Rough the tough stuff

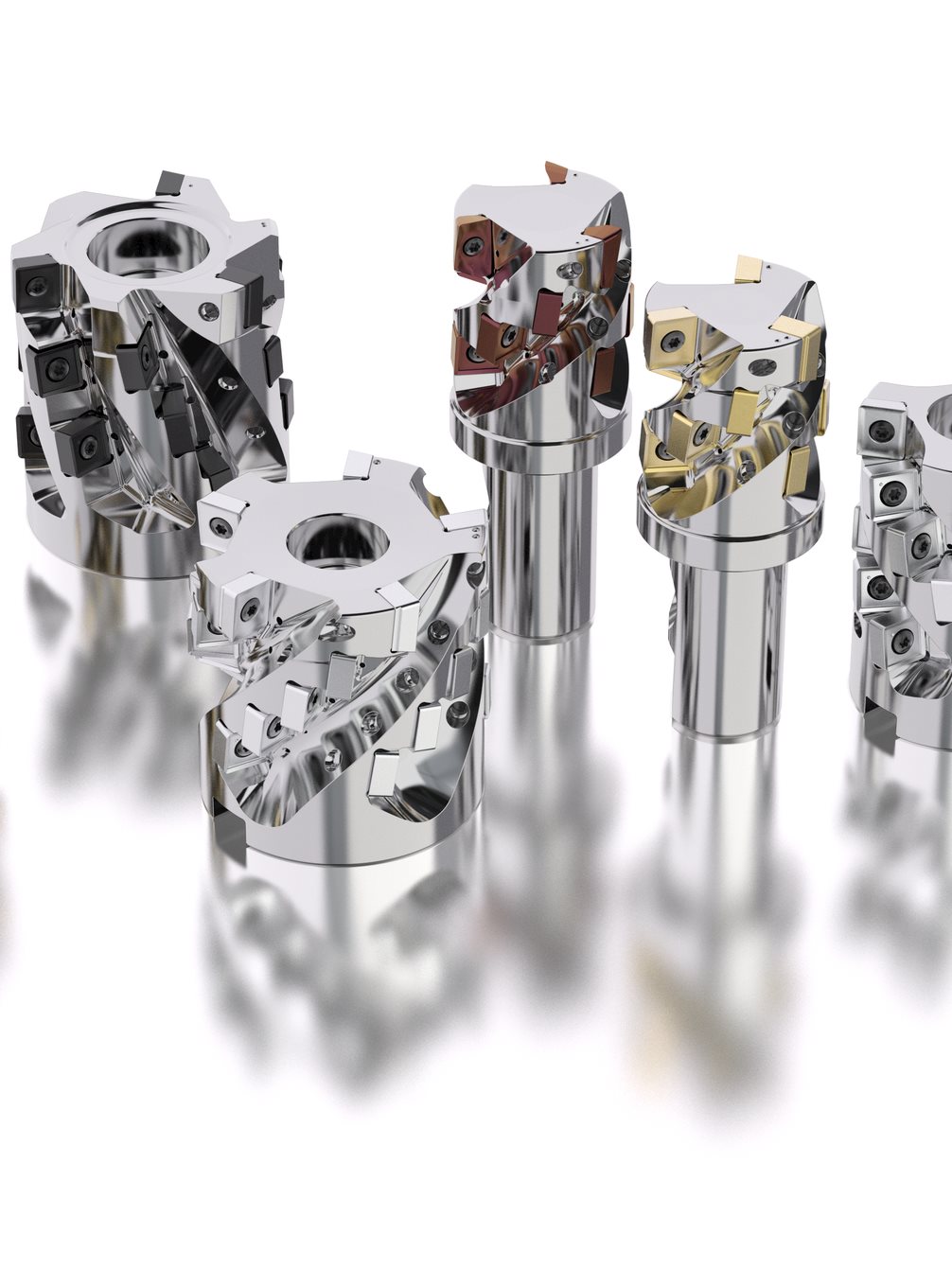

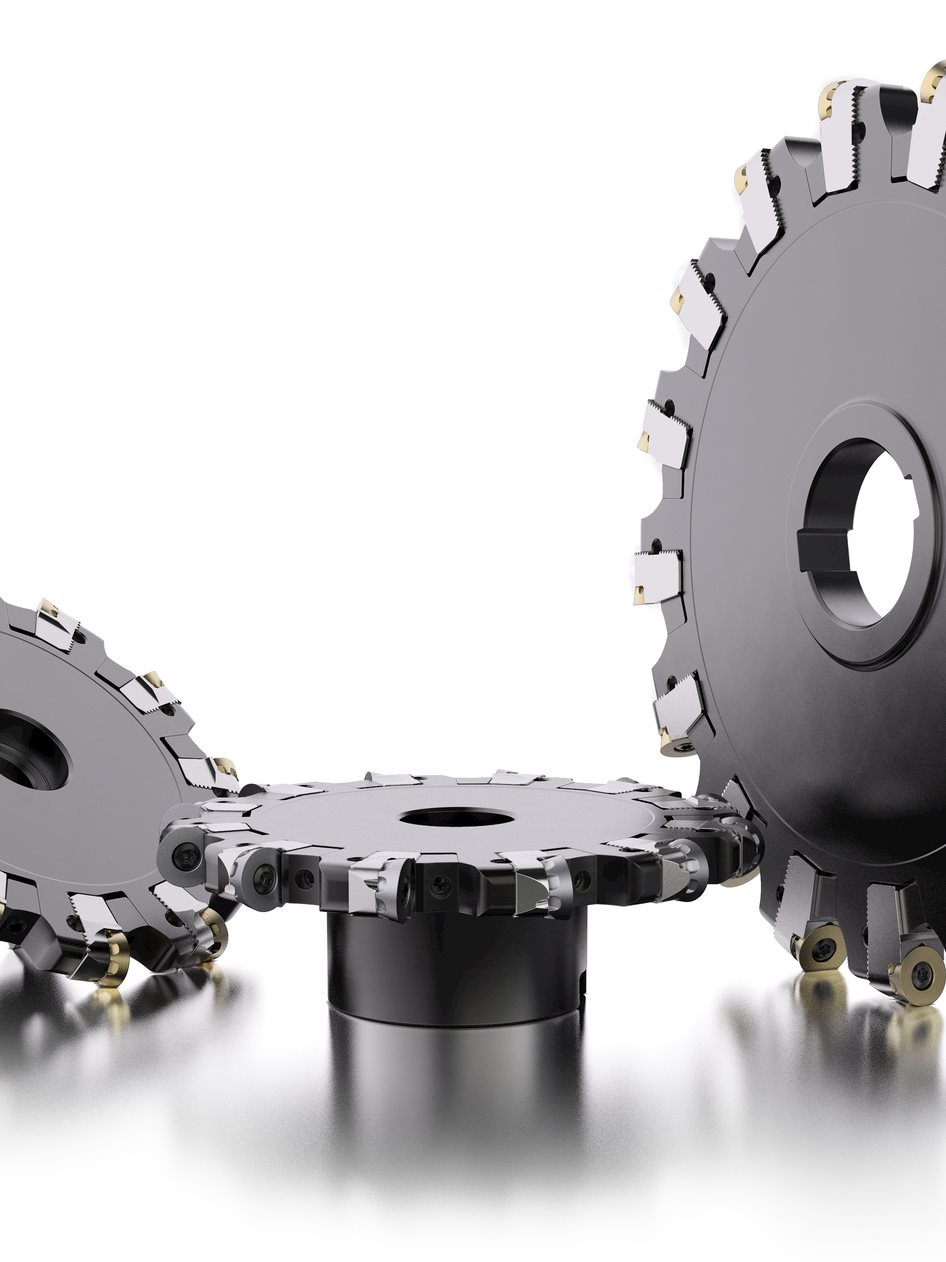

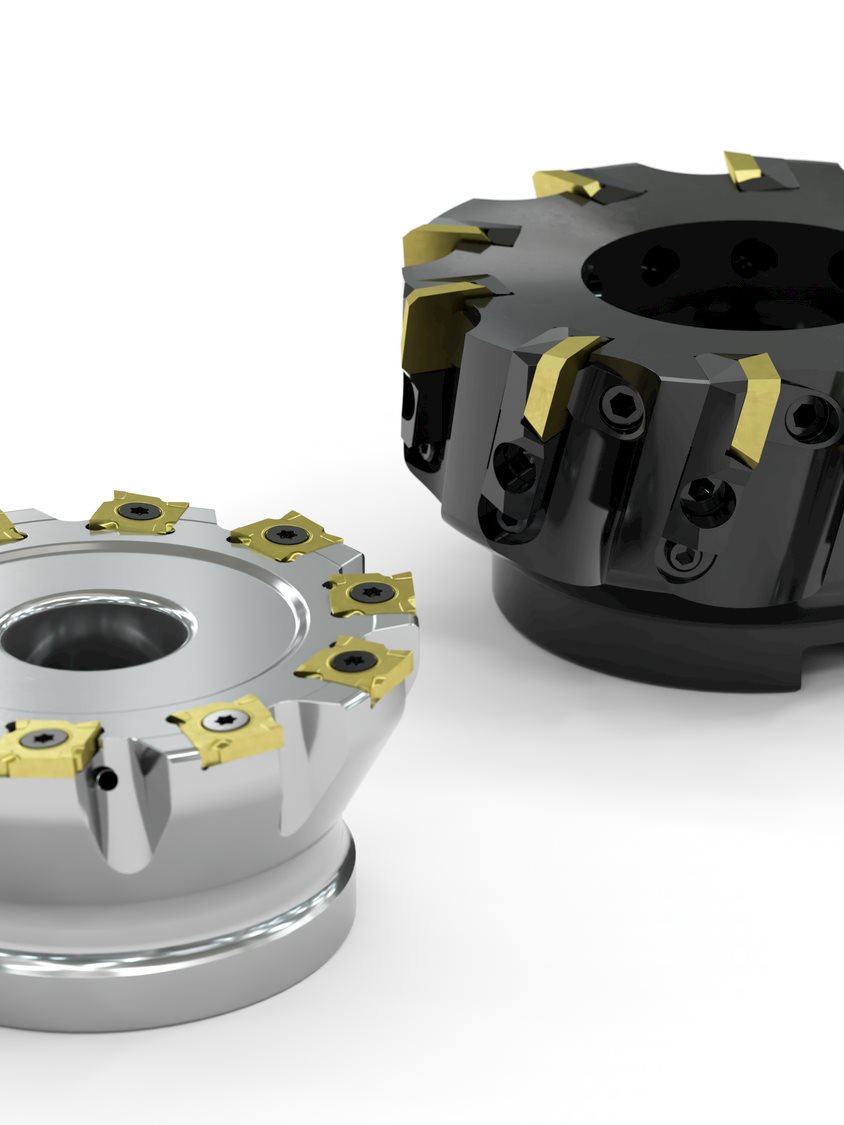

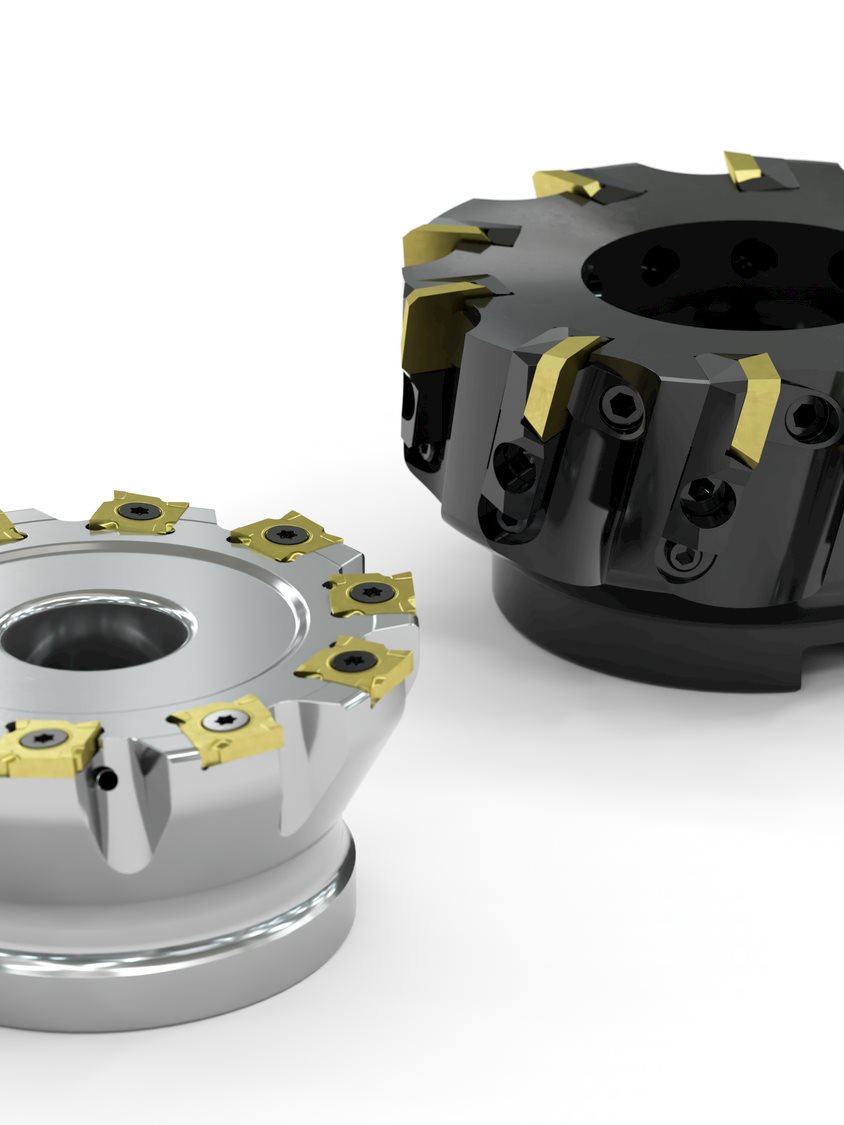

Versatile High-feed Milling that’s a cut above the others for ISO P, M and S materials

