Achieve outstanding tool life in Grooving and Parting-off

Discover the product range

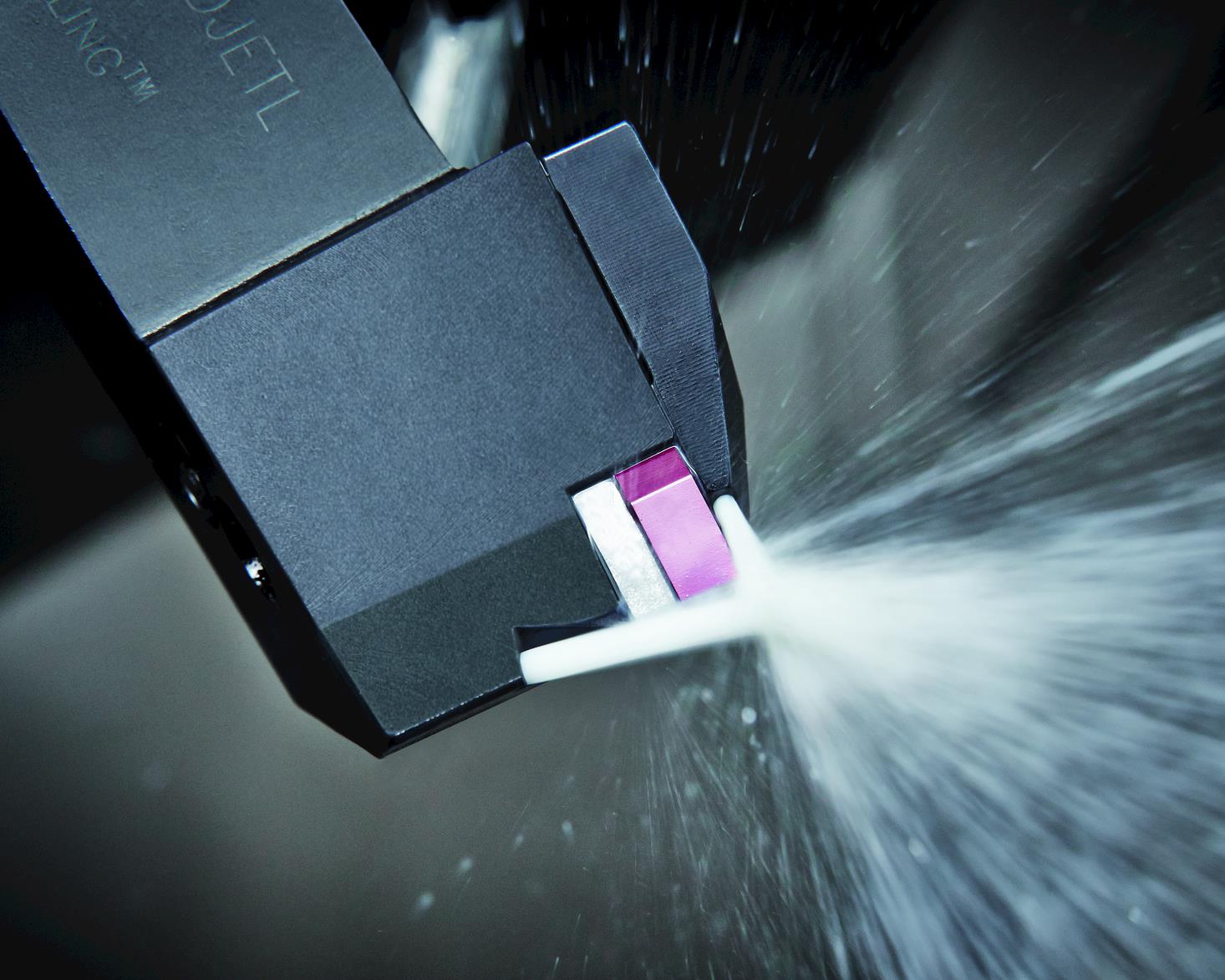

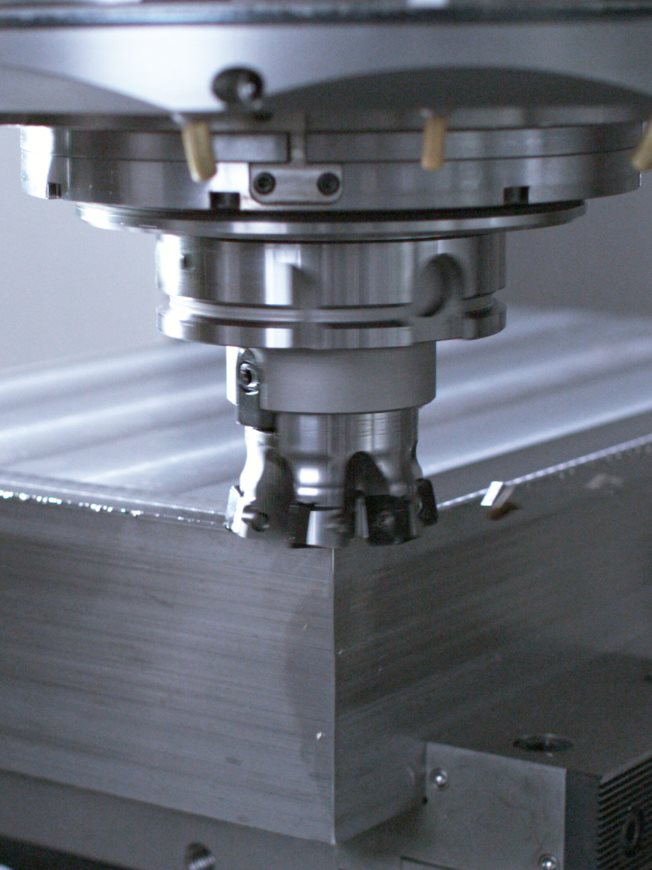

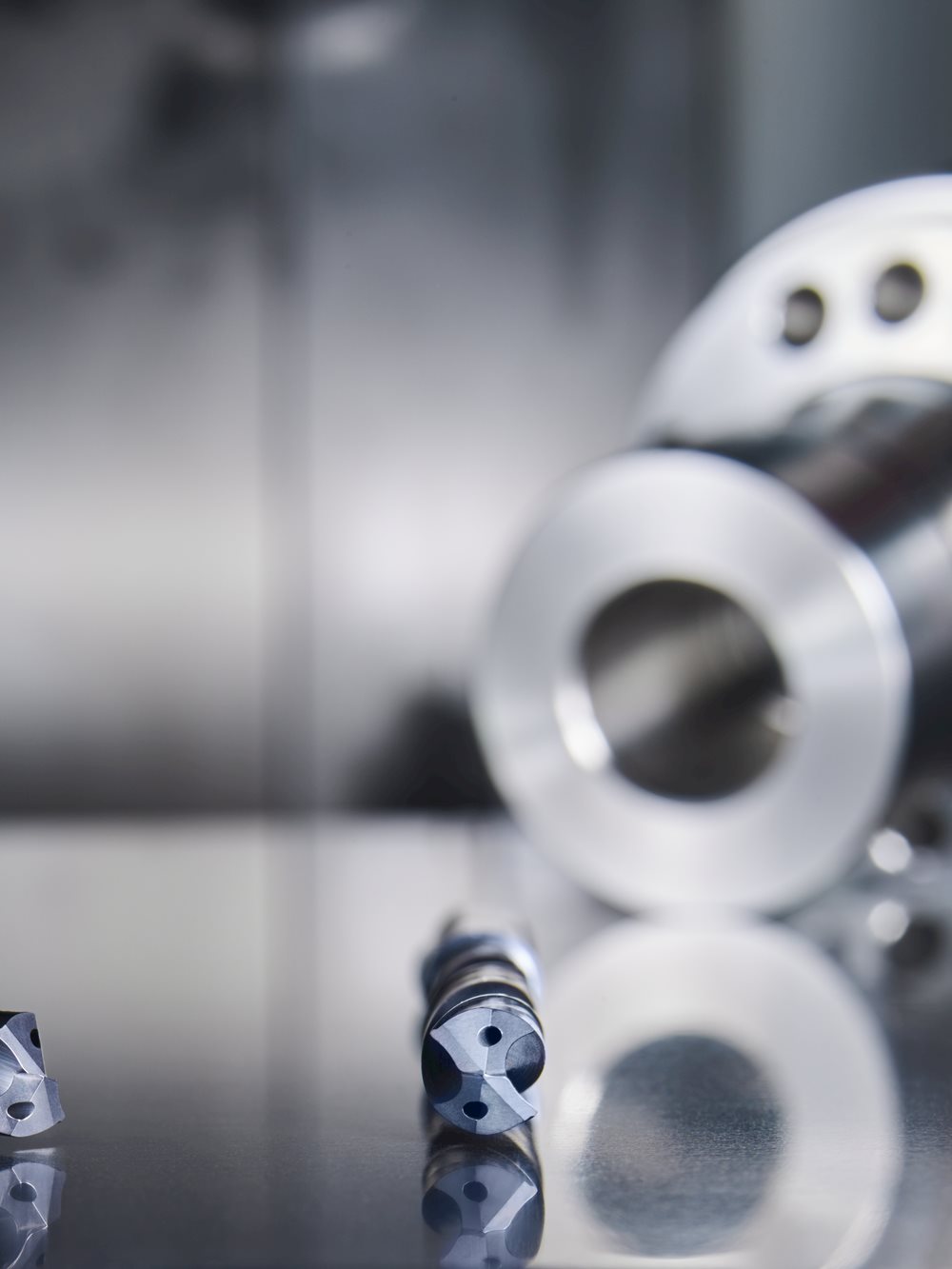

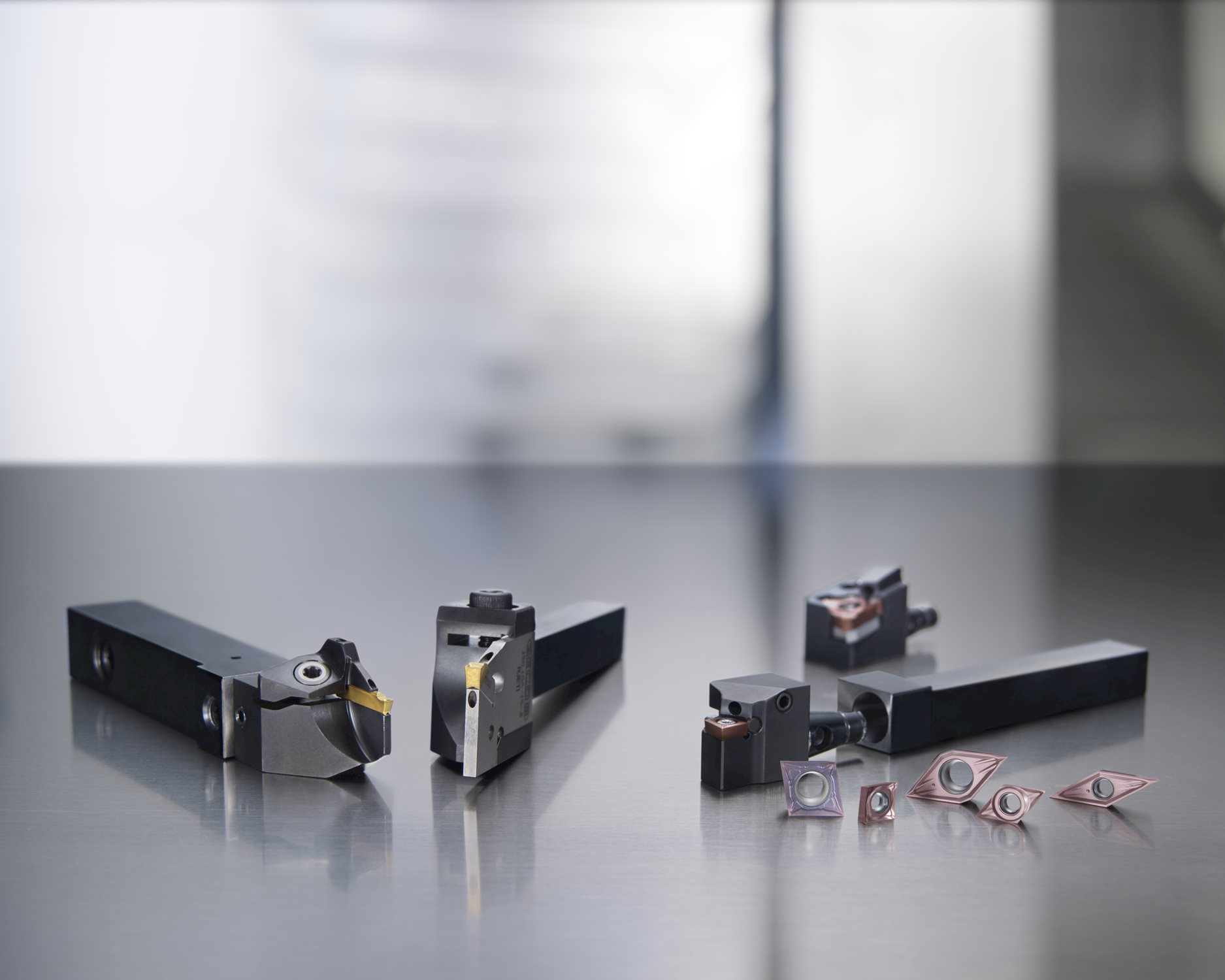

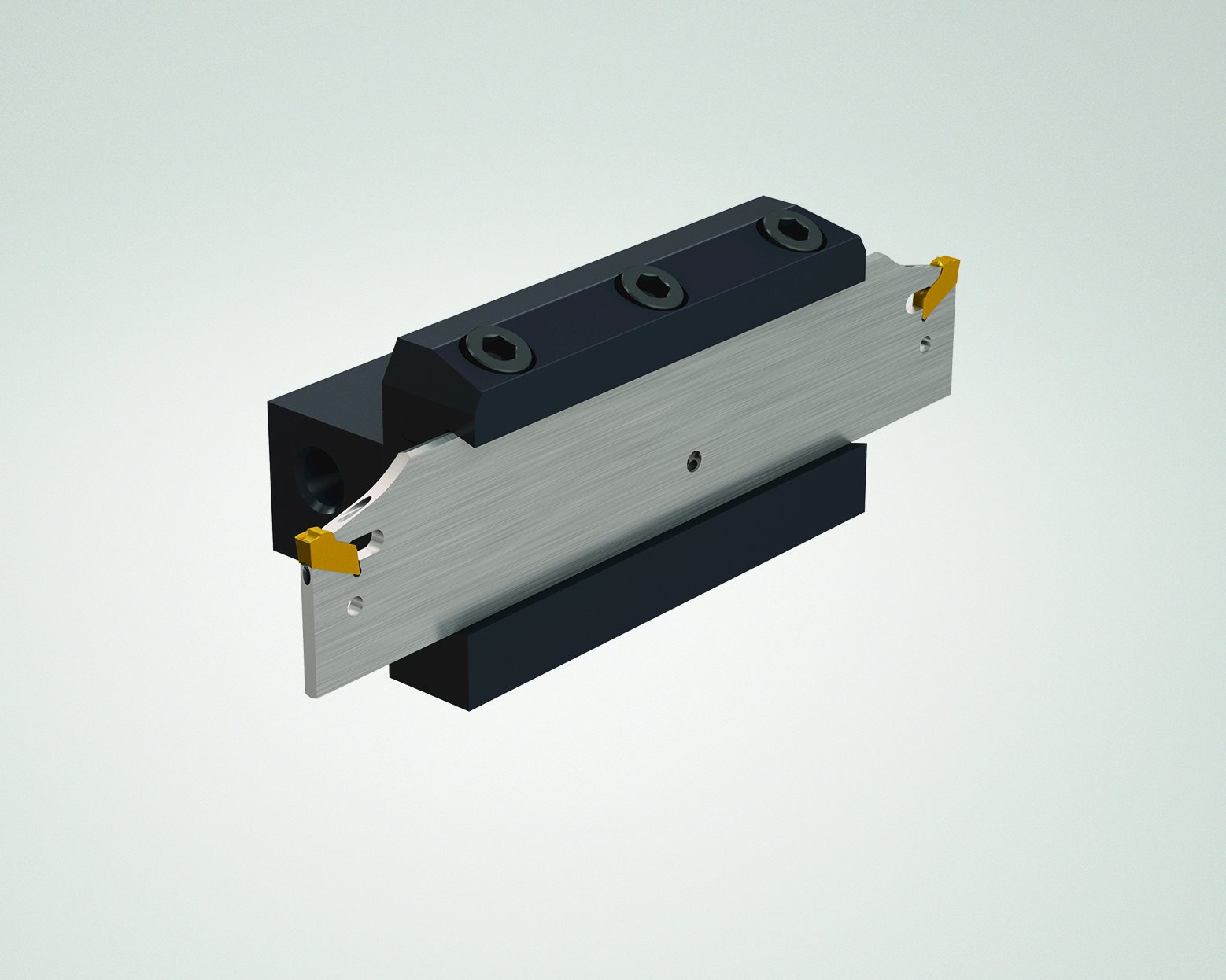

The deeper you cut, the more proper coolant becomes critical to chip formation and longer tool life in grooving and parting off. With coolant exactly where you need it, you can optimize the performance of your inserts while you machine stainless steel. Precisely aimed coolant with greater volume through dual outlets helps manage chips, achieve ideal surface finishes and protect the integrity of your processes.

