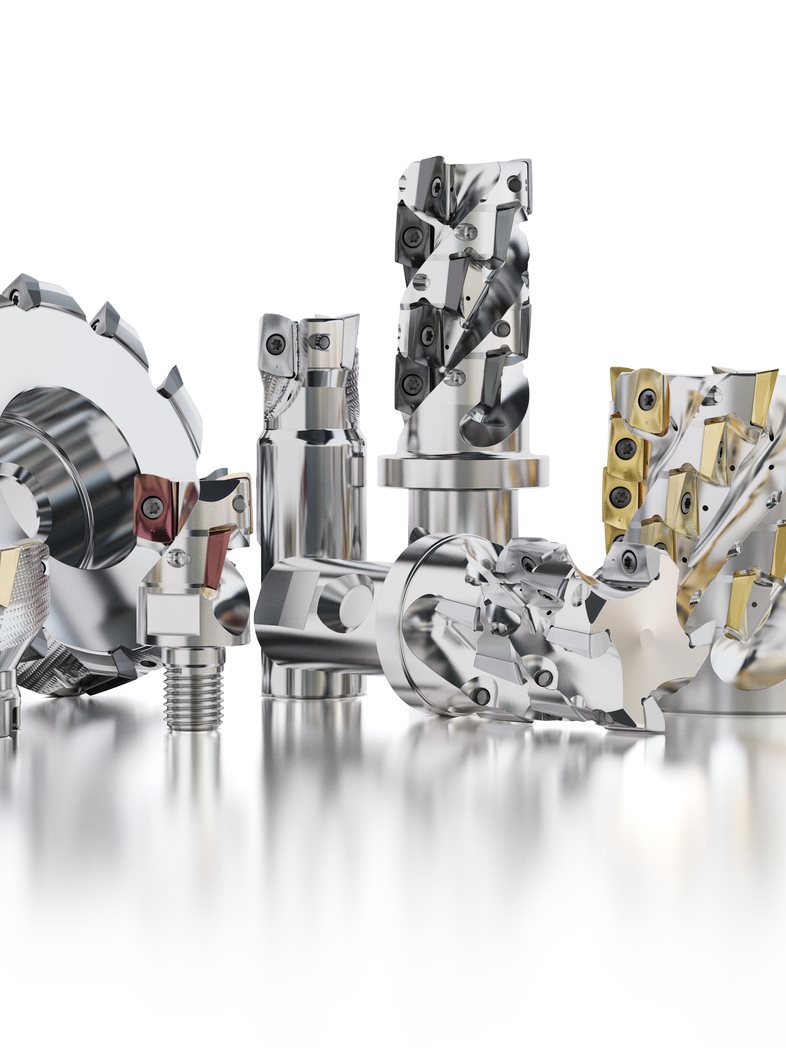

Cost effectively maximize productivity with Seco Helical cutters

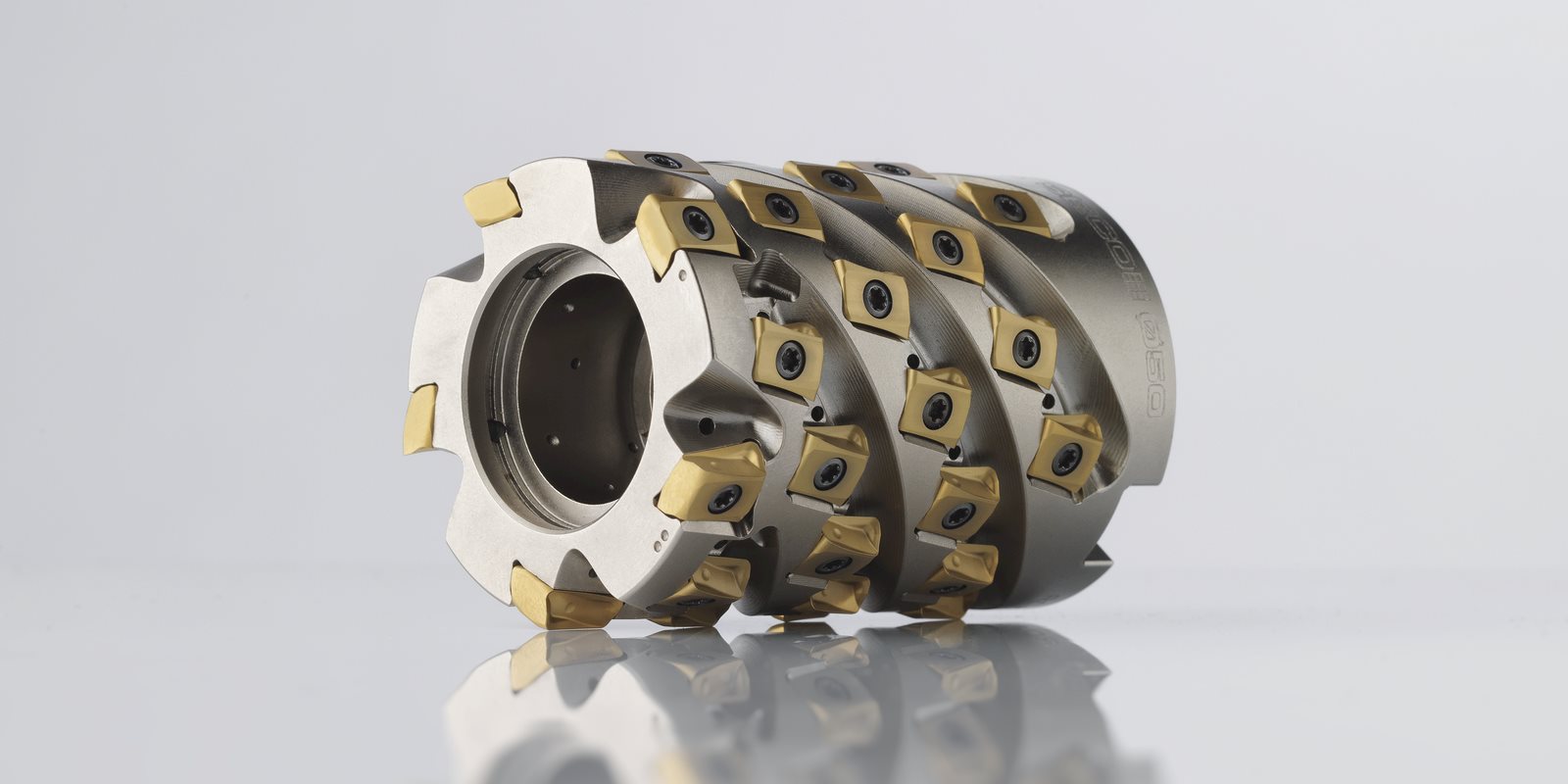

Remove more material faster, reduce production costs and boost profit margins with the Seco Helical SN8-13 rough milling system.Discover the Helical SN8 insert size 13 range