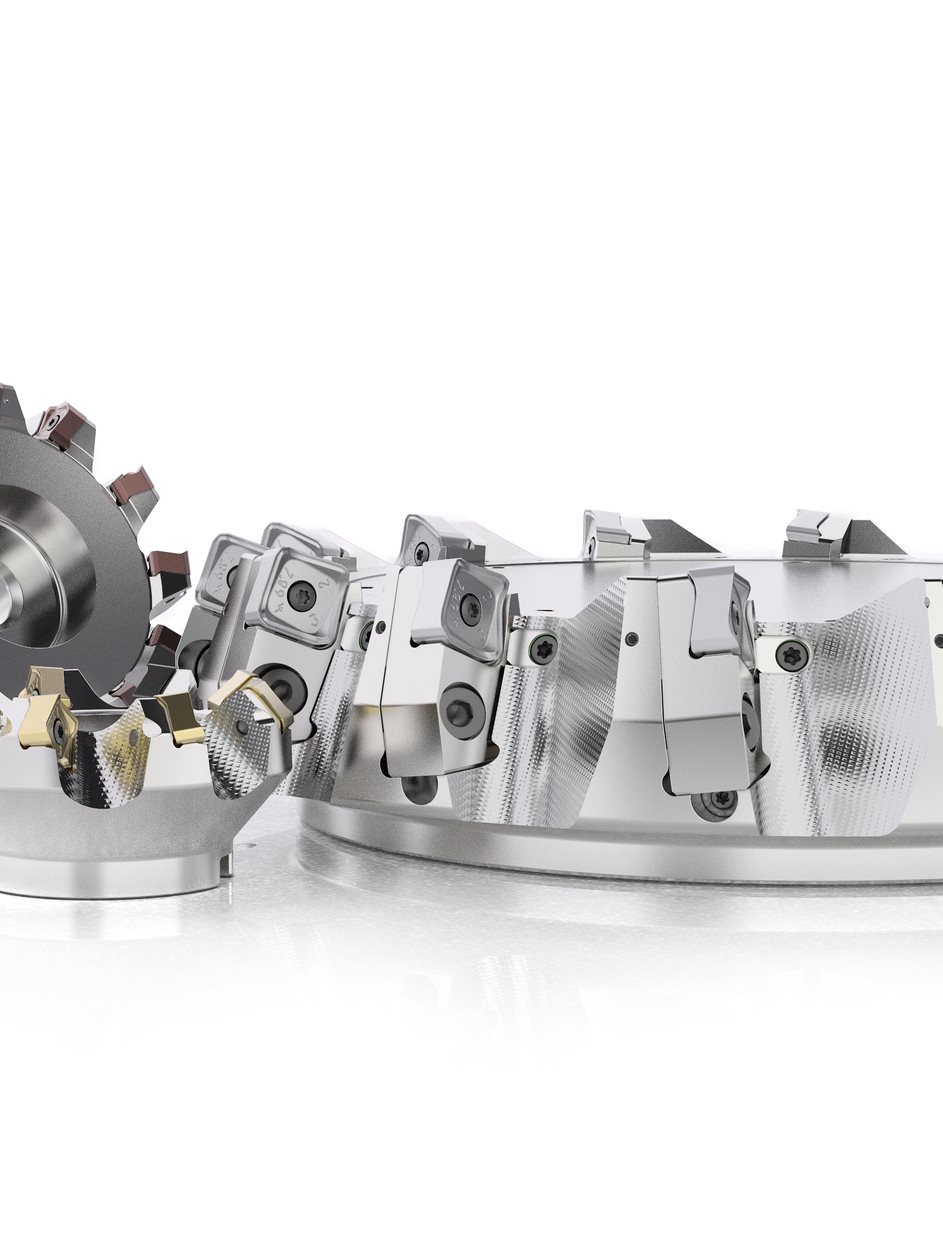

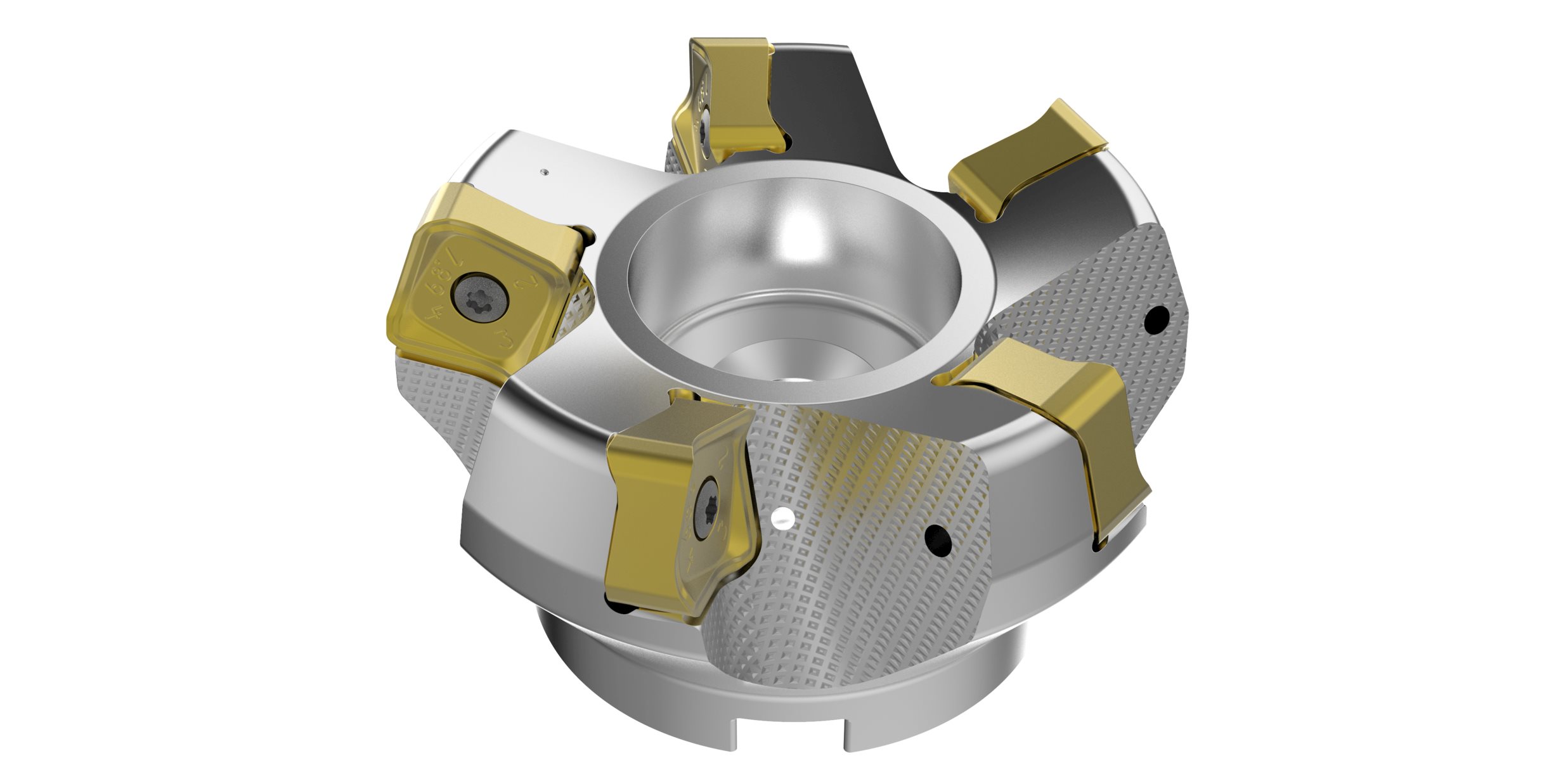

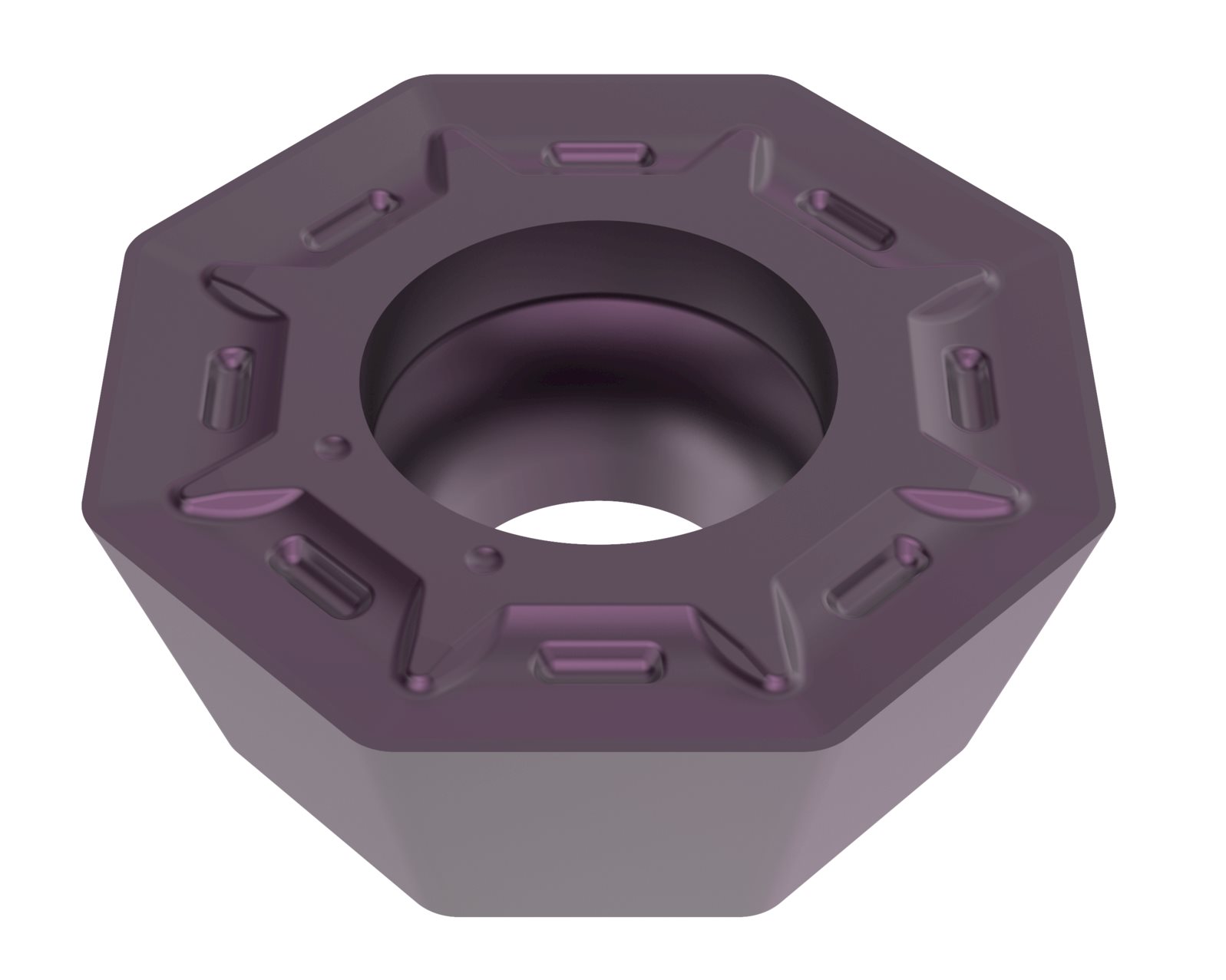

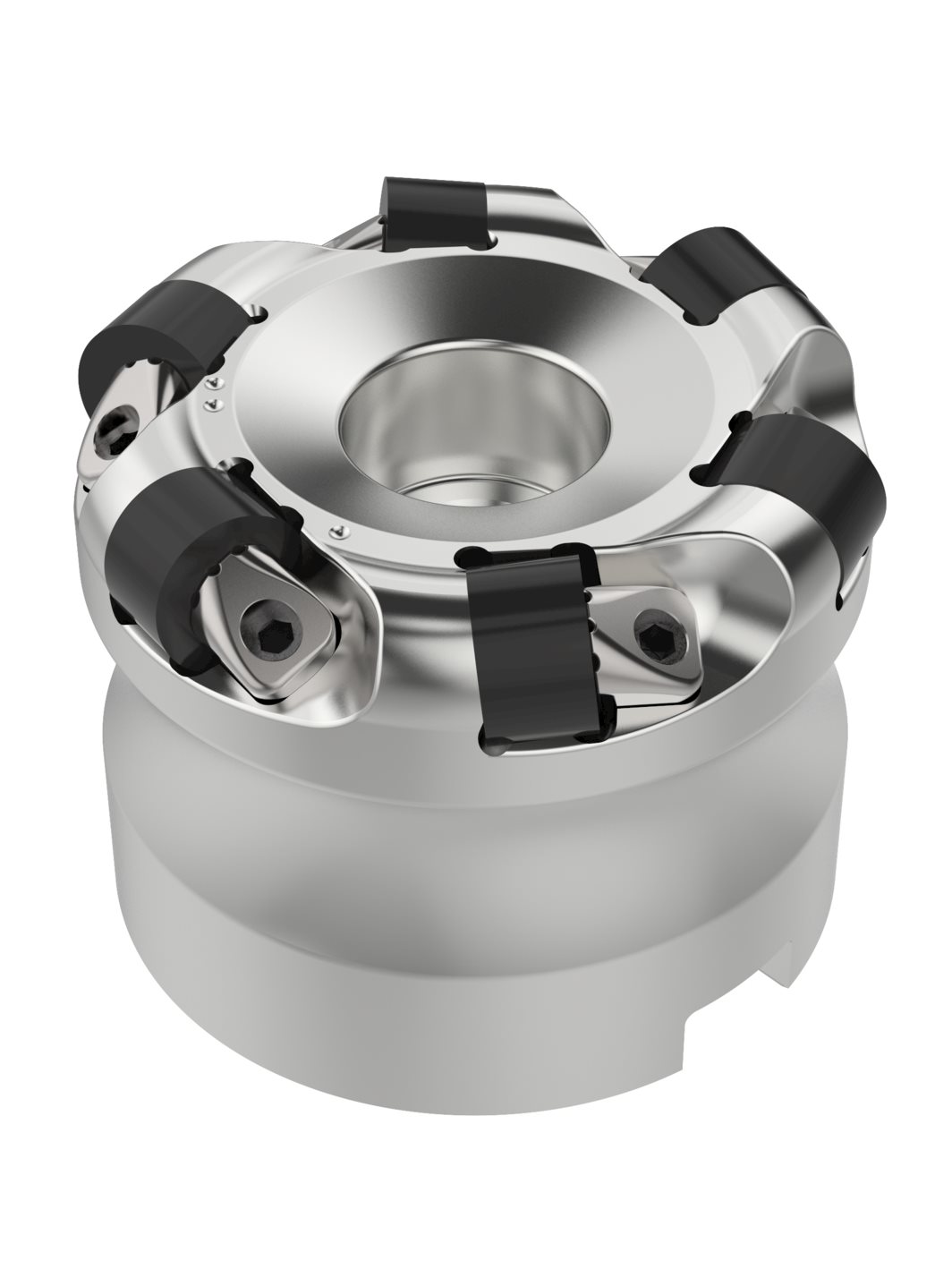

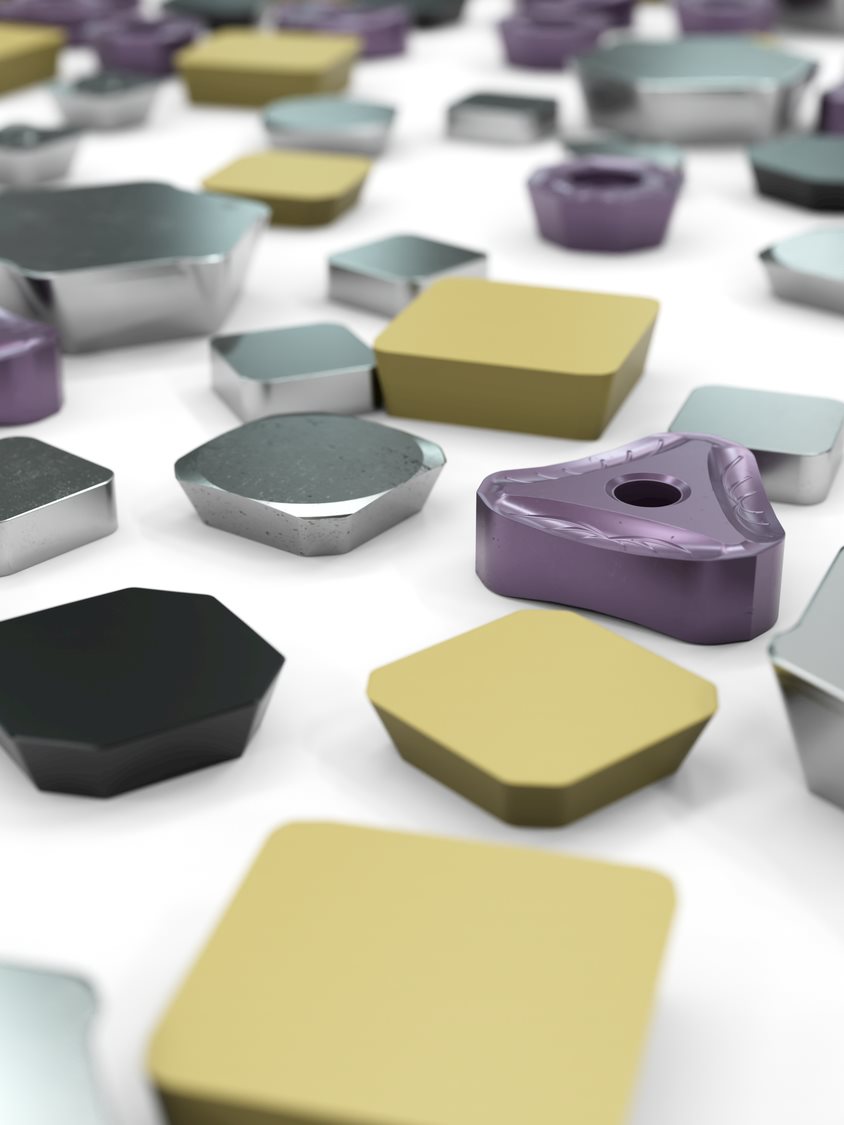

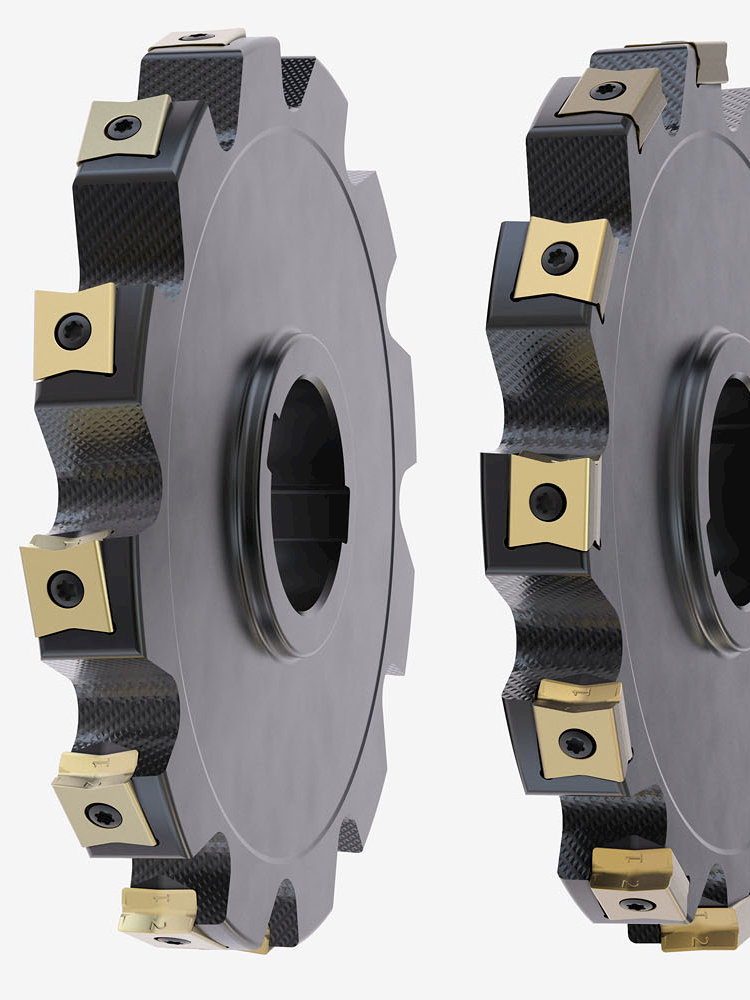

Discover the High Feed SP10 inserts range

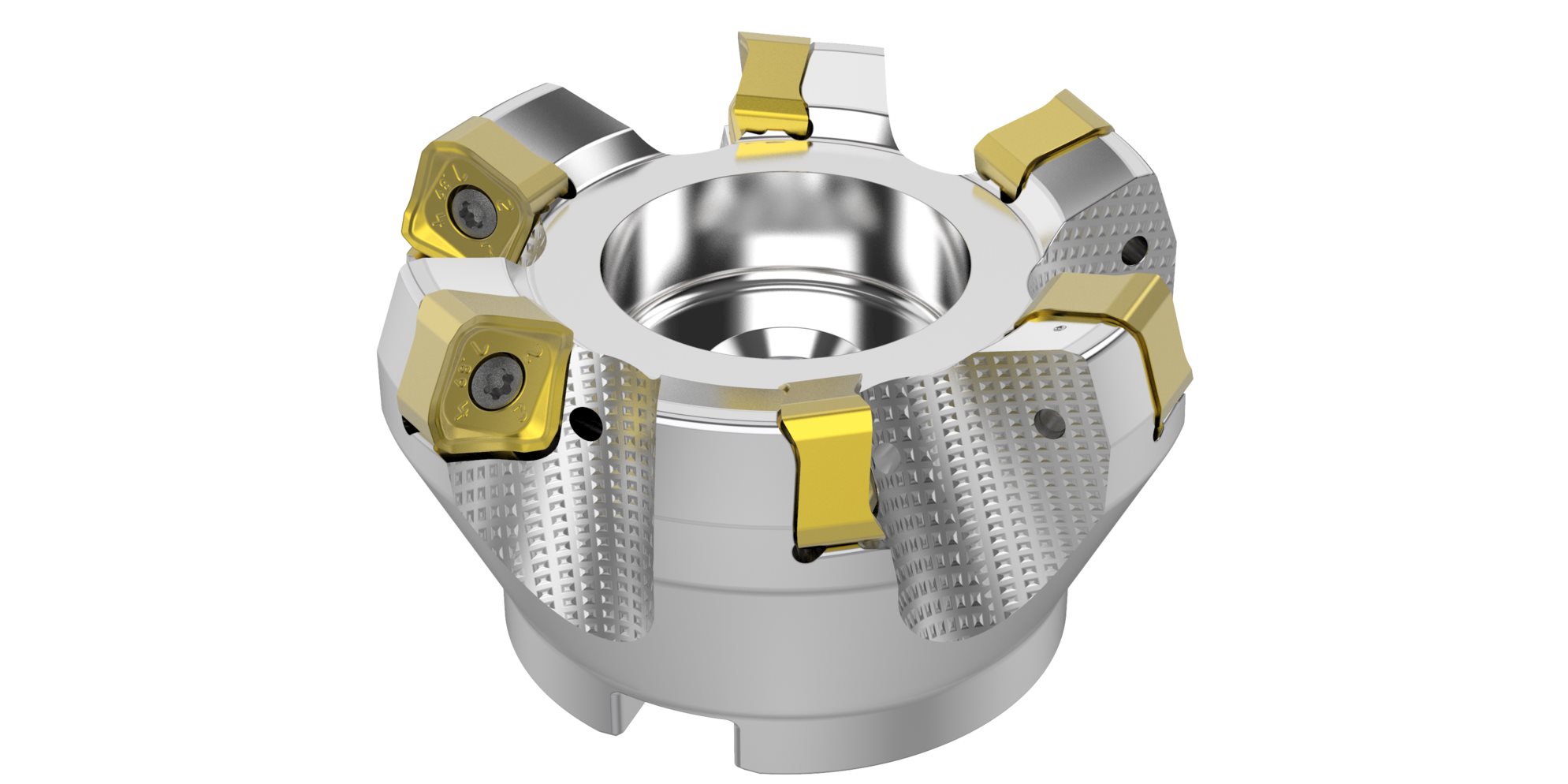

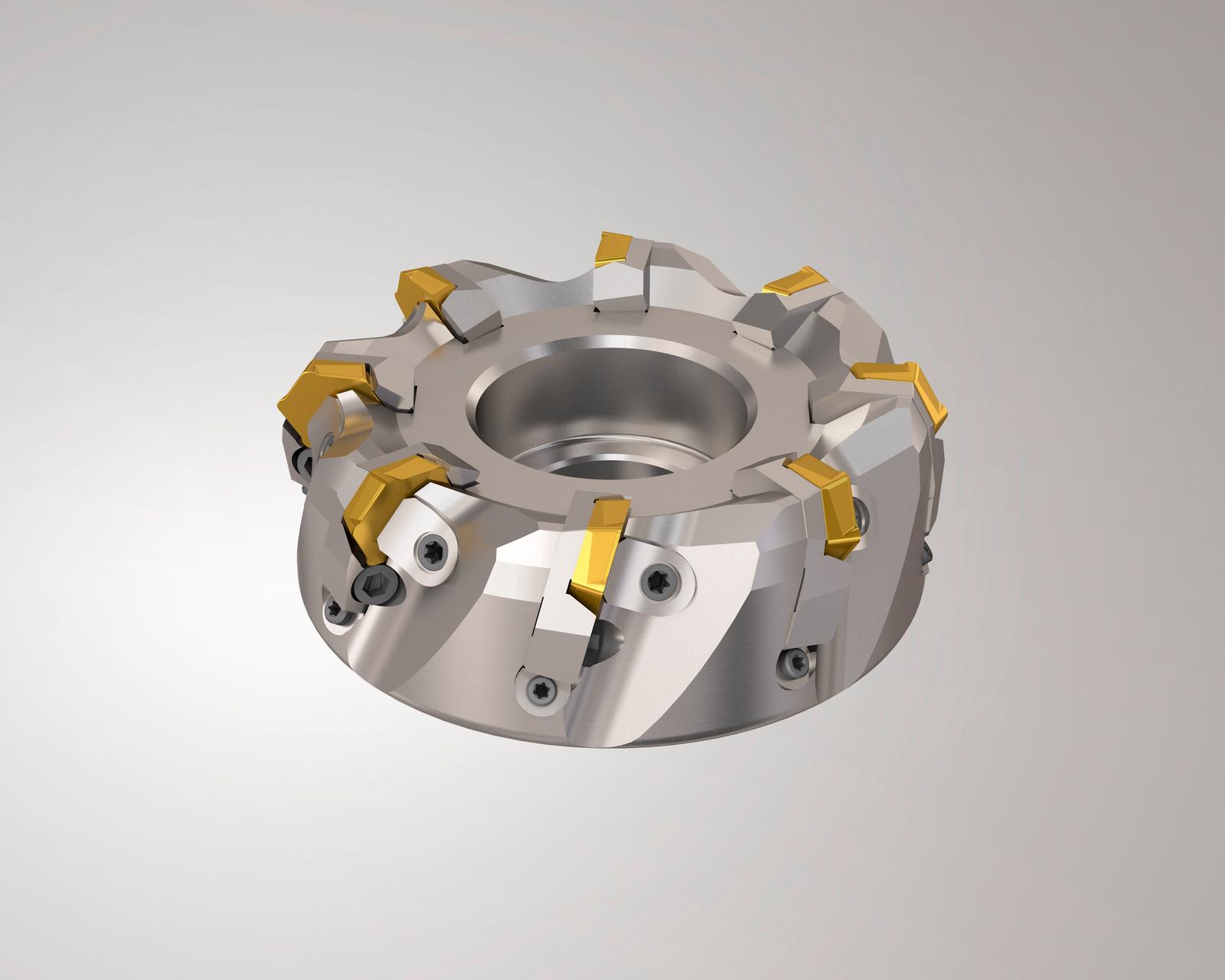

