 2024: Championing collaboration in the pursuit of manufacturing excellence

Webinar - Advances in Titanium alloy machinability

ITI 2024 | Aerospace A-Frame component machining demo

ITI 2024 | Aerospace Turbine disk component machining demo

GKN Aerospace continues to develop Additive Manufacturing technologies

New strategies and solutions take on ISO S materials

Seco Helical SN8-13

Factsheet - JH730 Solid End Mills addition

Engine Components