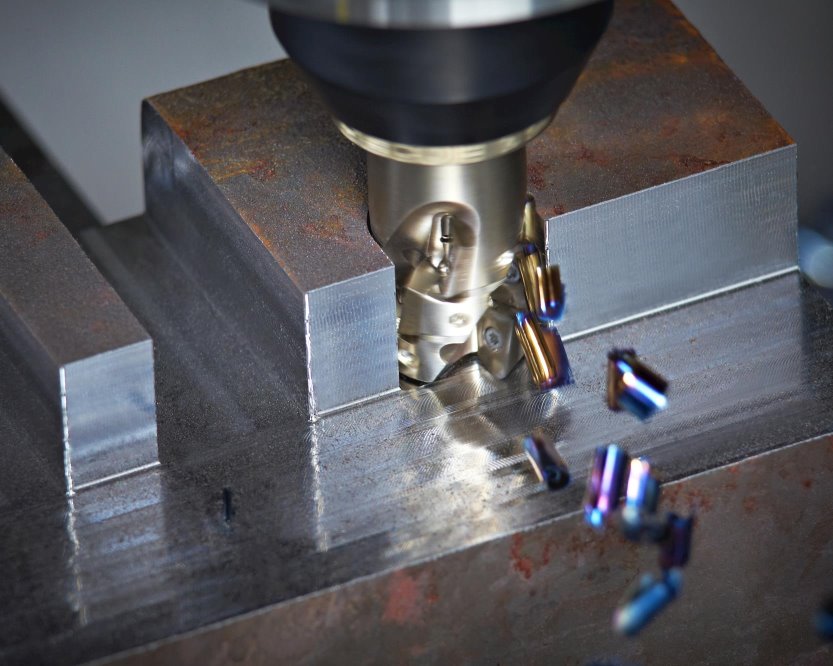

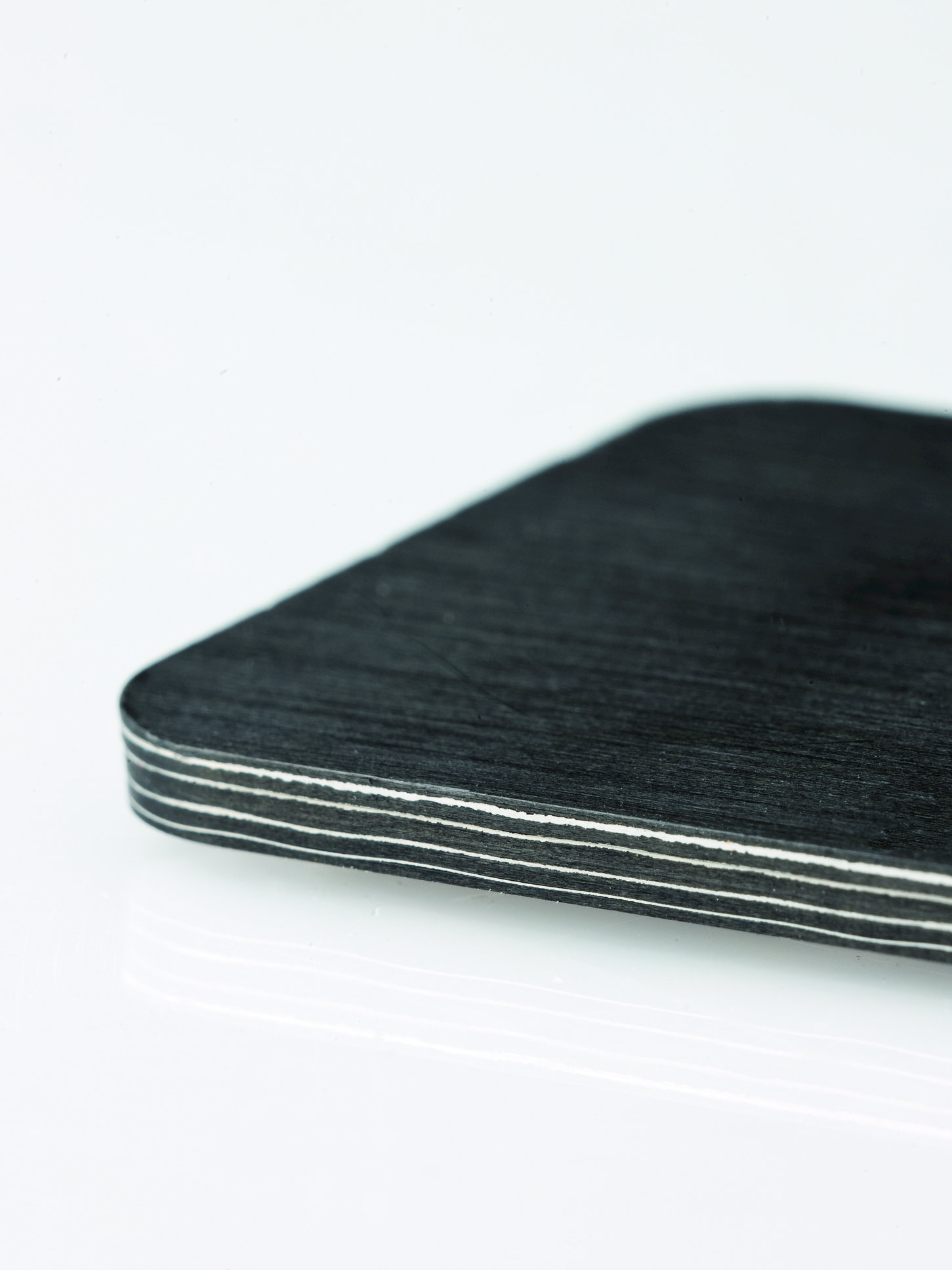

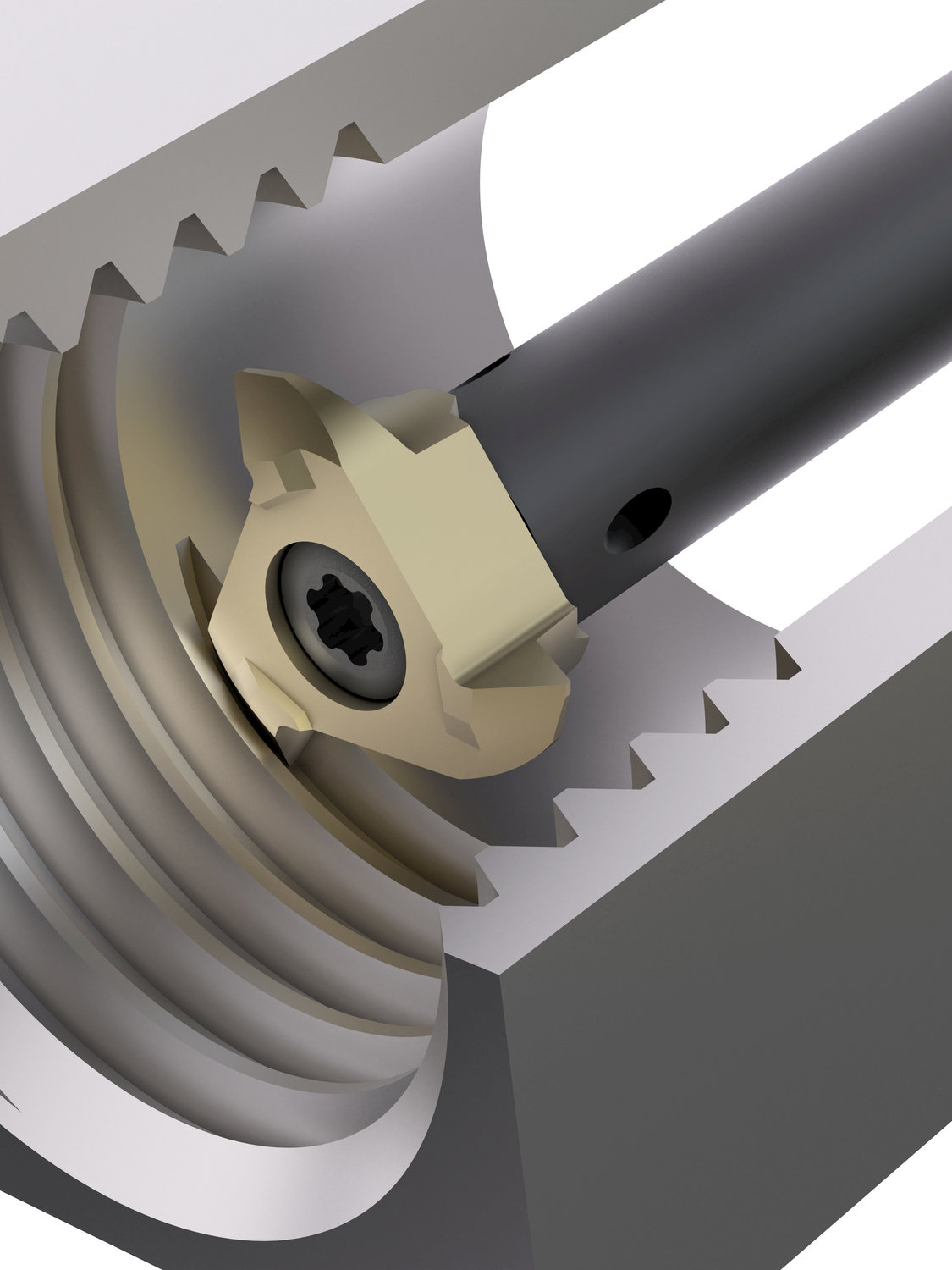

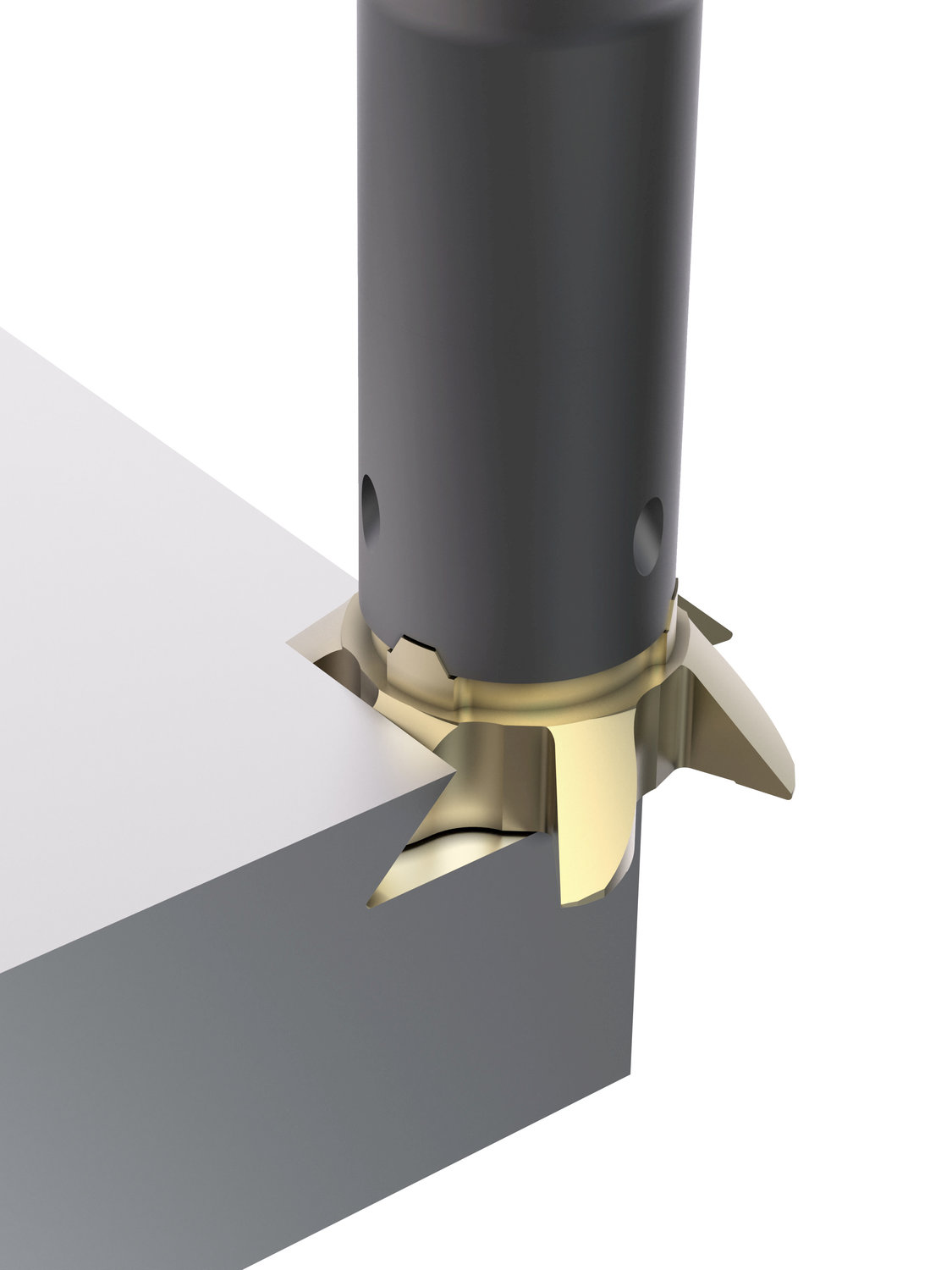

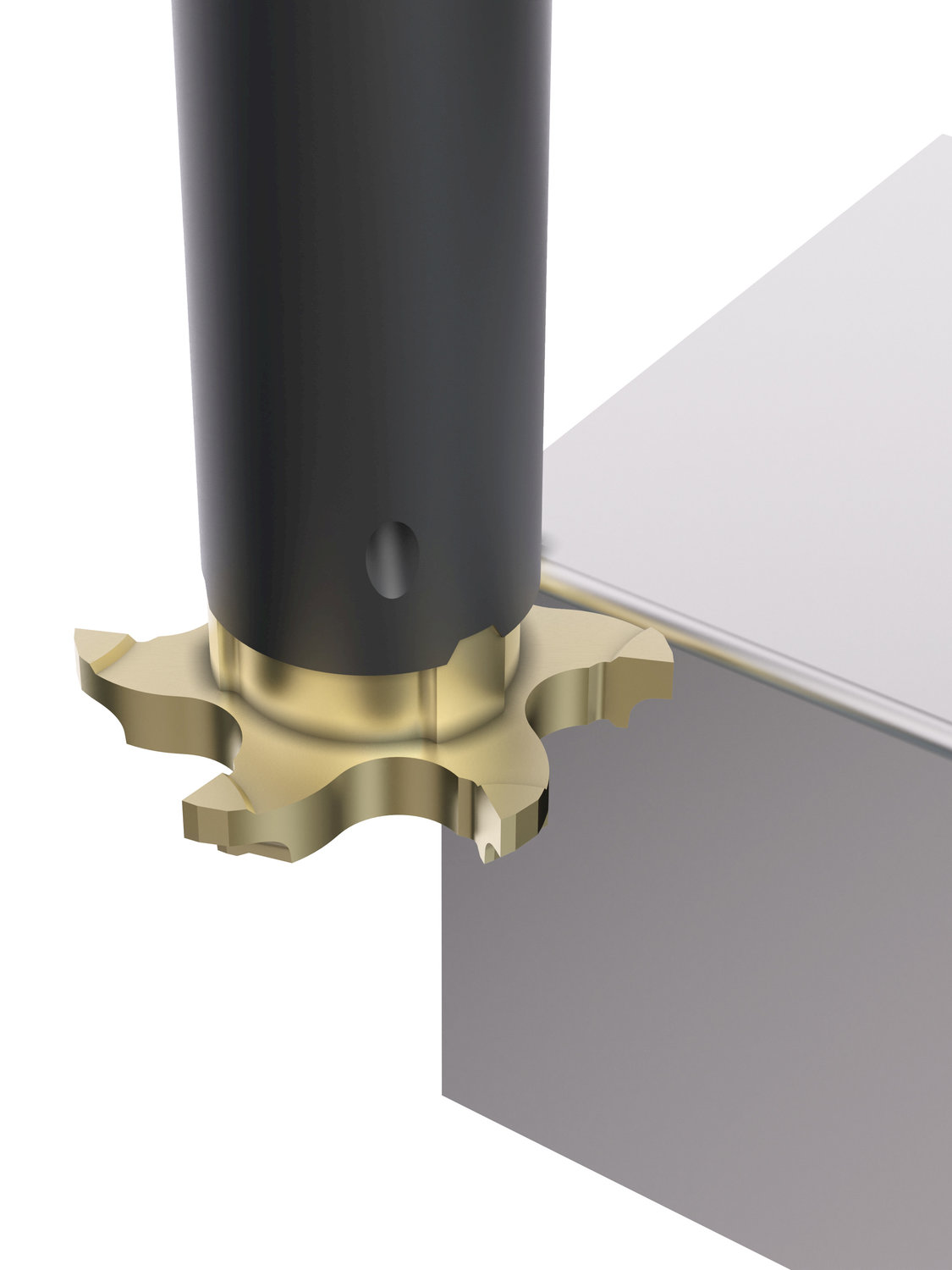

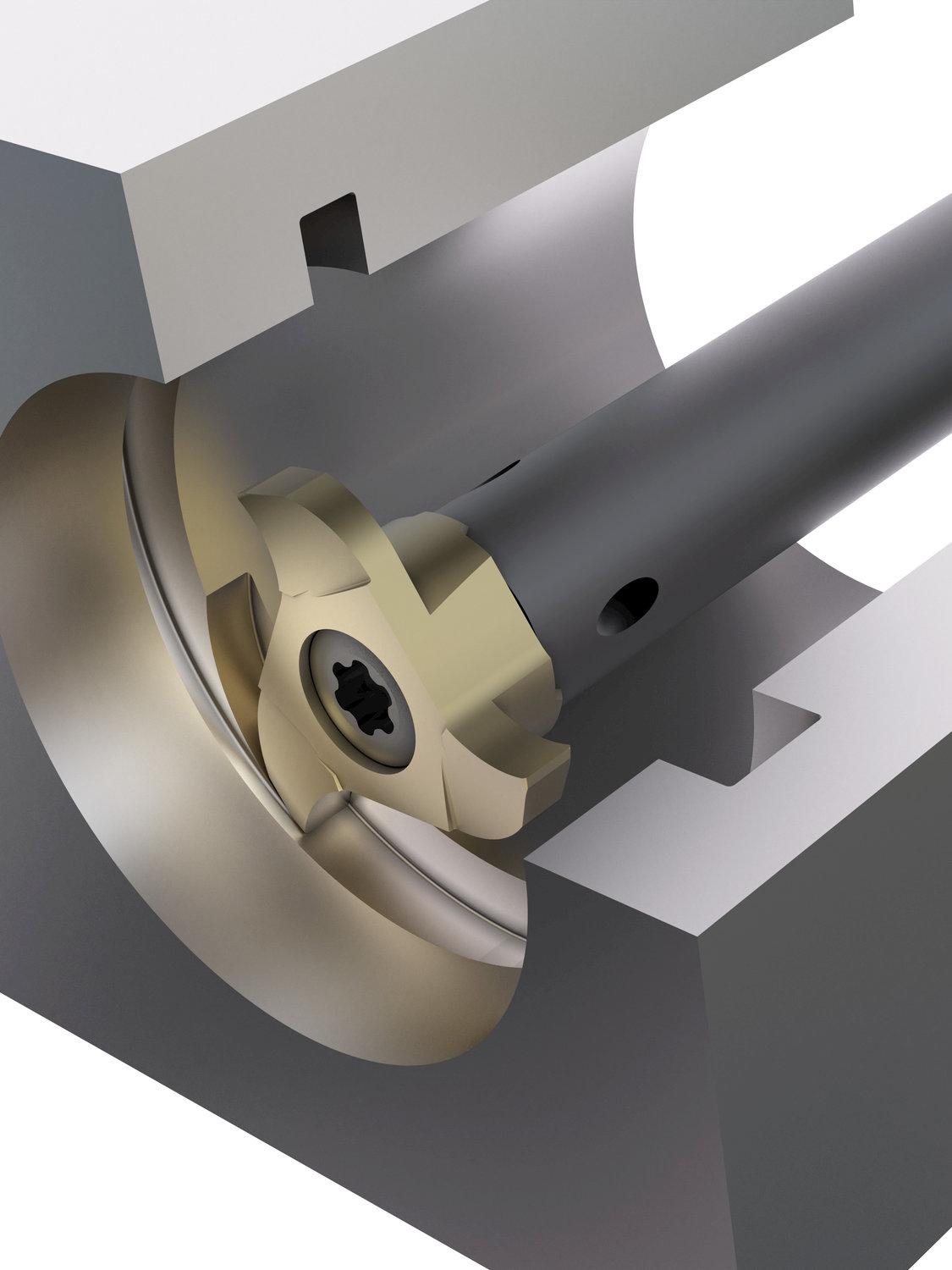

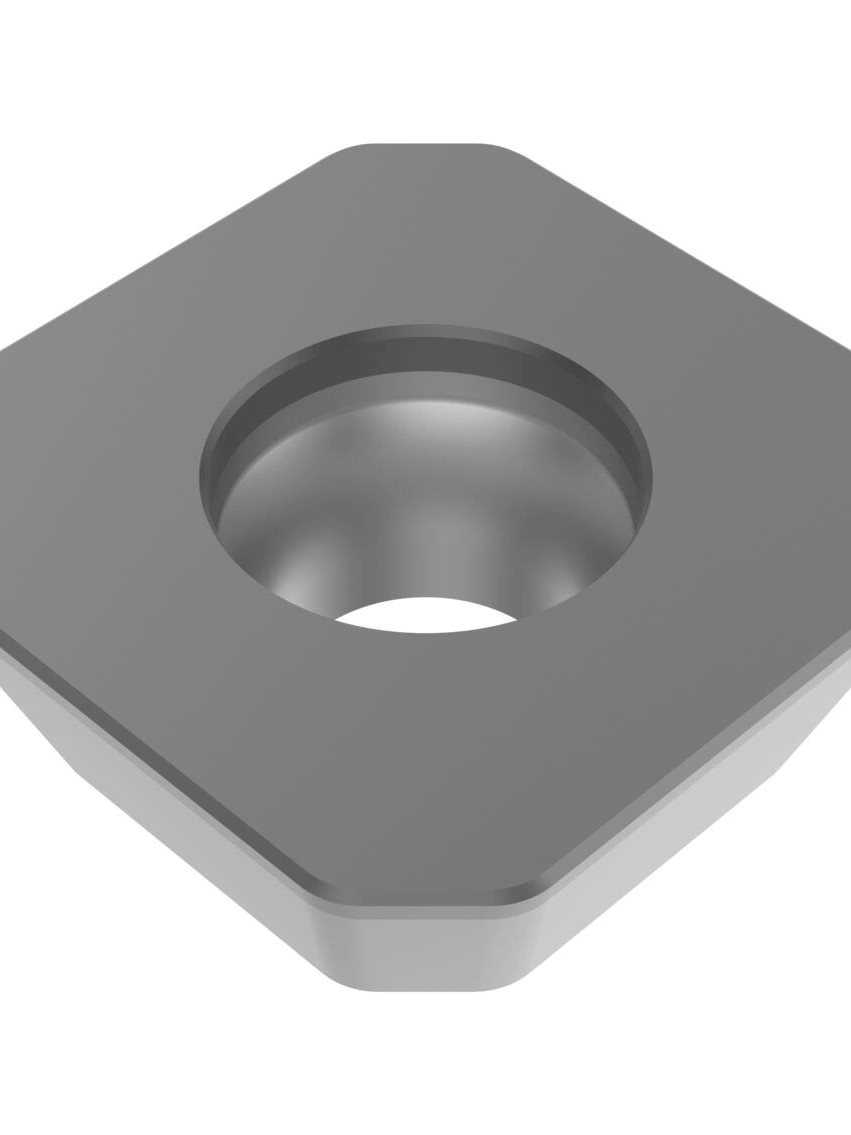

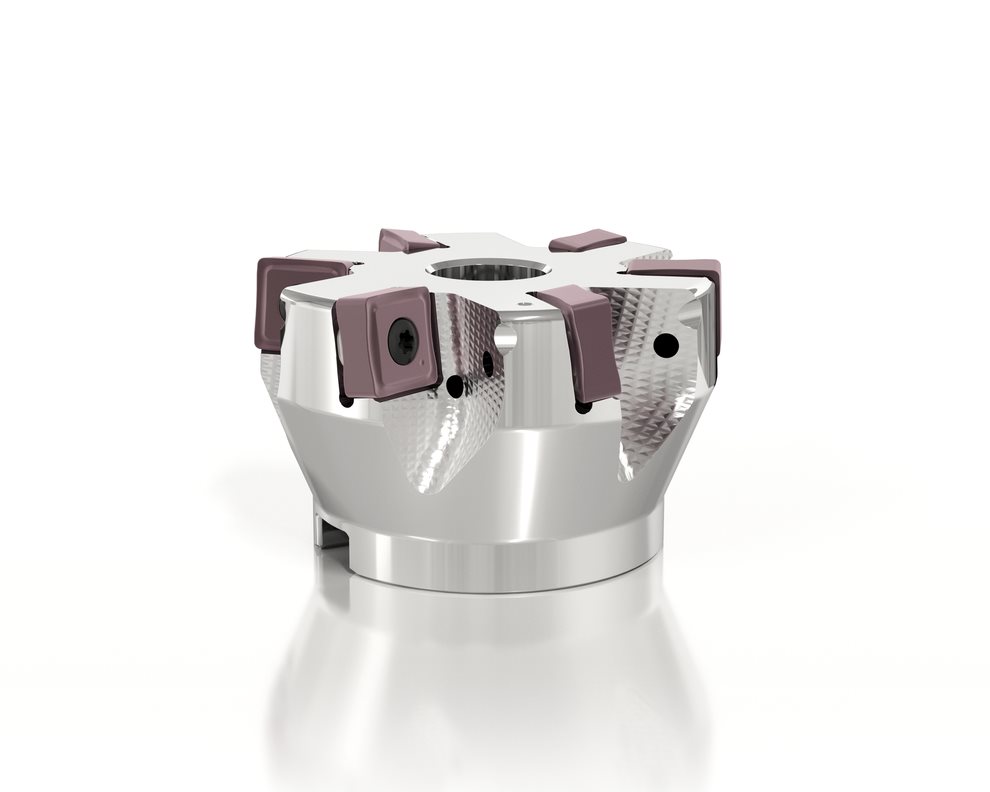

Keep pace with customer demands for reductions in part prices. With eight cutting edges, the doublesided helix inserts of the Seco Helical SN8-13 cutter deliver significantly lower costs per edge and boost rough milling efficiency. Built for difficult applications that involve parts with hard skins and material irregularities, the cutters offer three optimized geometries, long tool life and maximum chip evacuation to mill ISO P, M, K and S materials.

Your challenge:

Customers continue to demand price reductions, forcing shops to economize production operations while they maintain part quality and profit margins.

The Seco solution:

