REDUCE YOUR COST PER THREADED HOLE IN CAST IRON

Discover the product range

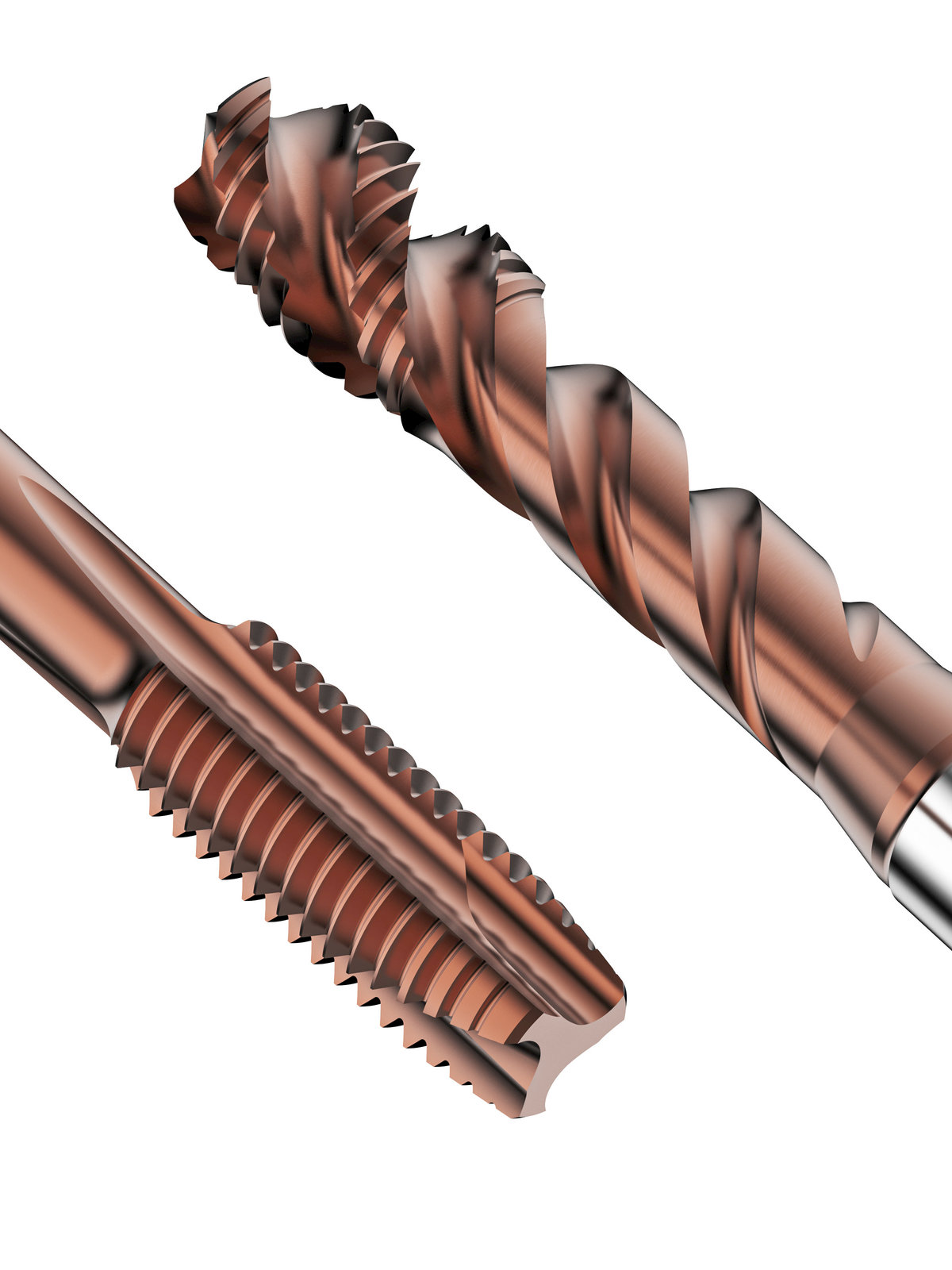

Optimizing threading operations in cast iron requires a great deal of trial and error, often with plenty of broken taps and poor cycle times along the way. Control cutting forces, keep chips moving and speed up your threading operations by up to 50% with the new line of threading taps for ISO K materials from Seco. And thanks to a newly redesigned geometry and grade combination, you can take advantage of these taps’ higher performance without sacrificing tool life.

