Remove materials in a faster and more reliable way

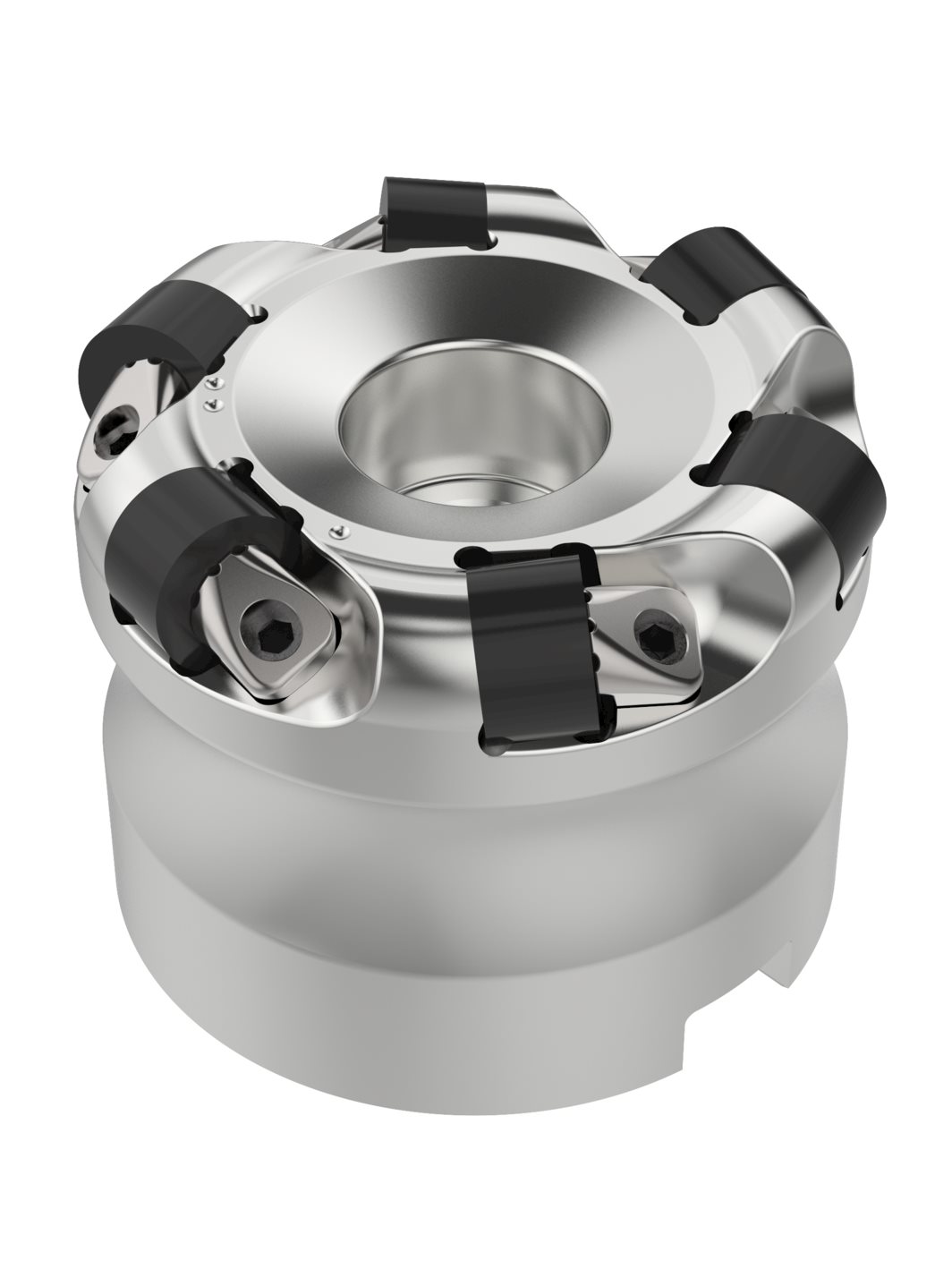

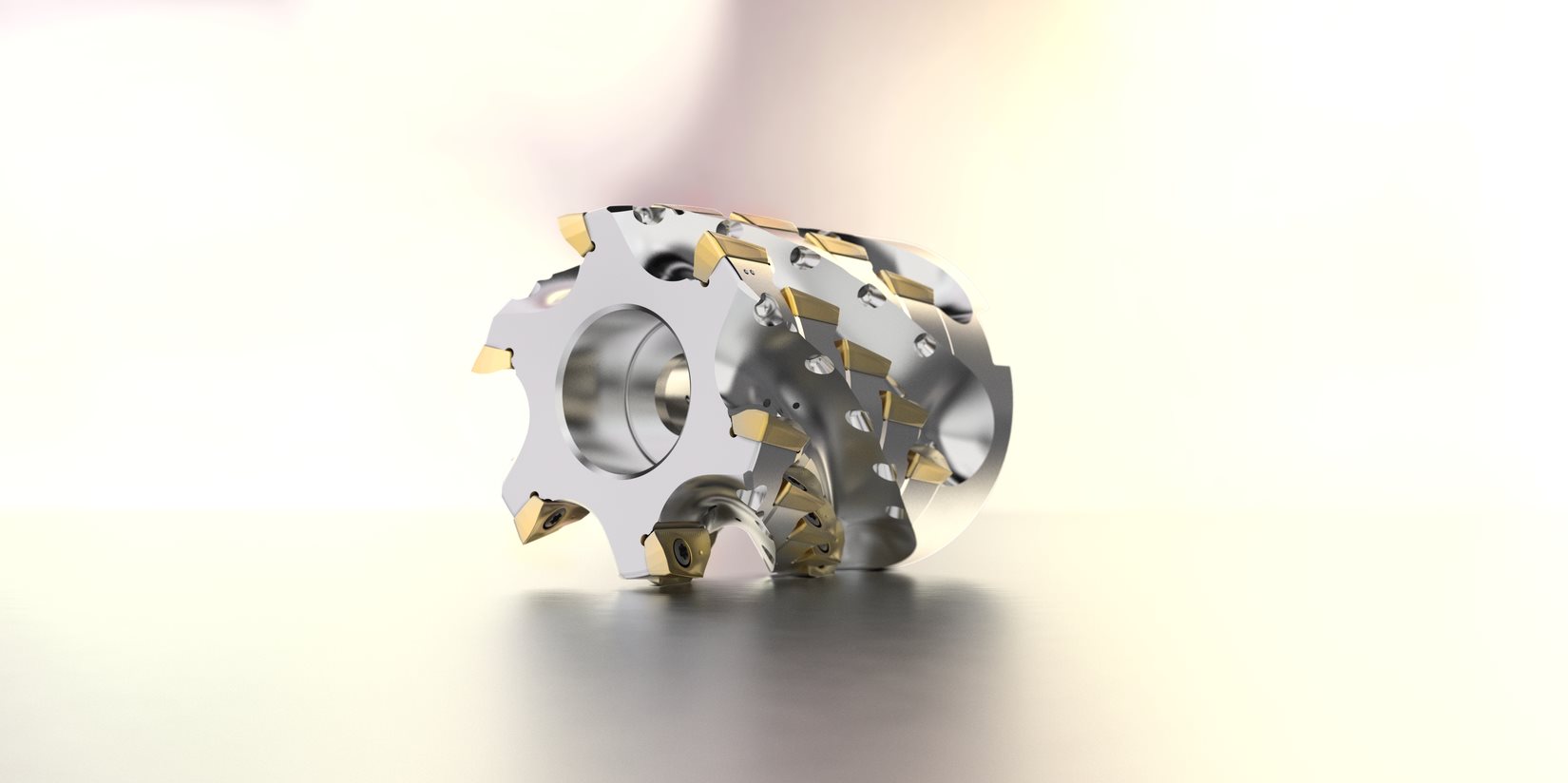

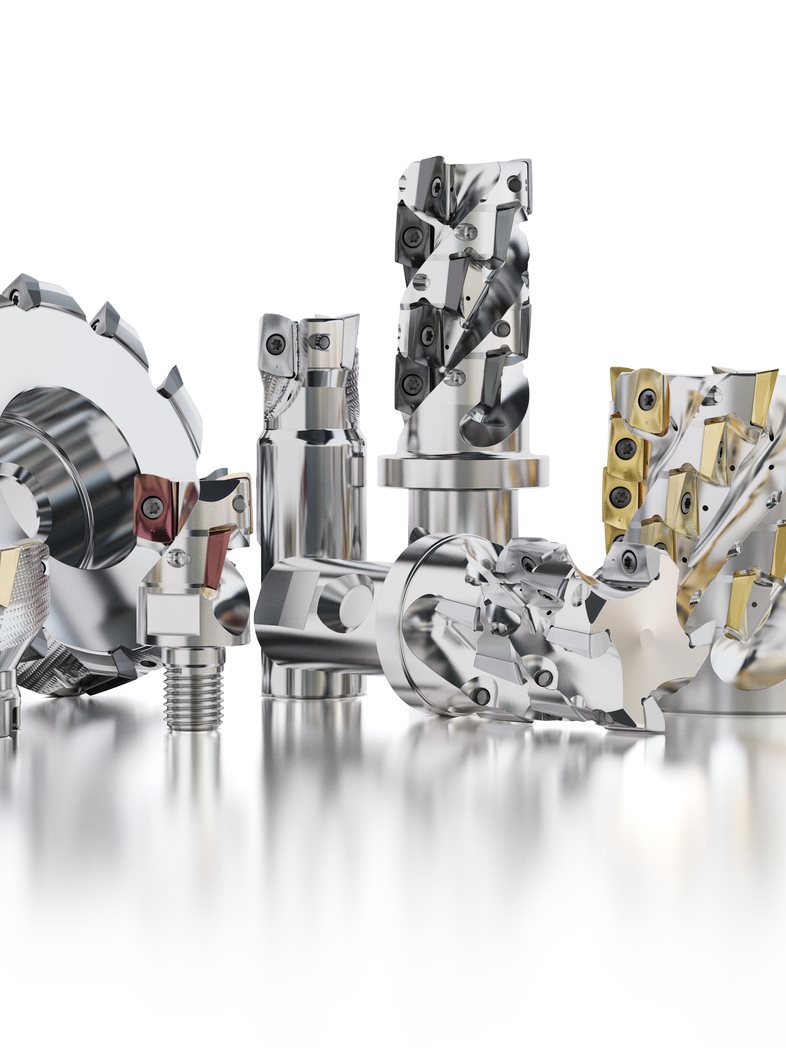

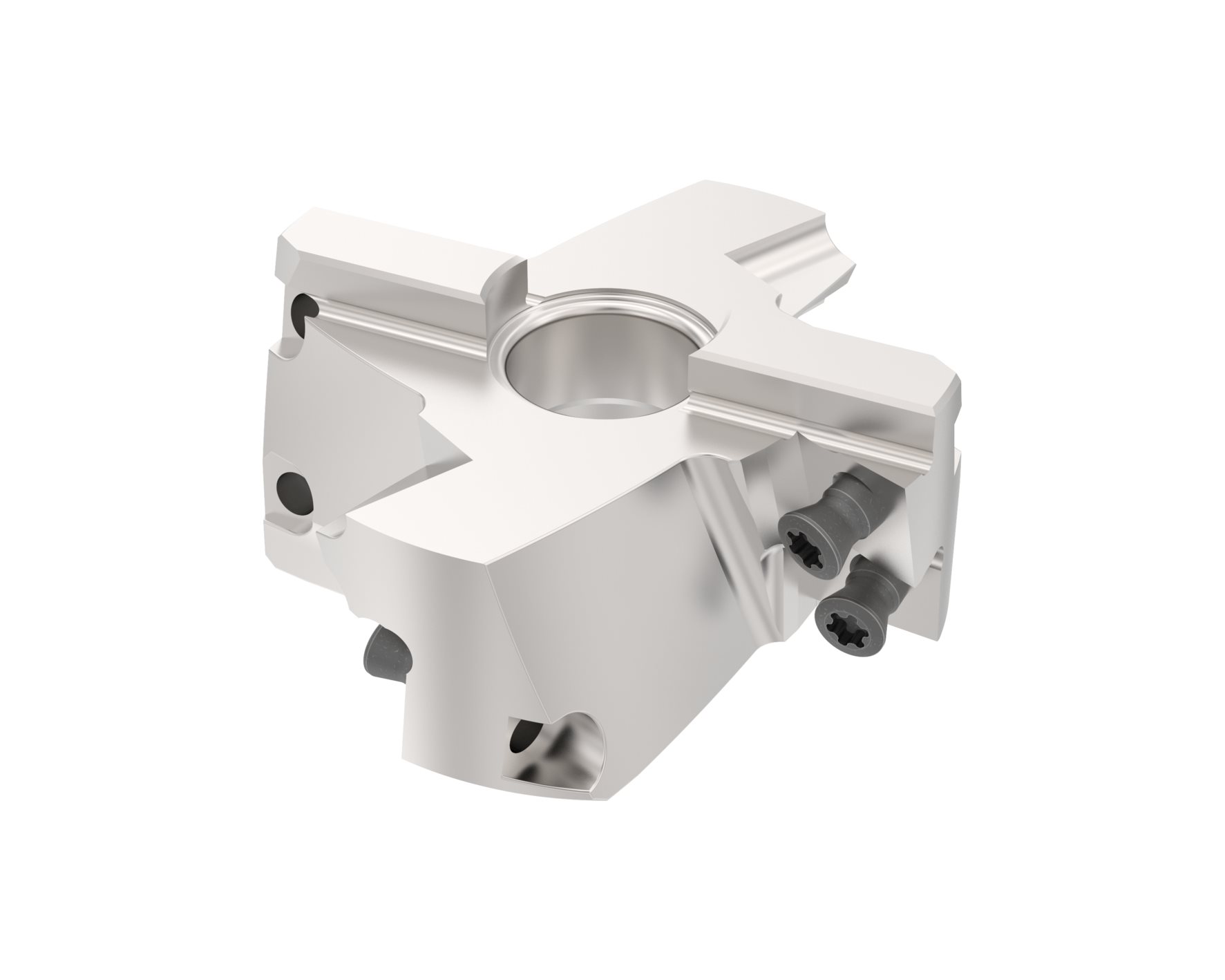