Discover the High Feed SP18 inserts range

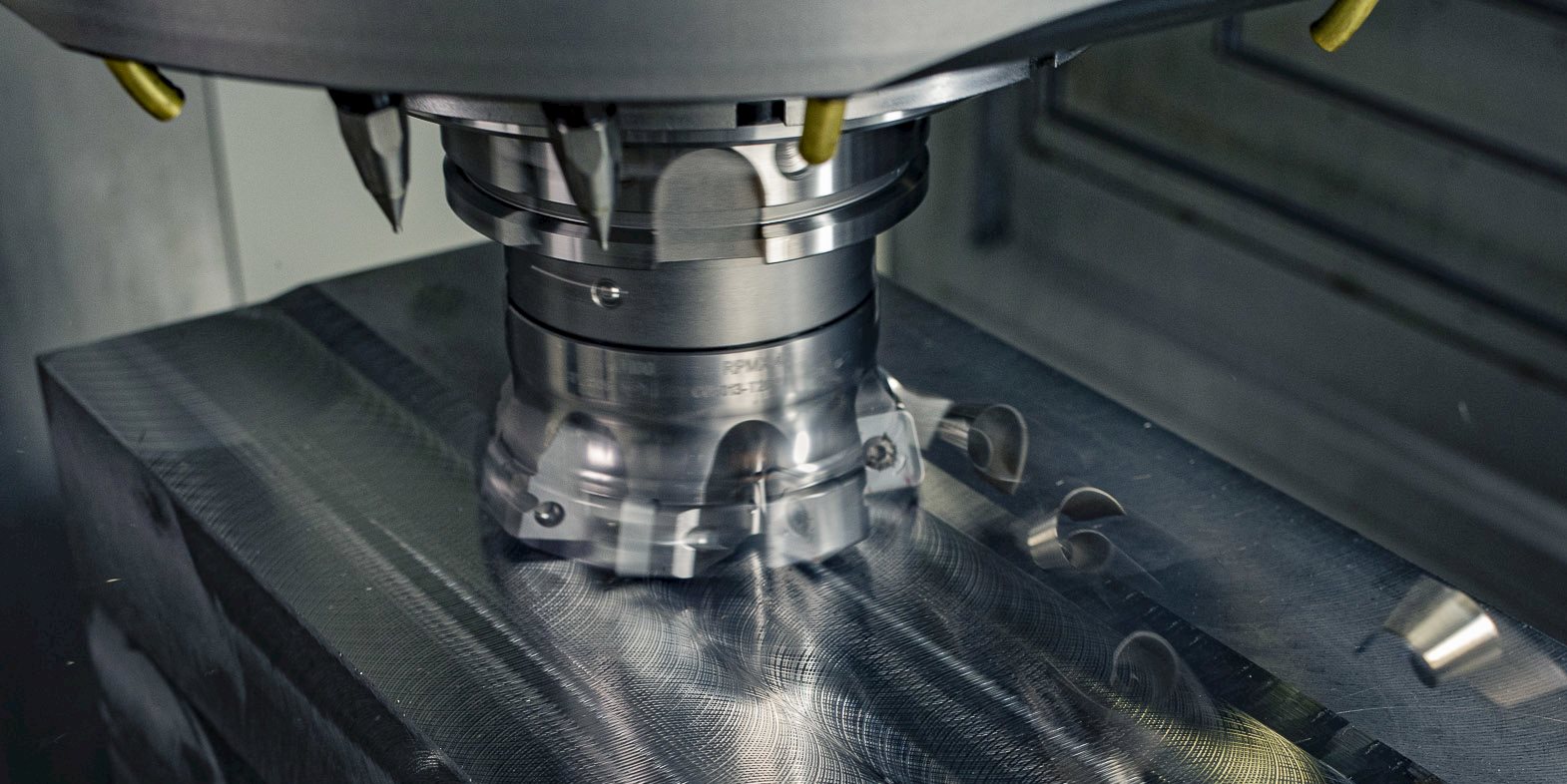

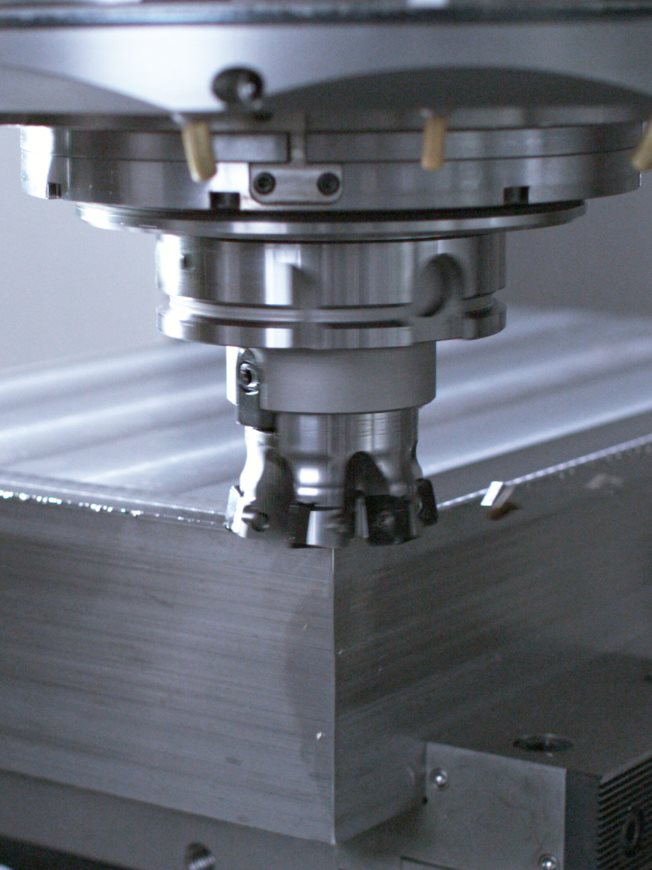

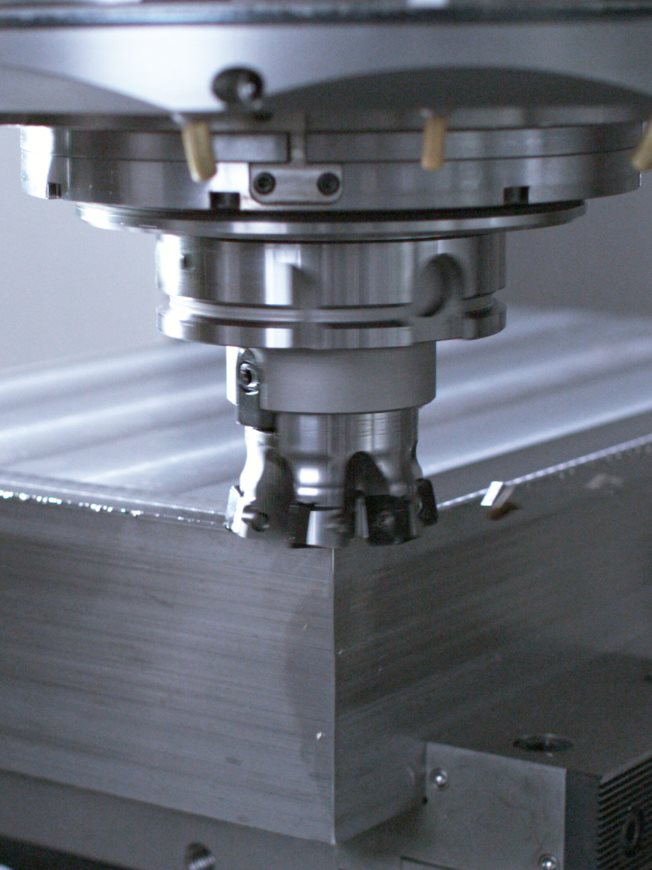

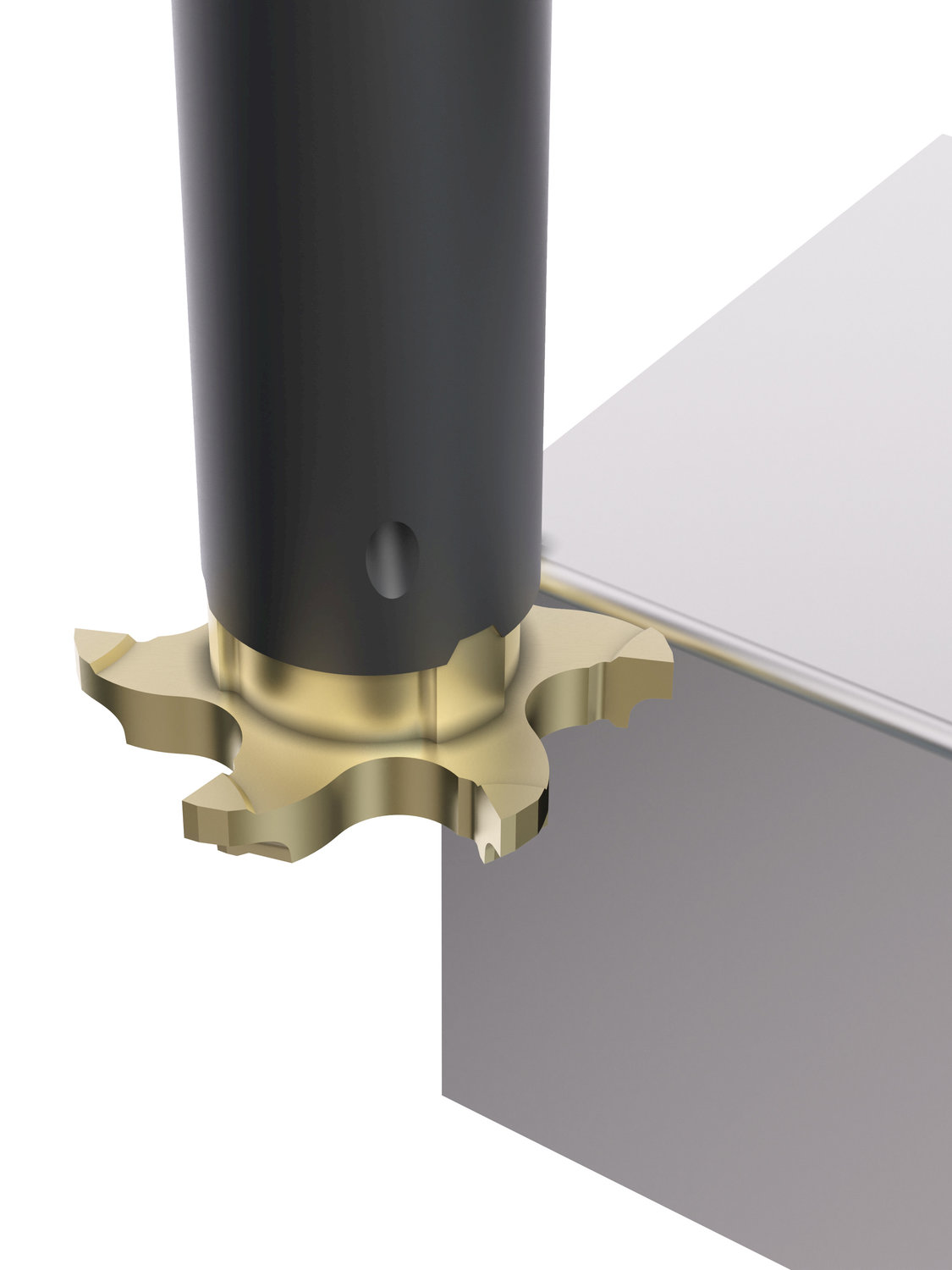

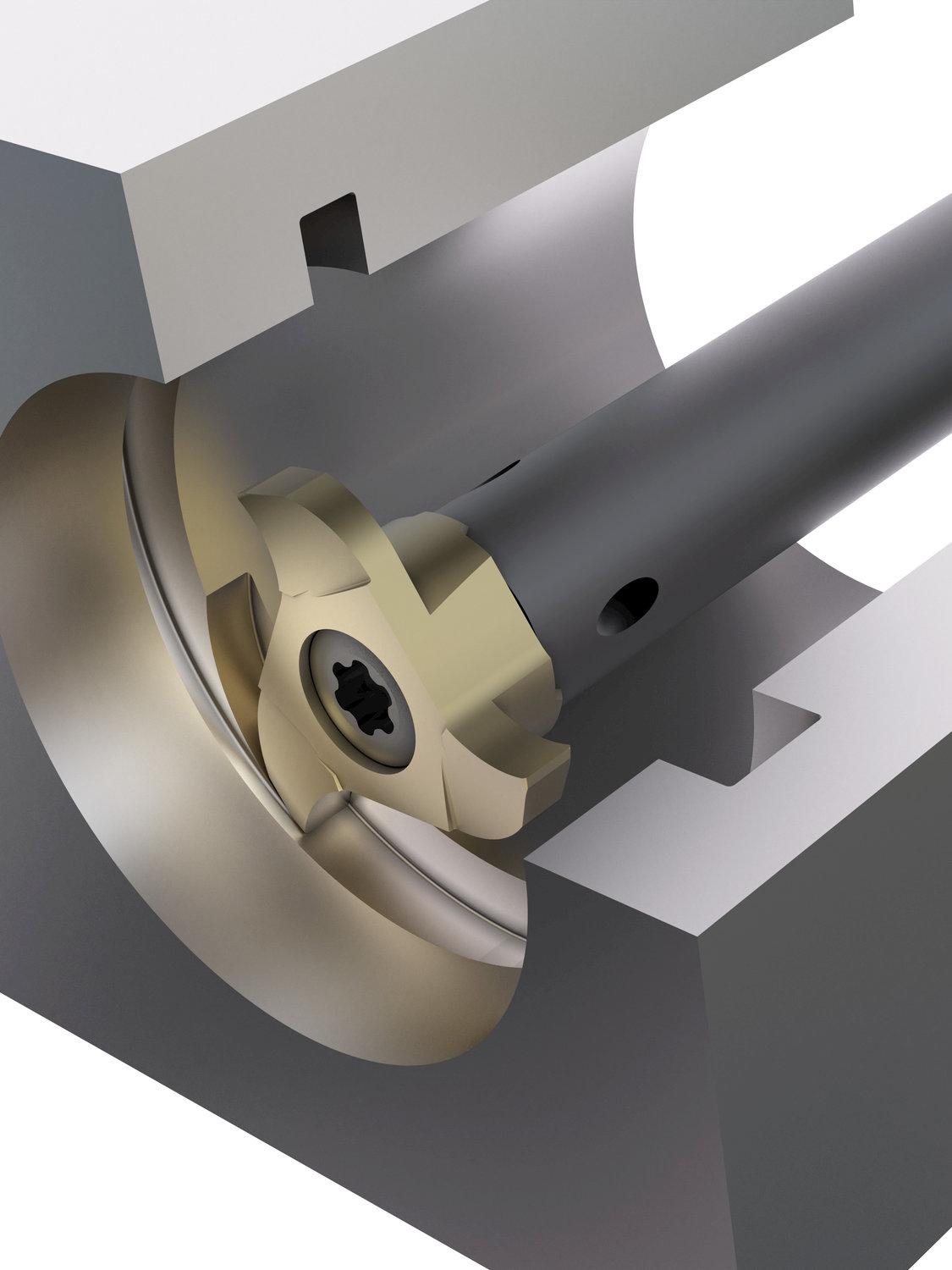

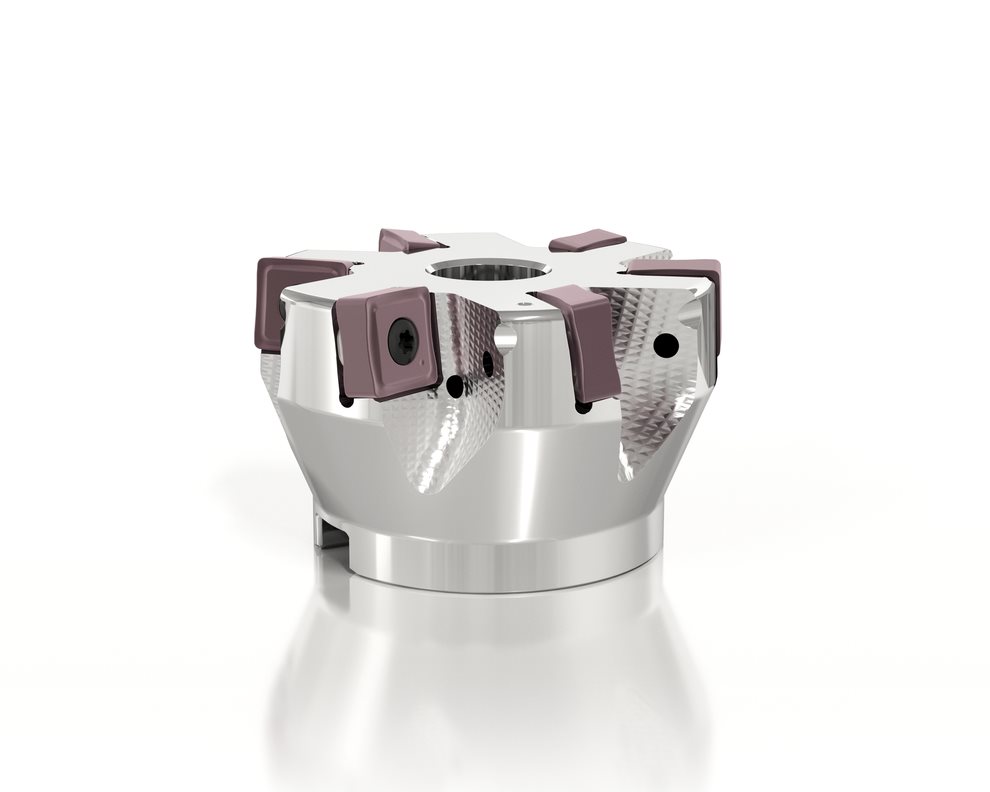

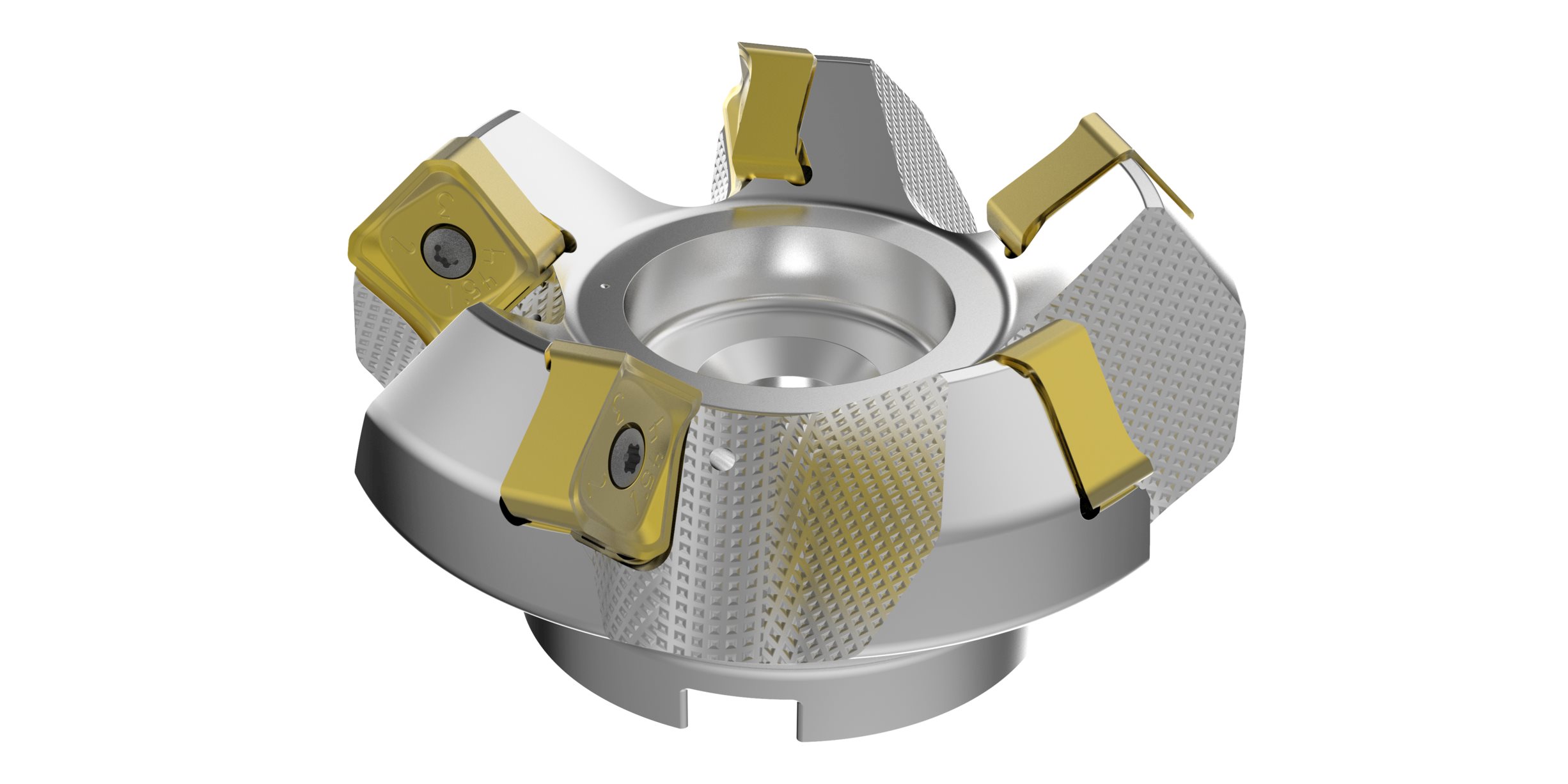

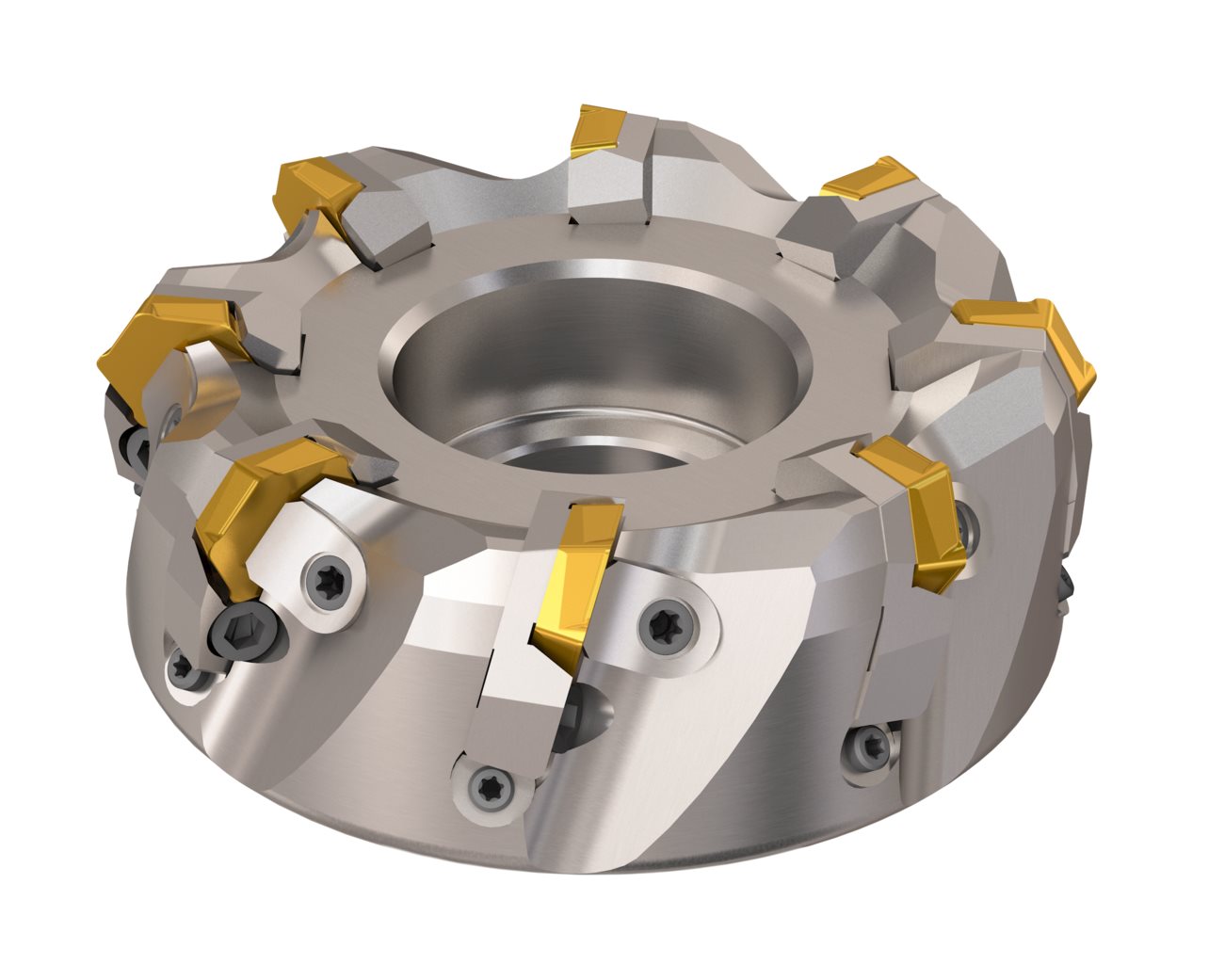

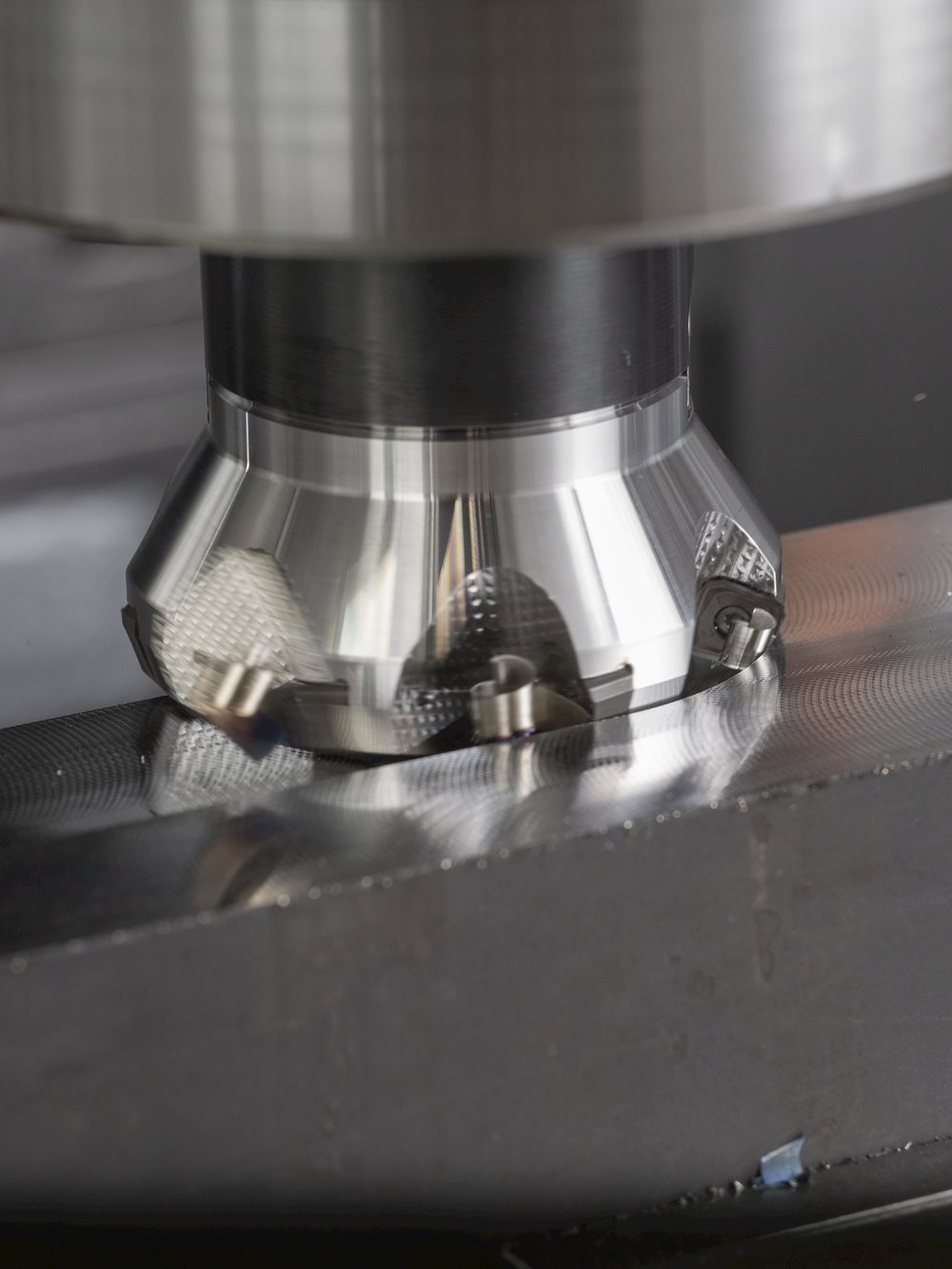

Challenging materials like tough steels, stainless steels, superalloys and titanium are hard to machine, causing built-up or notched insert edges that lead to broken inserts, machine downtime and increased tooling costs. Stand up to the tough stuff with the Seco High Feed SP that lets you mill ISO P, M and S materials effectively while you increase material removal rates and extend tool life.