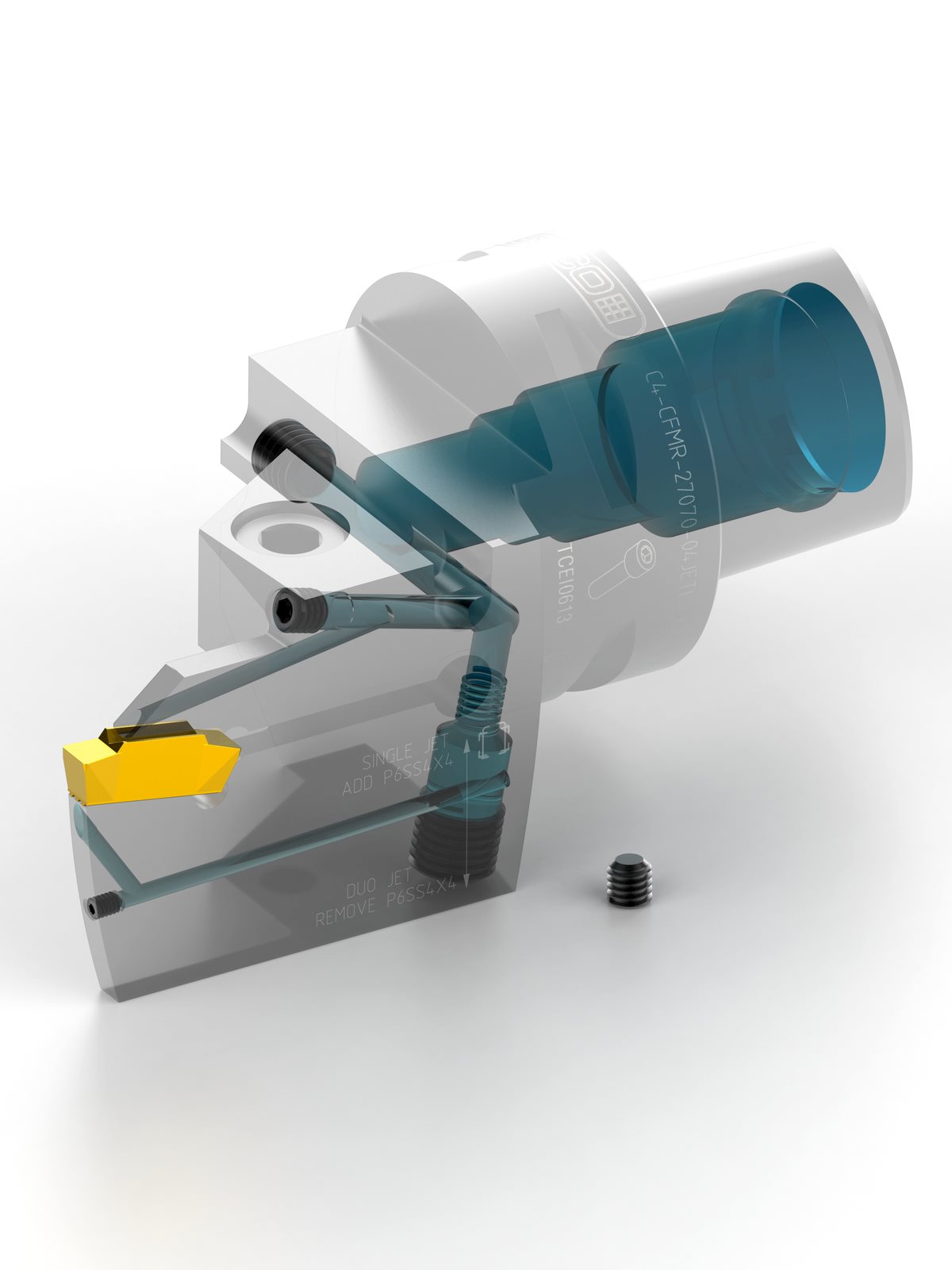

Your challenge: A single-jet solution for grooving and parting-off impacts performance, tool life and productivity.