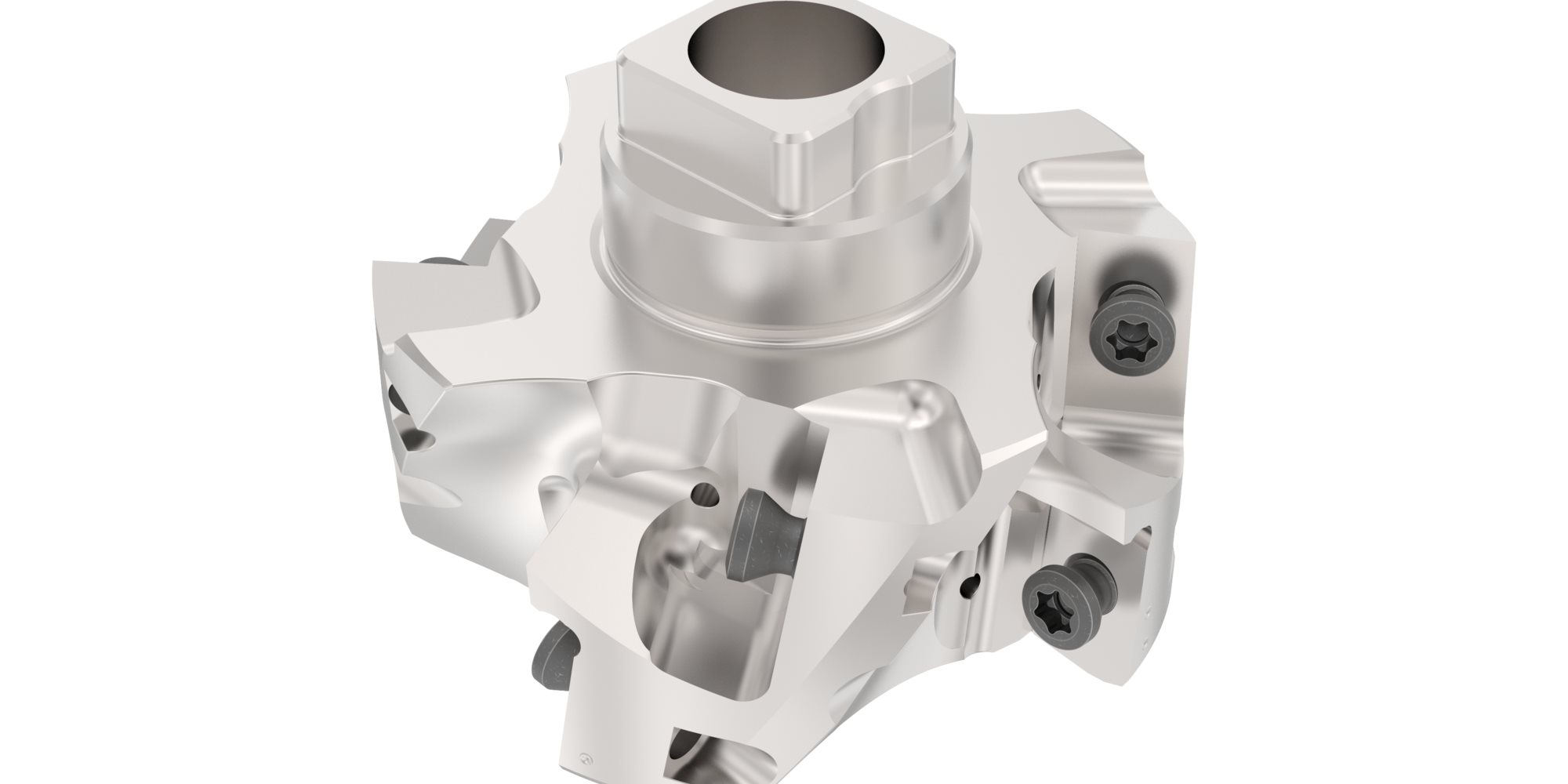

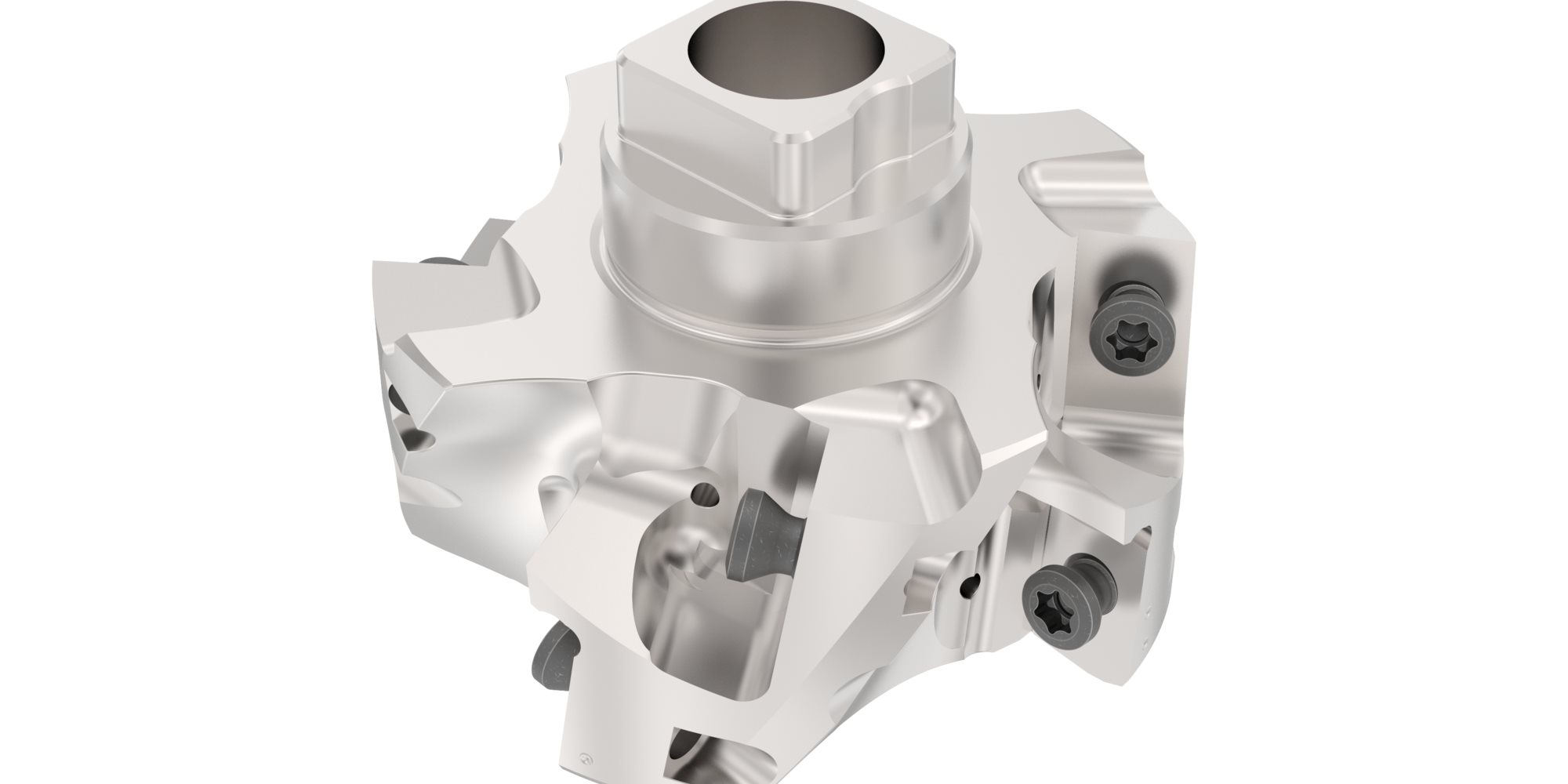

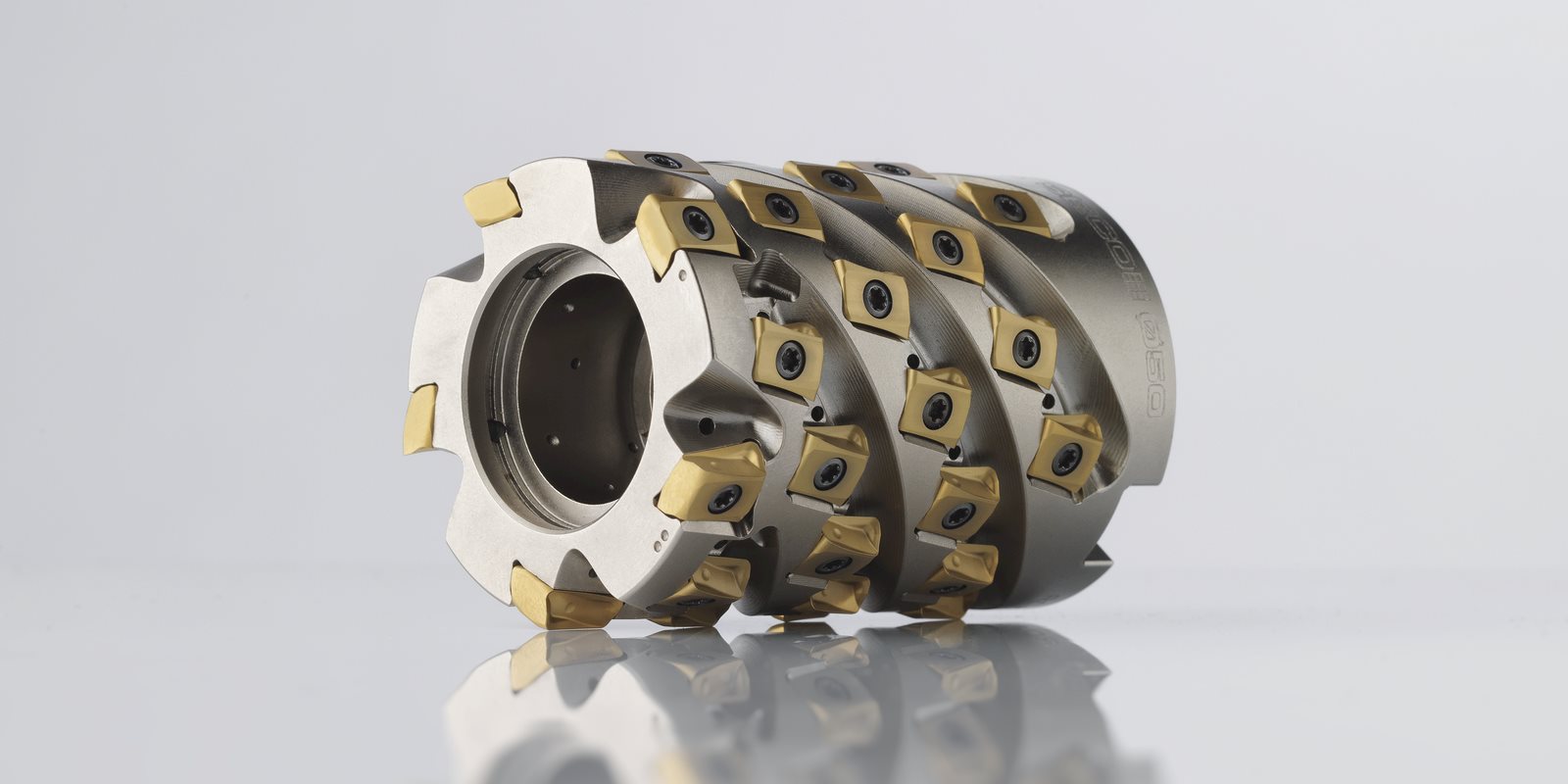

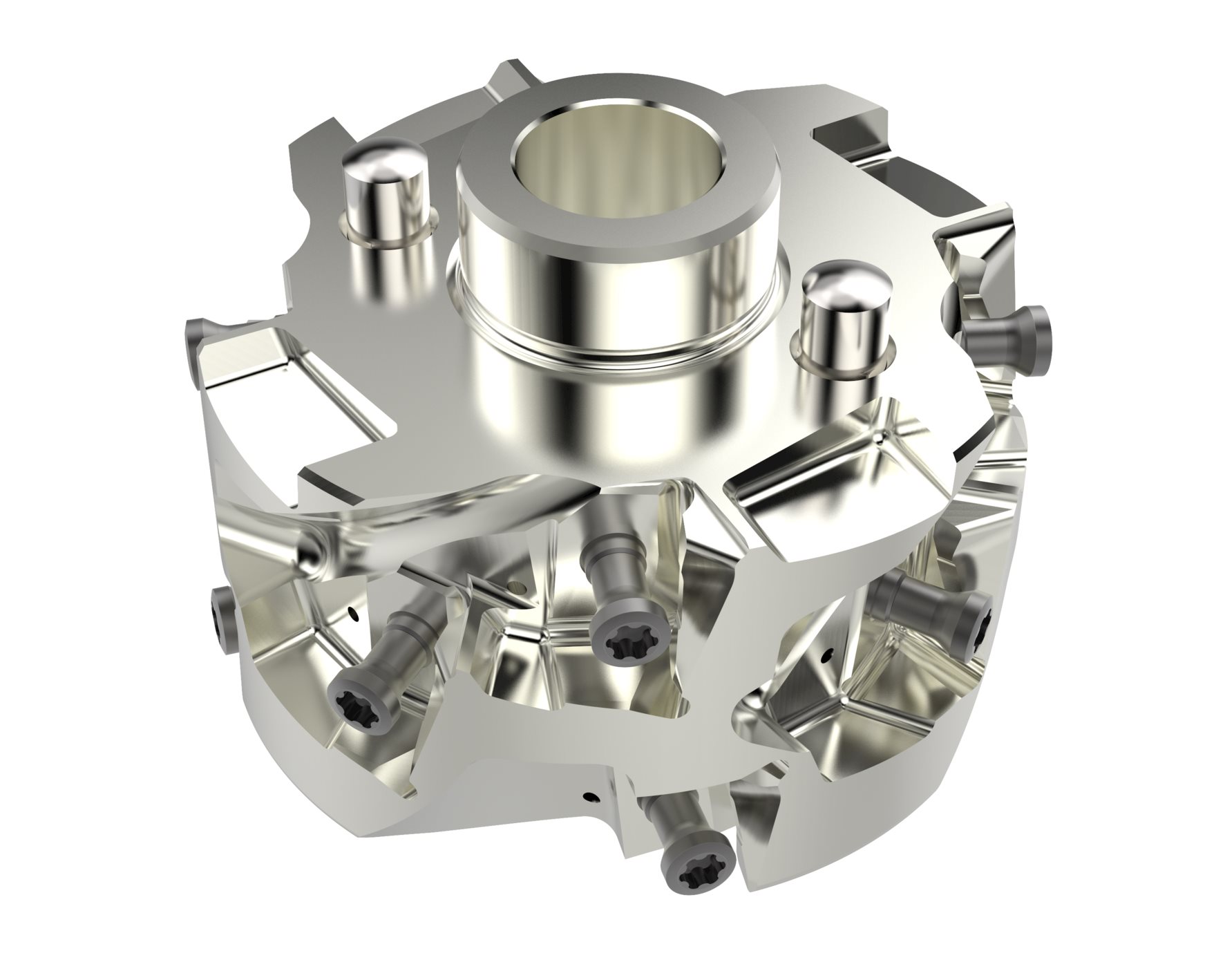

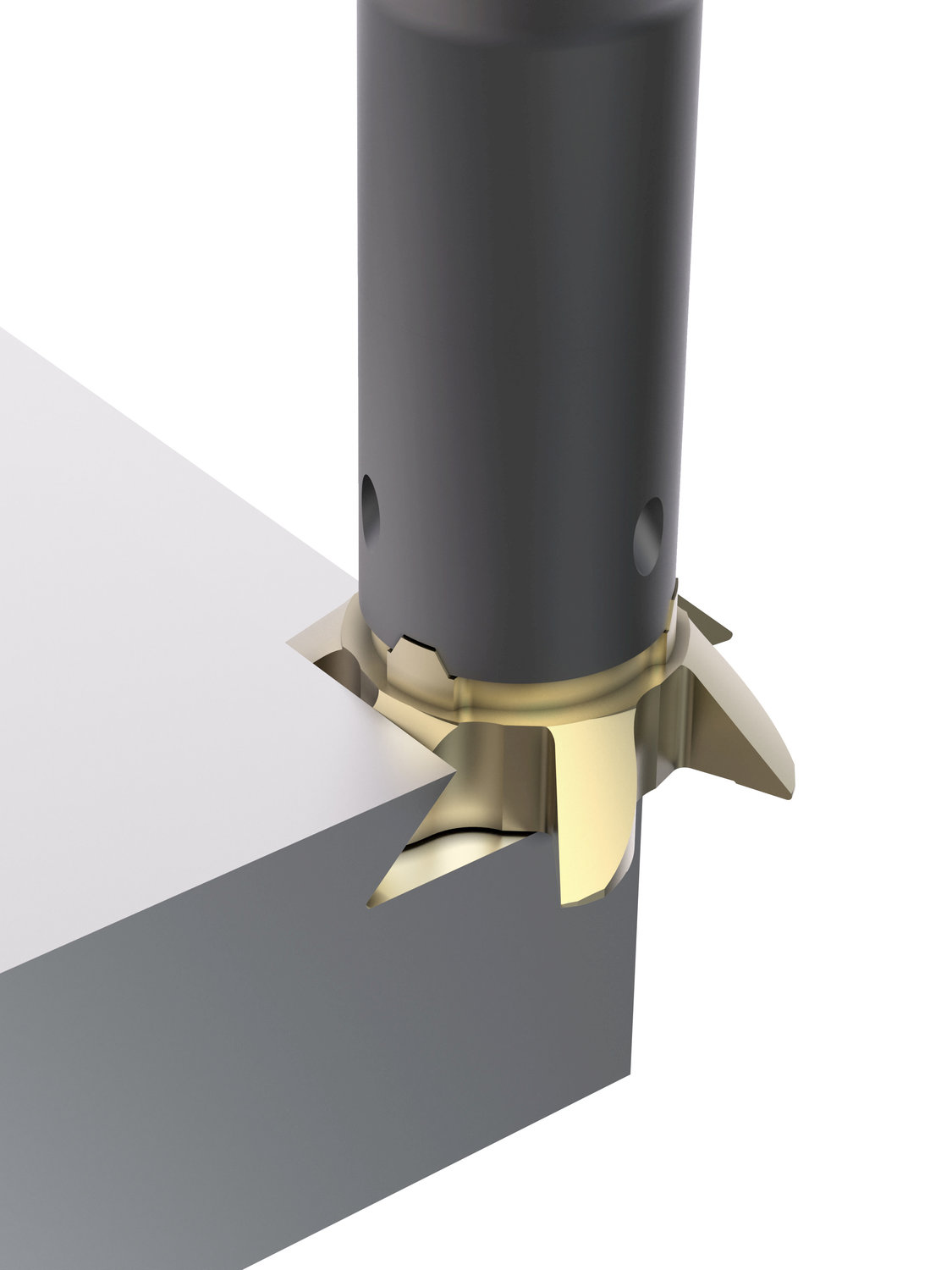