Your challenge:

Prematurely worn and broken milling inserts add time and cost when you mill challenging materials like steels, stainless steels, superalloys and titanium.

The Seco solution:

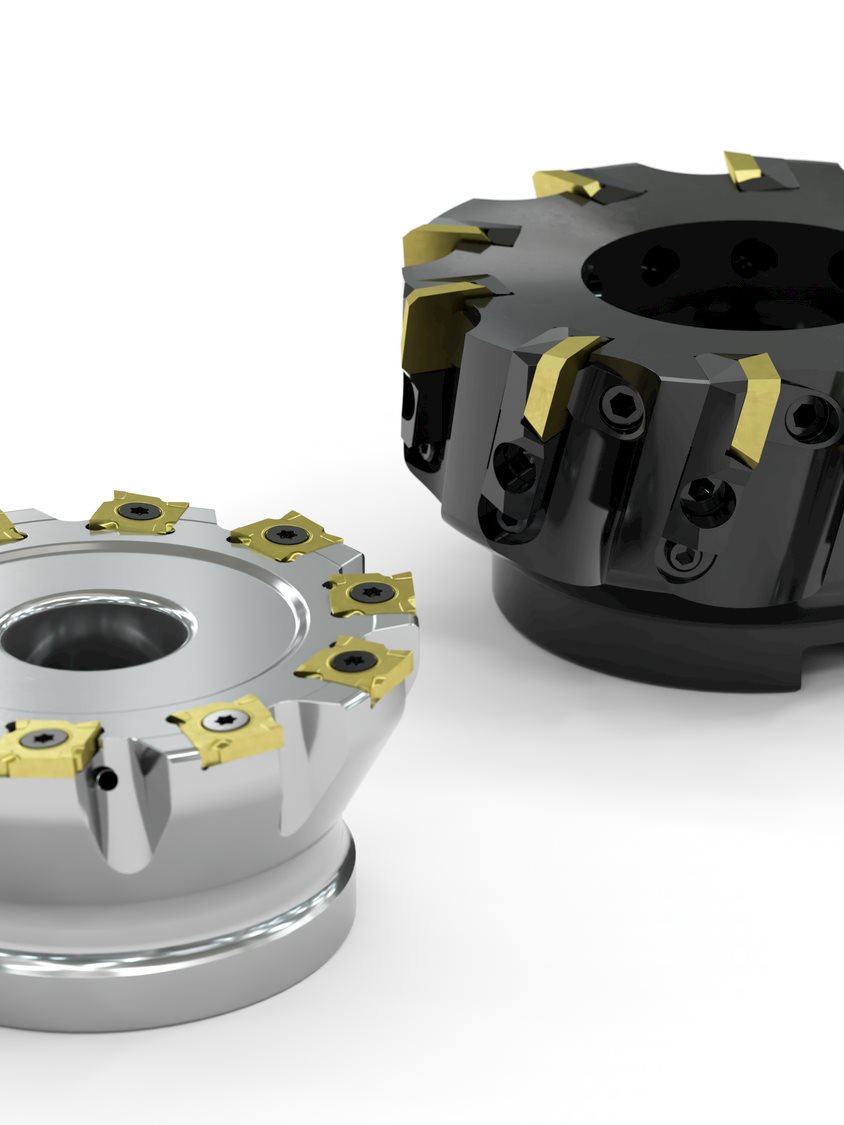

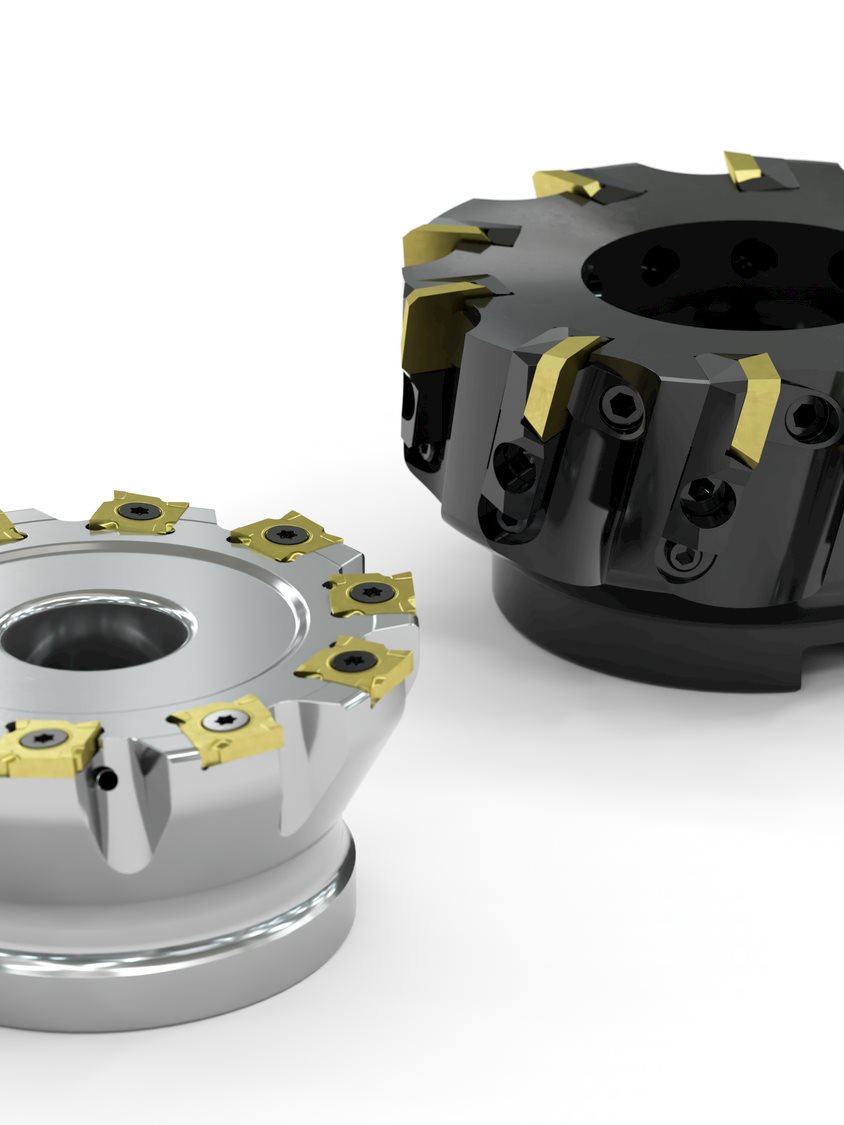

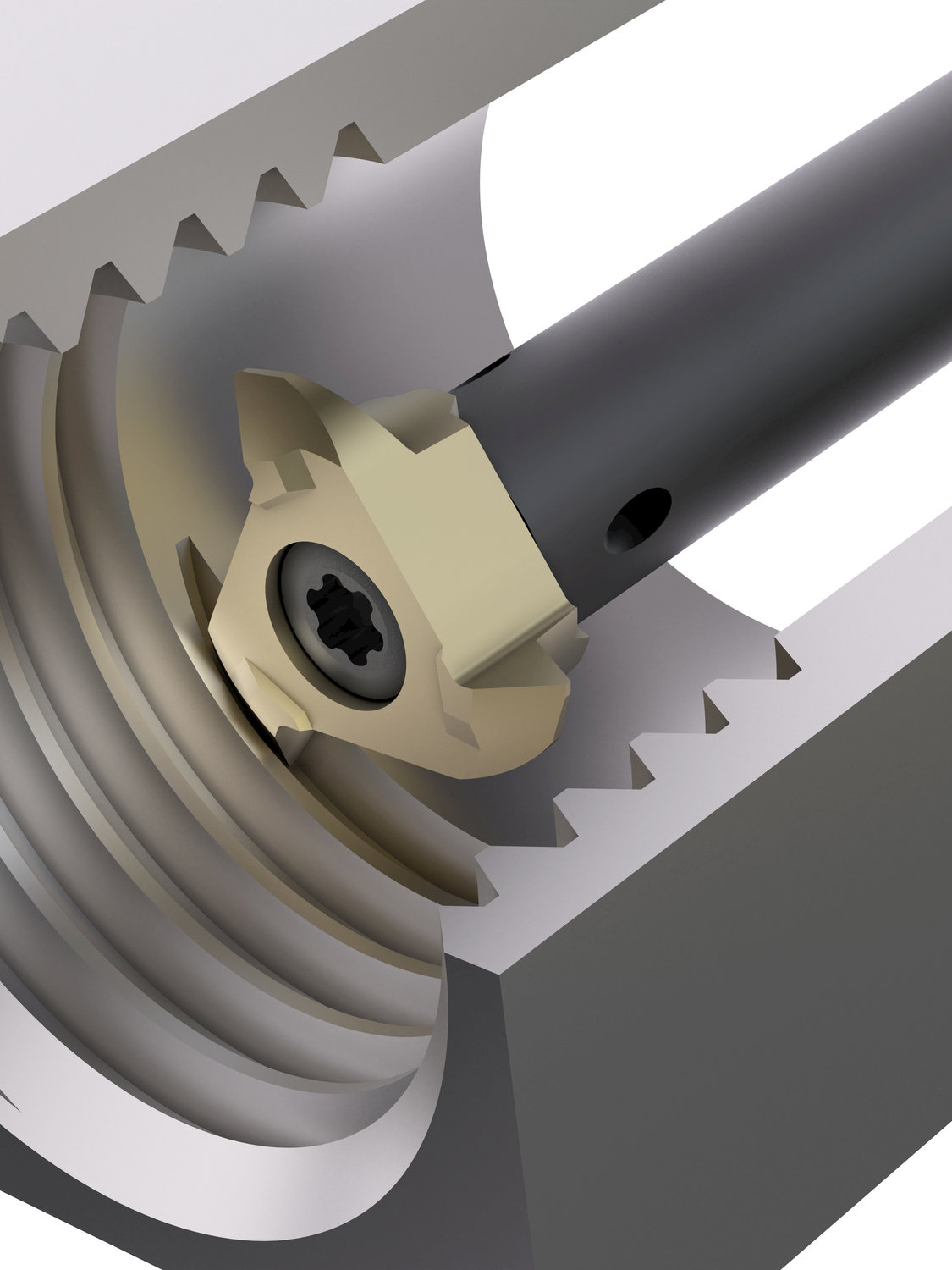

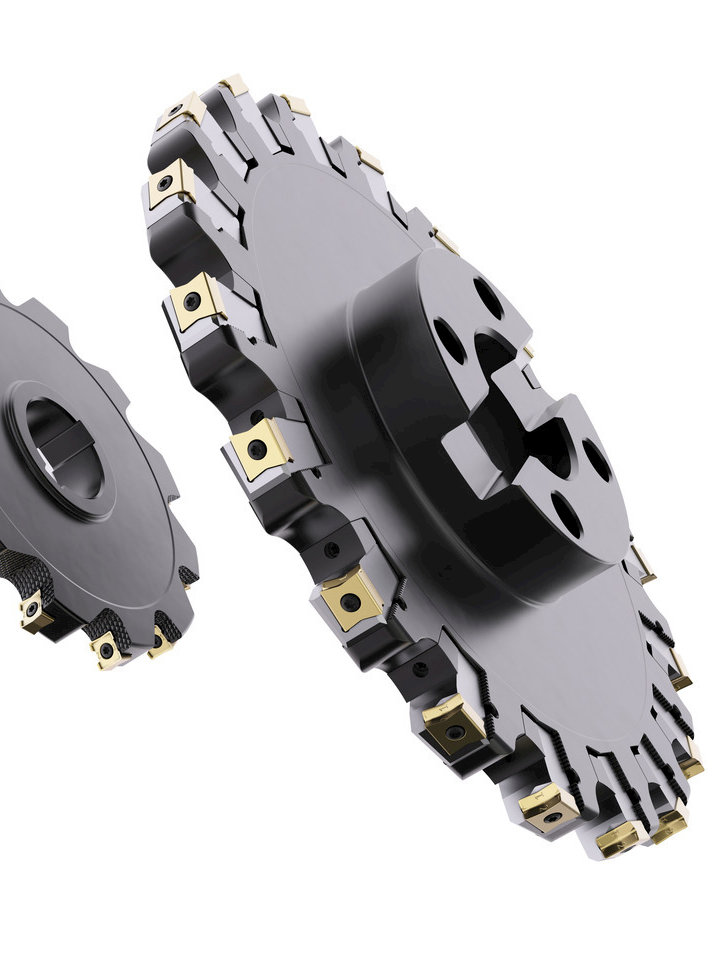

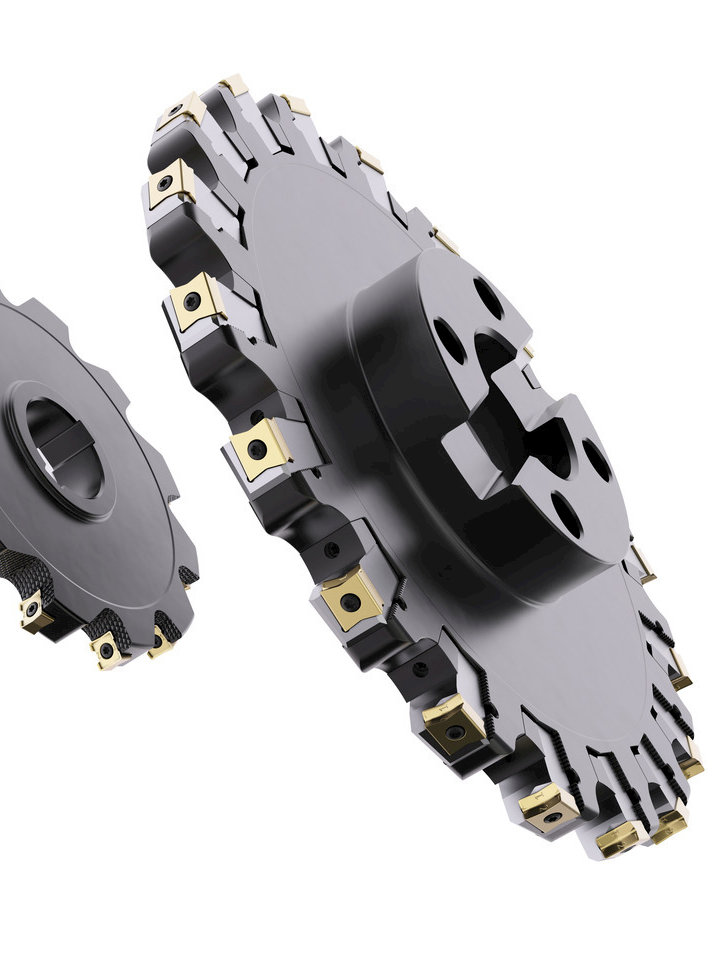

With a combination of dedicated cutting geometries and insert grades as well as optimized lead angles, the Seco High Feed SP increases material removal rates, maximizes chip evacuation and helps prolong tool life when milling ISO P, M and S materials, for an exceptional price/performance ratio.