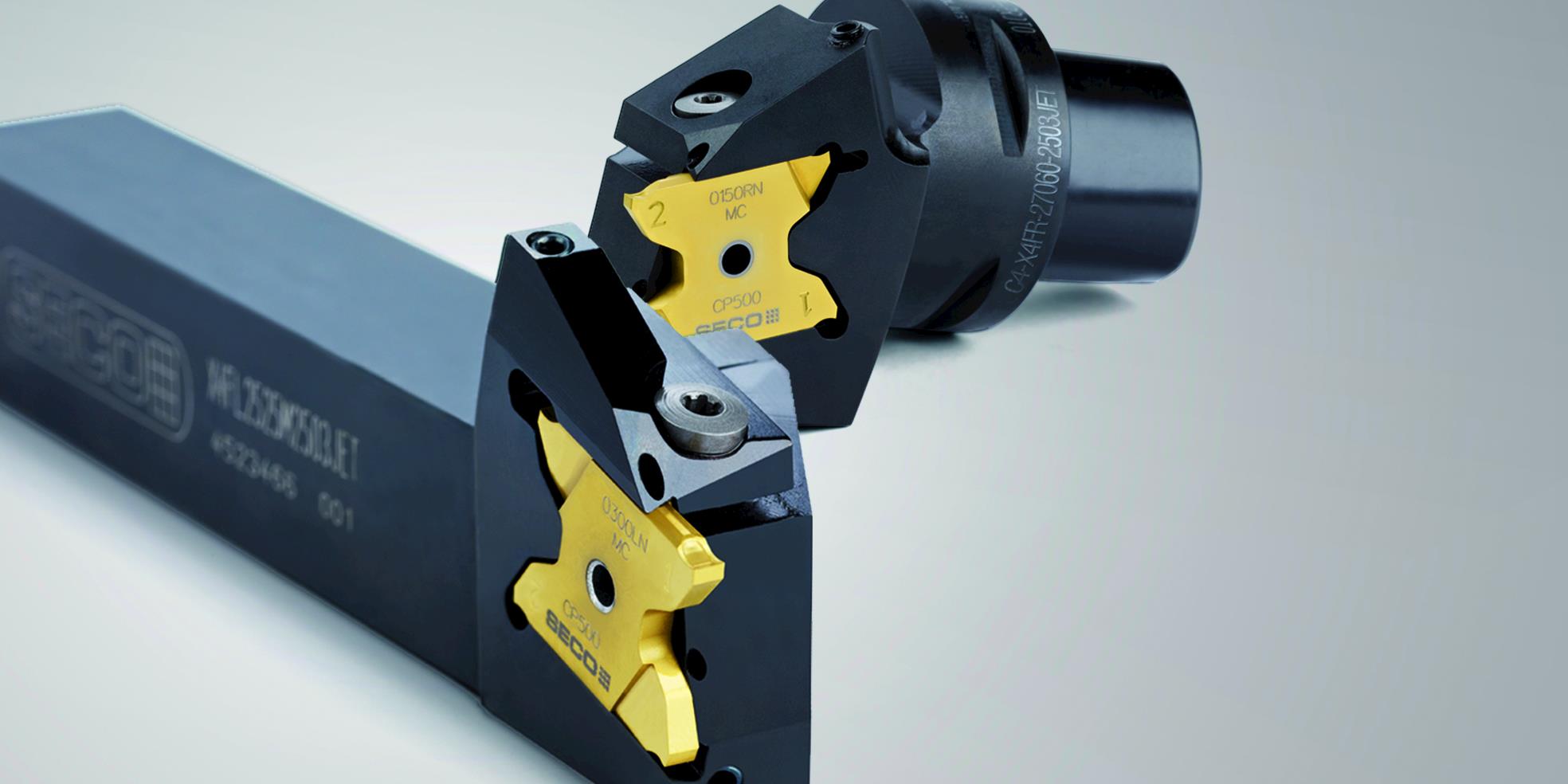

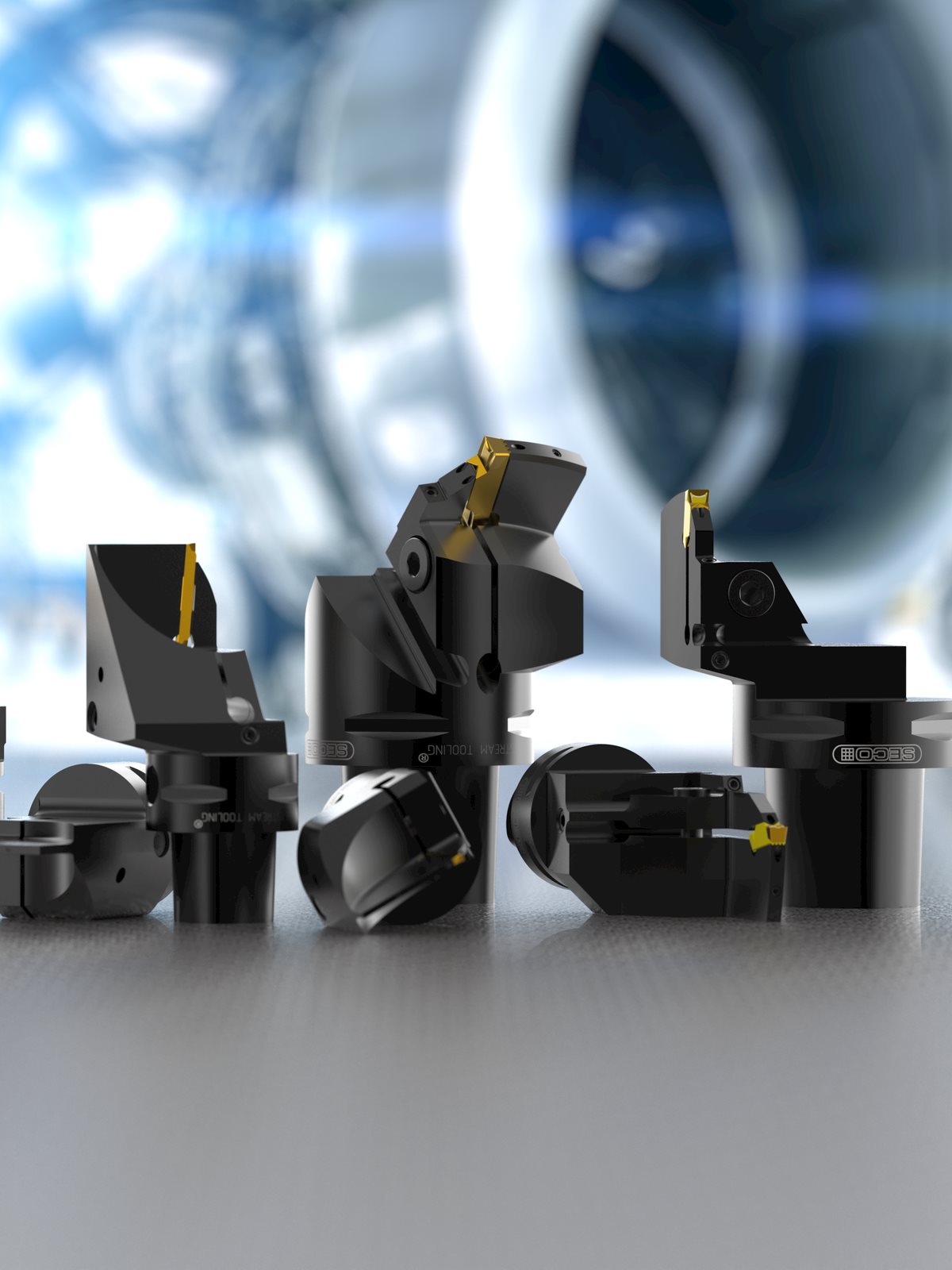

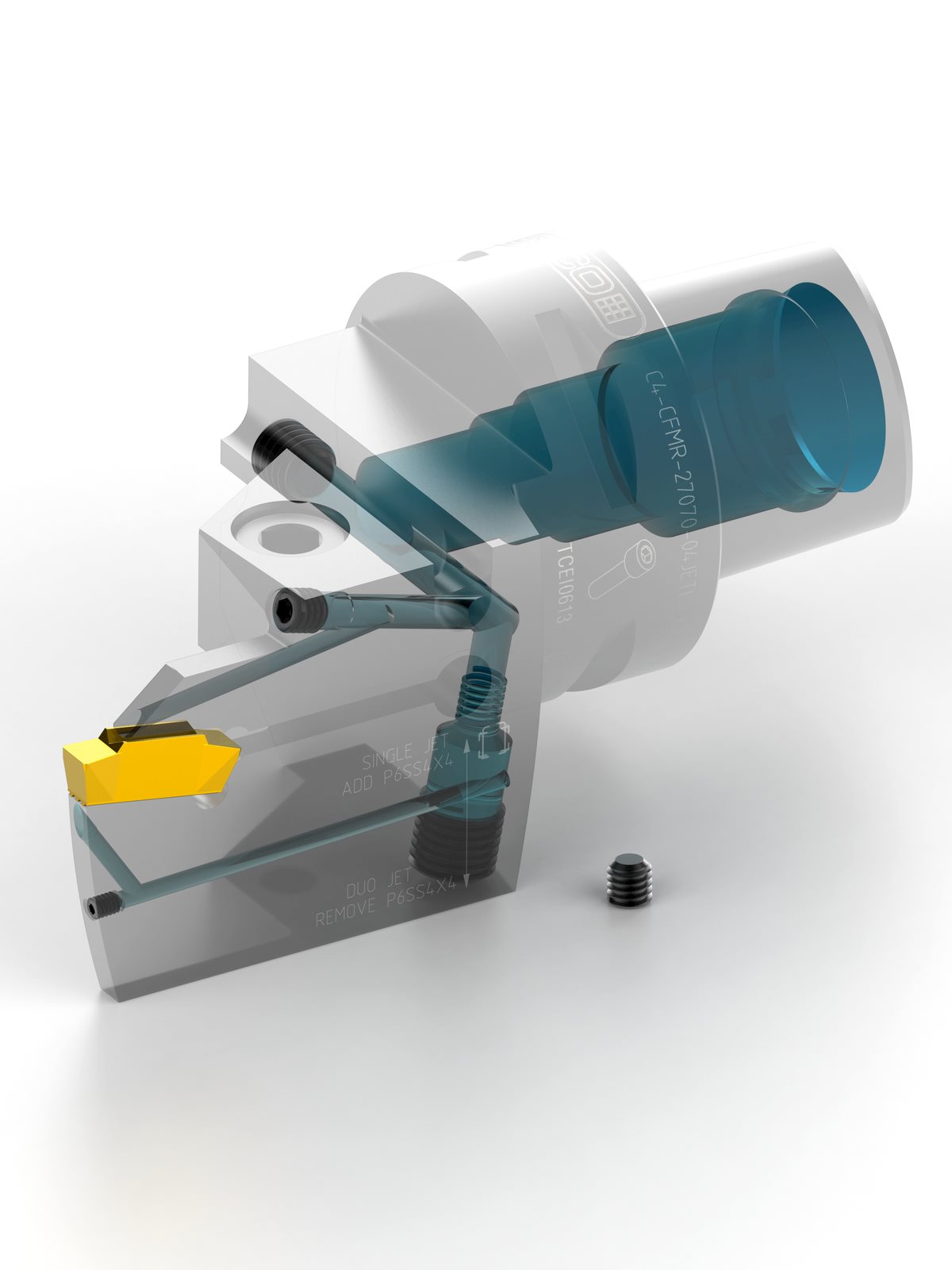