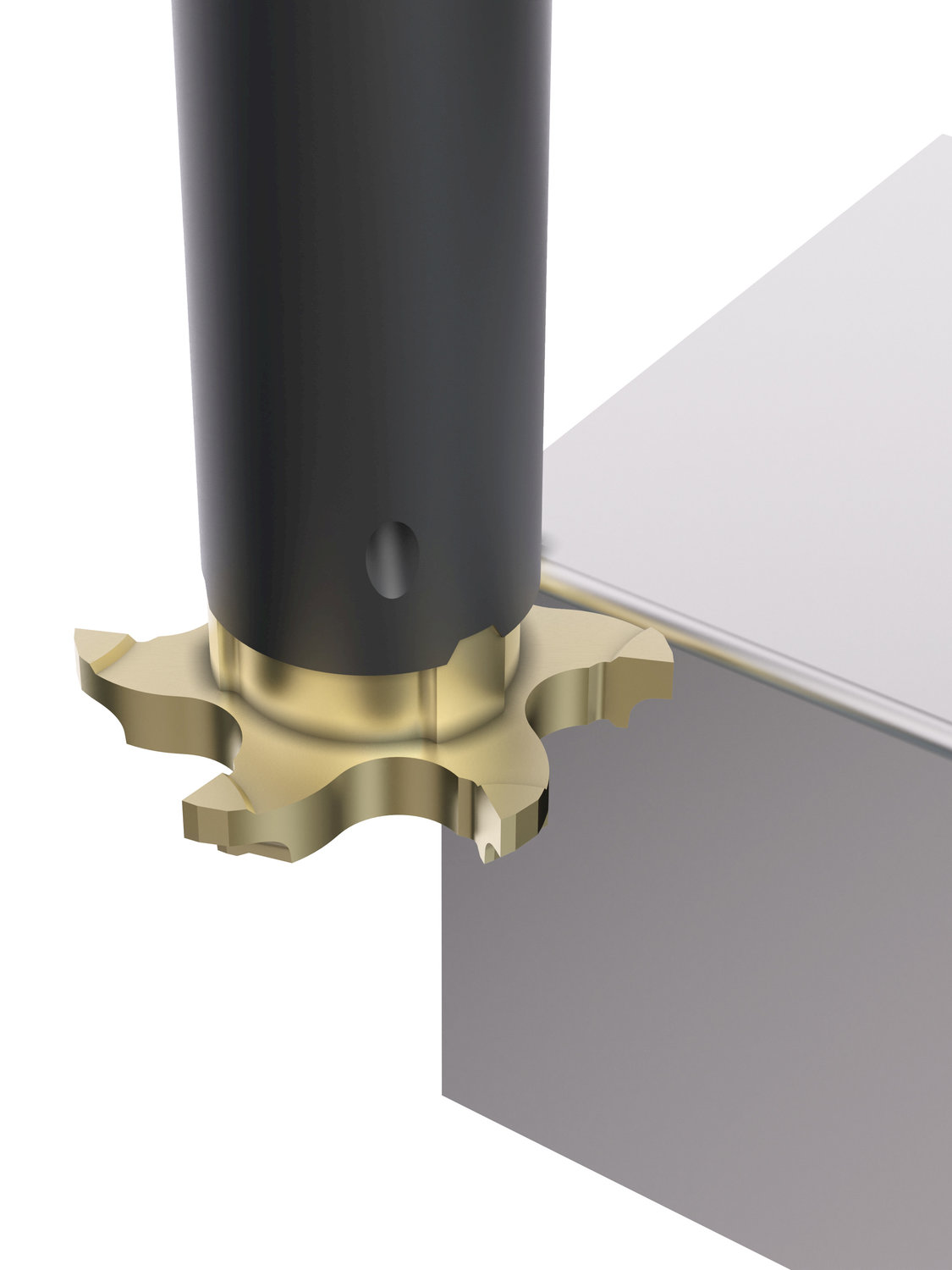

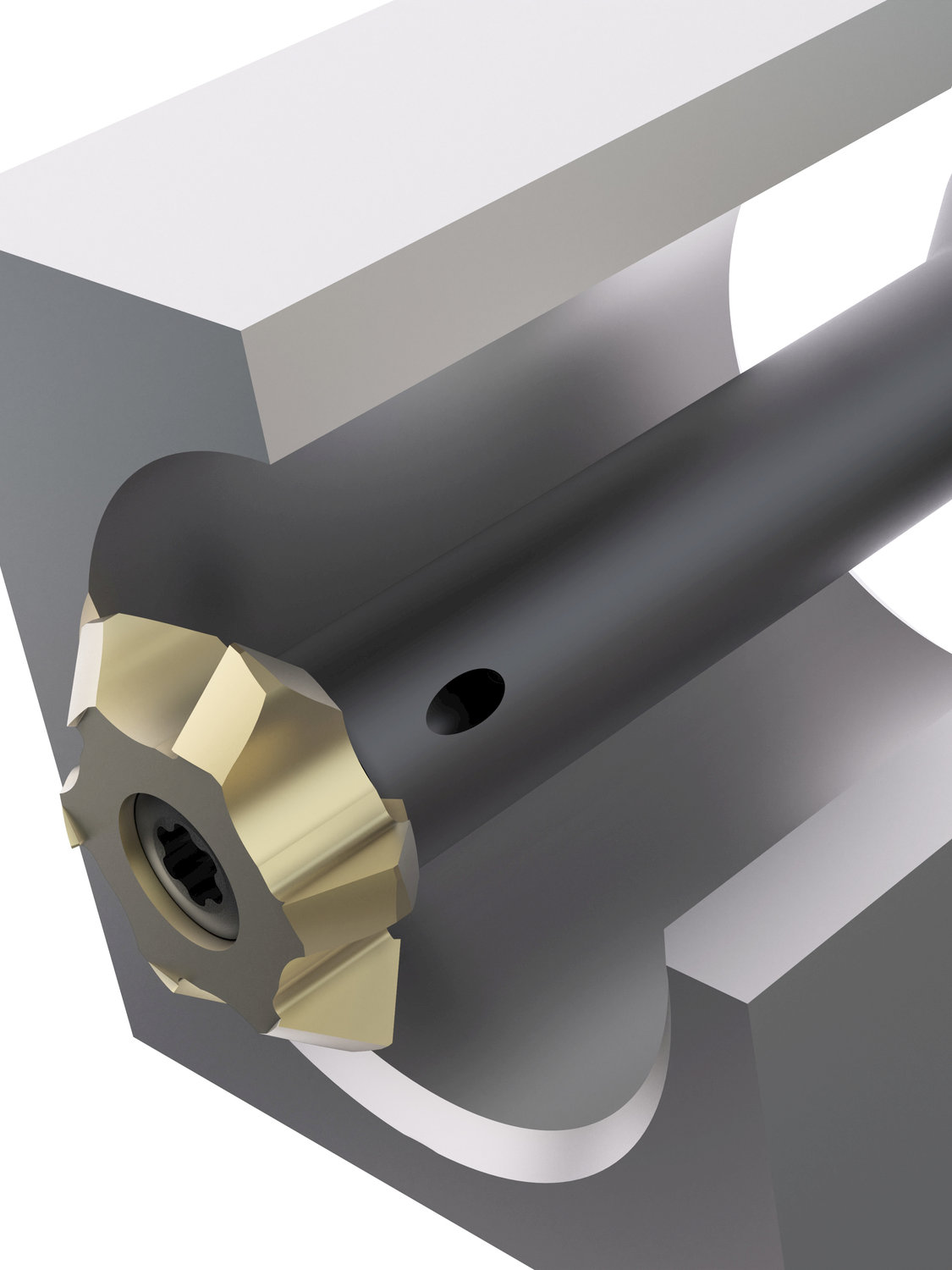

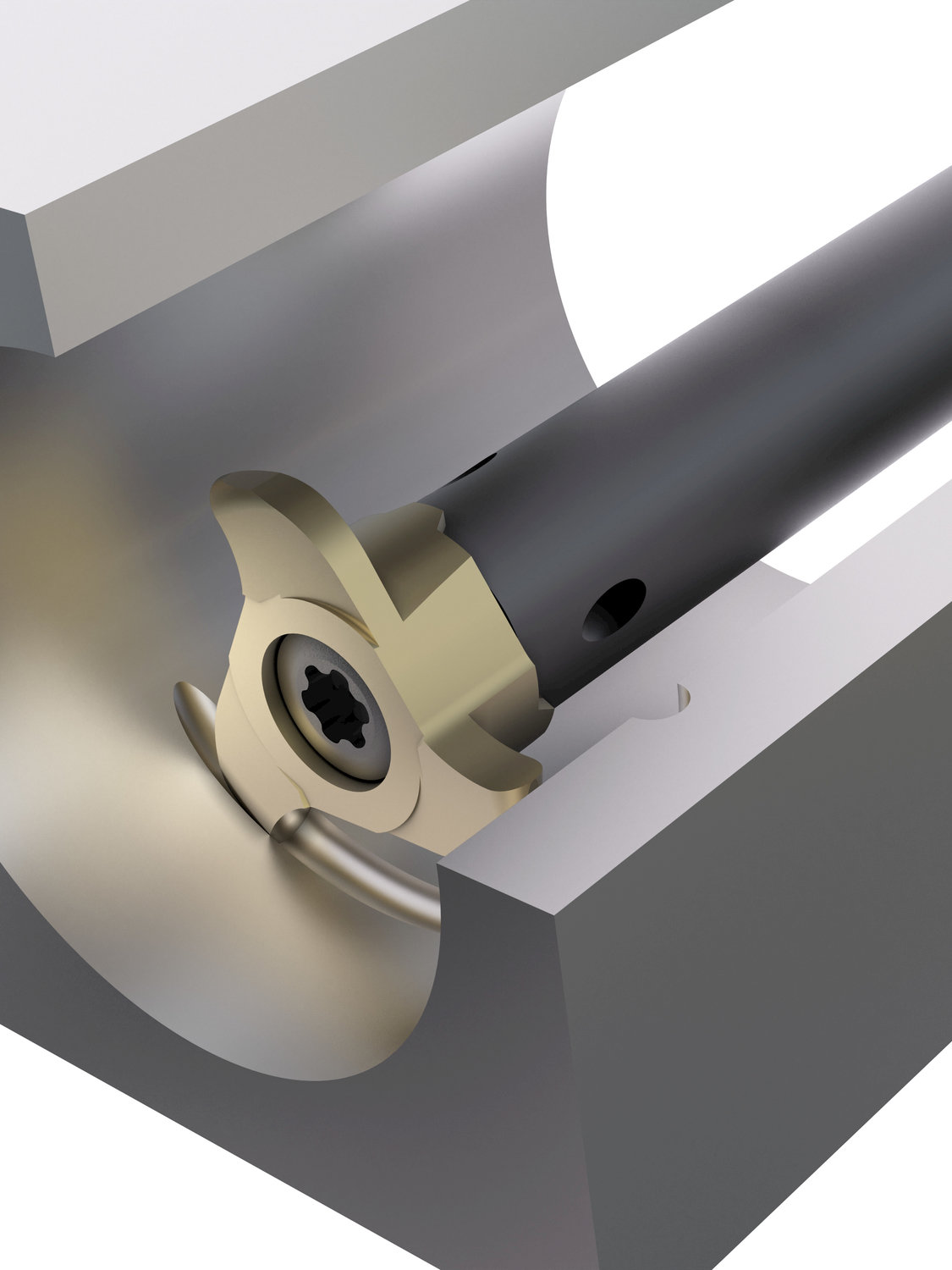

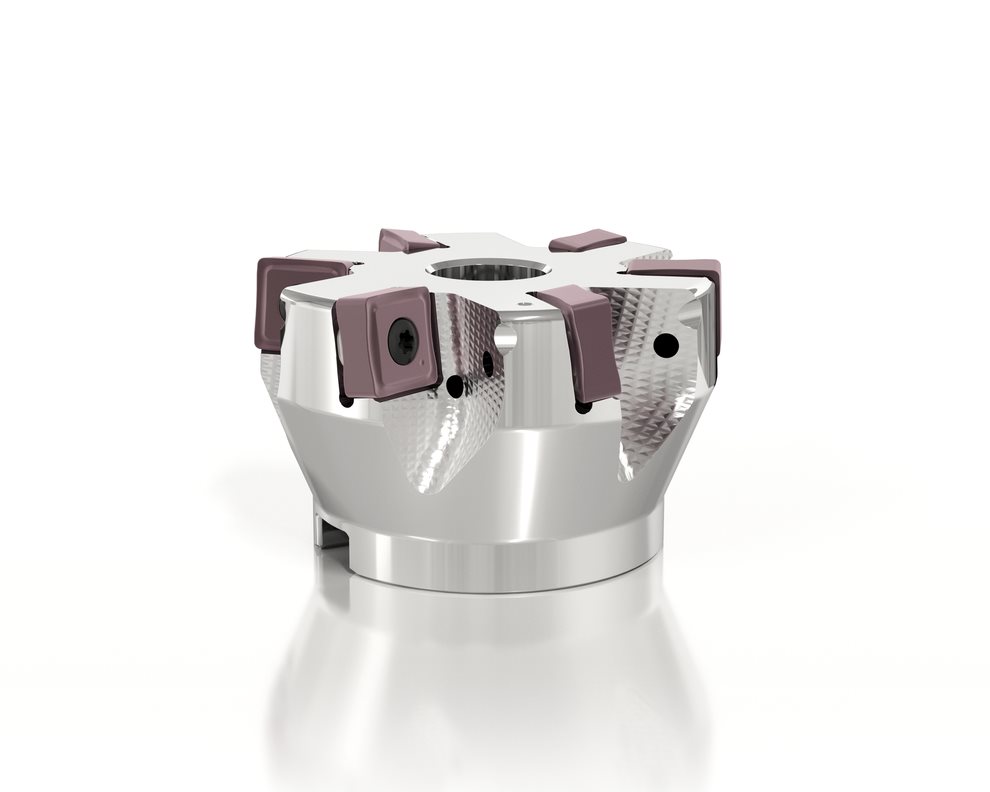

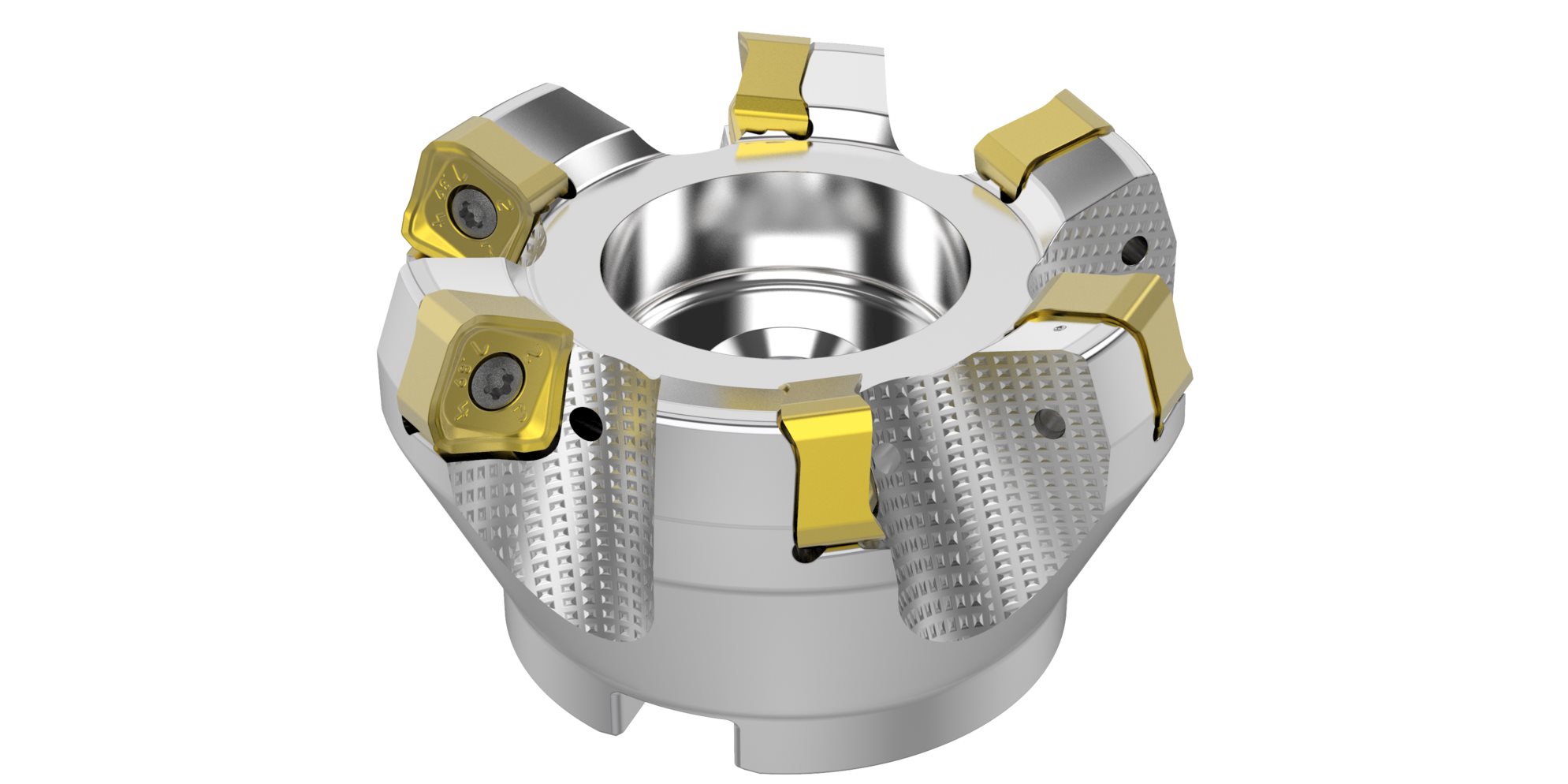