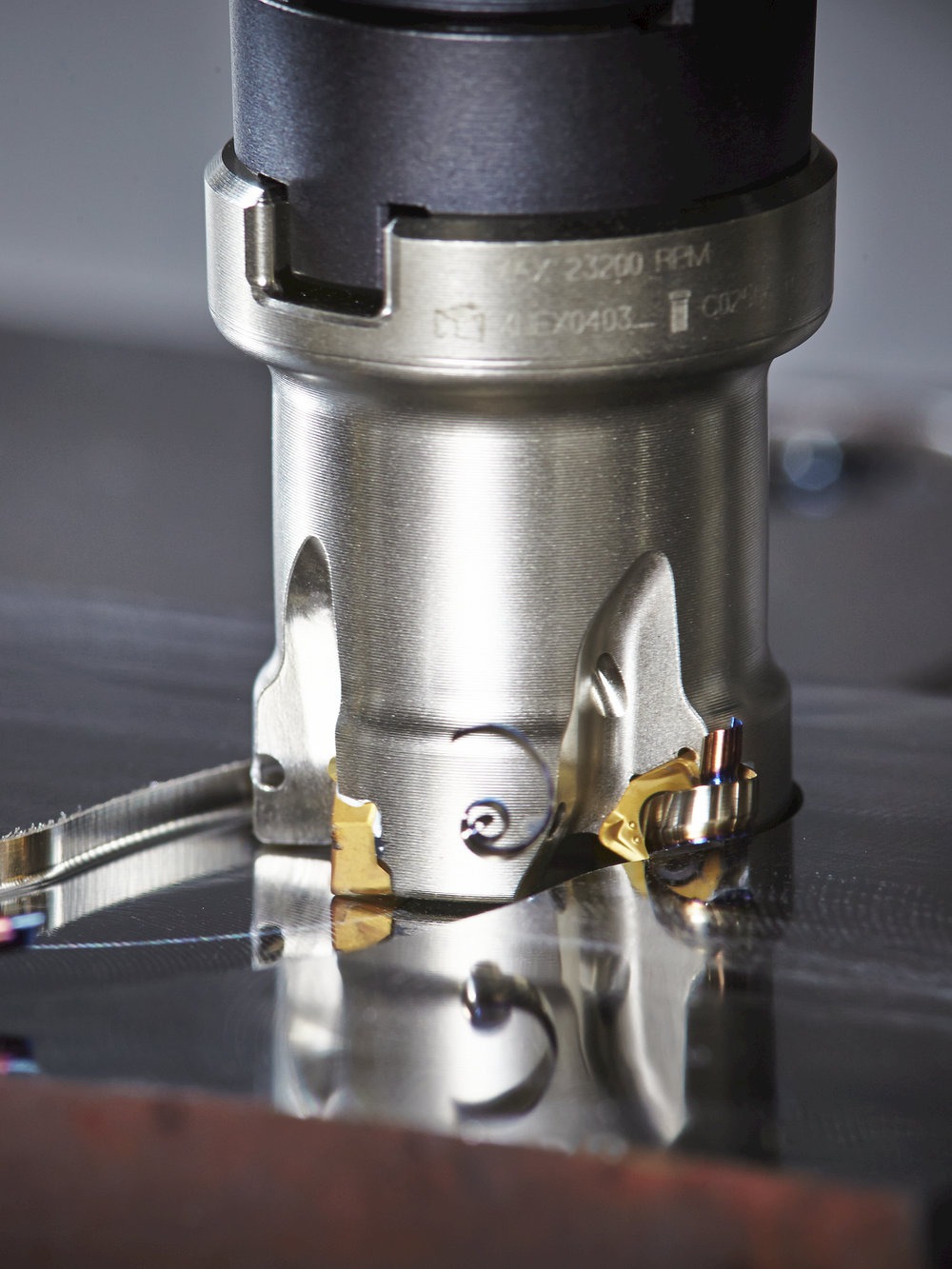

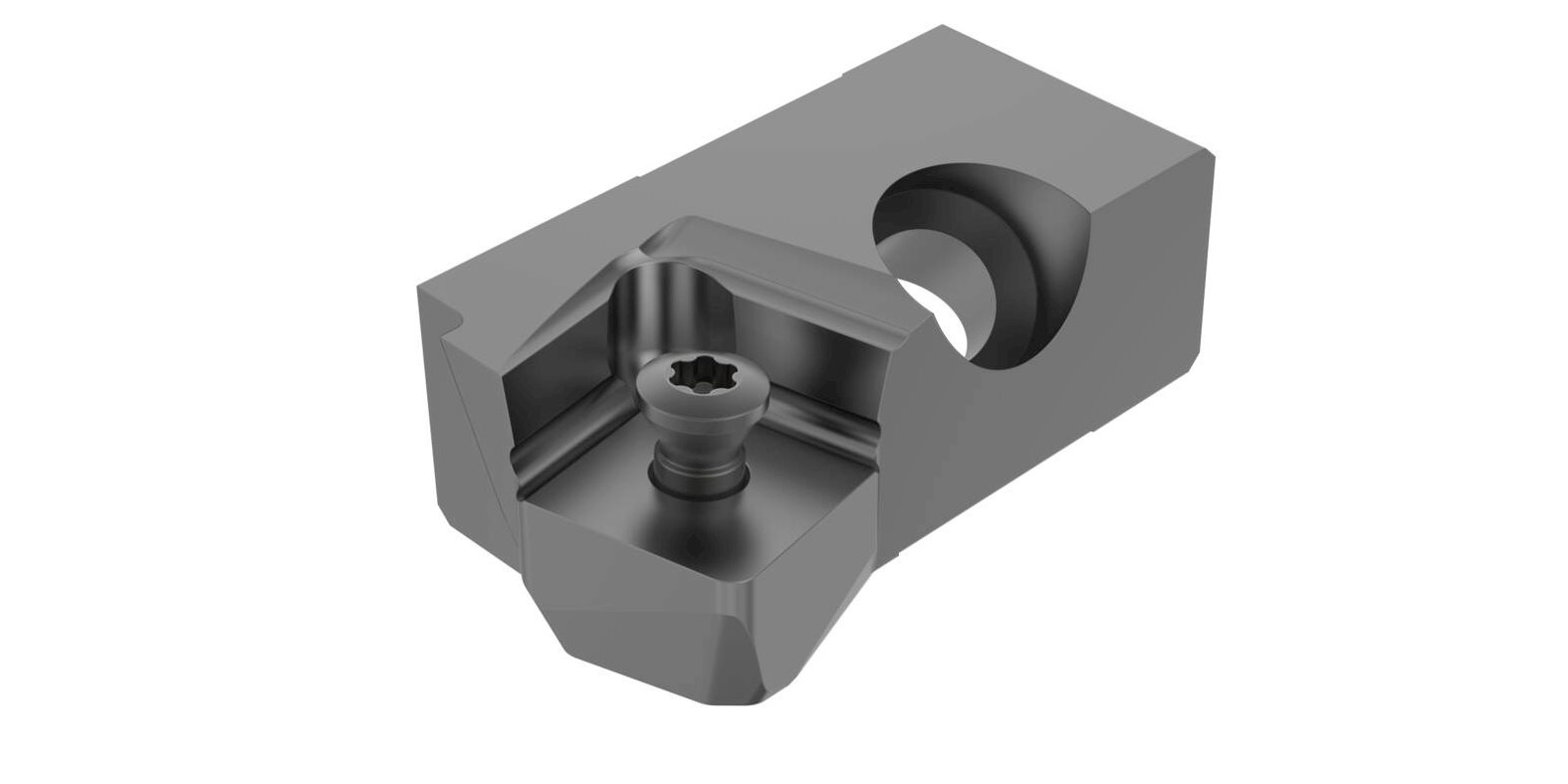

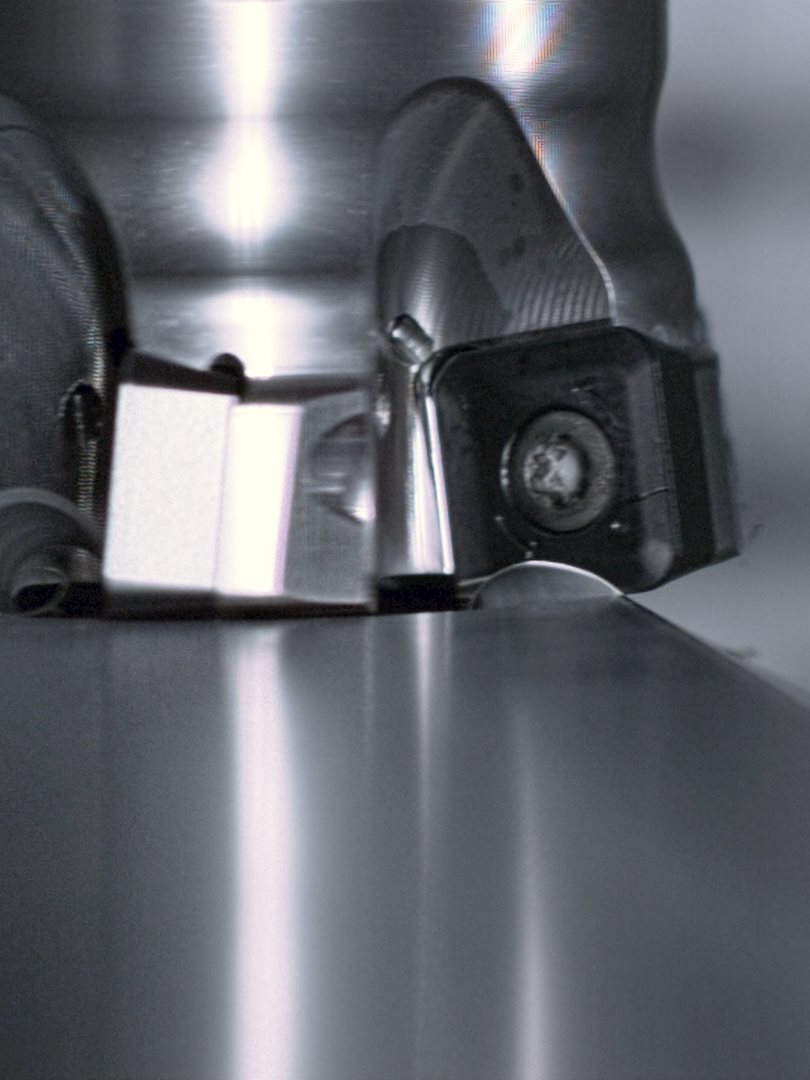

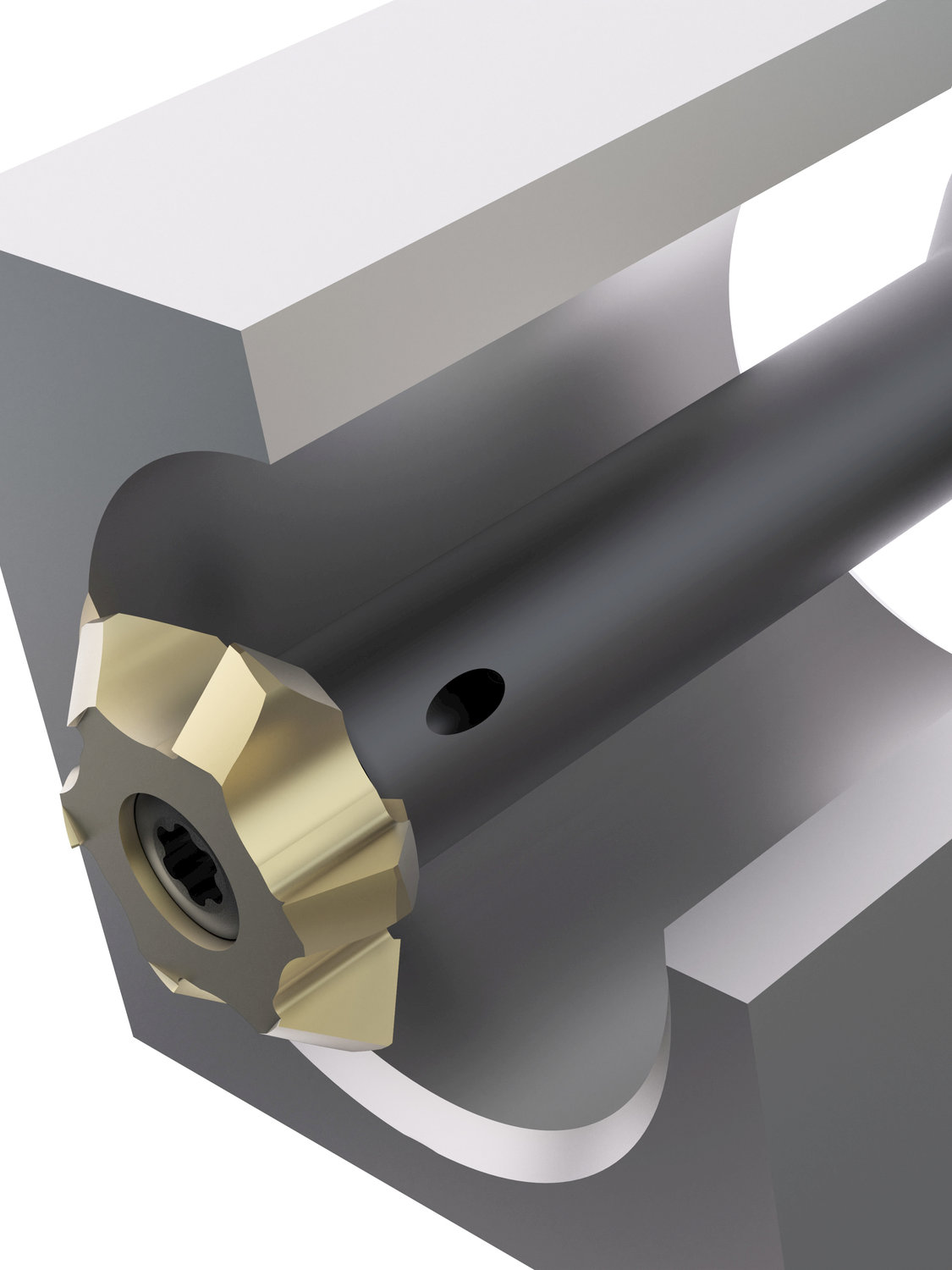

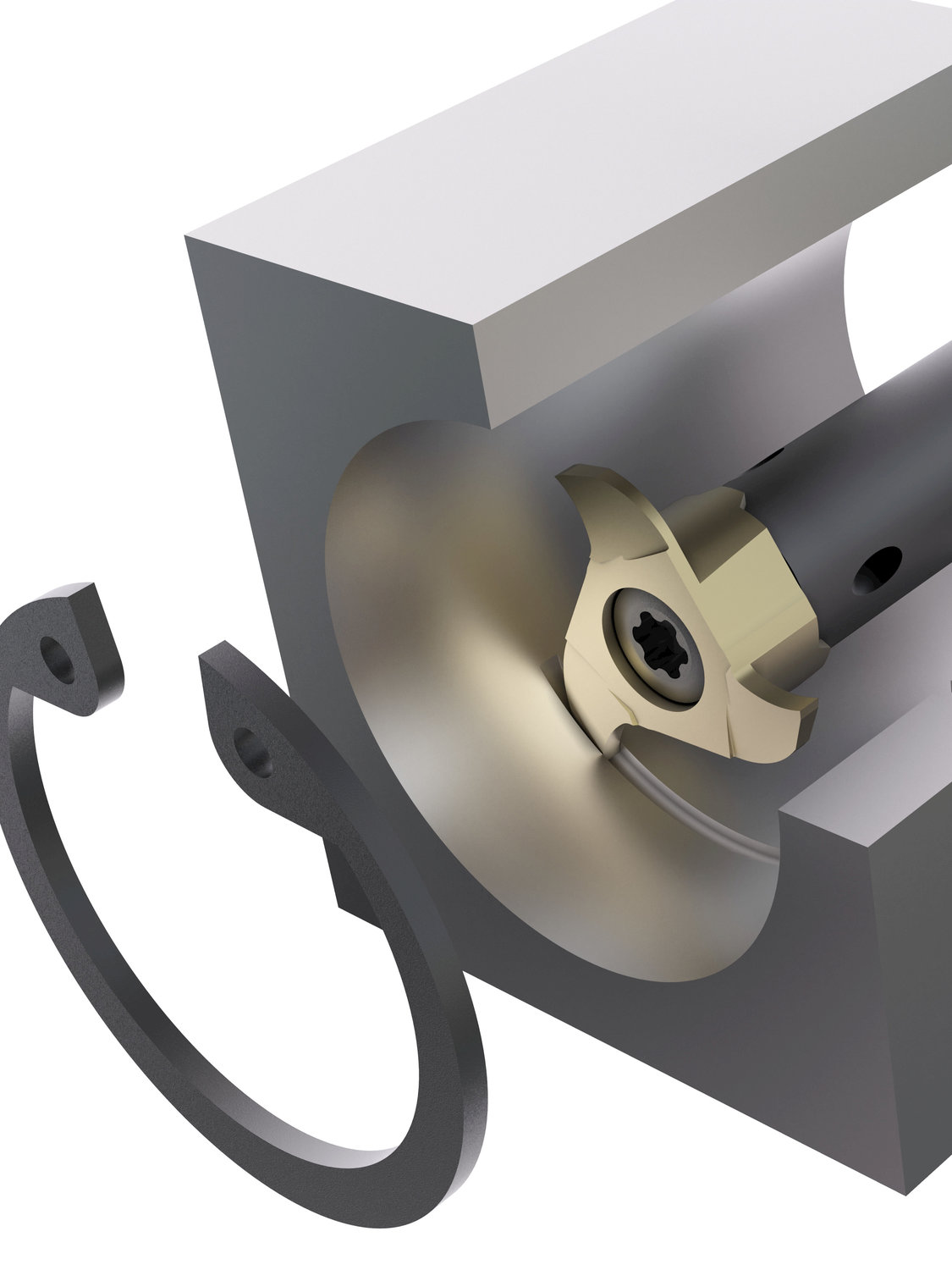

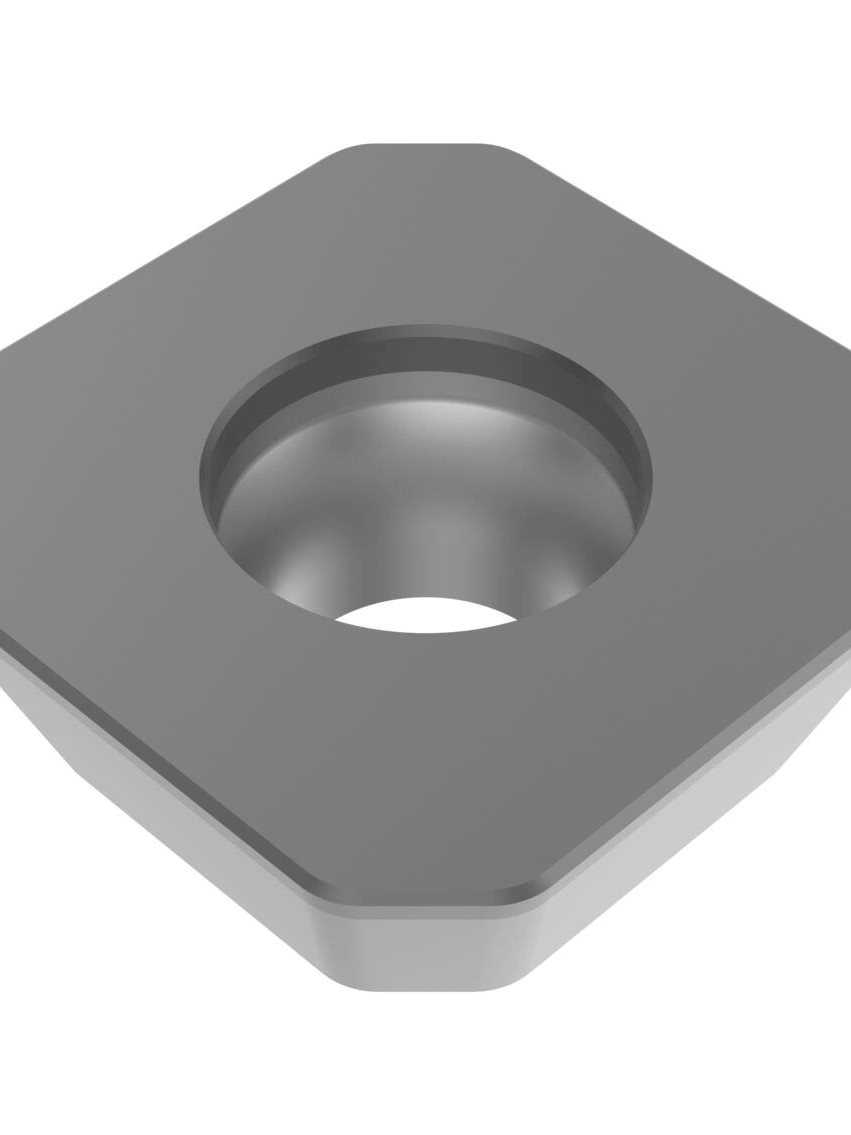

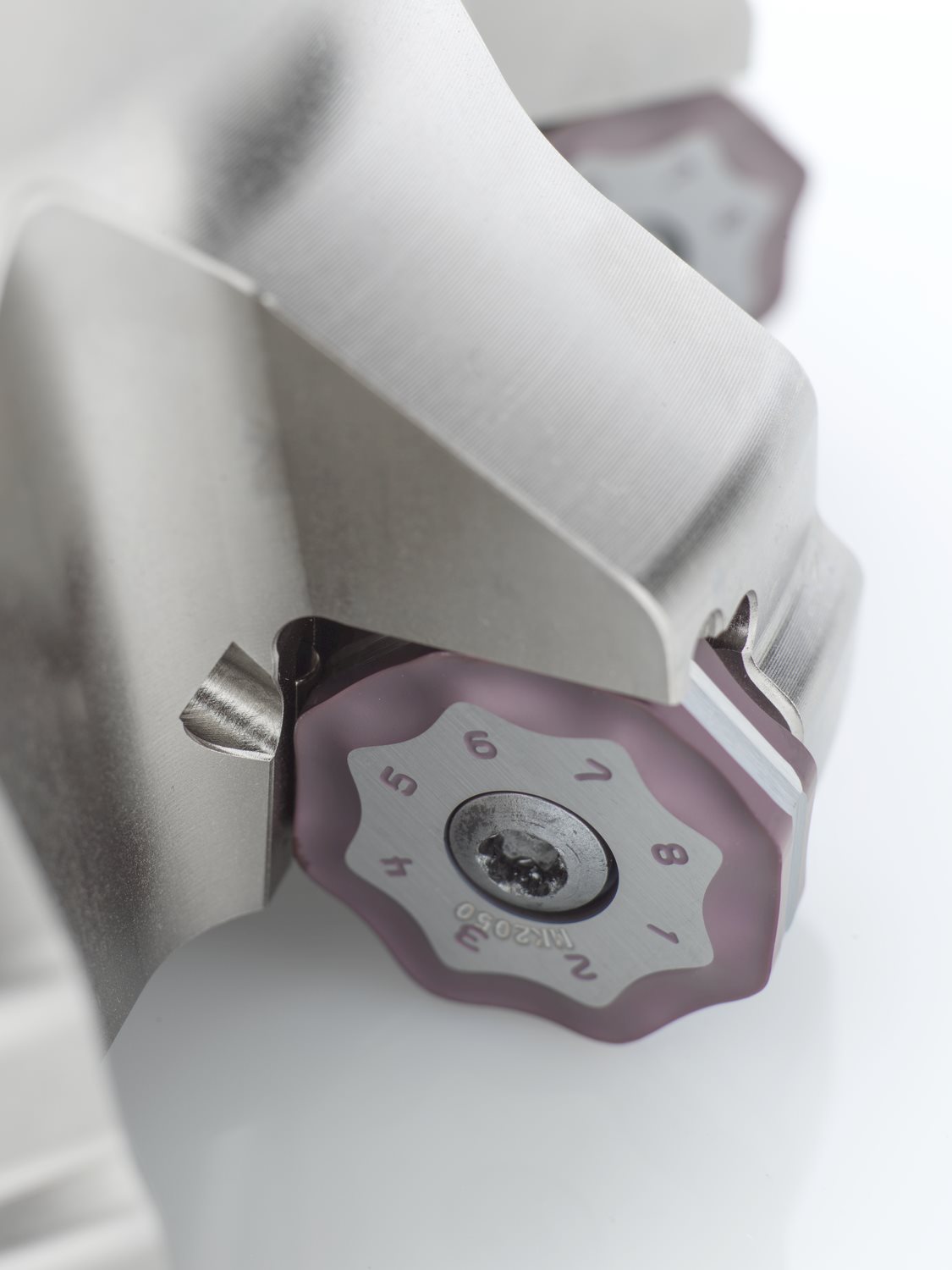

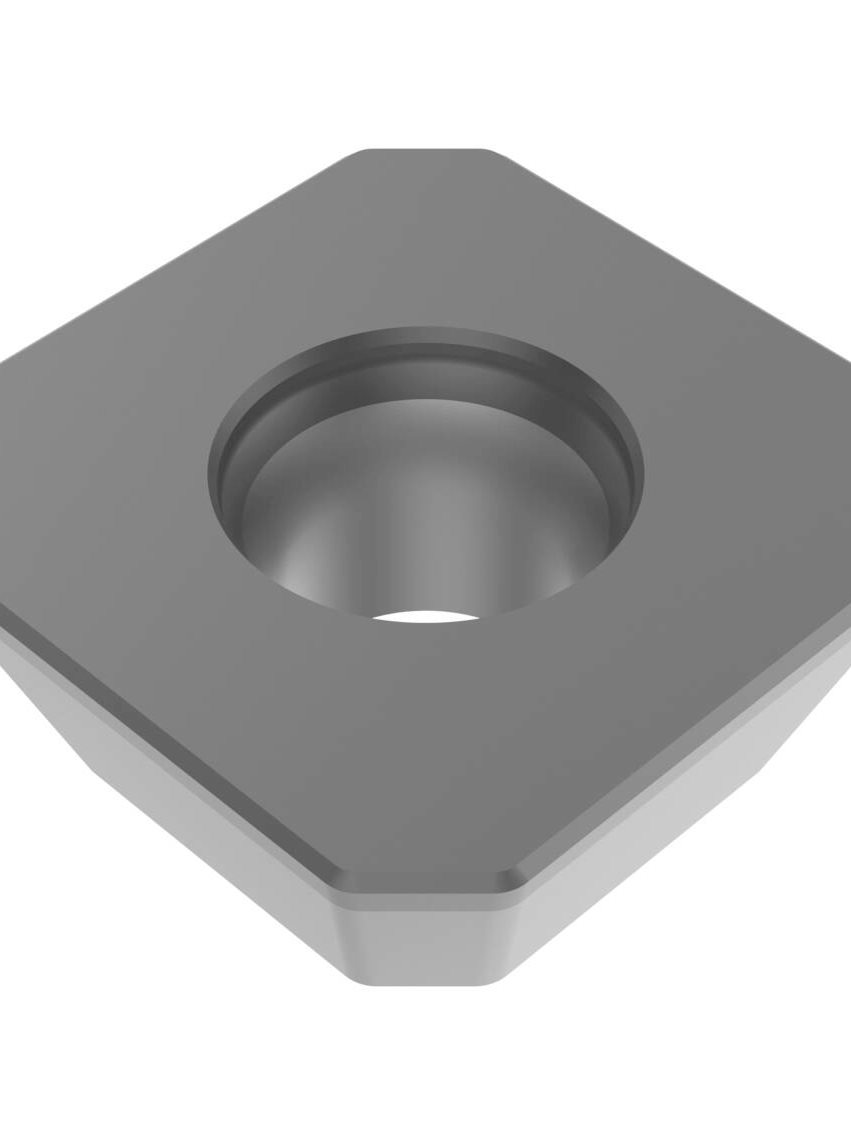

One incorrectly indexed milling cutter insert can bring your machining operations to a standstill, cost you valuable time and potentially force you to scrap parts. Make sure that doesn’t happen. The Seco High Feed SP features special designs, sizes and shapes to ensure ease of use and foolproof insert indexing.

Your challenge:

Inexperienced operators index milling inserts improperly, which causes unexpected machine downtime and production delays.

The Seco solution:

Designed for ease of use, Seco High Feed SP milling tools provide simple insert indexing and prevent operator mistakes through data matrix code scanning capability.