Your challenge: Slow cast iron threading operations are slowing down your shop’s production.

The Seco solution: Achieve the highest level of tapping performance – and the lowest cost per threaded hole – thanks to reoptimized geometries, a greater number of flutes and reduced friction.

Threading can be a delicate operation, one where chips and cutting forces must be handled with extreme care for effective process security. Handle all these challenges with ease thanks to the new ISO K threading taps’ advanced design. Using a specialized process that results in a harder, high-cobalt tool-steel substrate, Seco has also applied a new smoothed TiAlN coating for a smooth, hard surface that’s highly resistant to breakage. Best of all, this improved reliability can be applied in any coolant environment, whether machining dry, wet or through the use of MQL technology.

Your challenge: Poorly controlled, oversized chips cause scratching, tool wear and a lack of process security.

The Seco solution: Newly optimized flute shapes and a back chamfer make it easy to evacuate chips, even in deep holes.

Threading has a reputation for sensitivity, but there’s no need to be gentle with the new cast iron threading taps. A forgiving geometry, including a greater number of flutes and optimized grades, provides great results even with suboptimal cutting parameters. Meanwhile, additional reliefs on the threads and chamfer serve to reduce contact between the taps and workpiece, while the additional back chamfer allows for threading in deep holes with confidence.

Your challenge: Unpredictable tap tool life leads to poor performance and downtime.

The Seco solution: An increased number of flutes, improved hardness and greater chamfer and thread reliefs secure processes and prevent unexpected breakage.