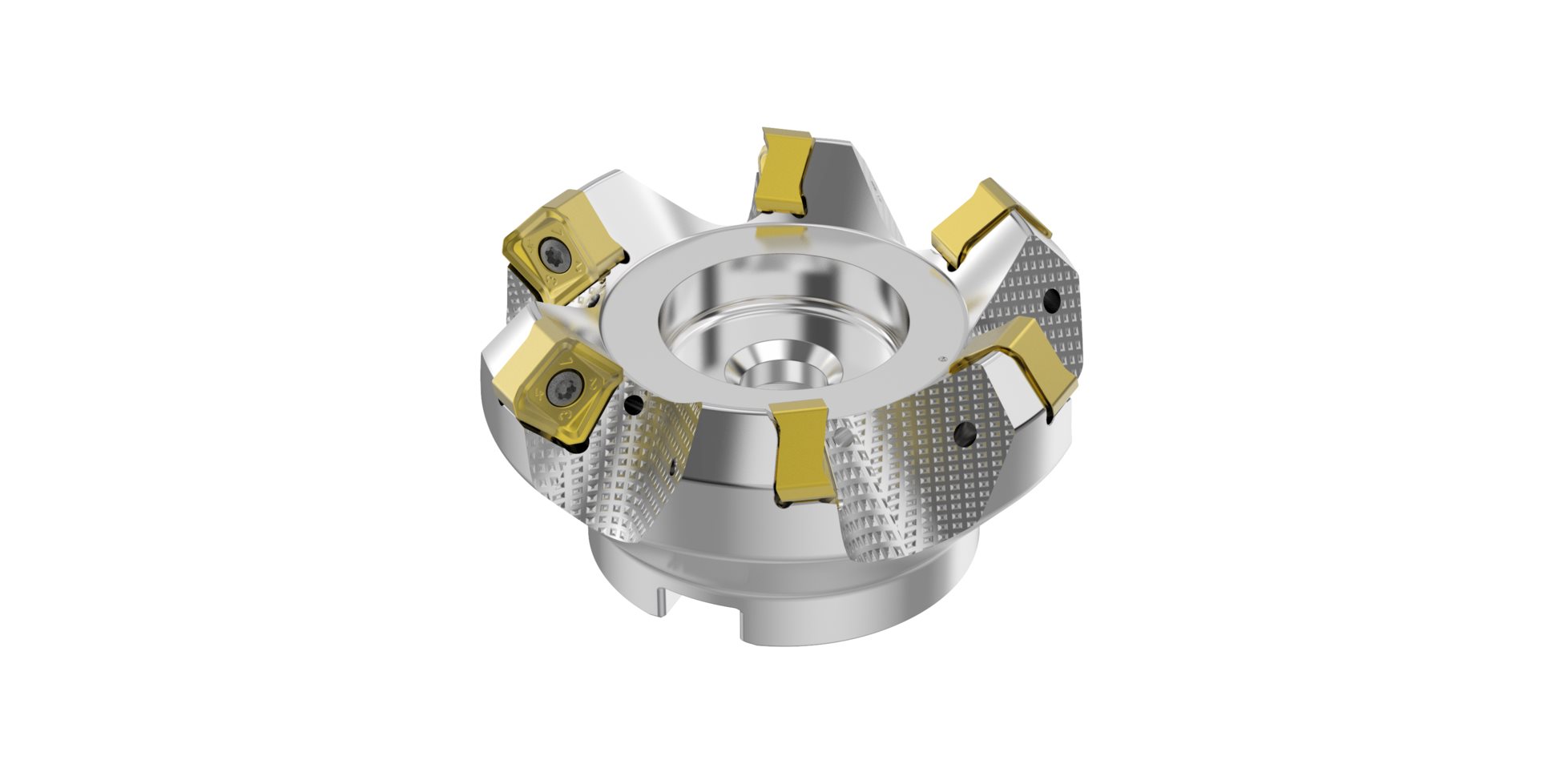

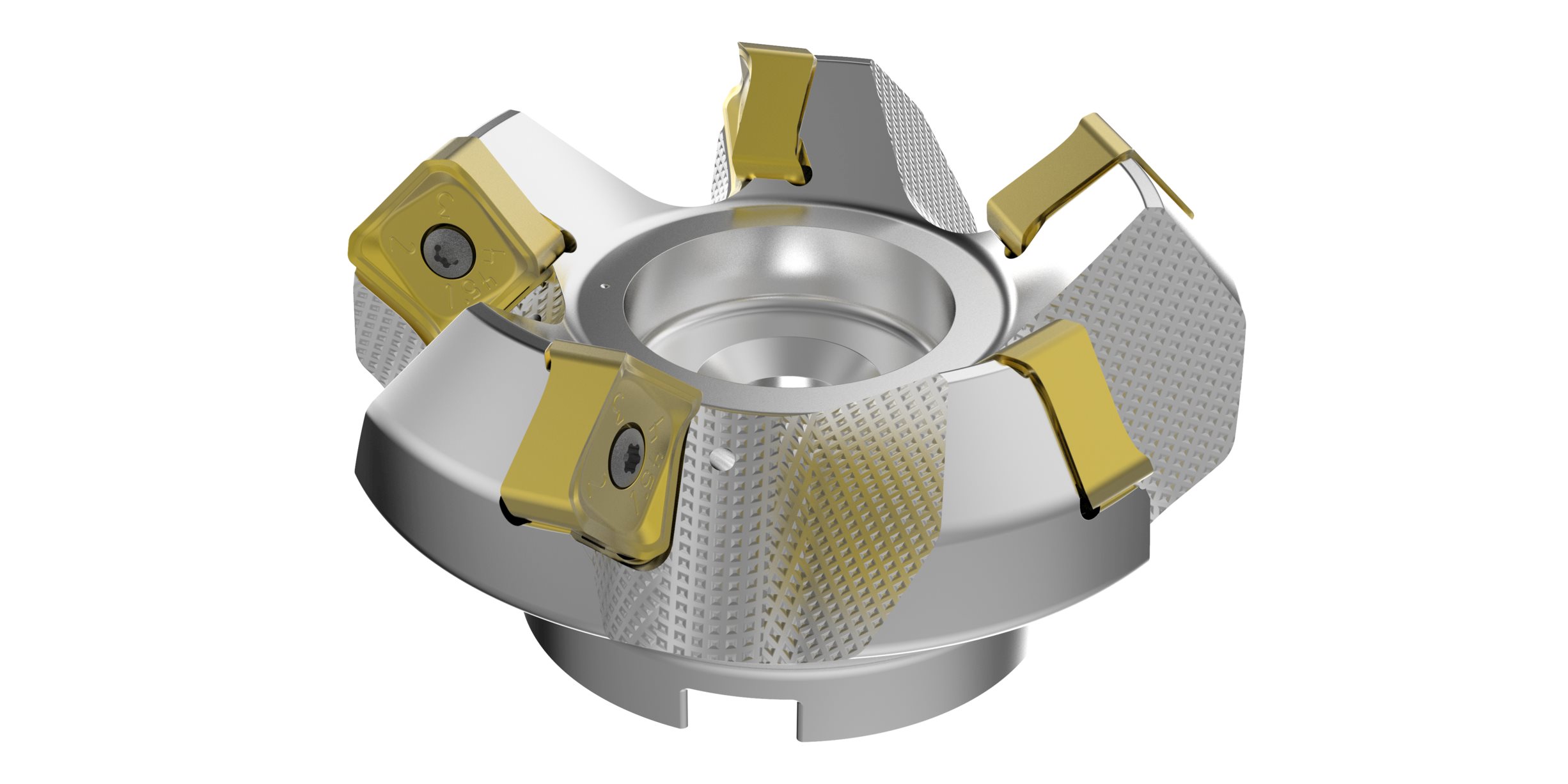

Get a higher depth of cut and more stable processes in any material with the new Turbo 16 Helical MillsDiscover the product range