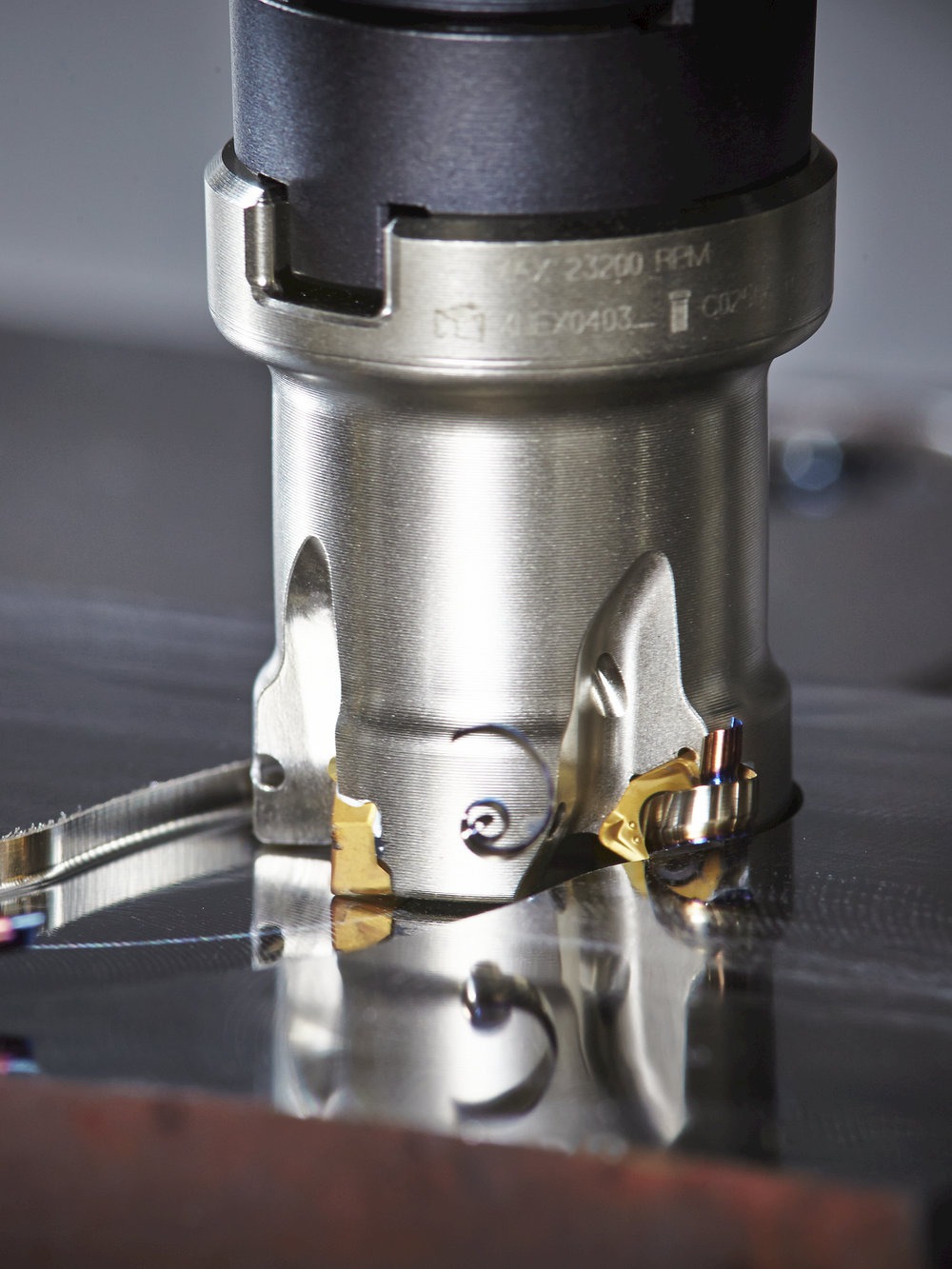

The Seco Helical SN8-13 features double-sided helix inserts with eight edges for a lower cost per edge that reduces production costs.