Discover the product range

Contact Us

Related content

ISO K Threading Taps - New Generation vs Old Generation Comparison

Threading Taps

Threading Application

Poster - Threading

Factsheet - Seco Taps

Webinar: How to Achieve High-Quality Threads in Machining

Seco T35 Taps: match Tooling to Materials

Seco Taps T30 & T35 in comparison | Seco Tools

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

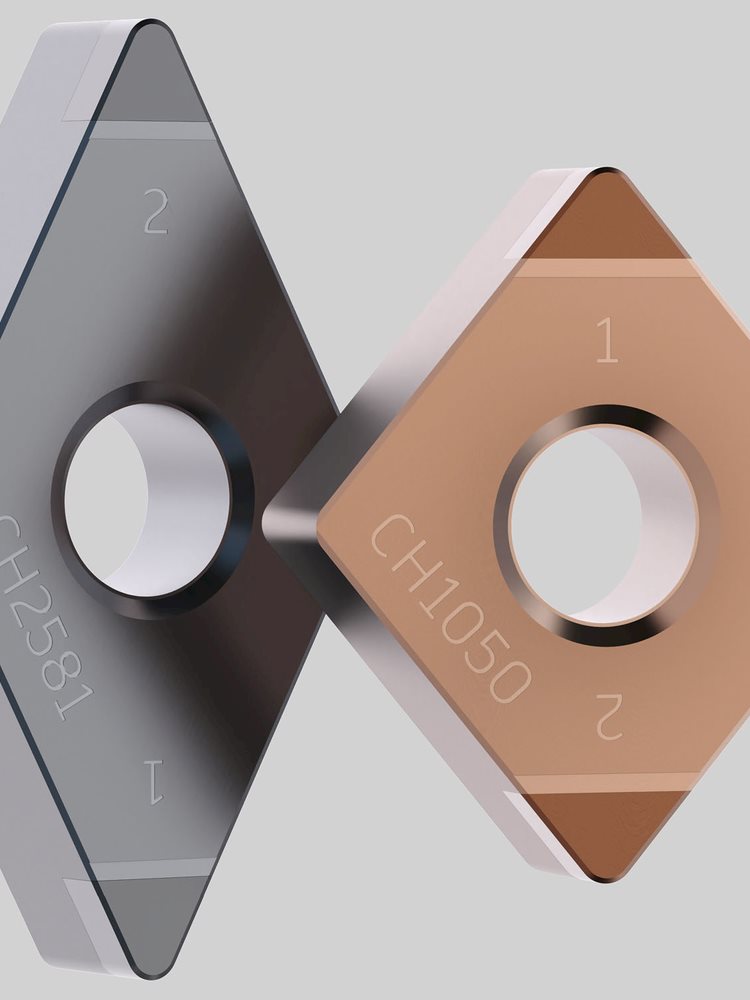

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

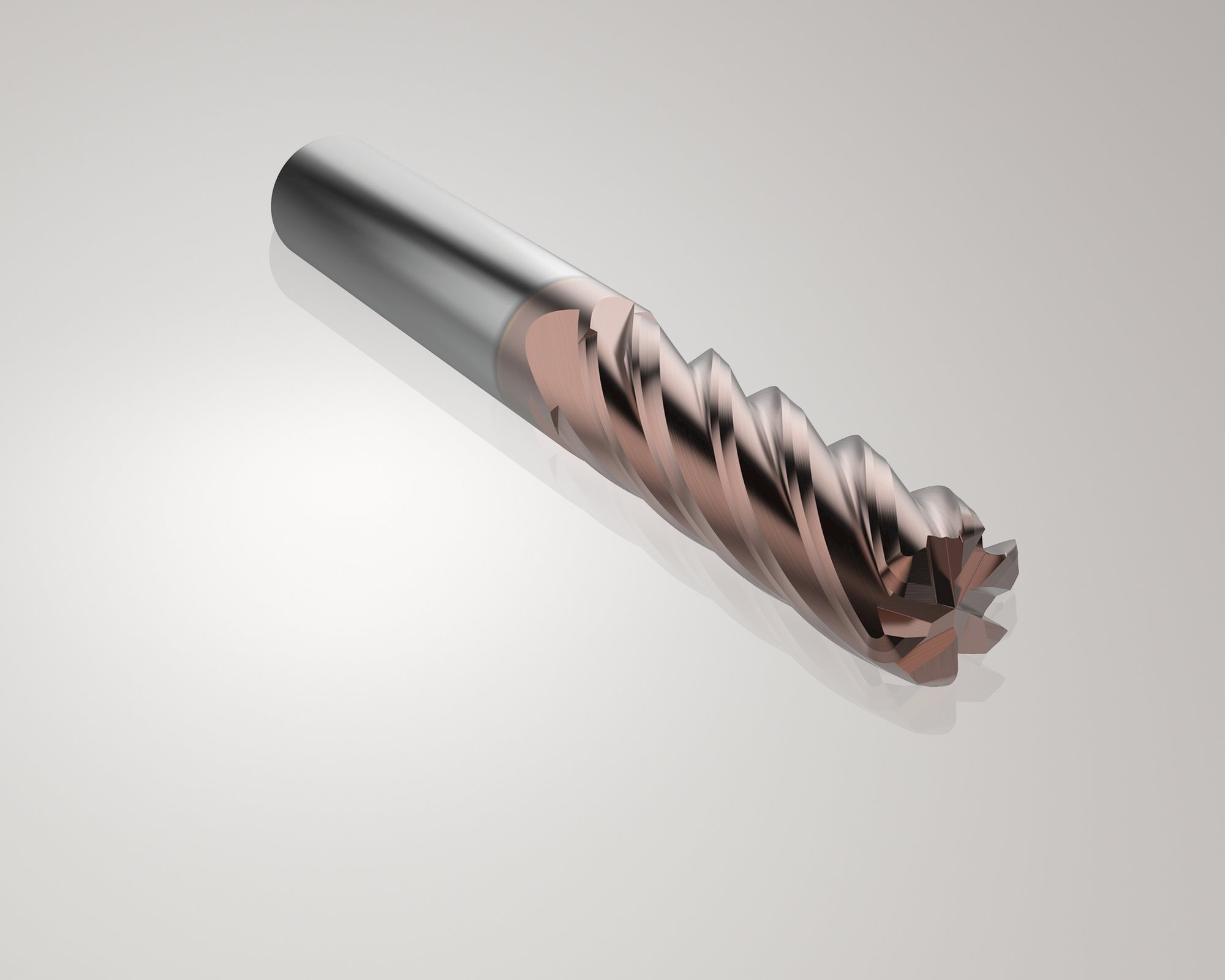

JS720 Solid End Mills addition

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

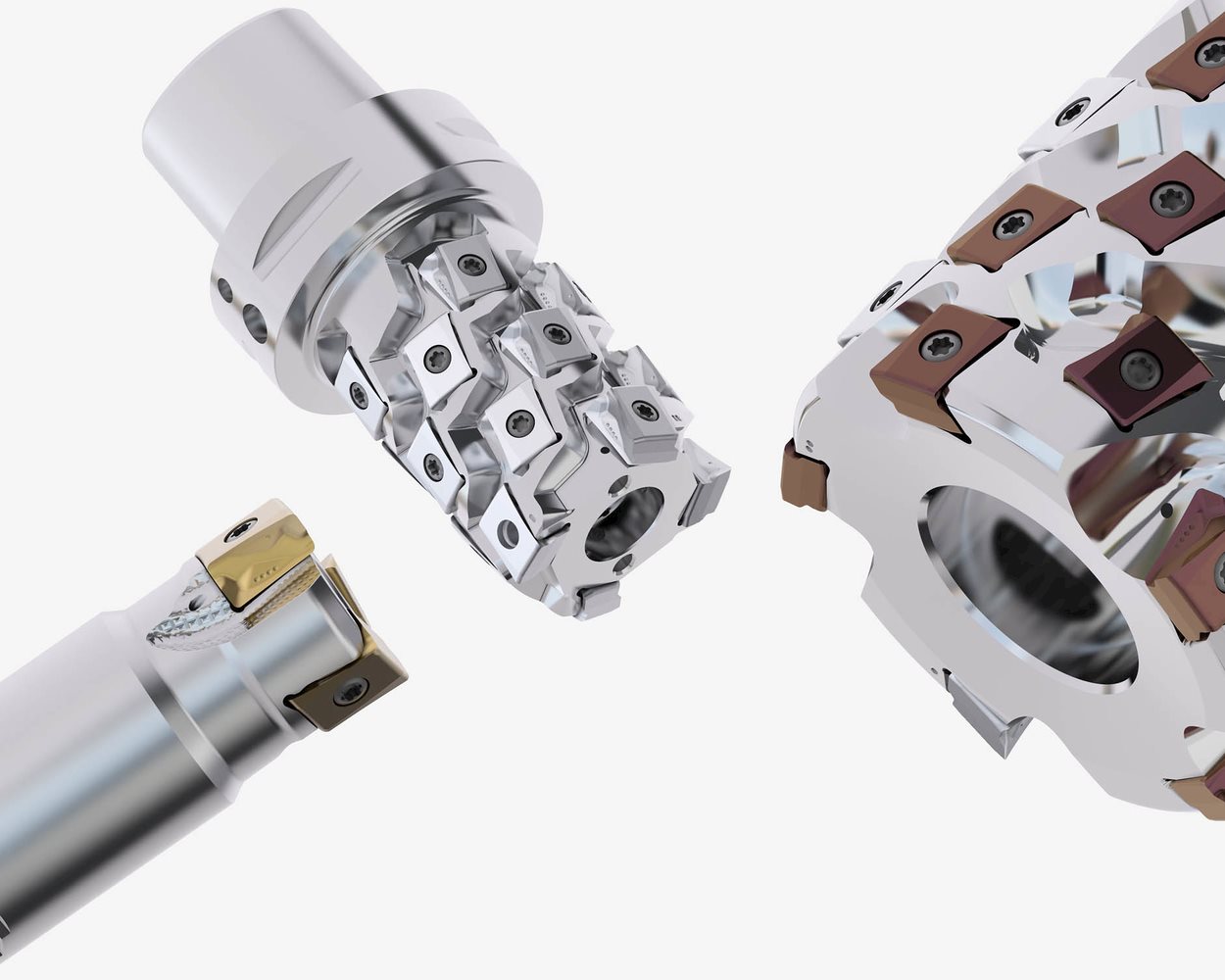

Square T4-12 Upgrades

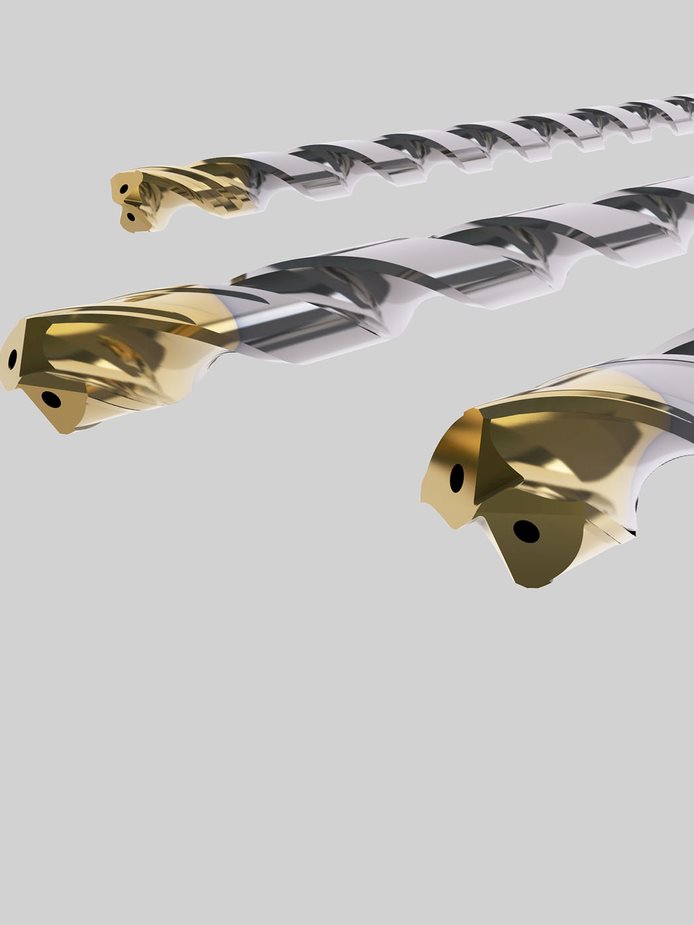