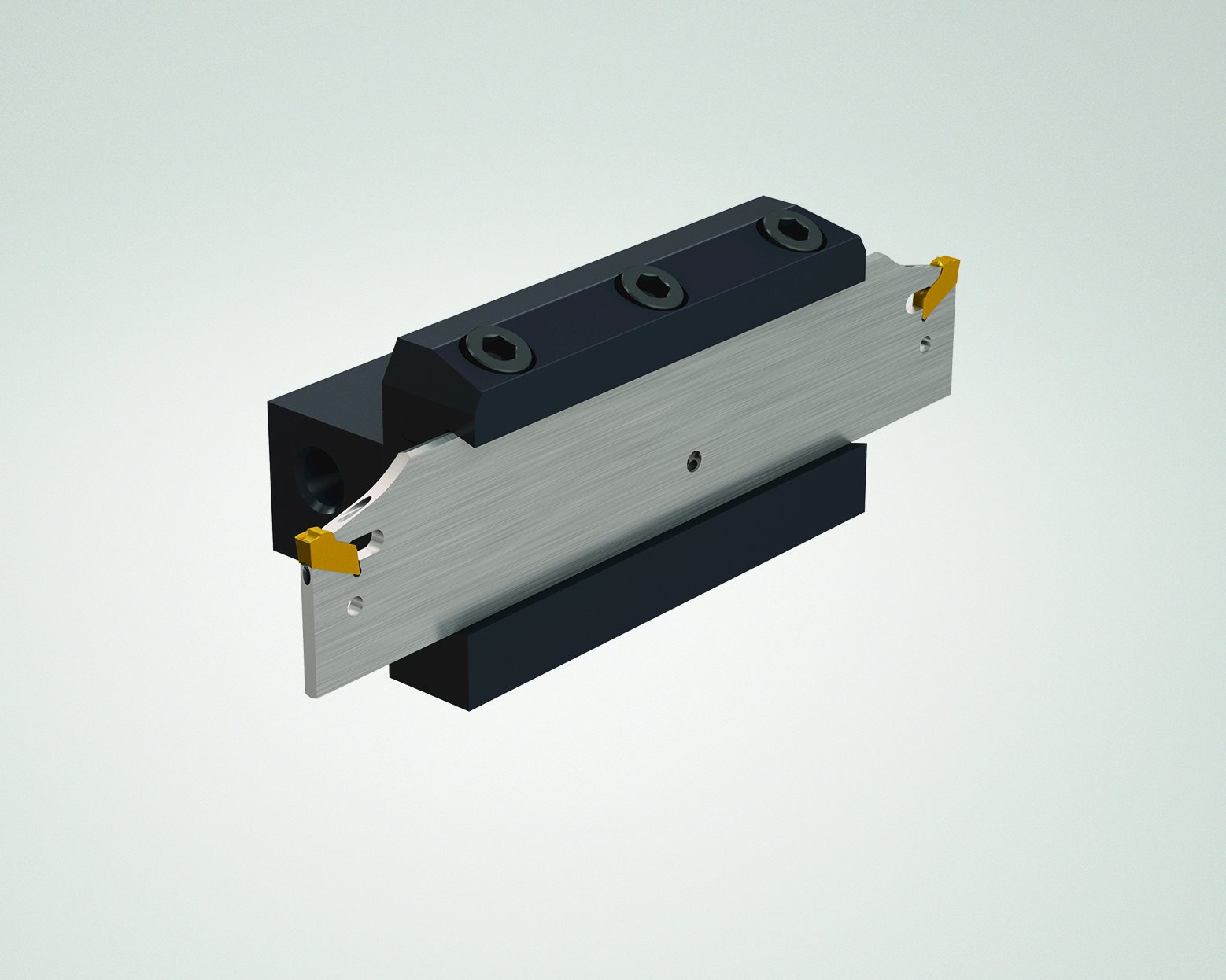

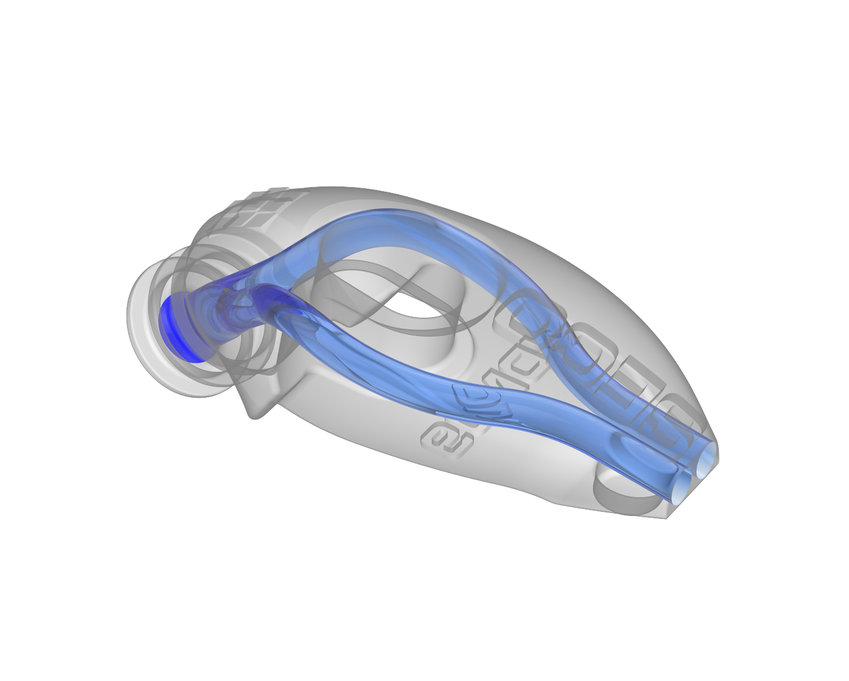

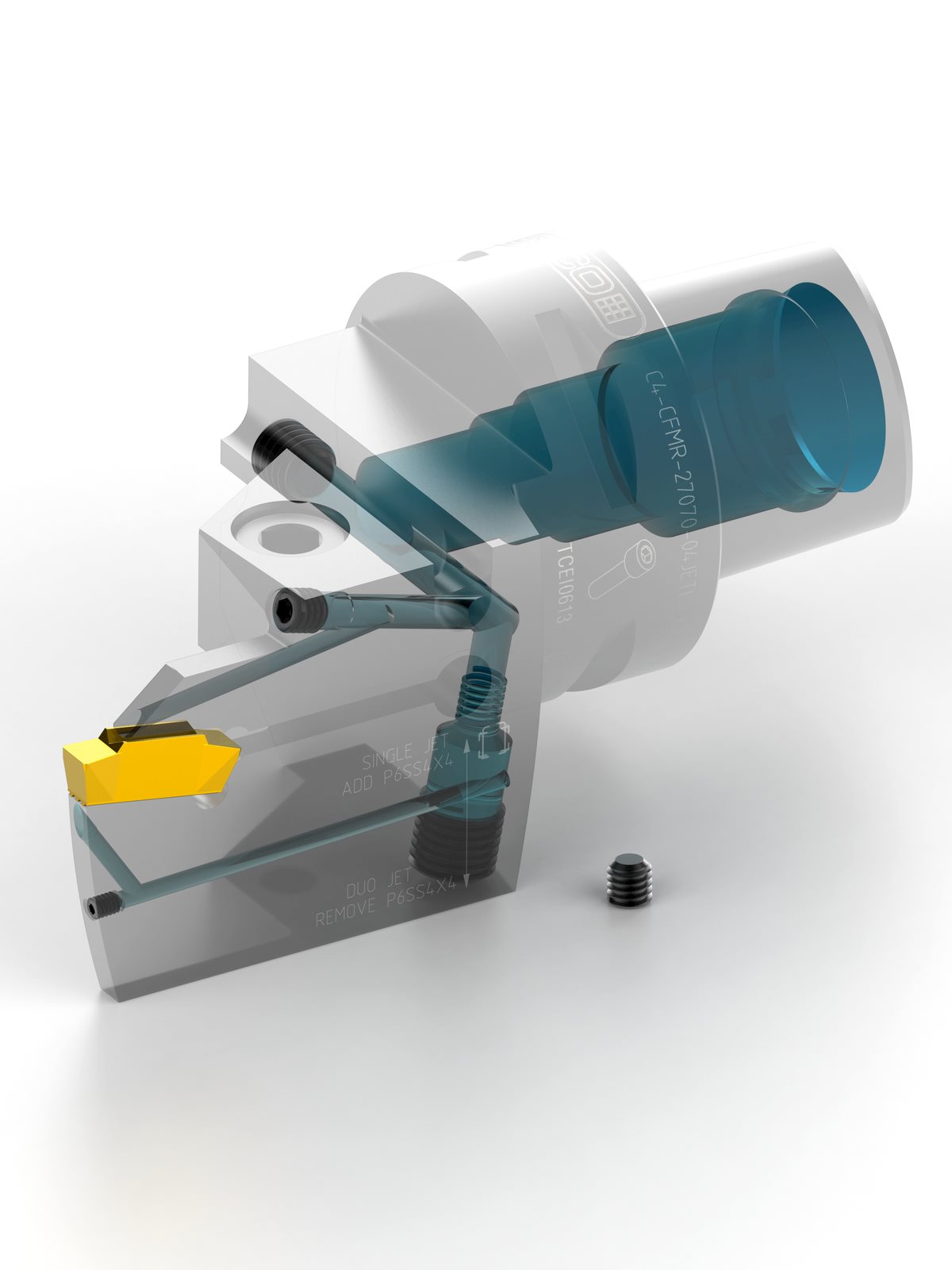

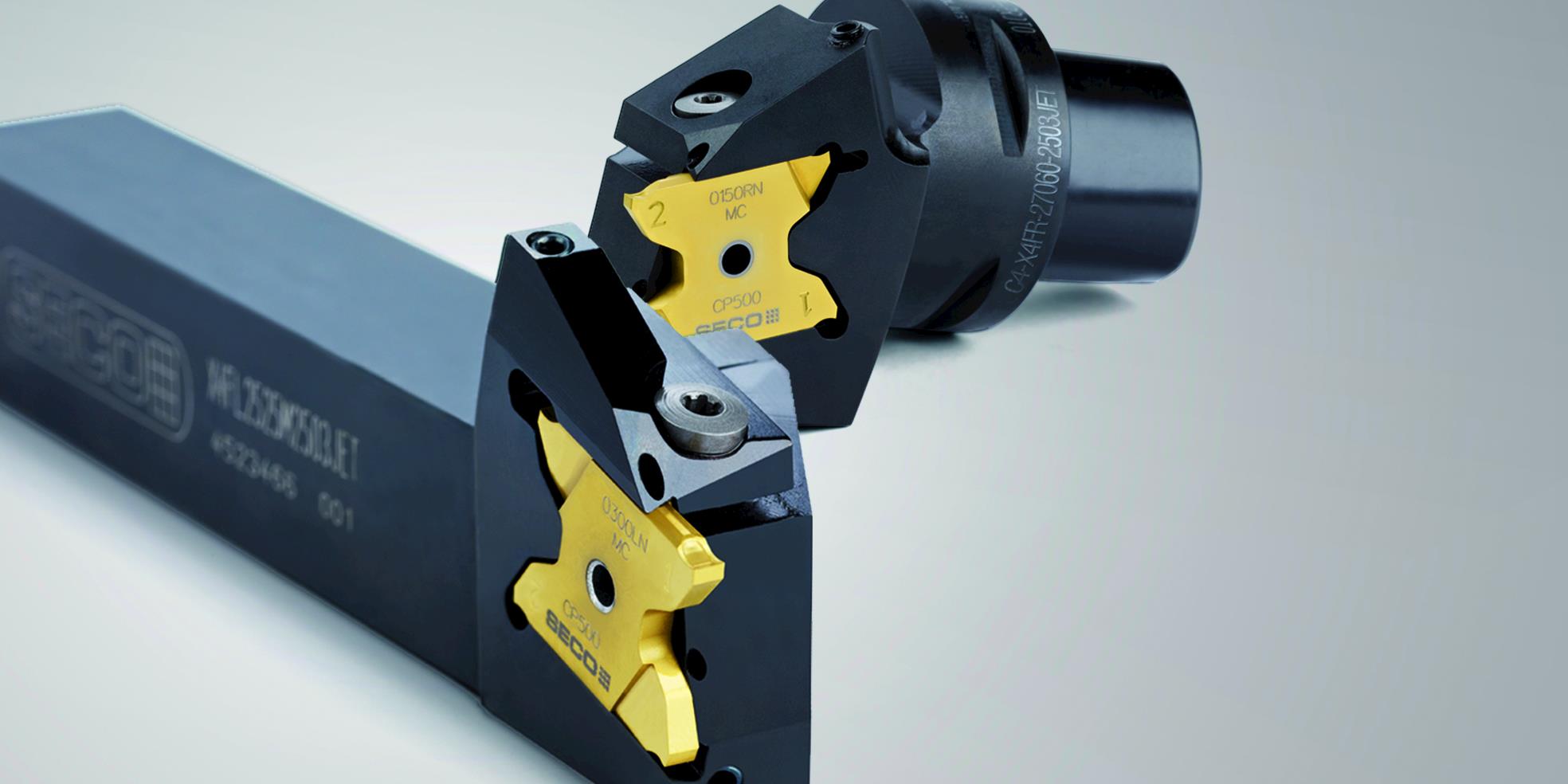