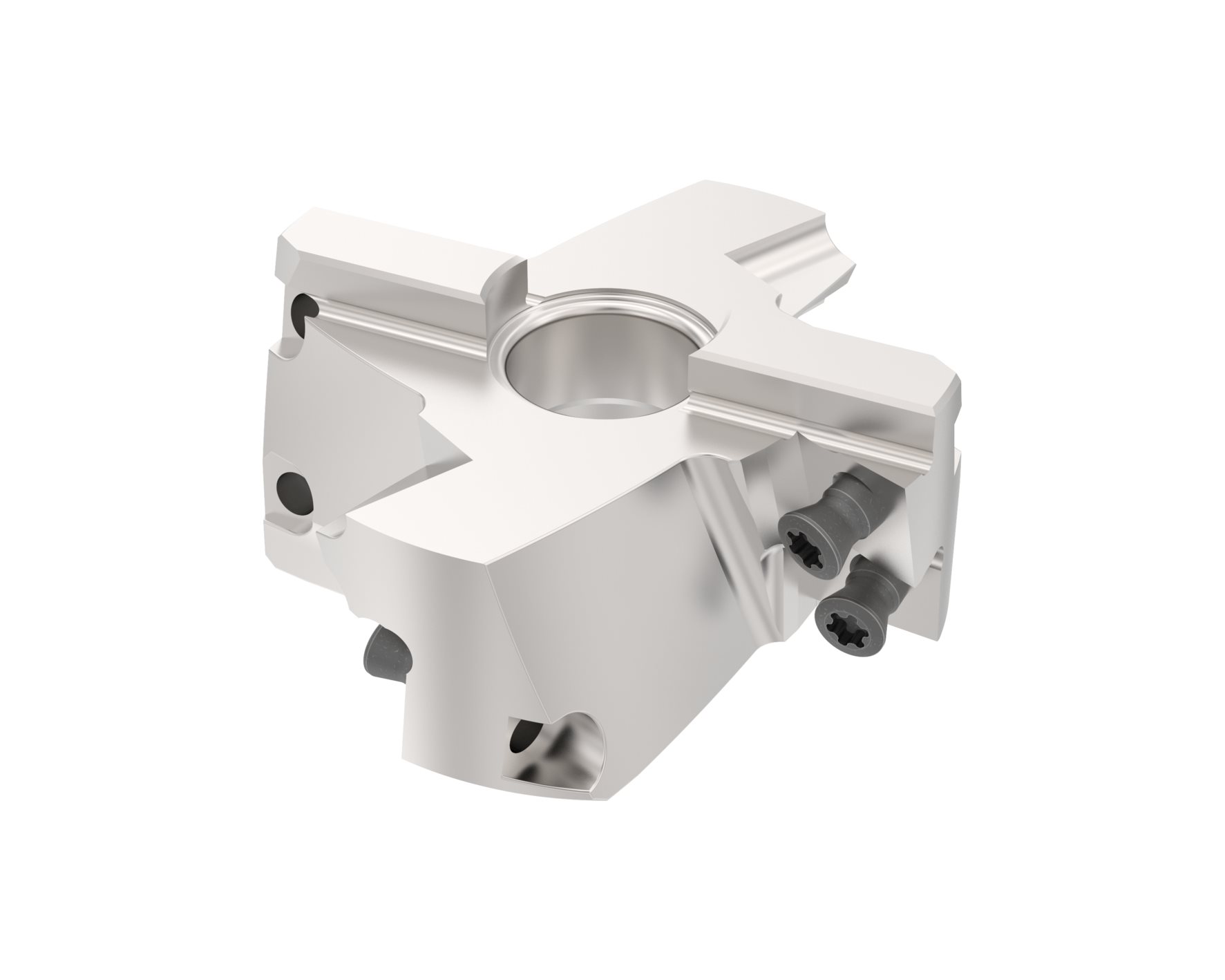

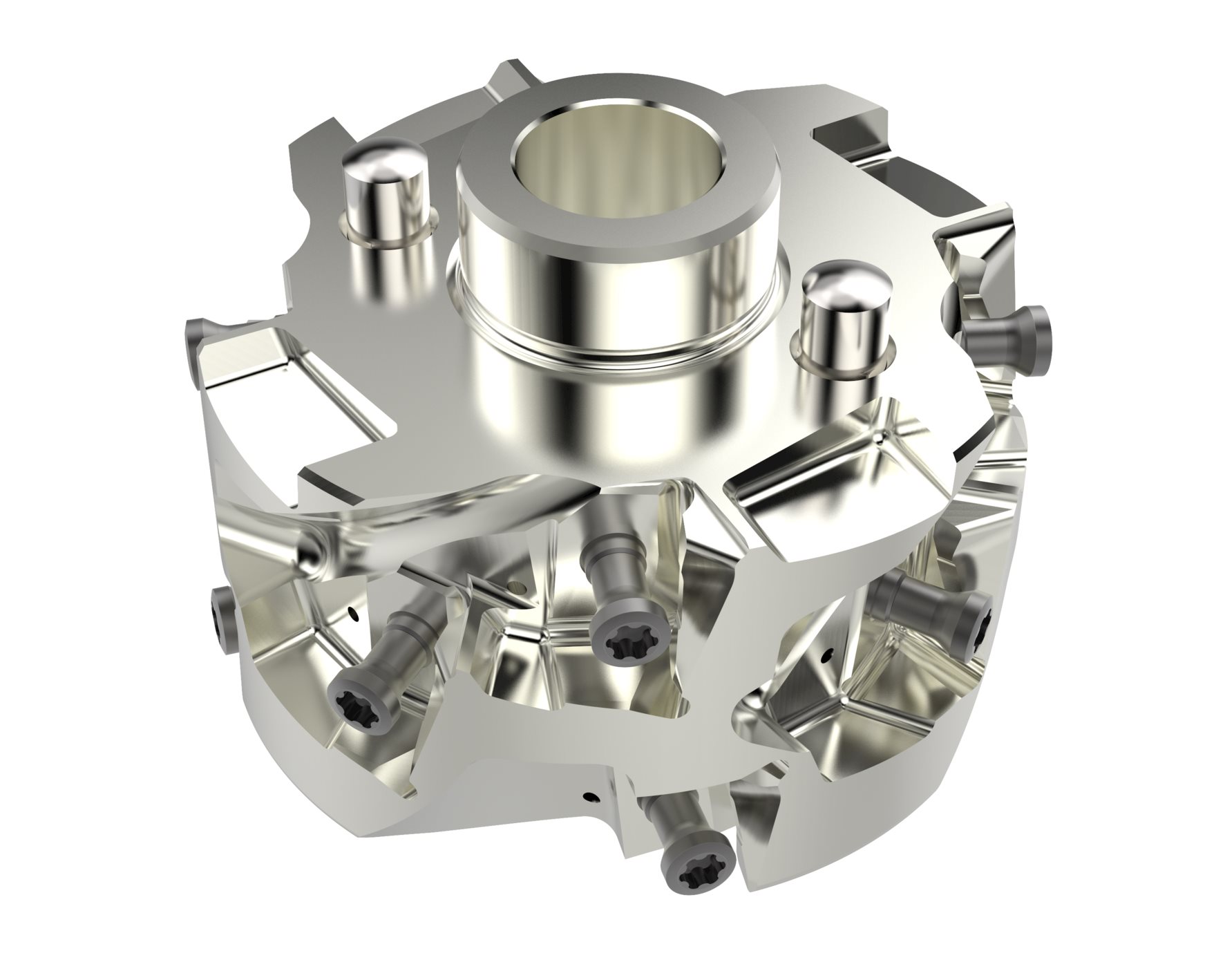

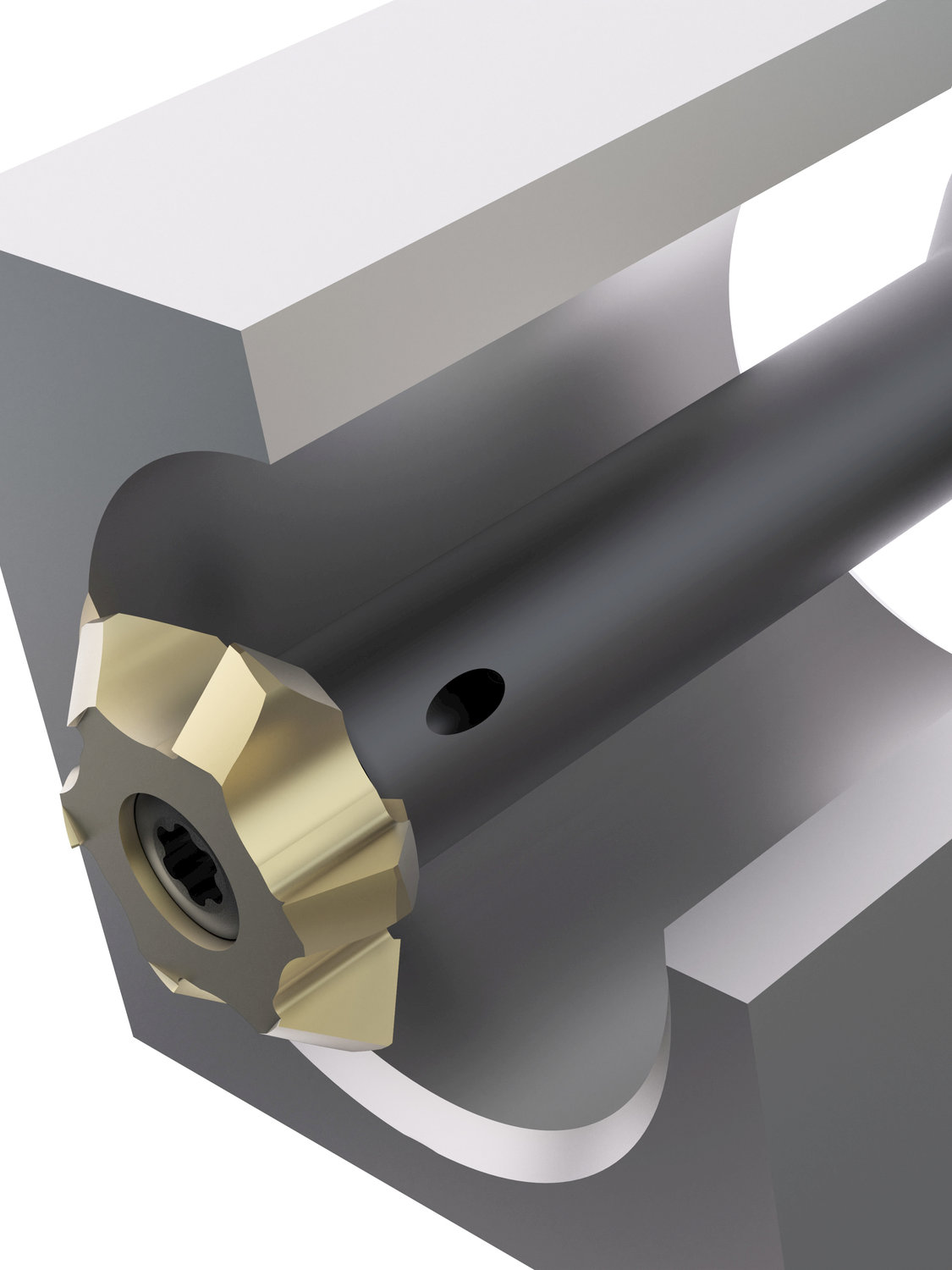

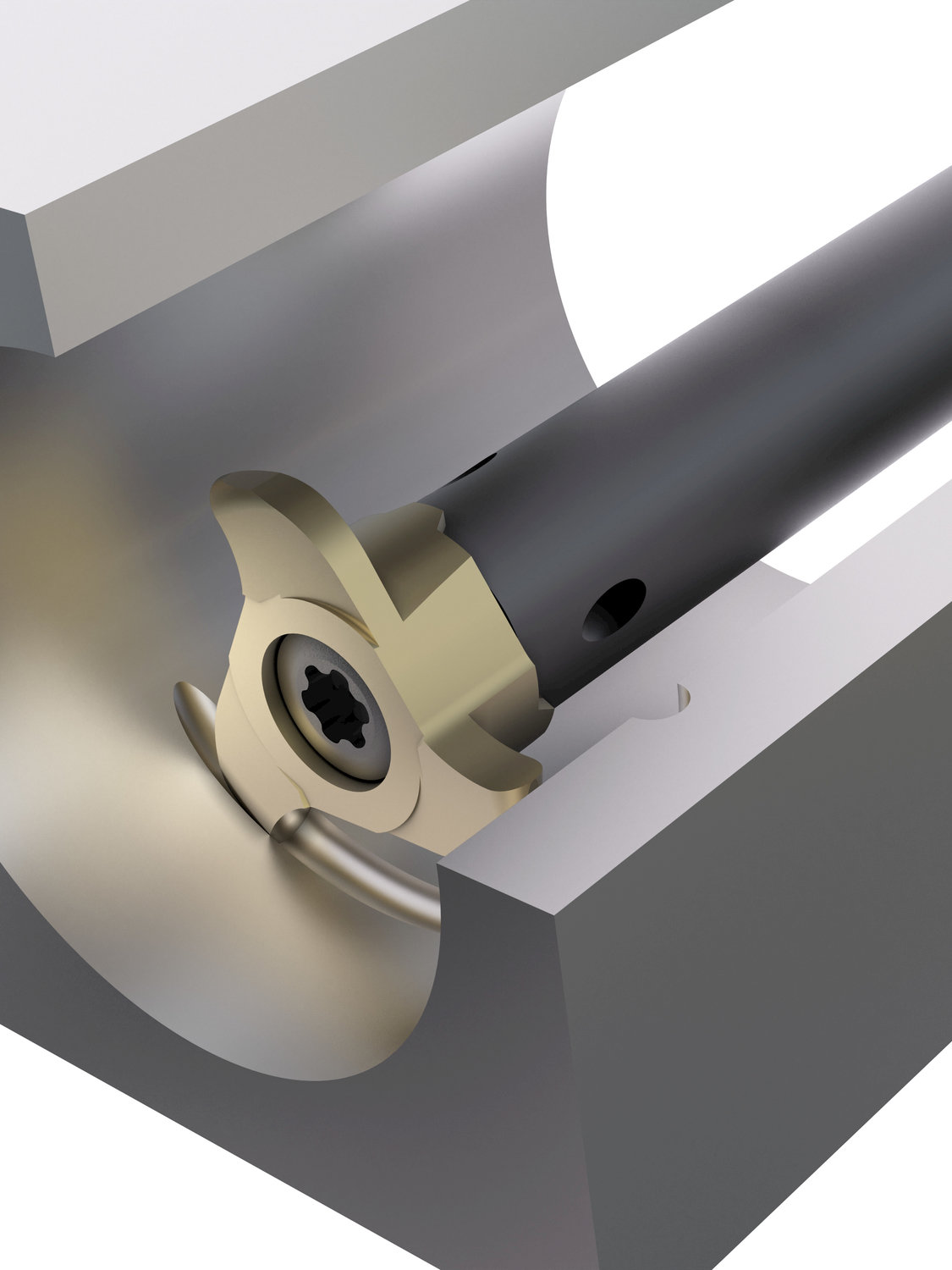

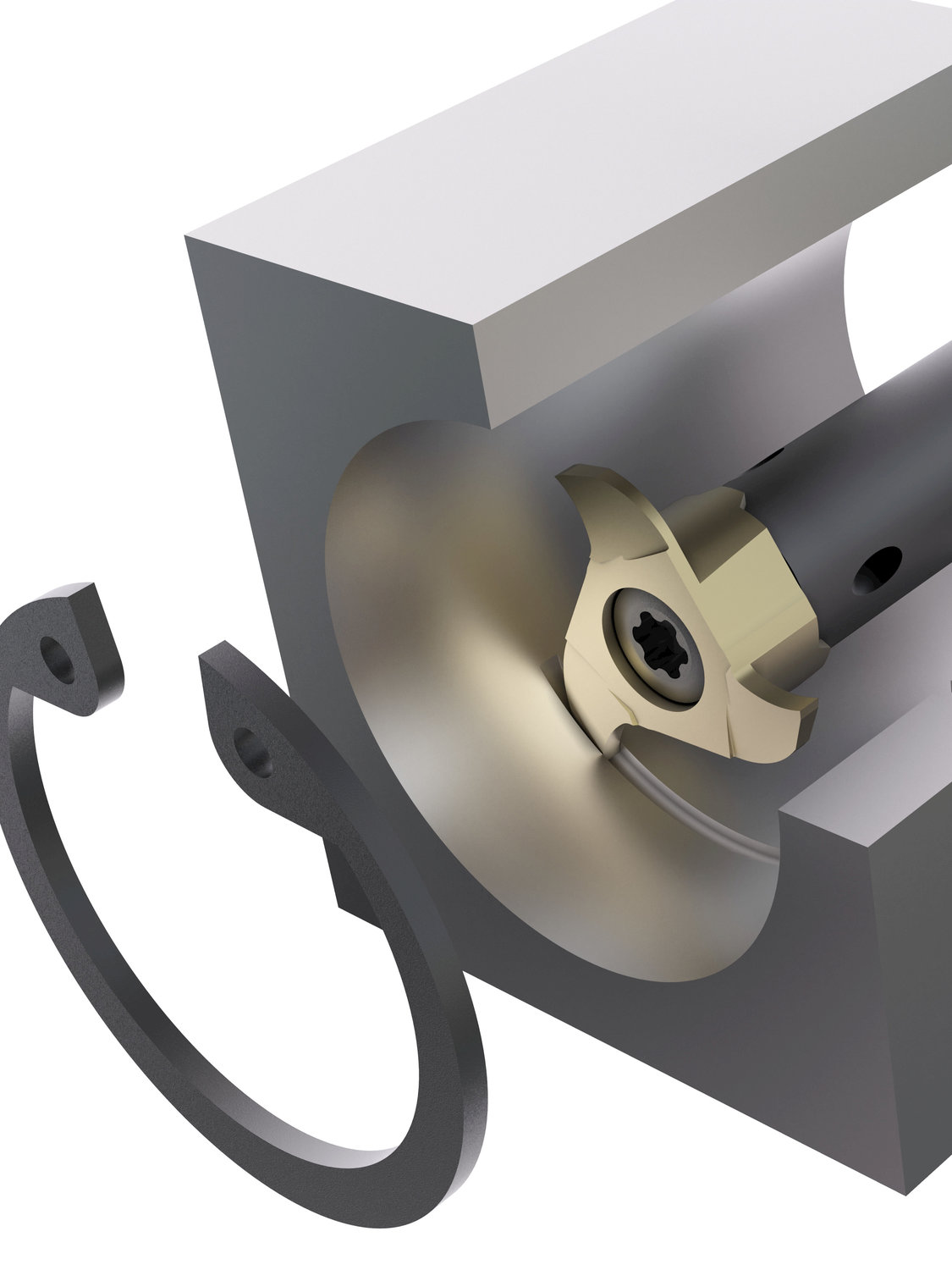

People make mistakes. Make sure they don’t when it comes to indexing inserts. The reliable and userfriendly design of the Helical SN8-13 cutter ensures the tool is robust and simple to use, while making it virtually impossible to mix the front and helix inserts. As a result, you gain process security to reduce the risk of scrapped parts and eliminate machine downtime that adds to production costs.

Your challenge:

Less-skilled workers make mistakes that often lead to machine downtime, quality issues and scrap – making it difficult to reduce production costs.

The Seco solution:

The design of the Seco Helical SN8-13 provides foolproof indexing of front and helix inserts to eliminate the risk of human error.