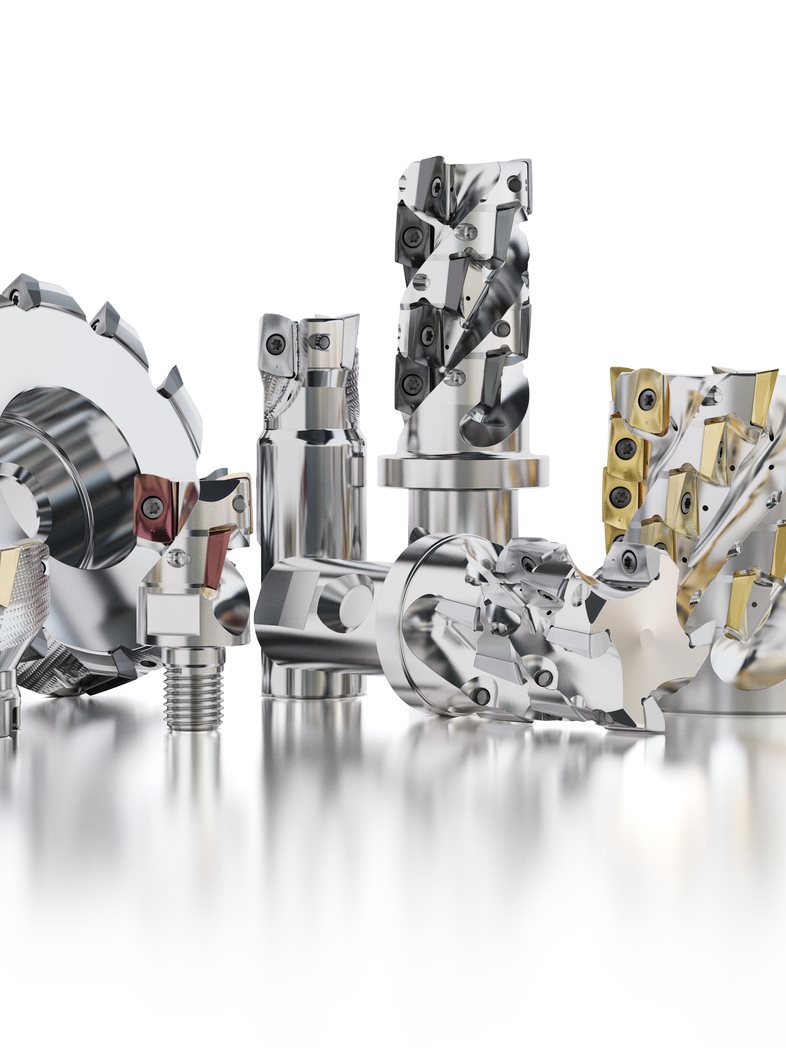

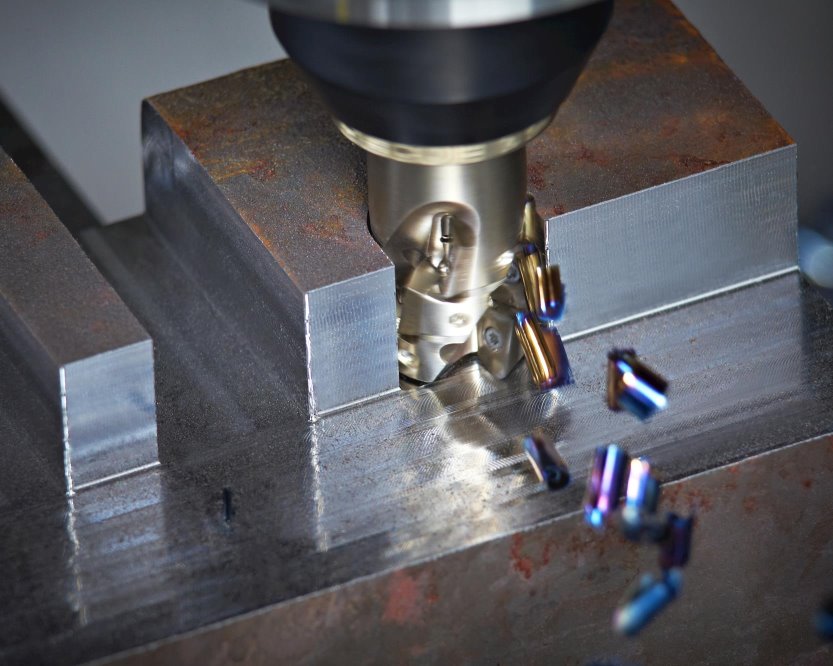

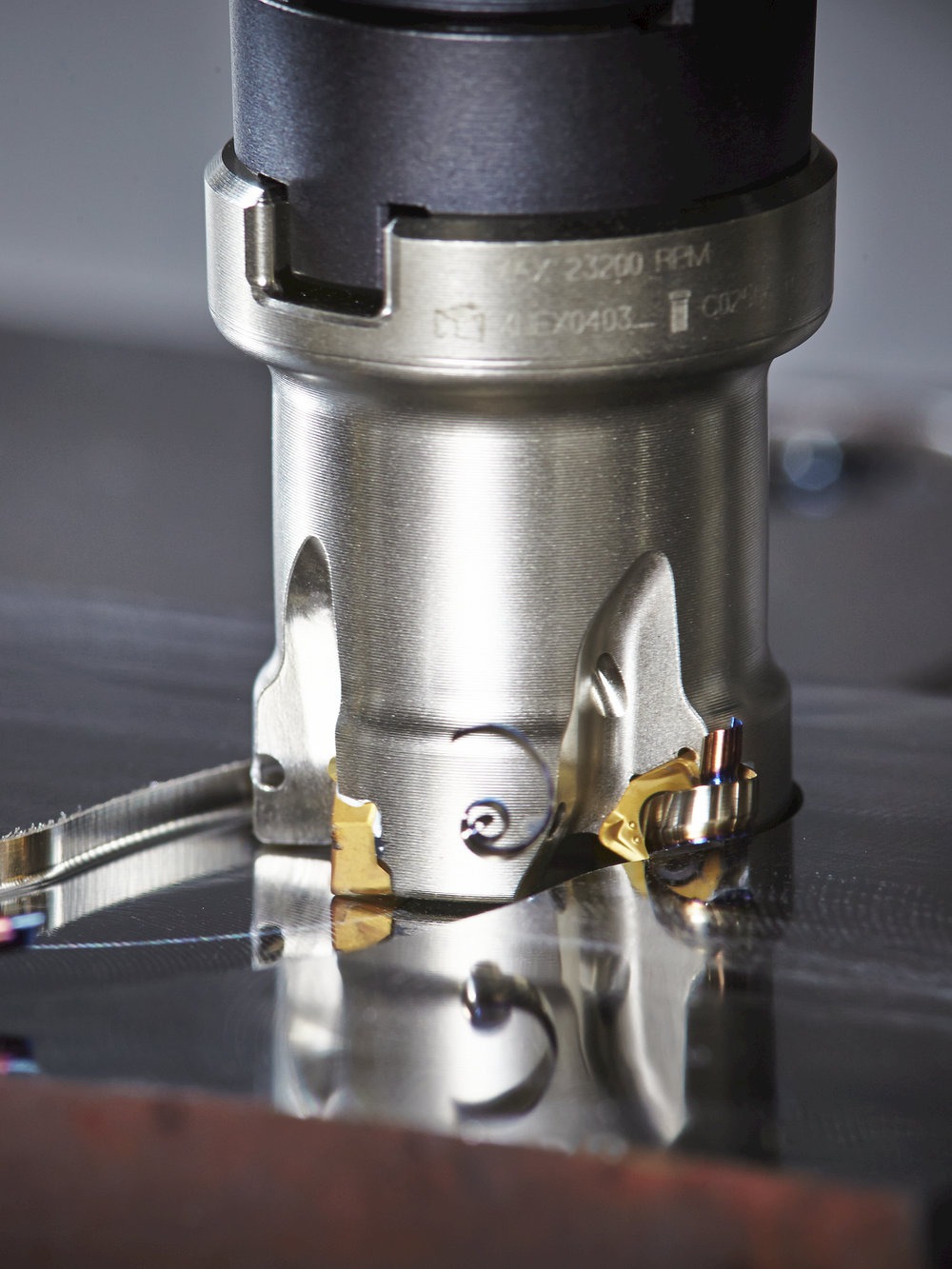

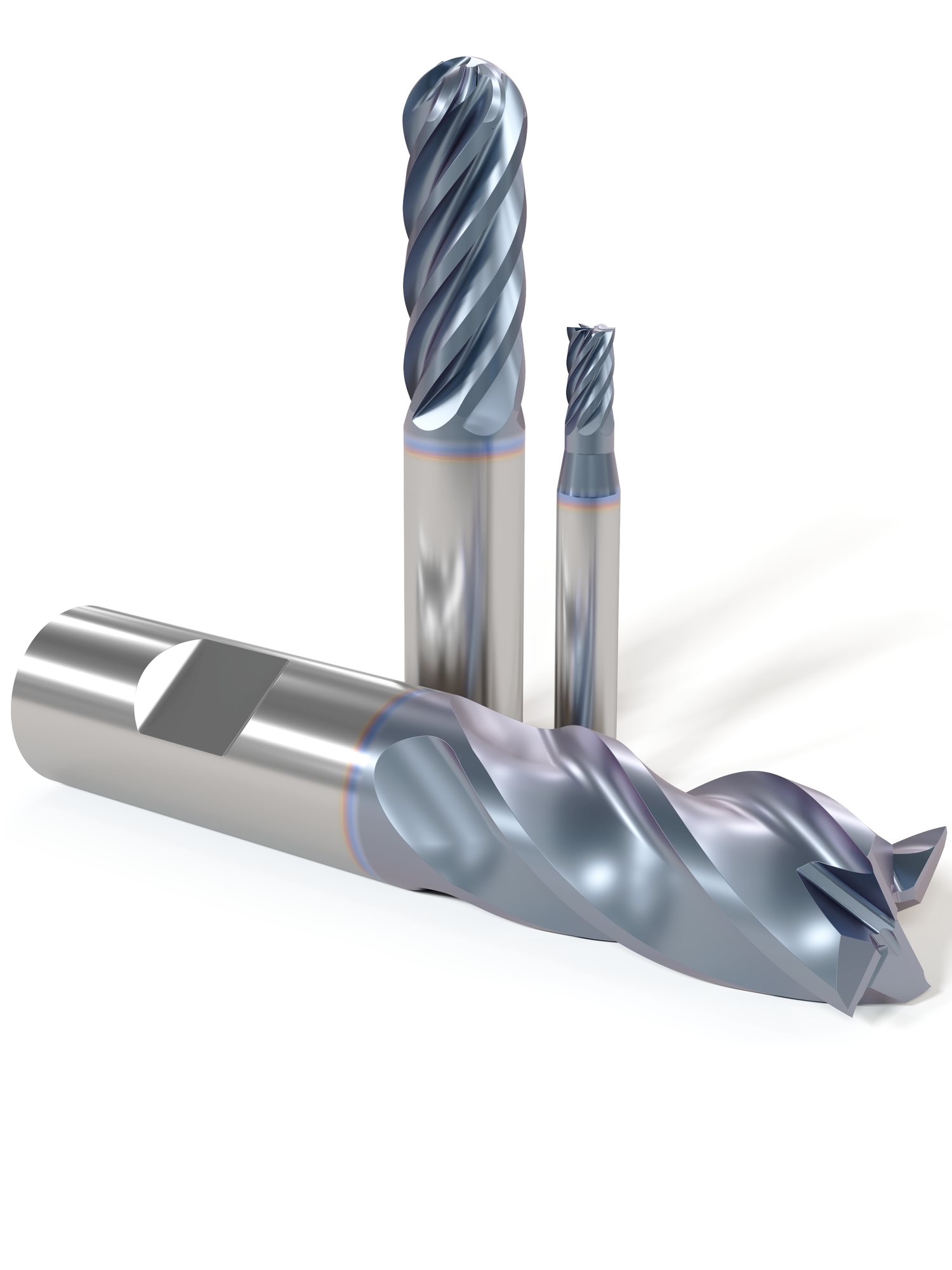

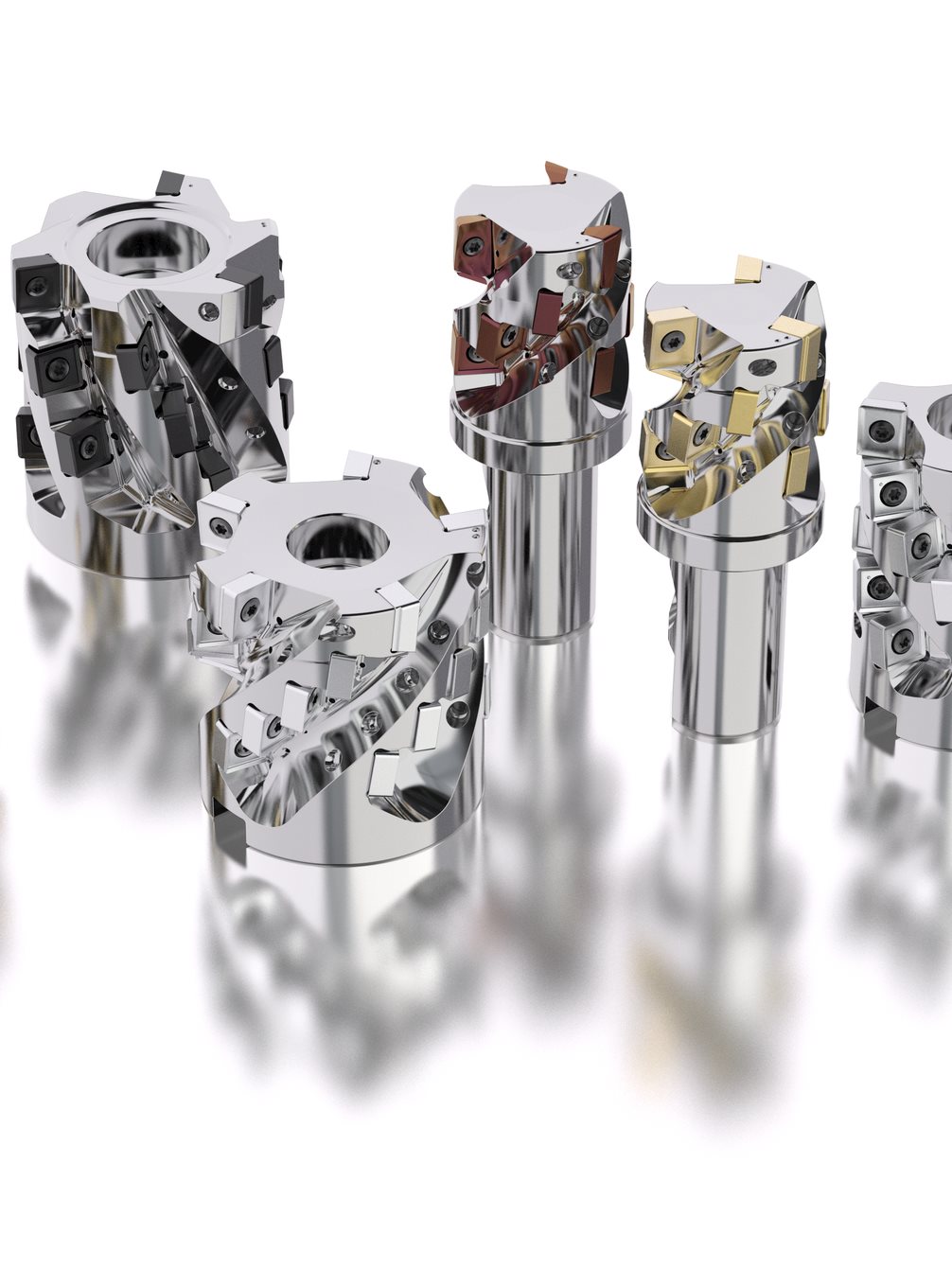

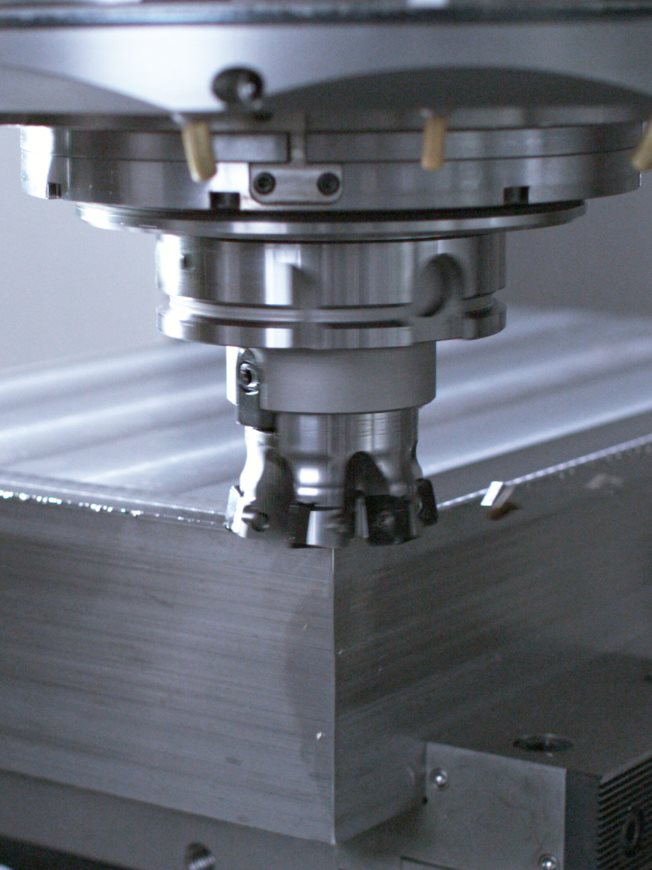

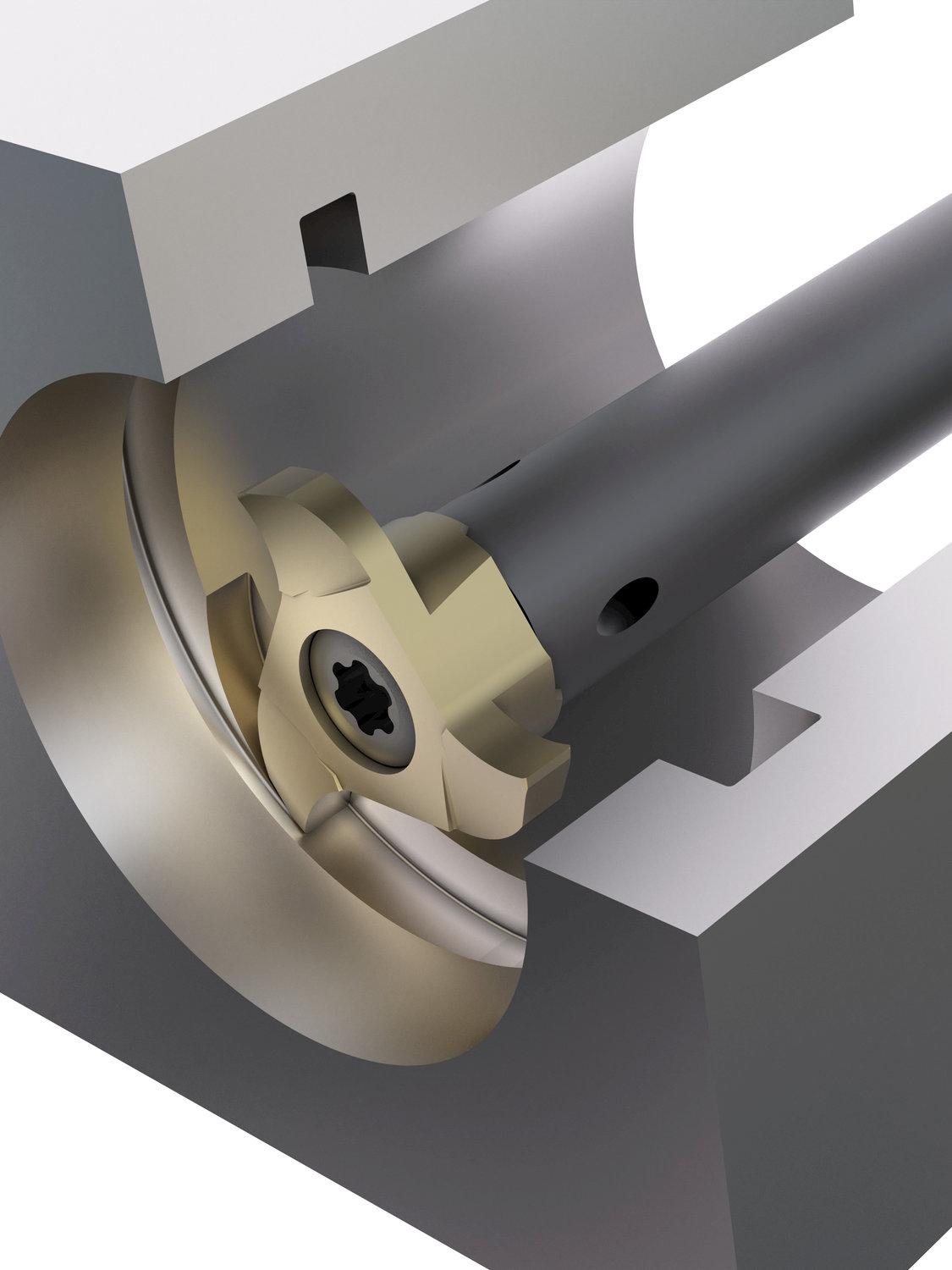

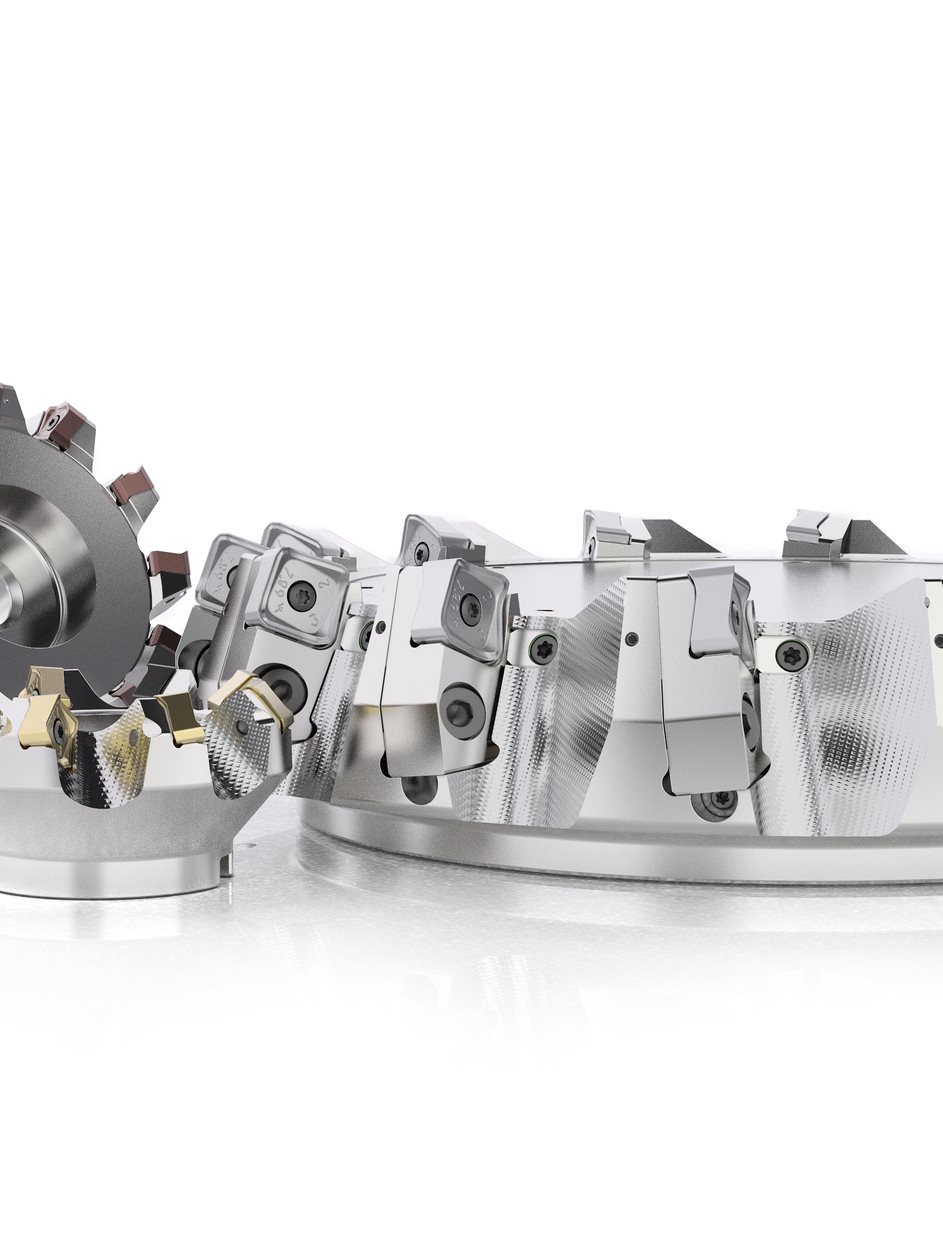

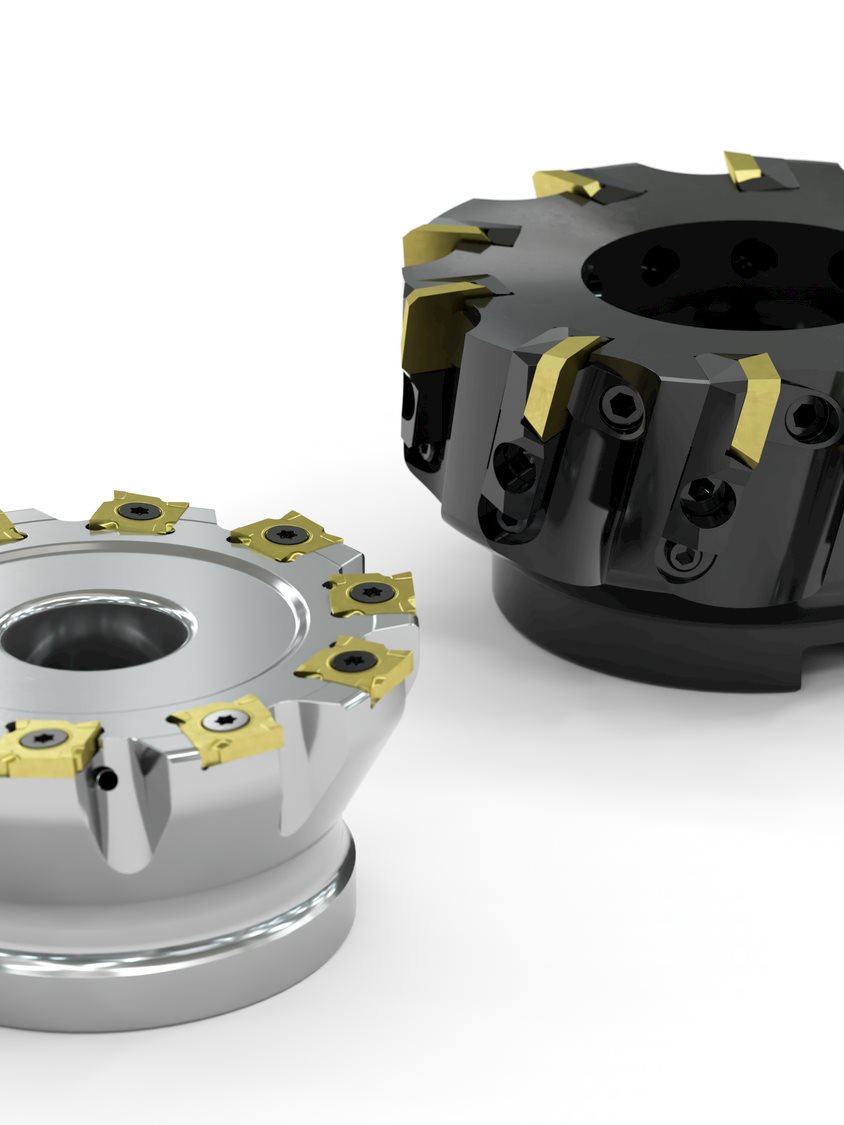

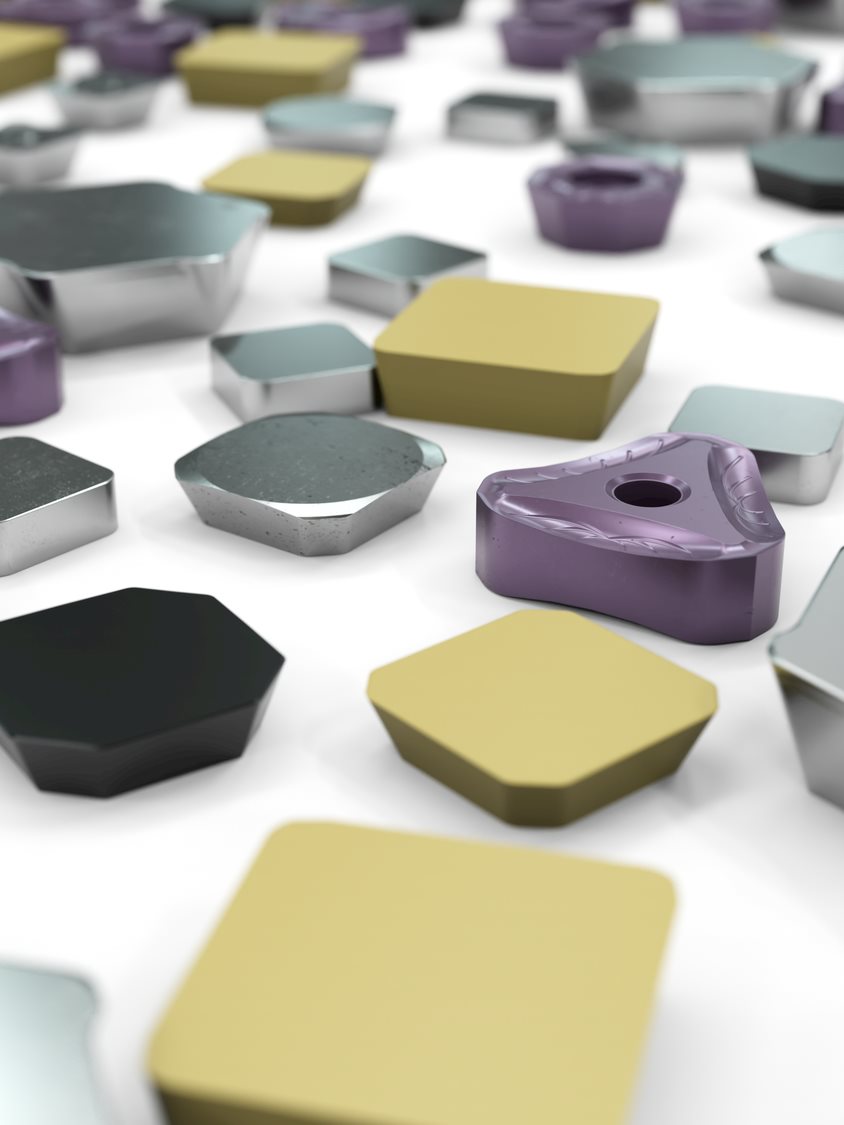

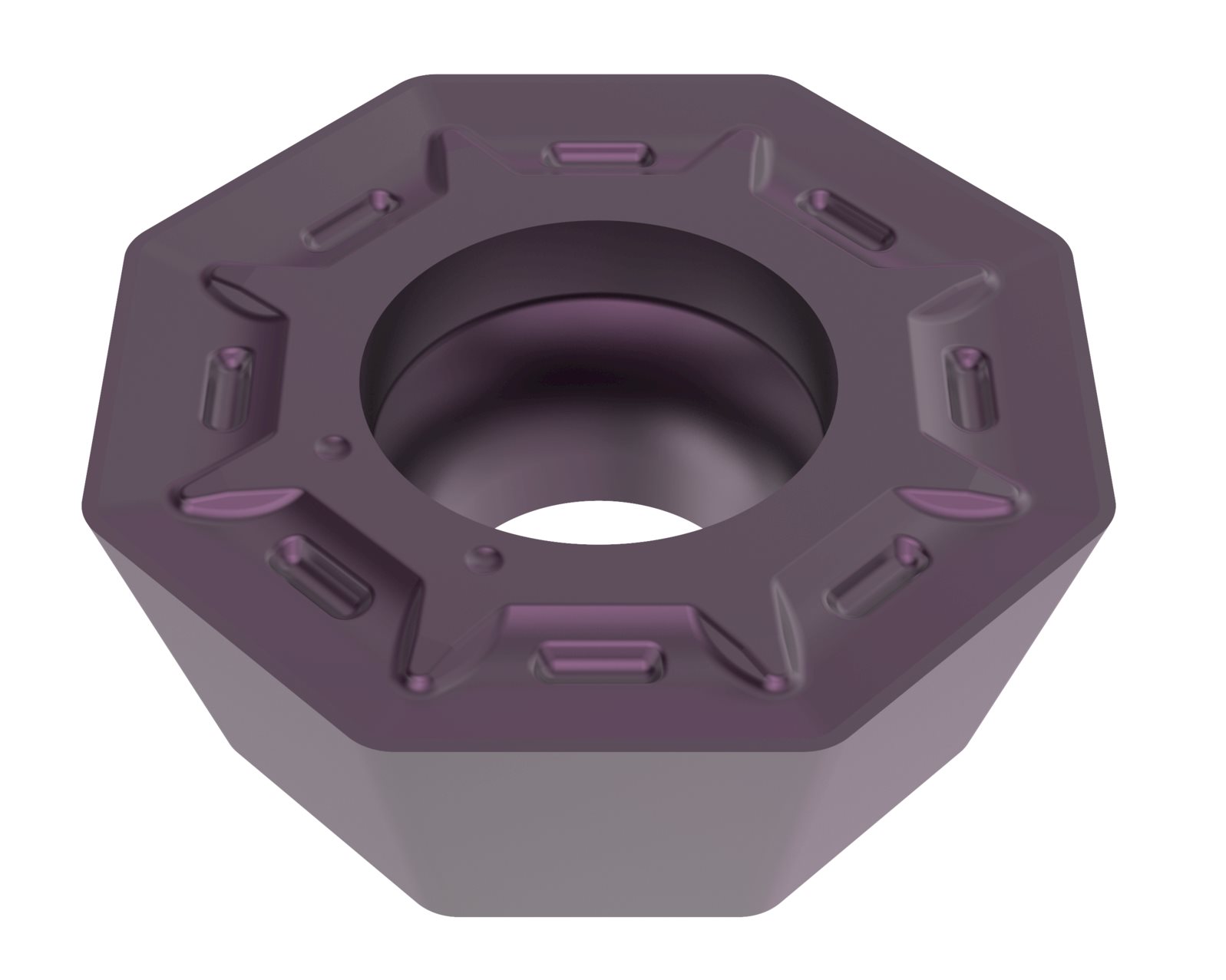

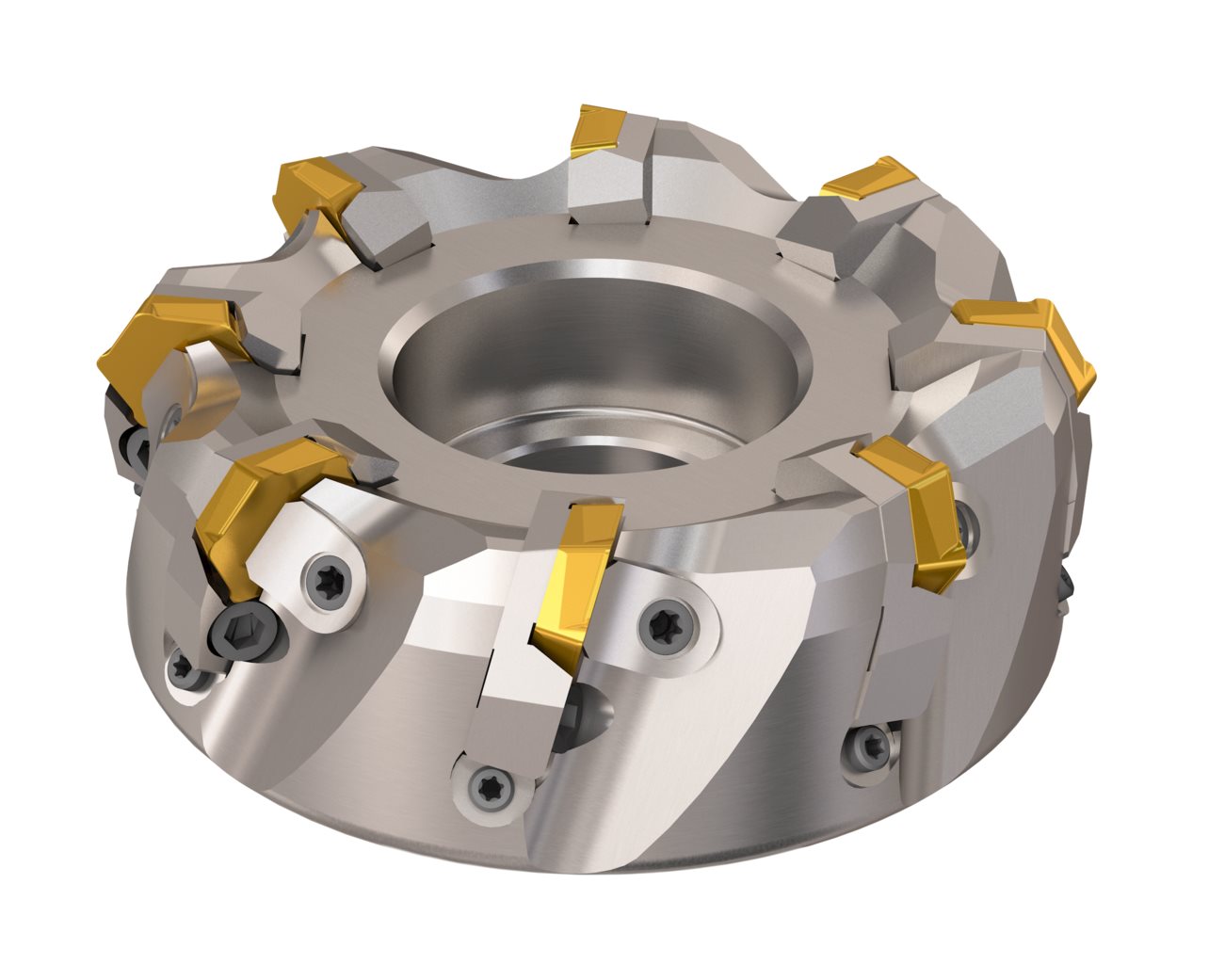

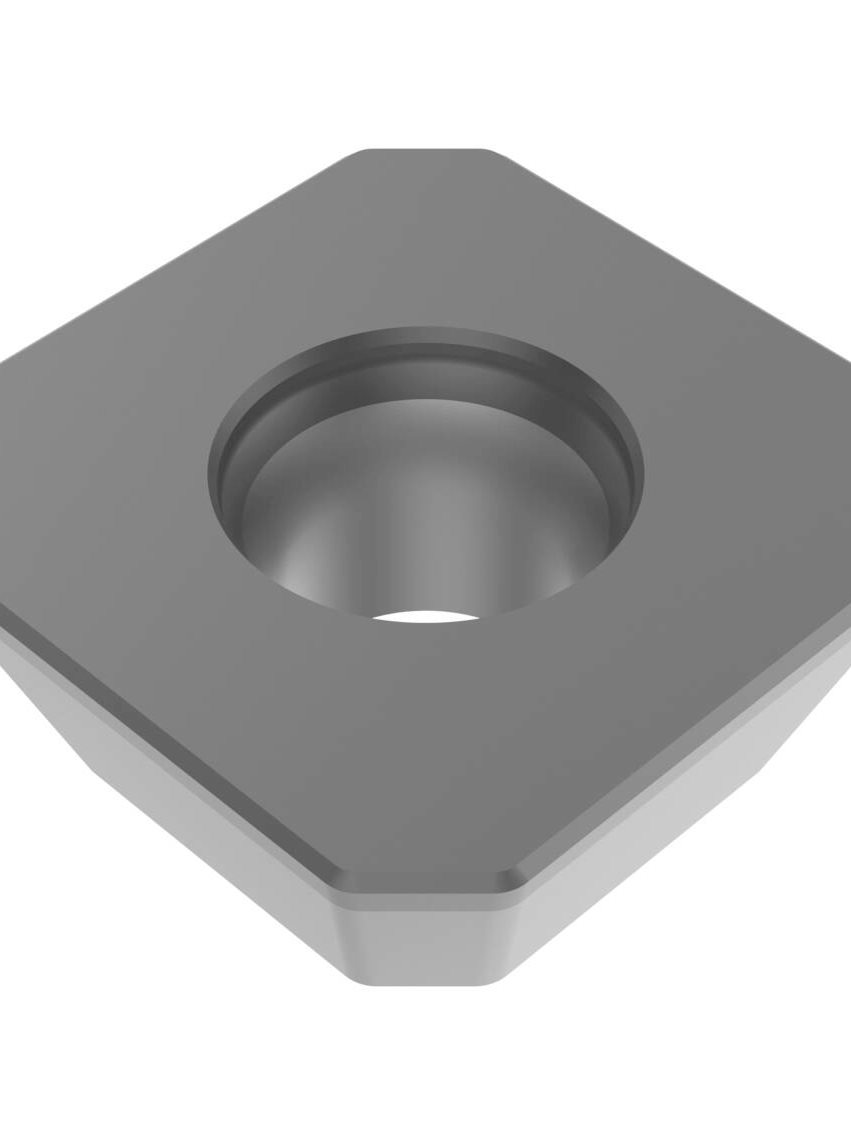