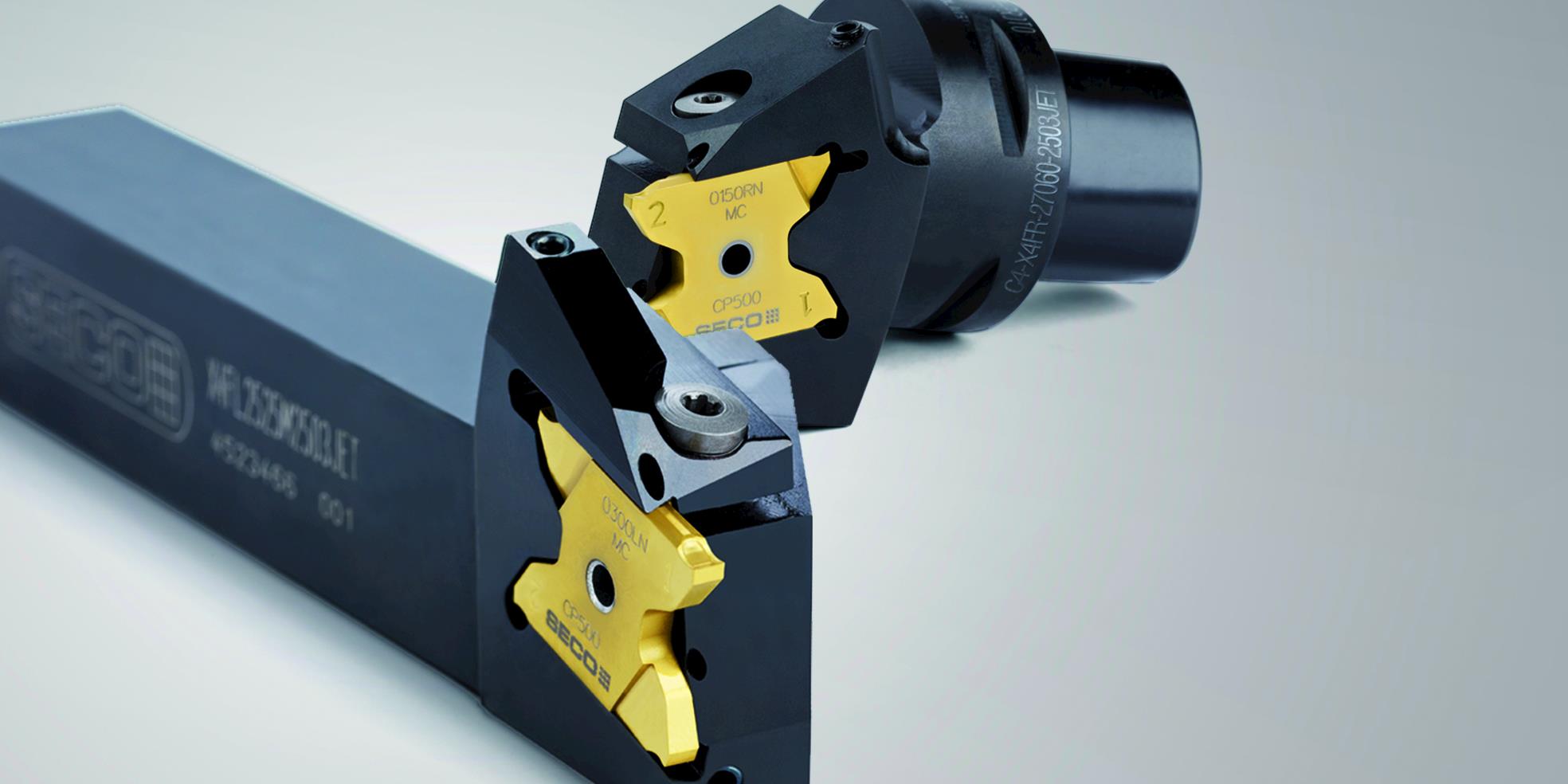

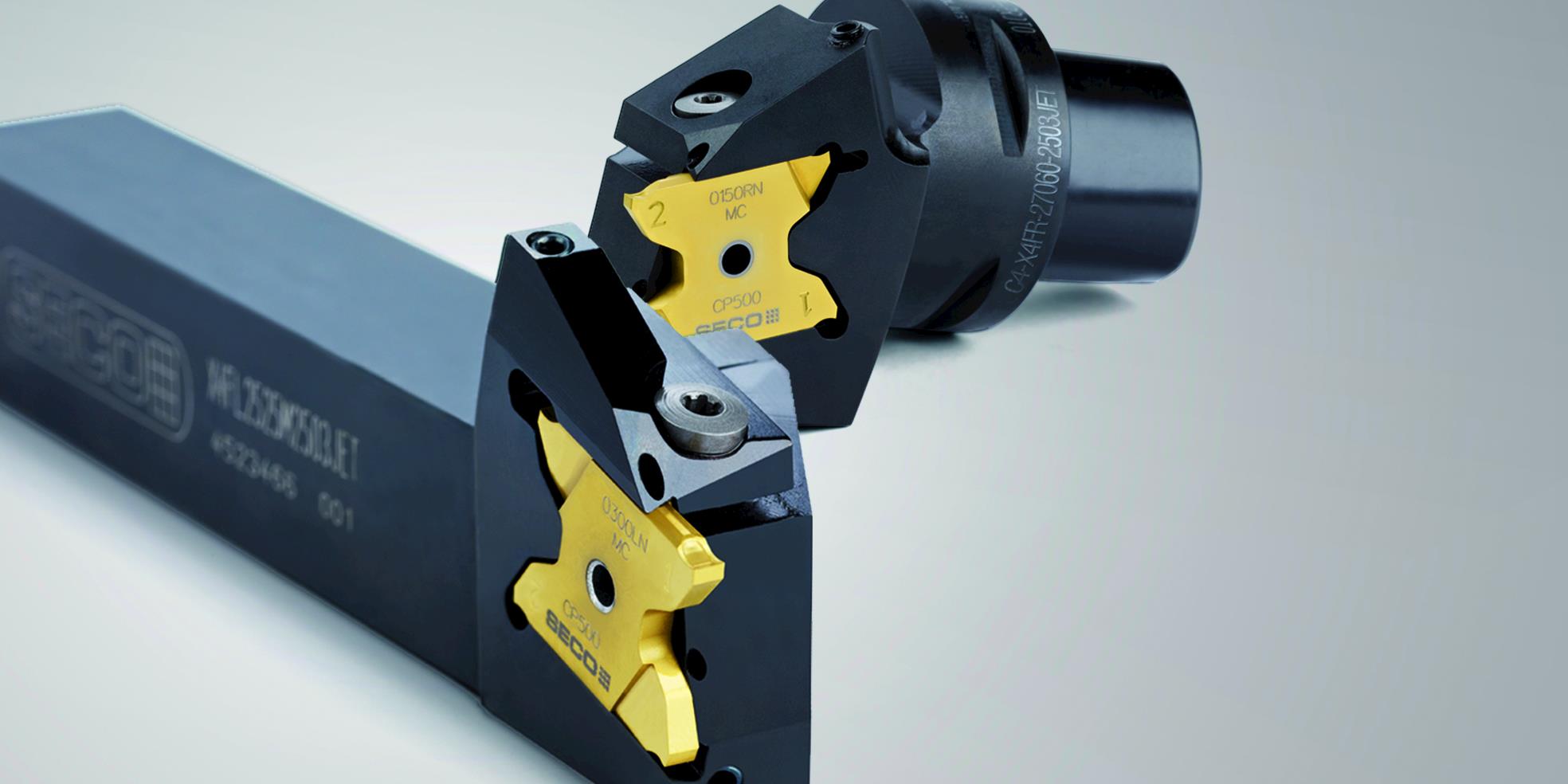

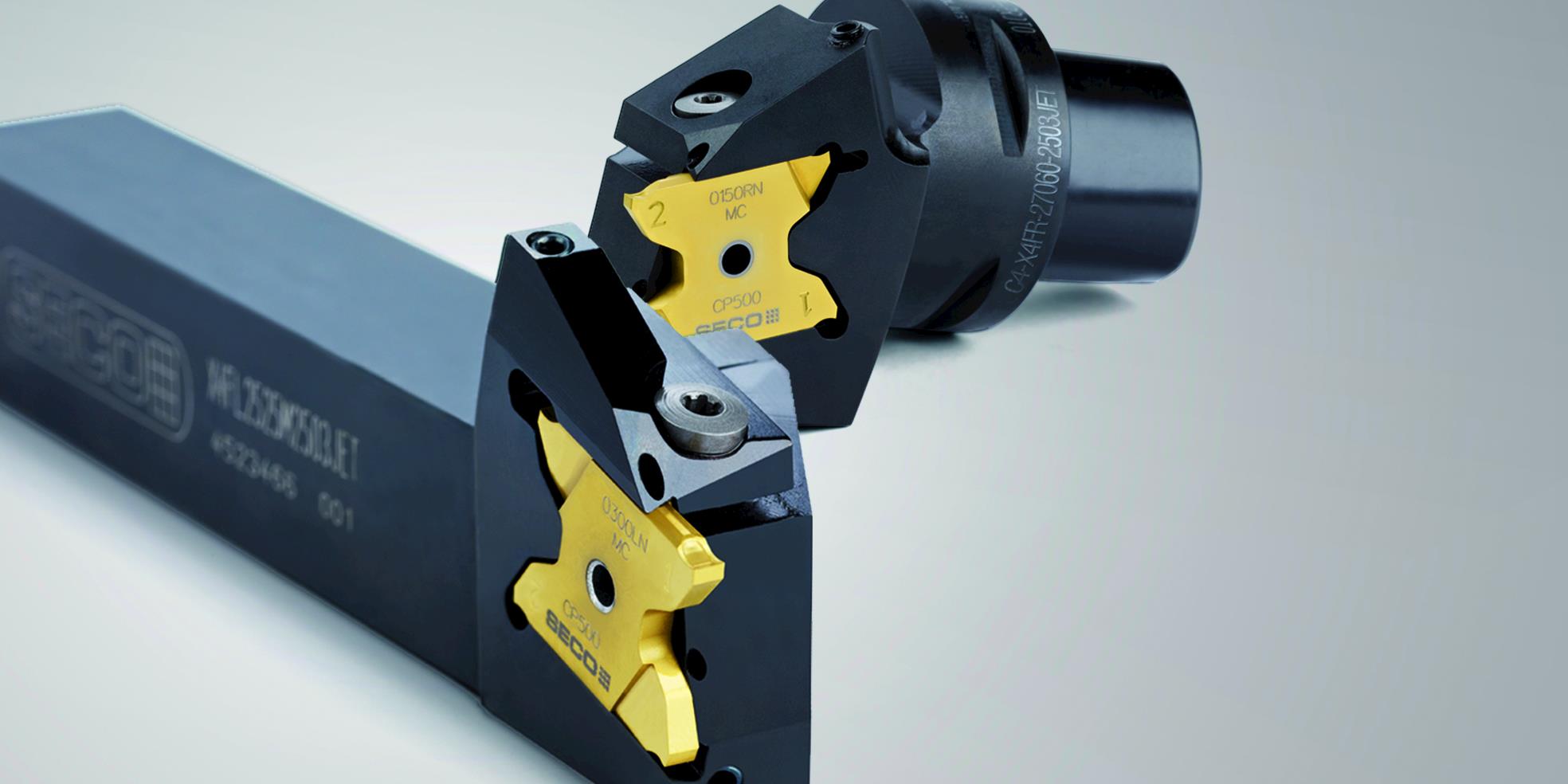

The Seco solution: Achieve longer tool life and greater process security with Jetstream Tooling® (JETI) Duo integrated holders for high-pressure through-tool coolant.