Universal Drills

Seco JSE510 Solid End Mill series

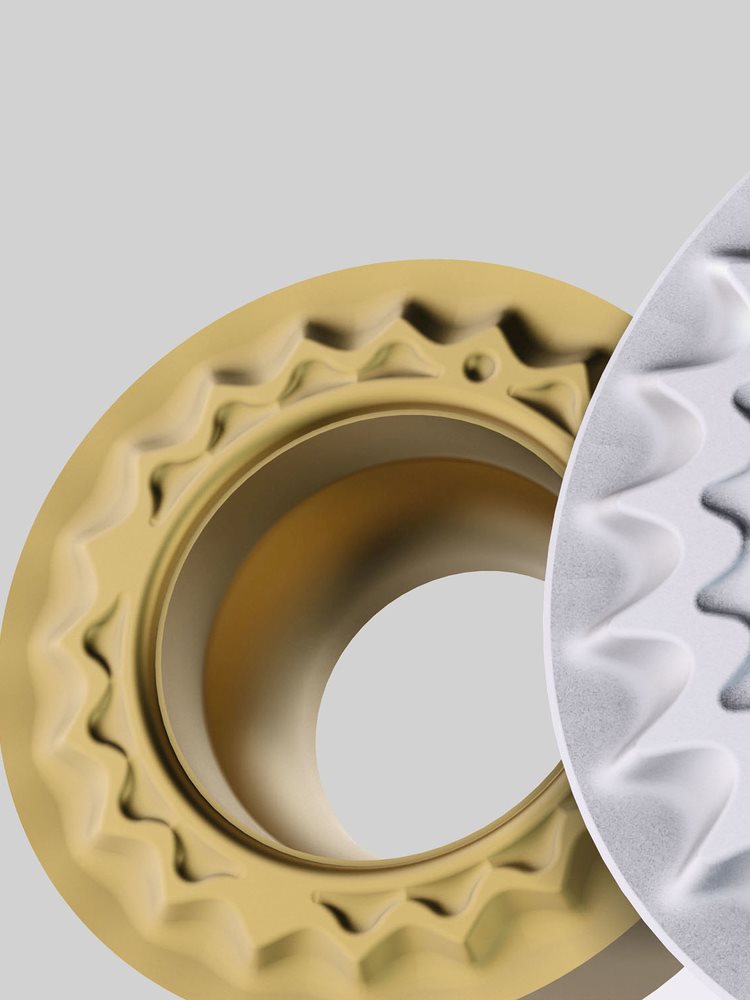

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Seco T30 Taps: a versatile universal geometry

Seco Taps T32 - T33 - T34

Enhancing Thread Tapping: Choosing the Perfect Tool for Success

New Seco Thread Cutting and Forming Taps Line to Provide Versatility and Cost-Effective Solutions

