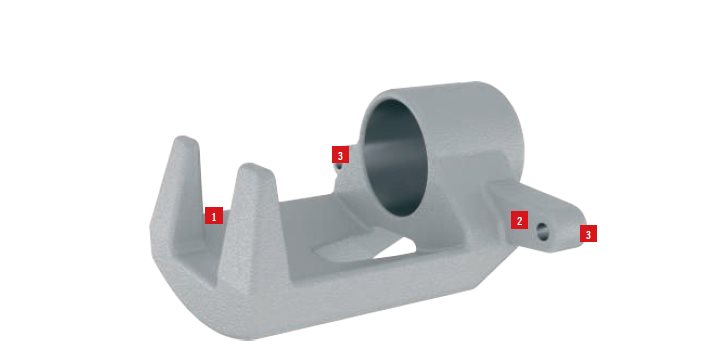

Brake Caliper

Brake calipers are the assemblies housing vehicle brake pads and brake pistons. But what are Brake Calipers made of and how to machine them...Brake calipers are the assemblies housing vehicle brake pads and brake pistons. As a critical safety component, brake calipers are made from nodular cast iron, and require custom tooling for generating radii and flat surfaces while maintaining critical surface finishes.

- Producing spot faces with maximum productivity and reliability.

- Drilling numerous holes with low cycle times, high quality and reliability.

Your Challenge: Milling brake pad locations with minimal setting and adjusting time.

Our Solution: Seco’s family of R335 disc milling cutters feature robust bodies for high tool life and incorporate a variety of features designed to optimize machining of cast iron. Positive rake angles reduce cutting forces and vibration to optimize accuracy and energy consumption, and the use of a constant rake angle over the radius maximizes chip evacuation. Your benefits include highly productive performance with extended tool life.

Product: R335.25 Milling Cutter

Your Challenge: Reducing cycle times for milling faces while maintaining quality and reliability.

Our Solution: Turbo square shoulder mills use hardened steel cutter bodies and strong, thick inserts to achieve incredibly reliable performance and high material removal rates. These tools provide soft, easy cutting and minimize power consumption through their super positive cutting rake. Your benefits include increased confidence in your applications and substantial time savings.

Product: Super Turbo Square Shoulder Milling Cutter

Your Challenge: Producing spot faces with maximum productivity and reliability.

Our Solution: The R417.19 custom tool uses a square positive insert and adjustable cartridge with a chamfering insert to combine spot facing and chamfering operations. The balanced cutter offers smooth cutting action and produces a constant chamfer value on a multispindle machine. Your benefits include cost reduction through process optimisation.

Product: R417.19 Spot Face and Chamfering Cutter

Your Challenge: Drilling numerous holes with low cycle times, high quality and reliability.

Our Solution: Providing high performance when dealing with angled exits or intersecting holes, the Seco Feedmax Chamfer Drill utilises the light-cutting geometry and a special edge preparation to increase process security and tool life. The tool also incorporates a low-friction coating, and uses four land margins to increase stability. Your benefits include maintaining productivity in challenging, high-tolerance holes.

Product: Seco FeedmaxTM Chamfer Drill