To satisfy customers and compete successfully, you need to meet speed up production and reduce per-part costs. Higher material removal rates cut cycle times and improve productivity in slot milling, side milling and many other processes. Versatile tooling enables you to cut more materials with fewer tools and inserts. Seco Helical Turbo 16 milling cutters offer the depths of cut and material versatility to tackle machining titanium, steels, cast iron, stainless steels and superalloys with high-performance results. This wide-ranging suitability means you can reduce tooling inventories and make superior parts with fewer tools and inserts.

Your challenge:

Meet industry and customer demands for increased production.

The Seco solution:

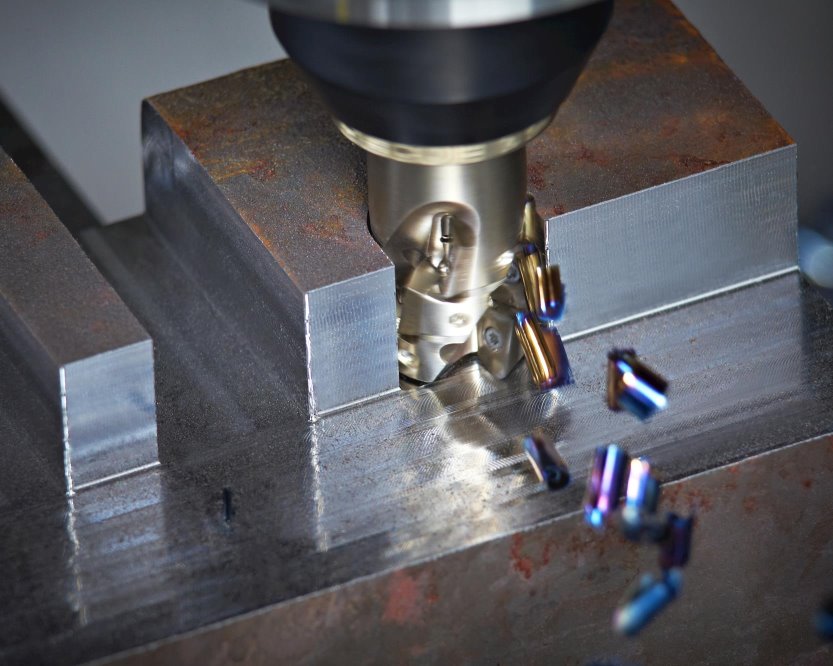

Achieve faster cycle times and the highest material removal rates in steels, stainless steels, superalloys and more with the outstanding depth of cut of Seco Helical Turbo 16 milling cutters

Your challenge:

Reduce high production costs that diminish your profitability.

The Seco solution:

Reach high material removal rates with fewer inserts while you cut the costs of parts and inserts with Seco Helical Turbo 16 milling cutters.