Machining Navigator / Catalog Threading

WEBINAR - UNLEASH YOUR TAPPING POTENTIAL

Video: Redesigned Threading taps for better threading in cast iron

Product Range Presentation - Seco Taps

Threading six different materials with one tap | Seco tools

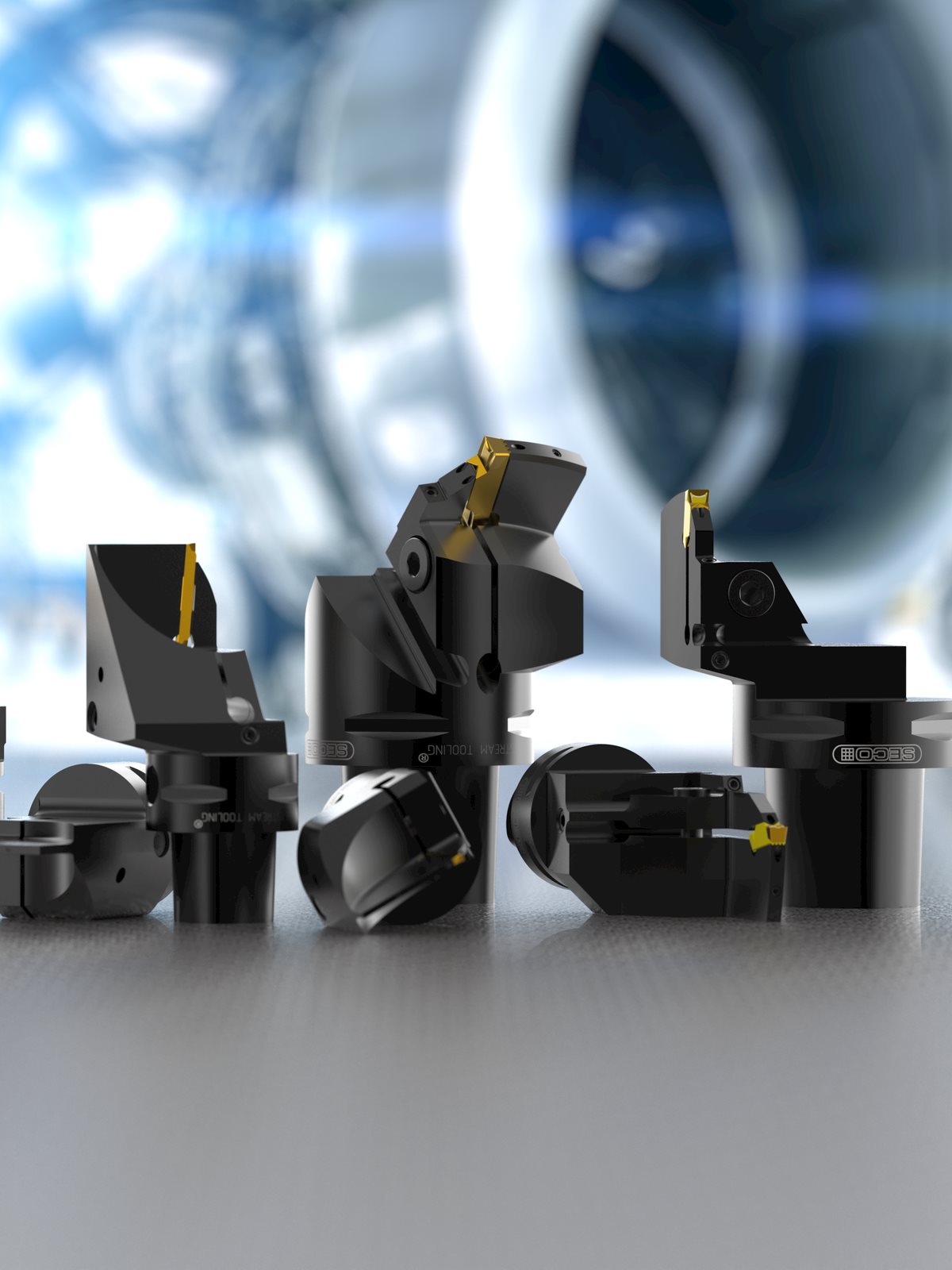

JETI conversion Grooving and Parting-off Capto

High Feed square cut size 14 insert

T35-SSC-H

Seco Component Guidance

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

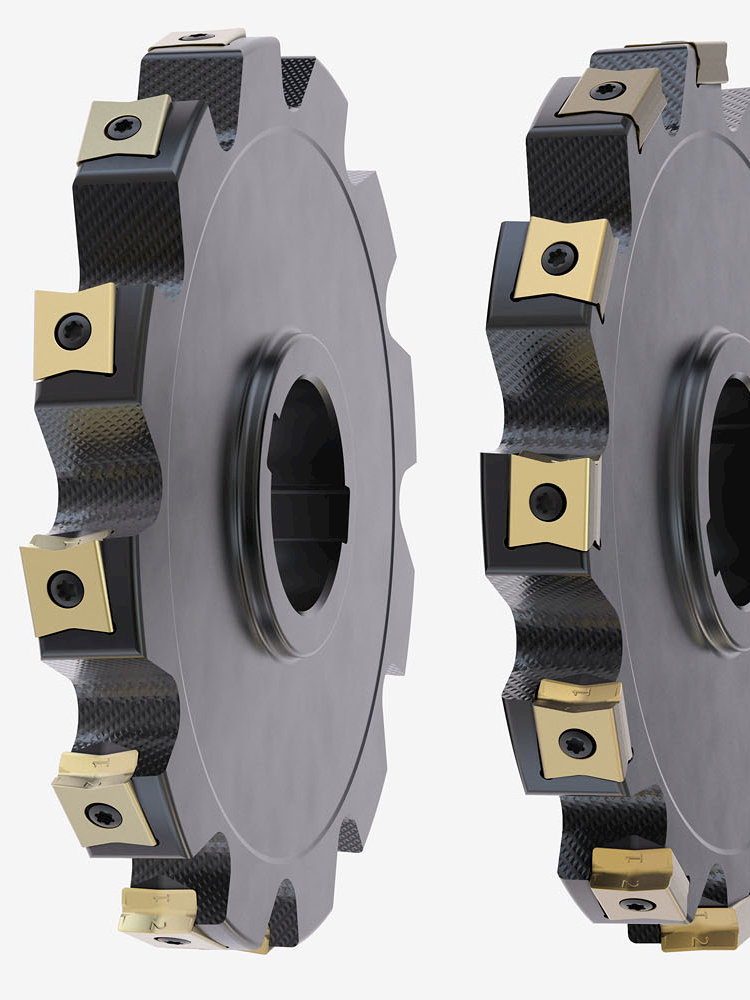

335.14 Disc Milling Cutter extension

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Threading Taps - T35-N

Threading Taps - T35-K

Threading Taps - T35-P

MTP-S001/S002/S011/S012/S042

MTP-S013/S043

MTH-S043/S101/S102/S111/S112/S142

MTH-S031/S041

MTH-S003/S004