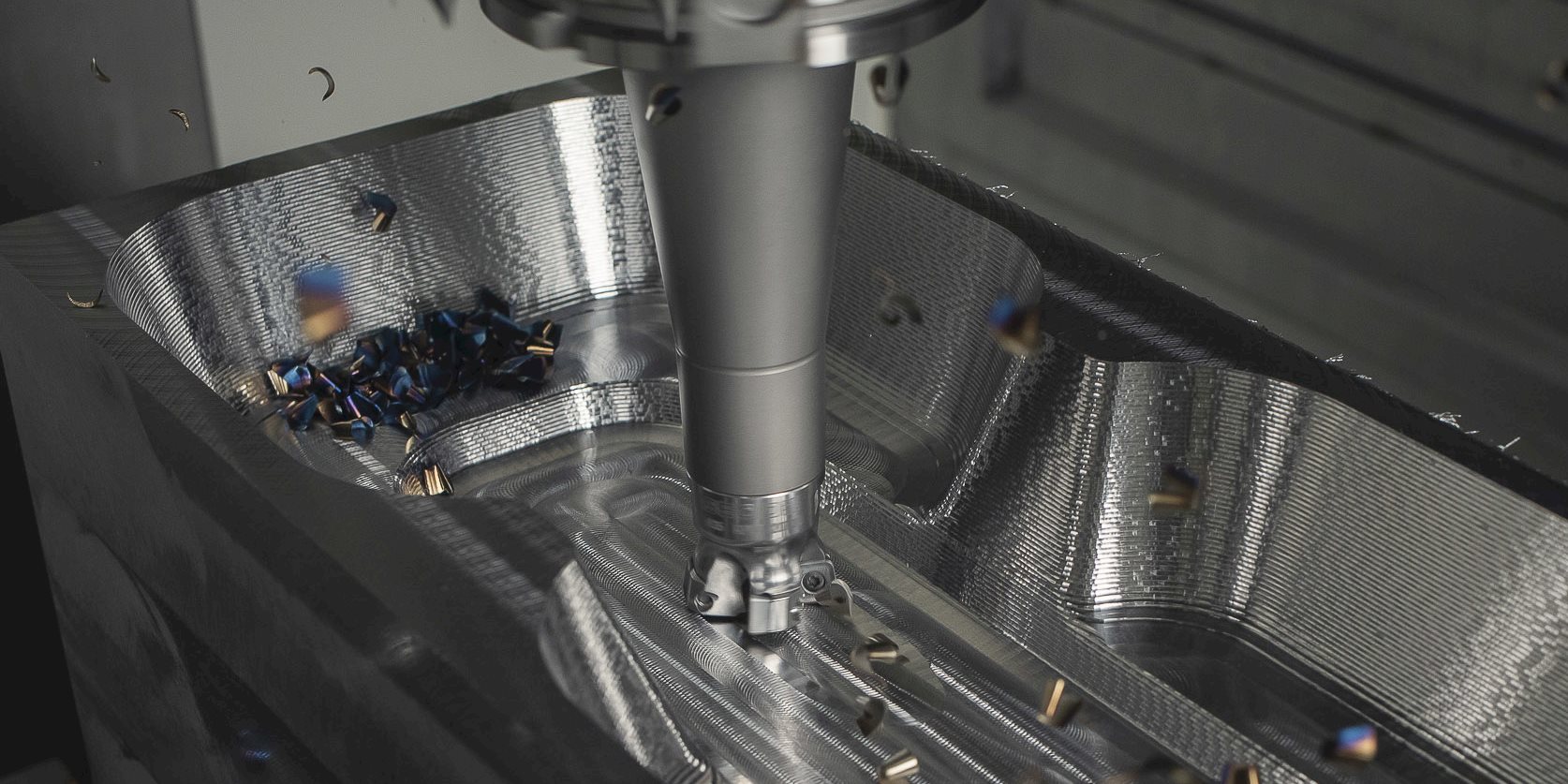

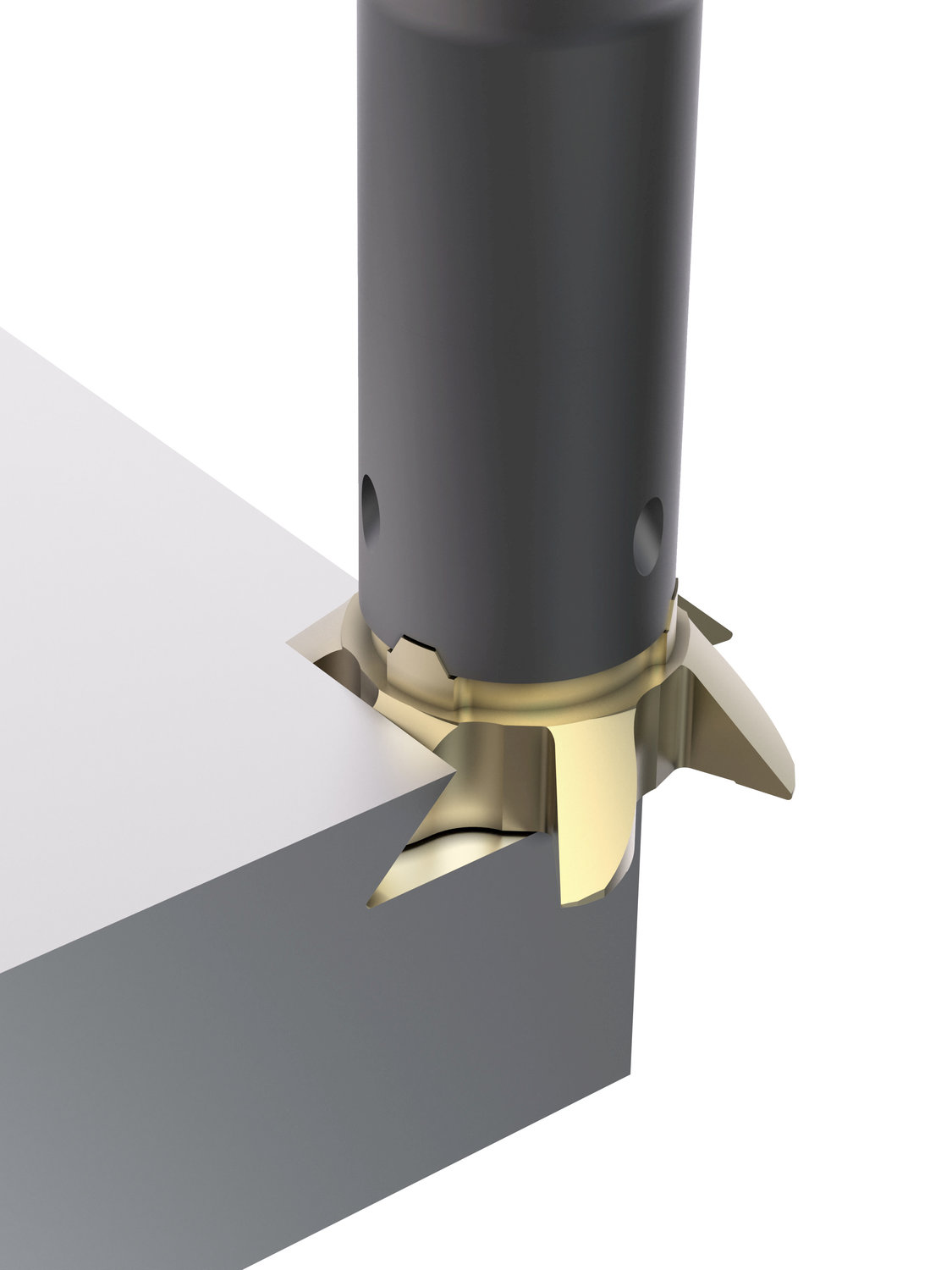

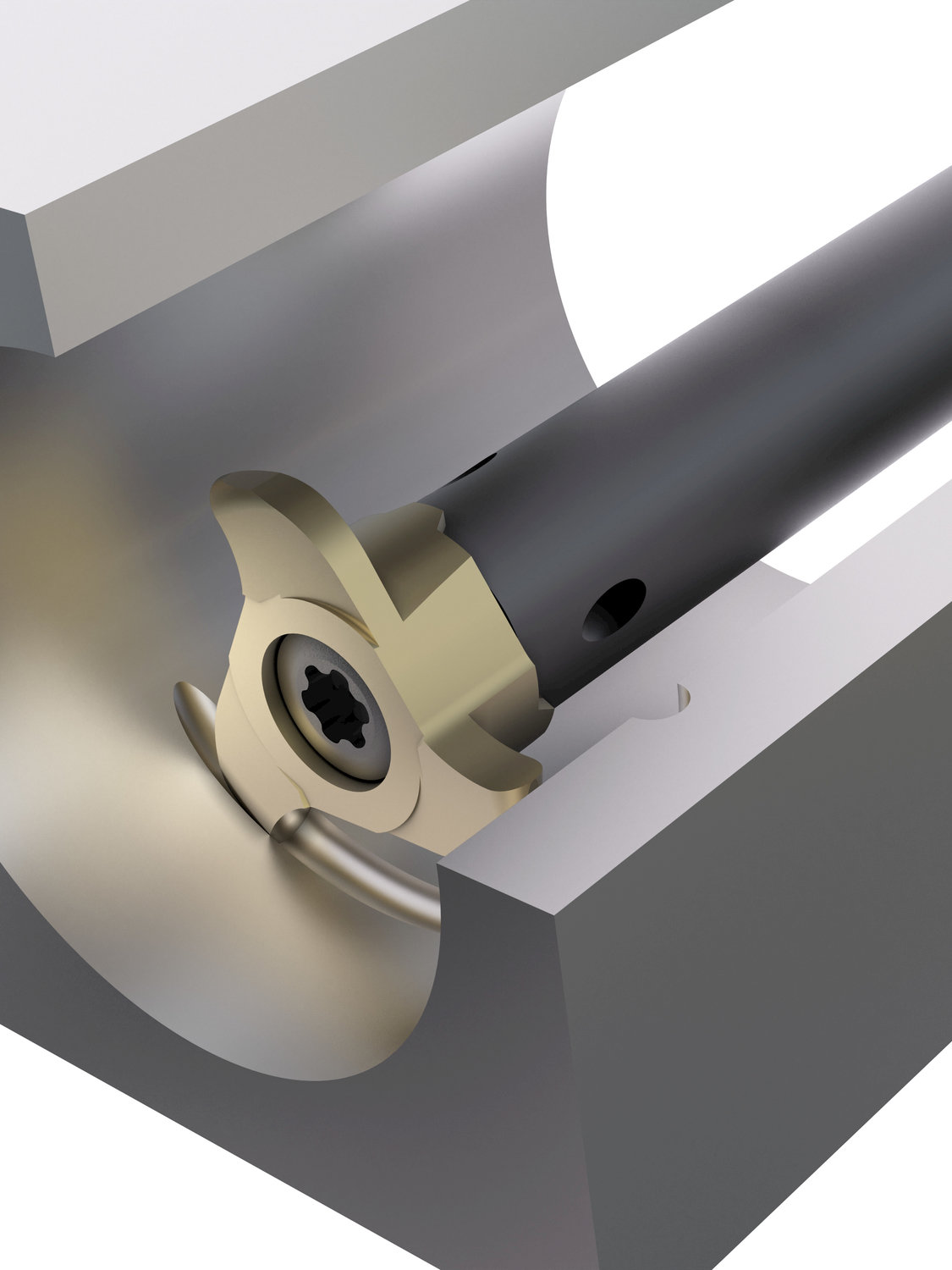

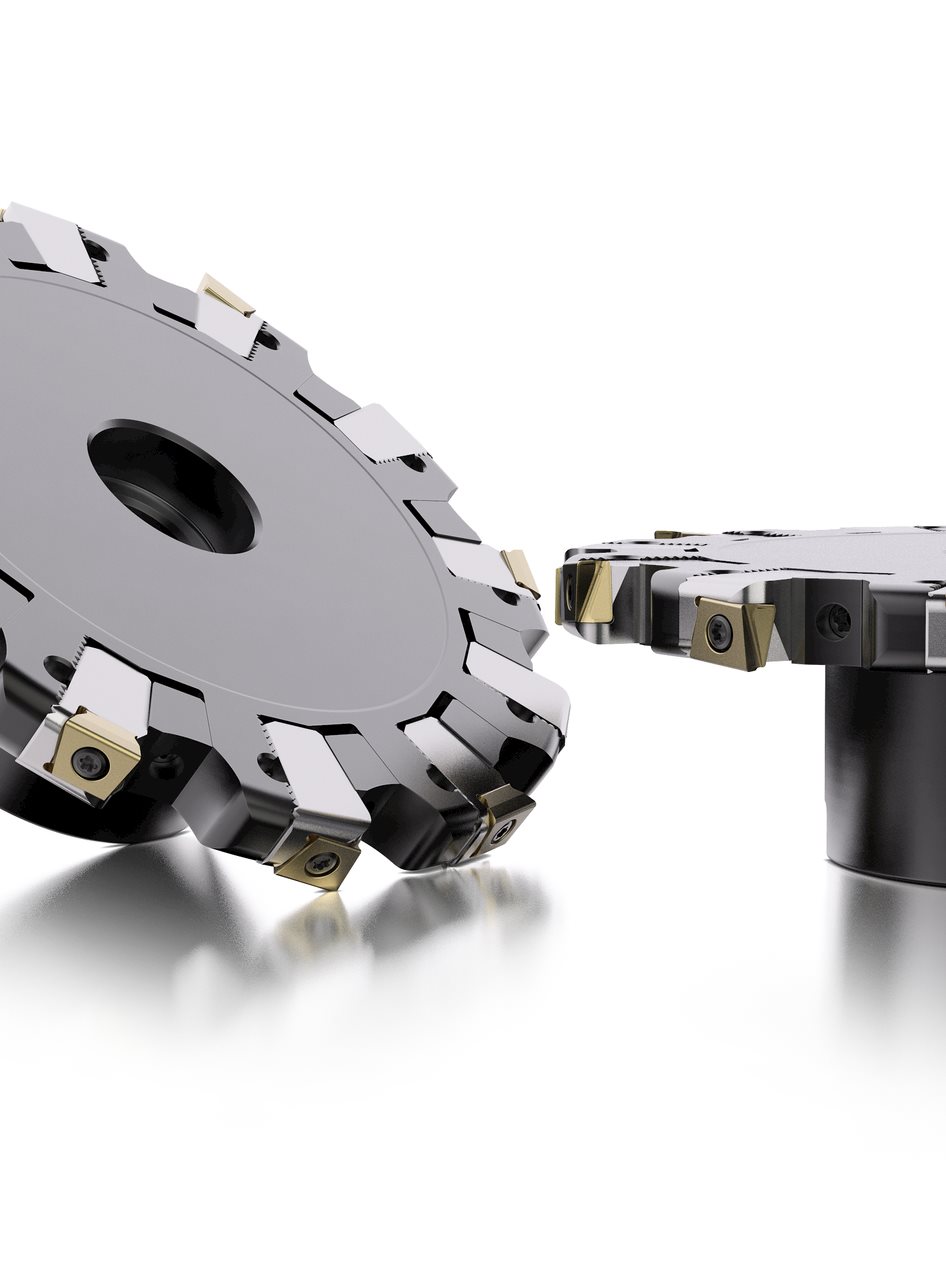

Whether you’re copy milling, ramping, pocketing, face milling or plunging, keep the same tool in your spindle for all your milling strategies with the Seco High Feed SP. This extremely versatile milling solution not only handles all your milling operations, but it also optimizes cutting performance for tough ISO P, M and S part materials.

Your challenge:

Various milling operations, especially in tough part materials, require switching to different tools for optimal machining performance.

The Seco solution:

With the versility to handle copy milling, ramping, pocketing, face milling and plunging, one High Feed SP optimizes all your high-feed milling operations while it provides peak performance in difficult-tomachine ISO P, M and S materials.

Discover the High Feed SP10 inserts range

Discover the High Feed SP18 inserts range

Contact Us

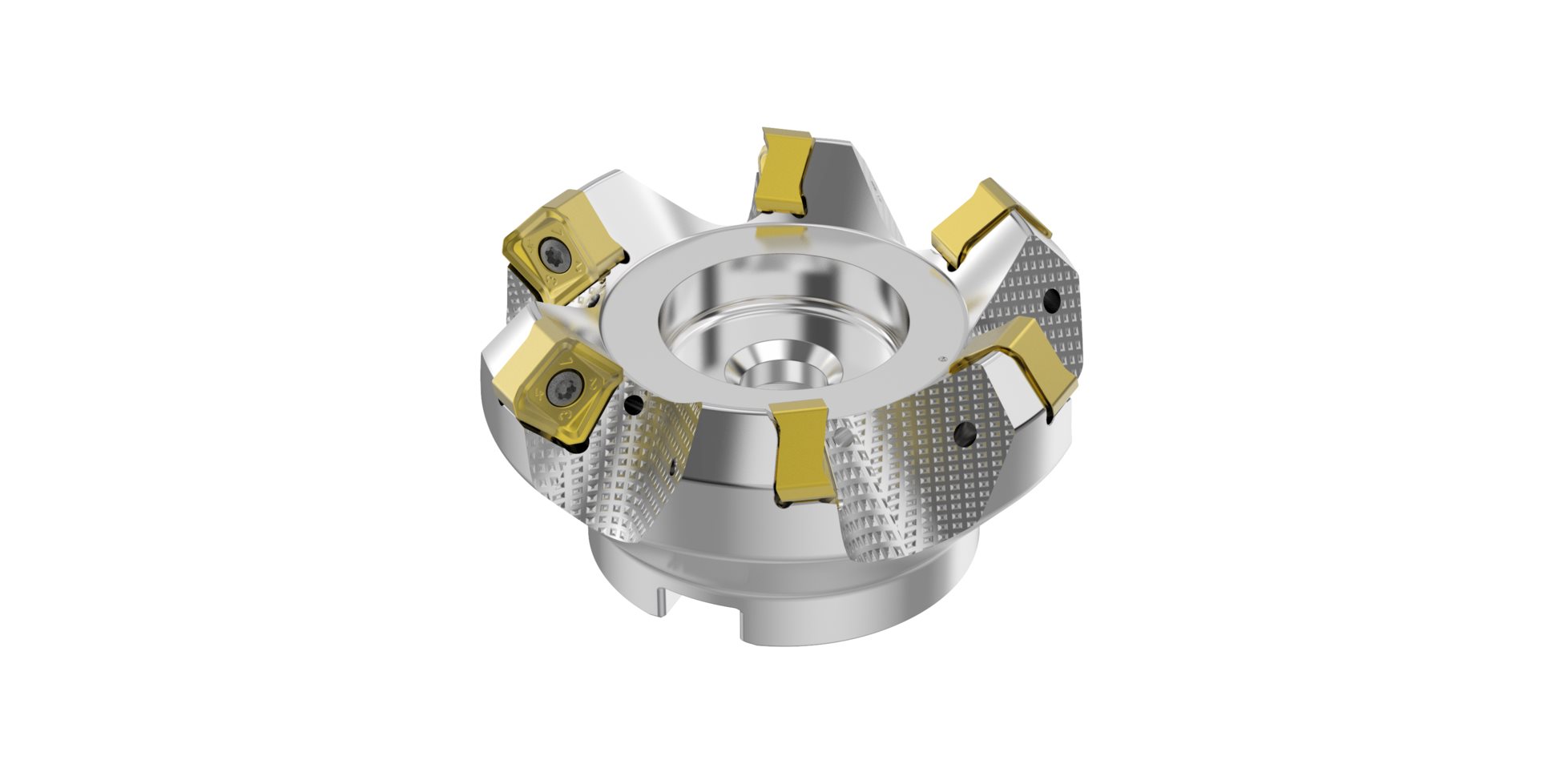

You can also have a look at our High Feed SP14 inserts range

Discover the High Feed SP14 inserts range

Related content

Suggest

Product Range Presentation- Seco HIgh Feed SP range

Factsheet - Seco High Feed SP

Easily Tackle Challenging Applications with New Seco High Feed SP Milling Systems

Face Milling Demo on a steel work piece | Seco tools

Rough Face Milling of a steel work piece | Seco Tools

High Feed SC for SP14 inserts - 4-cutting-edge - single-sided inserts

High Feed SP - Insert size 14

High Feed SP - Insert size 18

High Feed SP - Insert size 10

High Feed SP - 4 cutting edges single-sided inserts

Video: High Feed SP Mold & Die Roughing demo | Seco tools

Milling Cutters

High Feed SP18 - Spare Parts

High Feed SP18 - Cutters and Inserts

Seco Helical SN8-13

Seco News Summary 2022.2

335.25 Adjustable width

.38 - HSA Adjustable Pocket

.38 - CSA Cassette Pocket

.38 - SA Fixed Pocket

.38 SNFX1204 - KAPR 88° / 26° - 8 cutting edges

Finishing Solutions

SPK. / SPU. / SE. Insert shape

A Guide to Milling Grades, Materials and Solutions

Double Turbo 11 - Insert Size 11

High Feed vs Conventional Milling: Making the faster choice

Milling Cutter positioning. What it is? And why is it so important?

Octomill .43 - OO..0605

Choosing the right High Feed Milling Cutter

Milling Application

High Feed Mills

Mini Disc - 335.14 - Shanks

Mini Disc - 335.14 – Thread Milling

Mini Disc - 335.14 - Dove Tail

Mini Disc - 335.14 - Corner rounding

Mini Disc - 335.14 - Top and Bottom Chamfering

Mini Disc - 335.14 - Full radius profile

Mini Disc - 335.14 - For circlips groove

Mini Disc - 335.14 - General Grooving

335.14 - Replaceable Head Disc Cutters DC 6.7 - 50 mm (0.264 to 1.97”)

PCD and CBN square milling cutter .53

QuattroMill - Insert size 12

R220.60 - SP..19/28 - 4 cutting edges - KAPR 60°

Near 90 .88 SN.U12/16 - KAPR 88° - 8 cutting edges

Double Quattromill - SN.X14/22 - 8 cutting edges - KAPR 48° / 71°

Double Octomill - ON.U05/09 - 16 cutting edges - KAPR 40°

Quattromill .53 - SE.X1505

Quattromill .53 - SE.X1204

Quattromill .53 - SE.X09T3

Quattromill - SE.X 09/12/15 - 4 cutting edges - KAPR 45°

Near 90 .88 - SN.U1606

Near 90 .88 - SN.U1204

.30 SE..1203 - Adjustable Pocket - KAPR 88° - 4 cutting edges

Double Quattromill KAPR 71° .56 - SNMX2209ZN

Double Quattromill KAPR 71° .56 - SN.X1407ZN

Double Quattromill KAPR 48° .54 - SN.X1407AN

Double Quattromill KAPR 48° .54 - SNMX2209AN

Double Octomill .48 - ON.U0905

Double Octomill .48 - ON.U0504

Octomill .43 - OF..05T3

Octomill .43 - OF..0704

Octomill OO.T06 / OF..05/07 – 8 edges – KAPR 40°/43°

R220.23 REHR16

TNHF1206 Insert shape

ODMT05 Insert shape

HexaMill HP..1206 Insert shape

R220.13 SE Insert shape

R230.19 SNHQ1203 - Fixed Pocket - KAPR 90° - 4 cutting edges

QuattroMill - insert size 09

RPGN1204 - insert size 12

RNGN1207 - insert size 12

RNGN1204 - insert size 12

Ceramic round insert cutter .26 R.GN12

CBN Square Insert Cutter .74 SN..09

RNGN09 - insert size 09

CBN Round Insert Cutter .70 RNGN09

RNGN06 - insert size 06

Hexamill for Heavy Duty - 6-cutting-edge, Single-sided Inserts

Face Mills - Others

Milling Cutters for Advanced Materials

Face Mills

Turbo - XO...06/10/12/16/18 - 2 cutting edges

Double Turbo - 4 cutting-edge double-sided inserts

Seco Taps T32 - T33 - T34

335.25 - XNHQ & LNHQ Inserts

335.18 - LNK. Inserts

335.18 & .25 - Cassettes cutter - XN inserts

335.18 & .25 & .98 - Half side and face

335.98 - Fixed pockets - XN inserts

Seco JH724-JH726 Medical barrel Solid End Mills

335.18 & 335.25 - Half side and face

335.18 & 335.25 - cassettes cutter - Round inserts

Seco Hydraulic Chucks

Seco End Mills for Plug-and-Play Dental Milling

Helical LN4 - Spare parts

Helical LN4 - Cutters and Inserts

Helical LN4 - 2/4 Cutting Edges Single/Double-sided Inserts

335.18 Adjustable width

335.25 - Adjustable width

335.18 - Adjustable width