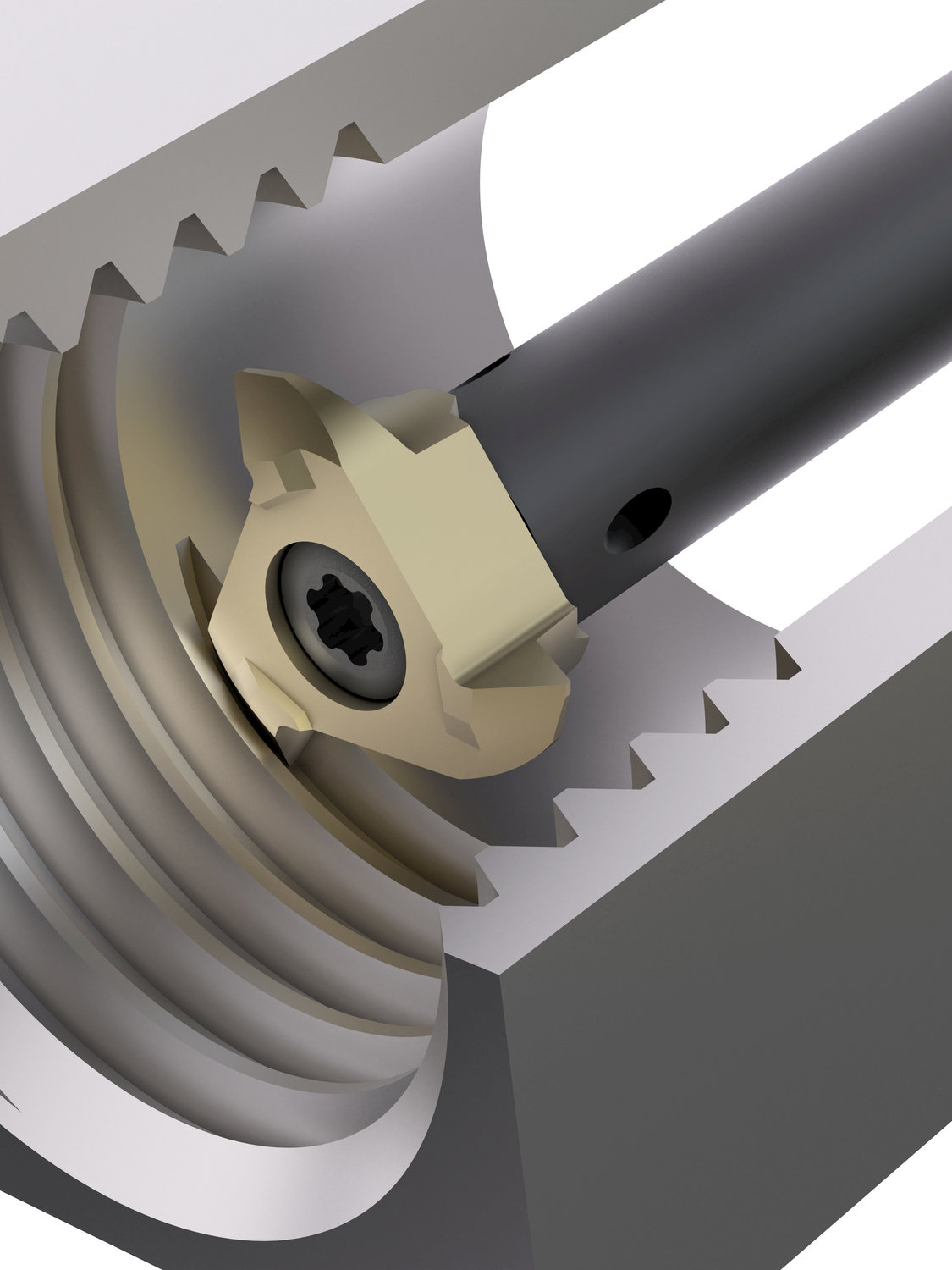

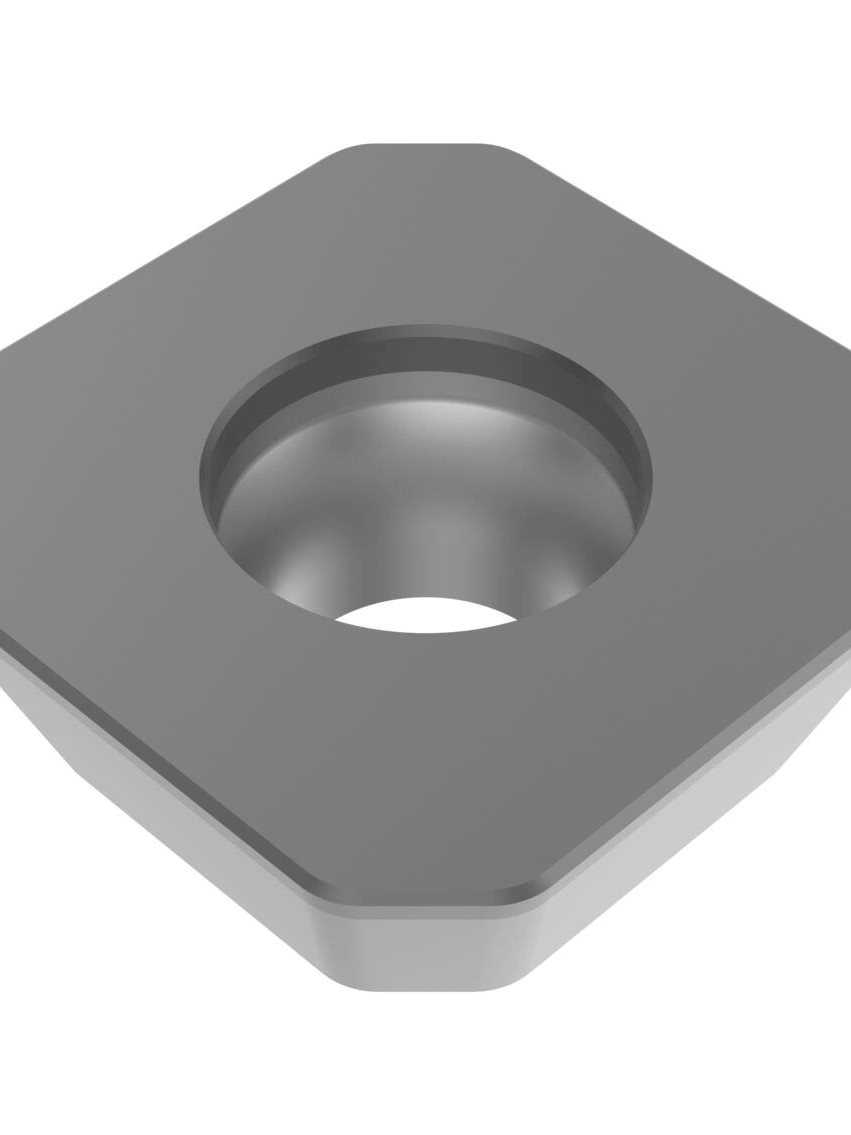

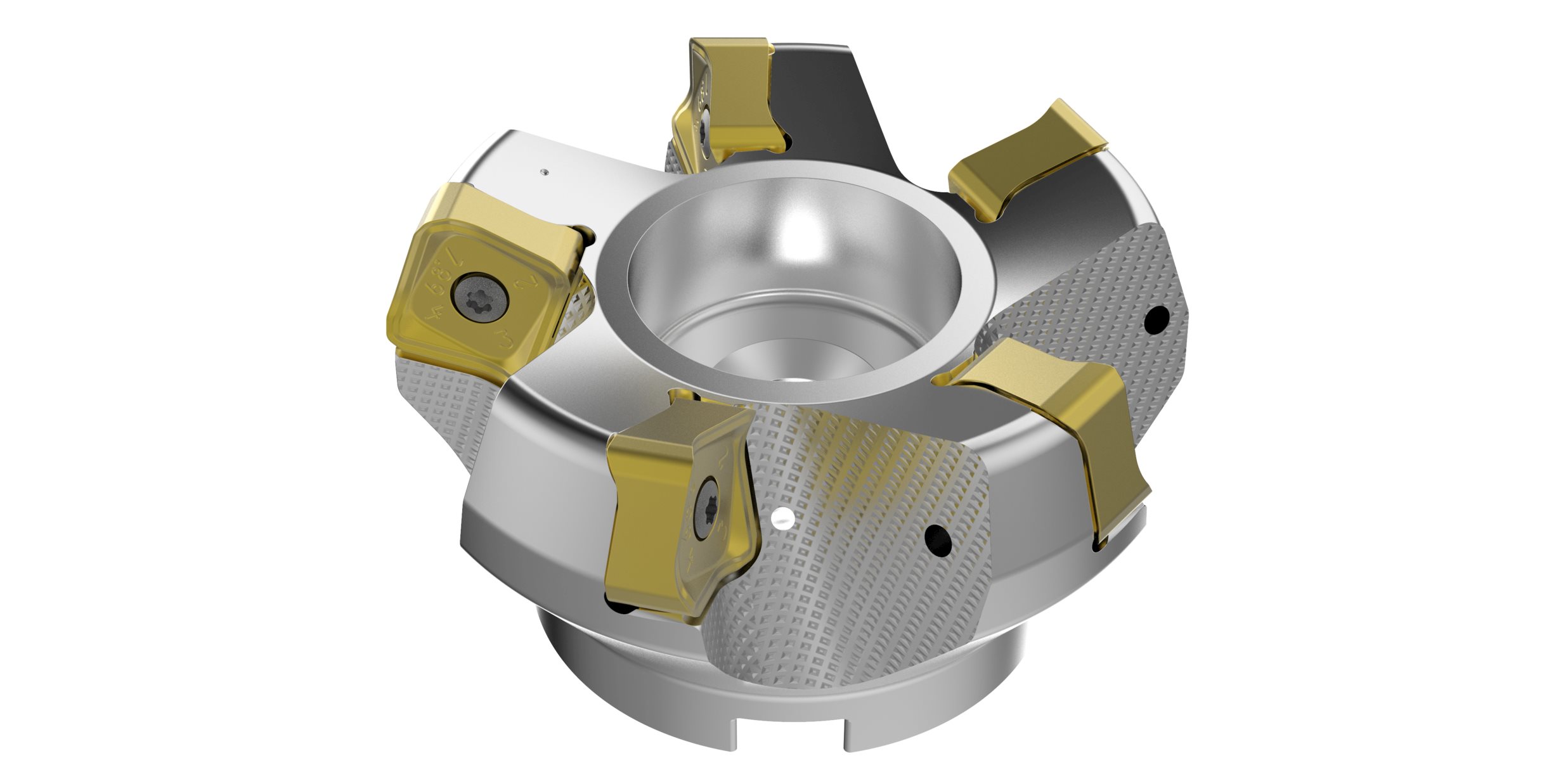

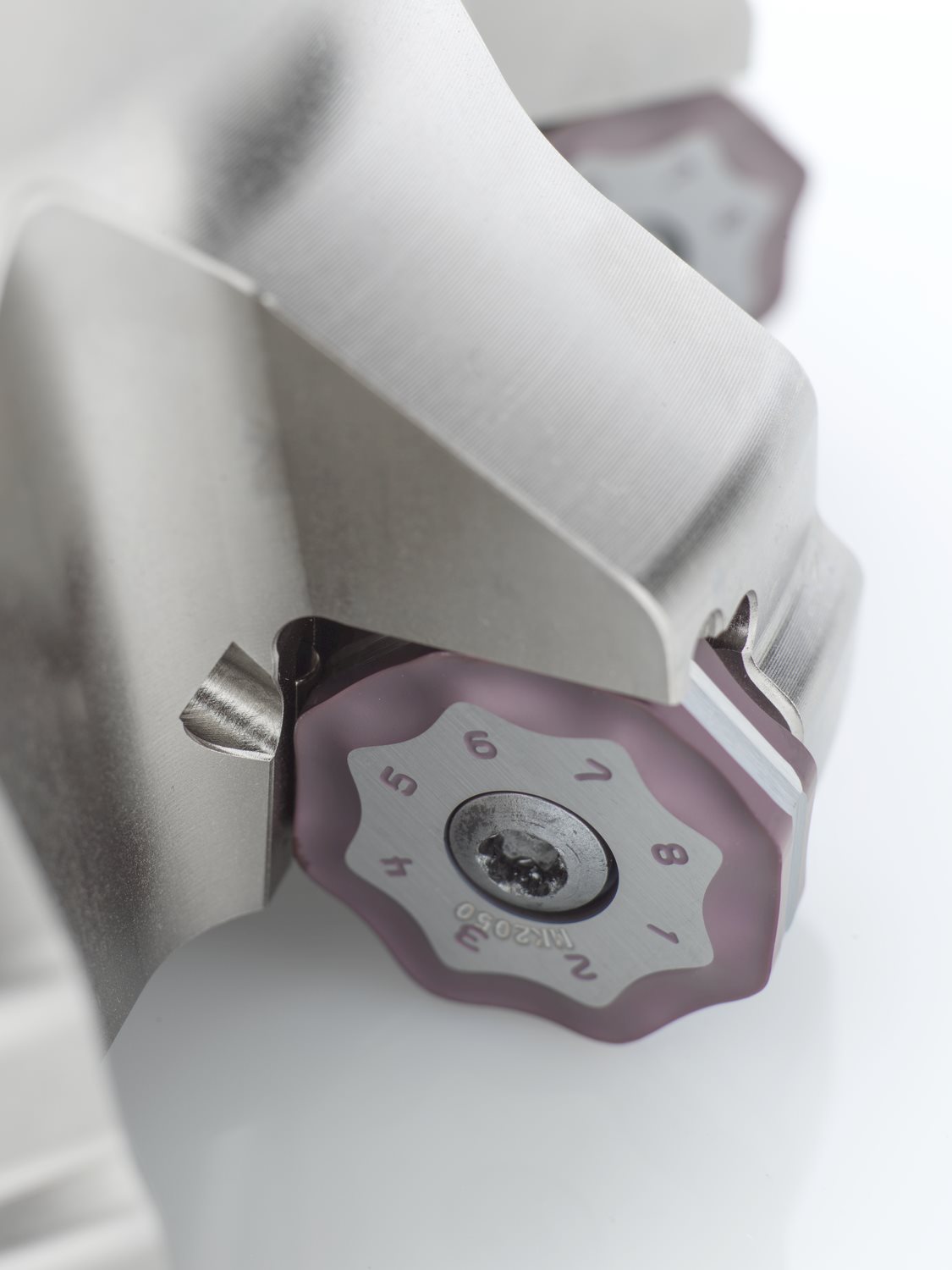

Unstable and poorly designed tools produce unsatisfactory part quality and short tool life that result in frequent, time-wasting tool changes and parts that fail quality-control testing. Additionally, helical tools make it easy to mix up front and helix inserts, especially for less-experienced operators during a skilled-labor shortage. The versatile, optimized tool geometry of Seco Helical Turbo 16 milling cutters smooths out machining performance and increases tool life in a long list of metals. The Seco Radius Error Preventing System (REPS) on these cutters makes insert mix-ups a thing of the past. Whether you're machining titanium and superalloys or slot milling and side milling less-challenging metals, these cutters give you the versatility you need for competitive success.

Your challenge:

Prevent quality-control and process-security problems that cause unplanned downtime and scrapped parts.

The Seco solution:

Optimized tool geometry achieves smooth machining and predictable, reliable tool life in a wide range of materials and cutting parameters with Seco Helical Turbo 16 milling cutters.

Your challenge:

Stop incorrect insert indexing of large-radius inserts at shift changes and with inexperienced operators.

The Seco solution:

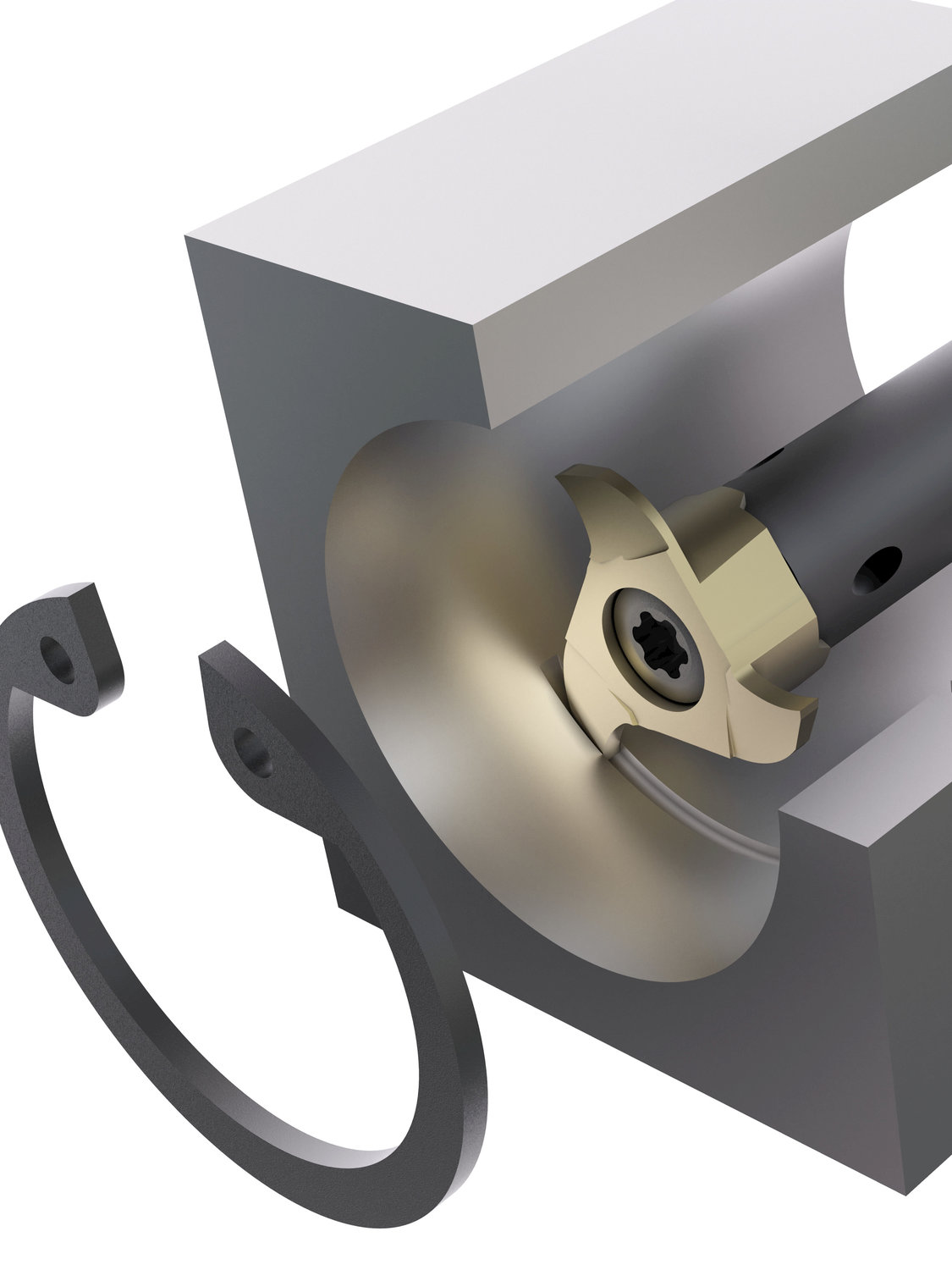

Easily eliminate mix-ups of front and helix inserts with the Radius Error Preventing System (REPS) on Seco Helical Turbo 16 milling cutters.

High-mix manufacturing forces your shop to take on a wider variety of machining metals and milling operations than you may be accustomed to using – and to broaden your production capabilities so you can compete. Instead of carrying an expensive, wasteful inventory of single-purpose tools, look to the versatility of Seco Helical Turbo 16 milling cutters to streamline your tooling and reduce its costs, at the same time that you produce high-quality parts with fewer tools and inserts. From side milling and slot milling to a wide range of other processes, these cutters enhance your versatility.

Your challenge:

Produce jobs that require more materials and milling operations than ever before.

The Seco solution:

Machine everything from cast iron to superalloys with versatile, flexible Seco Helical Turbo 16 milling cutters that handle a wide range of materials.

Your challenge:

Eliminate short-lived single-use tools that waste your tool inventory with unreliable performance.

The Seco solution:

Reduce tool inventory and boost cutting performance with the versatile Seco Helical Turbo 16 milling cutter series.

Discover the product range

Contact Us

Are you interested in Square Shoulder Milling ?

Discover our Turbo 16 Square Shoulder range

Related content

Suggest

Helical Turbo - Insert Size 16

Helical Turbo 16 Radii Indexing and Compatibility

BROCHURE - Turbo 16 MILLING CUTTERS FAMILY

FACTSHEET - Helical Turbo 16 MILLING CUTTERS

Helical Turbo 16 Prony Screw Setup

Helical Turbo 16 Replaceable end Assembly

Helical Mills

Milling Cutters

ACS540 / ACS540R End Mills

Niagara Cutter® HTA Coating Product Expansion

Semi-Standard Helical Cutter Program Introduction

Product Presentation - Turbo 16 Family

Seco Helical SN8-13

Helical LN4 - Spare parts

Helical LN4 - Cutters and Inserts

Helical LN4 - 2/4 Cutting Edges Single/Double-sided Inserts

Seco High Feed SP

Seco Helical SN8-13 Milling System Delivers Performance at a Lower Cost Per Edge

Helical Interpolate Like A Pro

Seco milling cutters reduce tooling inventory costs with versatility

Helical Heavy Duty

Helical SC12 - LH K=Z/2 - Spare parts

Helical SC12 - LH K=Z/2 - Cutters and Inserts

Helical SC12 - Left Helix K=Z/2

Helical SN8 - Left Helix K=Z/2

Helical SN8 - Left Helix K=Z

Helical SN8 - Right Helix Heavy Duty

Helical Turbo 18 - Spare parts

Helical Turbo 16 - Spare parts

Helical Turbo 12 - Spare parts

Helical SN8 - RH - Cutters and Inserts

Helical SN8 - RH - Spare parts

Helical SC12 - 2/4 cutting edges single-sided inserts

Helical Mills for Finishing

Helical T4 - 4 cutting edges tangential inserts

Helical SN8 - 2/8 cutting edges single/double-sided inserts

Helical Turbo - 2 cutting edges single-sided inserts

Helical SC12 - Left Helix K=Z

Helical T4-12 - Spare parts

Helical T4-12 - Cutters and Inserts

Helical Turbo 18 - Cutters and Inserts

Helical Turbo 16 - Cutters & inserts

Helical Turbo 12 - Cutters and Inserts

Helical Turbo - Insert Size 10

Helical Turbo - Insert Size 06

Helical T4 - Insert Size 12

Helical T4 - Insert Size 08

Helical Turbo - Insert Size 18

Helical Turbo - Insert Size 12

Helical SN8 - Right Helix General Machining

Video: Semi-Standard Helical Cutter Program Introduction

Helical Mills for SCET/ACET Inserts

High Feed Mills

Double Turbo 11 - Insert Size 11

Octomill .43 - OO..0605

High Feed SP - Insert size 14

High Feed SP - 4 cutting edges single-sided inserts

Mini Disc - 335.14 - Shanks

Mini Disc - 335.14 – Thread Milling

Mini Disc - 335.14 - Dove Tail

Mini Disc - 335.14 - Corner rounding

Mini Disc - 335.14 - Top and Bottom Chamfering

Mini Disc - 335.14 - Full radius profile

Mini Disc - 335.14 - For circlips groove

Mini Disc - 335.14 - General Grooving

335.14 - Replaceable Head Disc Cutters DC 6.7 - 50 mm (0.264 to 1.97”)

A Guide to Milling Grades, Materials and Solutions

PCD and CBN square milling cutter .53

QuattroMill - Insert size 12

R220.60 - SP..19/28 - 4 cutting edges - KAPR 60°

Near 90 .88 SN.U12/16 - KAPR 88° - 8 cutting edges

Double Quattromill - SN.X14/22 - 8 cutting edges - KAPR 48° / 71°

Double Octomill - ON.U05/09 - 16 cutting edges - KAPR 40°

Quattromill .53 - SE.X1505

Quattromill .53 - SE.X1204

Quattromill .53 - SE.X09T3

Quattromill - SE.X 09/12/15 - 4 cutting edges - KAPR 45°

Near 90 .88 - SN.U1606

Near 90 .88 - SN.U1204

.38 SNFX1204 - KAPR 88° / 26° - 8 cutting edges

.30 SE..1203 - Adjustable Pocket - KAPR 88° - 4 cutting edges

SPK. / SPU. / SE. Insert shape

Double Quattromill KAPR 71° .56 - SNMX2209ZN

Double Quattromill KAPR 71° .56 - SN.X1407ZN

Double Quattromill KAPR 48° .54 - SN.X1407AN

Double Quattromill KAPR 48° .54 - SNMX2209AN

Double Octomill .48 - ON.U0905

Double Octomill .48 - ON.U0504

Octomill .43 - OF..05T3

Octomill .43 - OF..0704

Octomill OO.T06 / OF..05/07 – 8 edges – KAPR 40°/43°

R220.23 REHR16

TNHF1206 Insert shape

ODMT05 Insert shape

HexaMill HP..1206 Insert shape

R220.13 SE Insert shape

R230.19 SNHQ1203 - Fixed Pocket - KAPR 90° - 4 cutting edges

QuattroMill - insert size 09

RPGN1204 - insert size 12

RNGN1207 - insert size 12