MTH-S001/S002/S011/S012/S032/S042/S044

MTP-N001-A/N002-A

MTP-N001/N002

MTH-N001/N002

MTP-M003-A/M004-A

MTP-M003/M004

MTH-M003-A/M004-A

MTH-M003/M004

MTP-P003-A/P004-A

MTP-P003/P004/P011

MTP-P001/P002

MTH-P003-A/P004-A

MTH-P003/P004/P011

Threading Taps - ISO-S

Threading Taps - ISO-N

Threading Taps - ISO-M

Threading Taps - ISO-P

MTS-K002-A

MTS-K101-A/K102-A

MTS-K101/K102/K111/K121/K131/K141

MTS-K002

Threading Taps - ISO-K

T33B-FSCC

T33B-FSCE

T33A-FSCE

T33-FSCE

T33-FSCC

T33-FSNC

T33-FNC

T35-R45UC-N

T35-SSB-H

T35-PSB-H

T35A-R15SC-H

T35-R15SC-H

T35B-SSE-K

T35B-SSC-K

T35A-SSE-K

T35A-SSC-K

T35-SSE-K

T35-SSC-K

T35-R40SC-P

T32-R40HC

T32-PHB

T35-PSB-P

Threading Taps - T35-H

T34-R45CC

T34-PCB

T34A-R45HE

T34-R45HE

T34A-R45HC

T34-R45HC