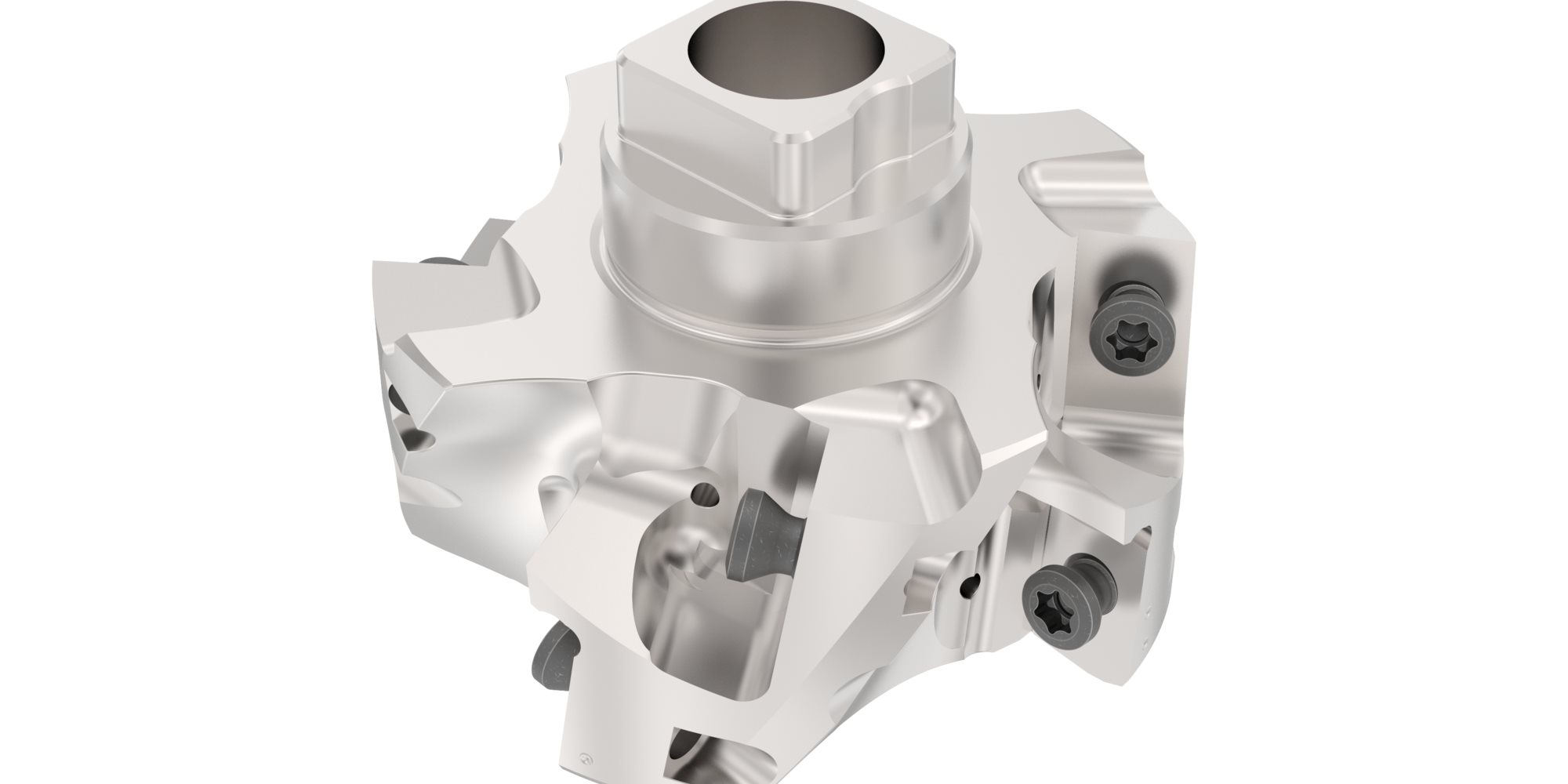

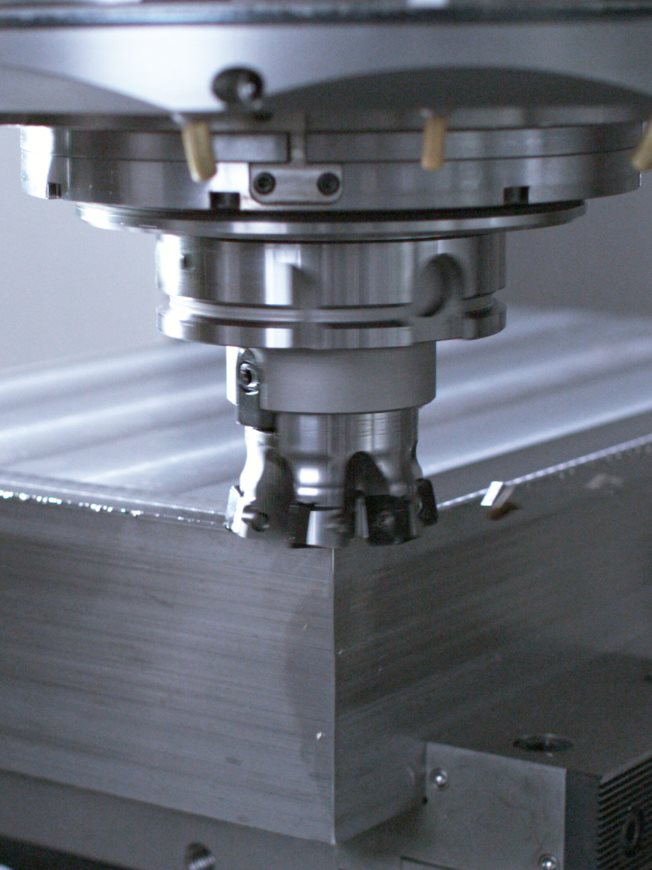

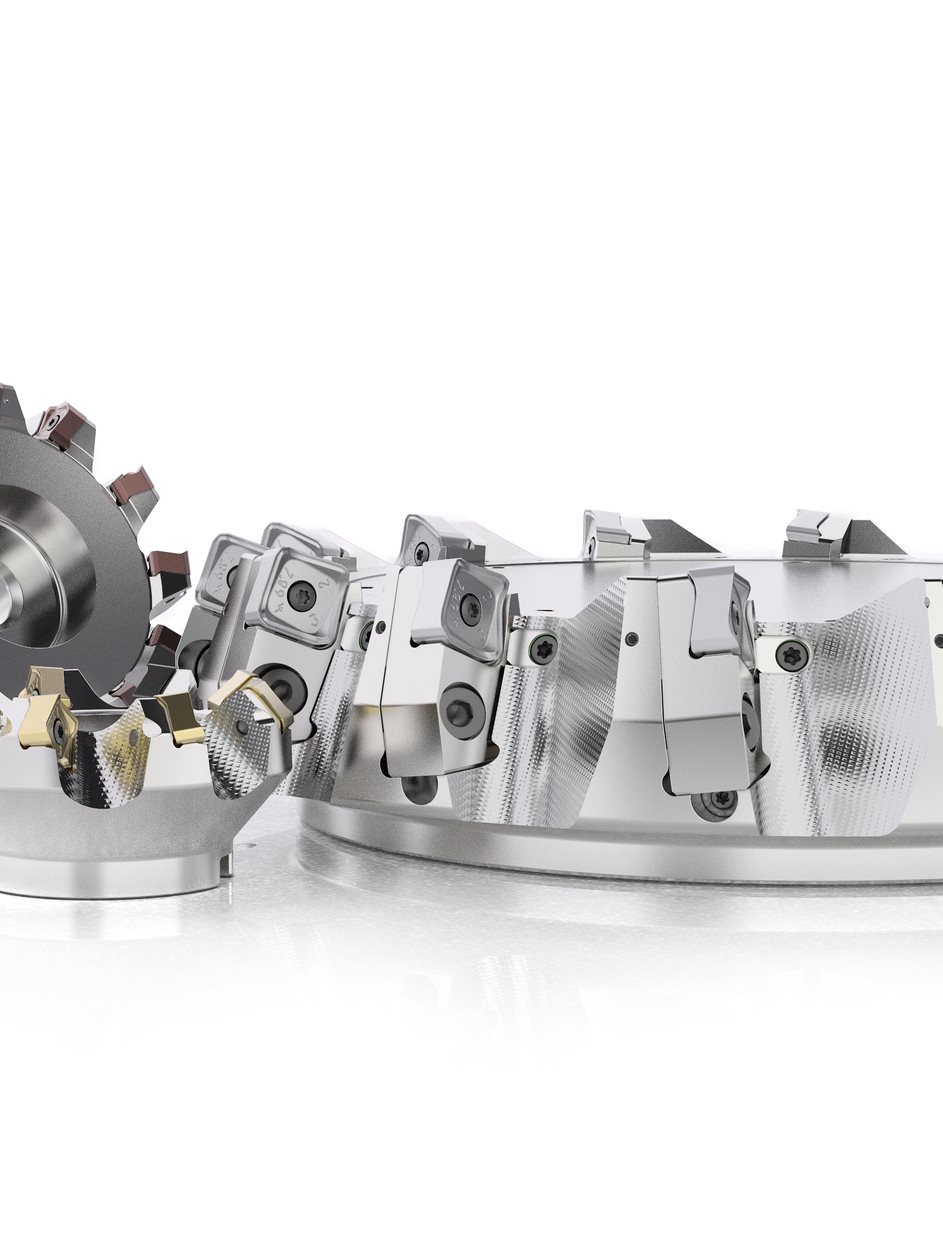

Don’t let challenges like demanding production environments, long reach and weak fixture situations, difficult part materials or low machine power hold you back. The Seco Helical SN8-13 cutter optimizes helical slotting and side milling, as well as circular interpolation rough milling operations. Easily overcome those tough situations with applicationspecific sub-family designs that offer left or righthand helixes, half and full effective teeth options, two front insert and many radii choices.

Your challenge:

High productivity, long reach, weak fixtures, difficult material and low machine power situations hinder rough milling operations.

The Seco solution:

Optimized for various applications, the sub-families within the Seco Helical SN8-13 cutter system offer various helix hands, teeth designs, front insert and many radii options.

Discover the Helical SN8 insert size 13 range

Contact Us

Are you interested in Helical Milling ?

Discover our Helical Mills range

Related content

Suggest

Product Range Presentation - Seco SN8-13

Factsheet - Seco SN8-13

Helical SN8 - 2/8 cutting edges single/double-sided inserts

Seco Helical SN8-13 Milling System Delivers Performance at a Lower Cost Per Edge

Helical SN8 - Right Helix General Machining

Helical SN8 - RH - Cutters and Inserts

Helical SN8 - RH - Spare parts

Helical SN8 left helix design | Seco Tools

Helical Mills

Aerospace

Milling Cutters

Video: Winning Solutions in Aerospace

Heavy Machining Tools

Helical SN8 - Left Helix K=Z/2

Helical SN8 - Left Helix K=Z

Helical SN8 - Right Helix Heavy Duty

Seco News Summary 2022.2

Seco sustainable & versatile solutions made for your best performance

Helical SN8 heavy duty design | Seco Tools

Helical SN8 half effective design | Seco Tools

Heavy Machining

Heavy Milling

The new materials set to shape the future of the aerospace industry

Composite Materials: Flying High!

8 tips to machine titanium alloys

Reducing the carbon footprint in structural aerospace components

Towards a leaner and greener aviation industry

Why making an aeroplane pylon is a true collaborative process

Addressing the Aerospace Machining industries skills gap, one customer at a time

Video: Why is Wire-Arc Additive Manufacturing important when machining a Blisk?

Seco Taps T32 - T33 - T34

Inspiration Through Innovation

Inspiration Through Innovation 2024 Aerospace and Medical

Helical LN4 - Spare parts

Helical LN4 - Cutters and Inserts

Helical LN4 - 2/4 Cutting Edges Single/Double-sided Inserts

Seco High Feed SP

Lift-off for Mettis Group

Helical Interpolate Like A Pro

Seco milling cutters reduce tooling inventory costs with versatility

Video: Advanced Tooling for Aerospace Disc Manufacturing

Helical Heavy Duty

Helical SC12 - LH K=Z/2 - Spare parts

Helical SC12 - LH K=Z/2 - Cutters and Inserts

Helical SC12 - Left Helix K=Z/2

Helical Turbo 18 - Spare parts

Helical Turbo 16 - Spare parts

Helical Turbo 12 - Spare parts

Helical SC12 - 2/4 cutting edges single-sided inserts

Helical Mills for Finishing

Helical T4 - 4 cutting edges tangential inserts

Helical Turbo - 2 cutting edges single-sided inserts

Helical SC12 - Left Helix K=Z

Helical T4-12 - Spare parts

Helical T4-12 - Cutters and Inserts

Helical Turbo 18 - Cutters and Inserts

Helical Turbo 16 - Cutters & inserts

Helical Turbo 12 - Cutters and Inserts

Helical Turbo - Insert Size 10

Helical Turbo - Insert Size 06

Helical T4 - Insert Size 12

Helical T4 - Insert Size 08

Helical Turbo - Insert Size 18

Helical Turbo - Insert Size 16

Helical Turbo - Insert Size 12

Industries

FACTSHEET - Helical Turbo 16 MILLING CUTTERS

Helical Milling Cutter Comparisons on Steel (P4)

Helical Milling Cutters on Low Carbon Steel

Helical Turbo 16 Prony Screw Setup

Helical Turbo 16 Radii Indexing and Compatibility

Helical Turbo 16 Replaceable end Assembly

Video: Semi-Standard Helical Cutter Program Introduction

Helical Mills for SCET/ACET Inserts

High Feed Mills

Octomill .43 - OO..0605

High Feed SP - Insert size 14

High Feed SP - 4 cutting edges single-sided inserts

Mini Disc - 335.14 - Shanks

Mini Disc - 335.14 – Thread Milling

Mini Disc - 335.14 - Dove Tail

Mini Disc - 335.14 - Corner rounding

Mini Disc - 335.14 - Top and Bottom Chamfering

Mini Disc - 335.14 - Full radius profile

Mini Disc - 335.14 - For circlips groove

Mini Disc - 335.14 - General Grooving

335.14 - Replaceable Head Disc Cutters DC 6.7 - 50 mm (0.264 to 1.97”)

A Guide to Milling Grades, Materials and Solutions

PCD and CBN square milling cutter .53

QuattroMill - Insert size 12

R220.60 - SP..19/28 - 4 cutting edges - KAPR 60°

Near 90 .88 SN.U12/16 - KAPR 88° - 8 cutting edges

Double Quattromill - SN.X14/22 - 8 cutting edges - KAPR 48° / 71°

Double Octomill - ON.U05/09 - 16 cutting edges - KAPR 40°

Quattromill .53 - SE.X1505

Quattromill .53 - SE.X1204

Quattromill .53 - SE.X09T3

Quattromill - SE.X 09/12/15 - 4 cutting edges - KAPR 45°

Near 90 .88 - SN.U1606

Near 90 .88 - SN.U1204