Tackle the challenges machining stainless steels, superalloys and other challenging materials of any thickness with your best setup for successful results and optimal process security. That setup starts with greater coolant volume and pressure, which help ensure better cuts and longer tool life, improved chip formation and evacuation, and surface finishes that meet your expectations. To ensure excellent turning and avoid tool deformation, rely on dual coolant streams with Jetstream Tooling® (JETI) Duo toolholders for parting-off and grooving, now available for Capto holders.

Your challenge: Low-pressure coolant systems and unique applications require the use of only one coolant channel.

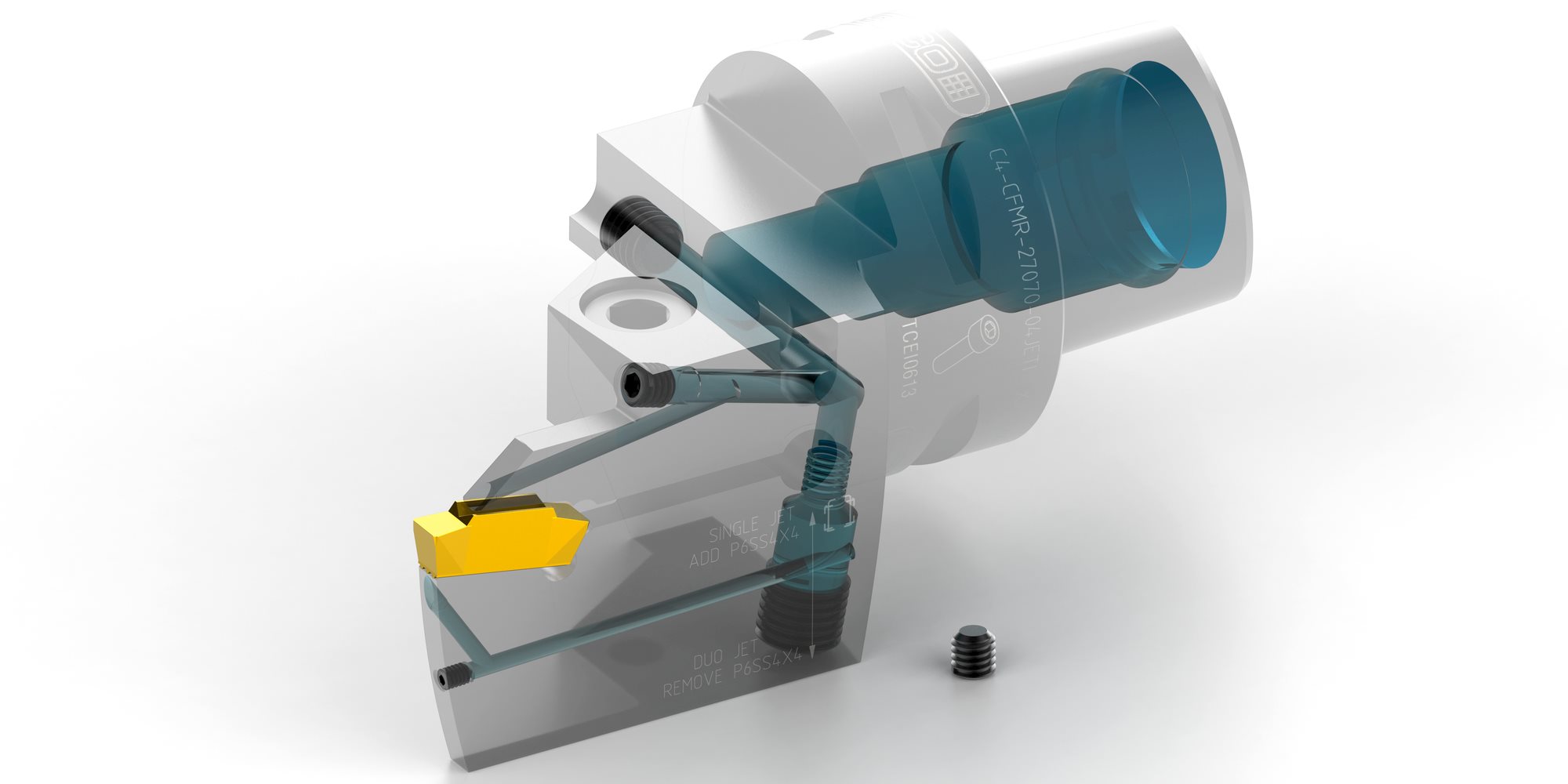

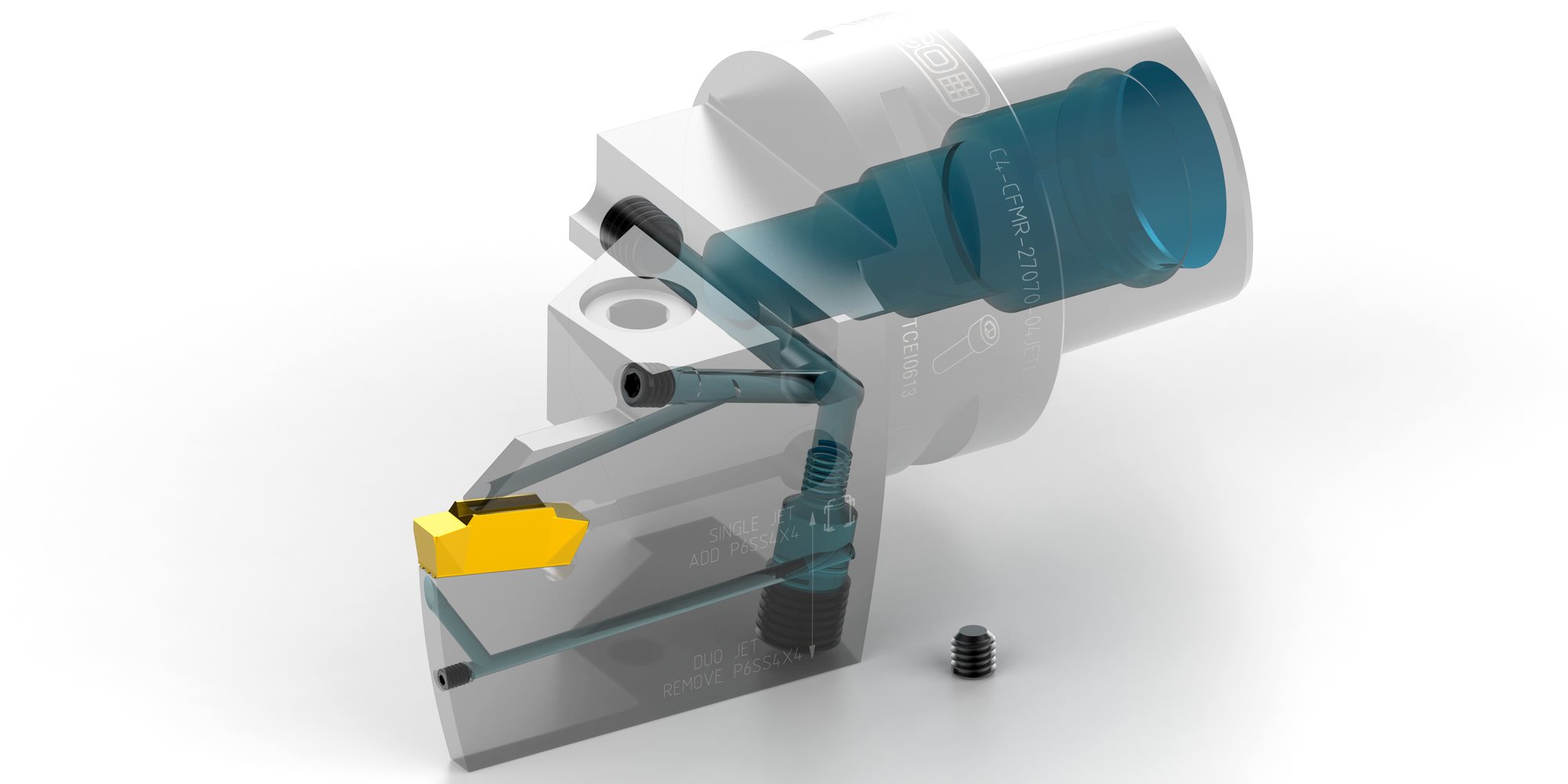

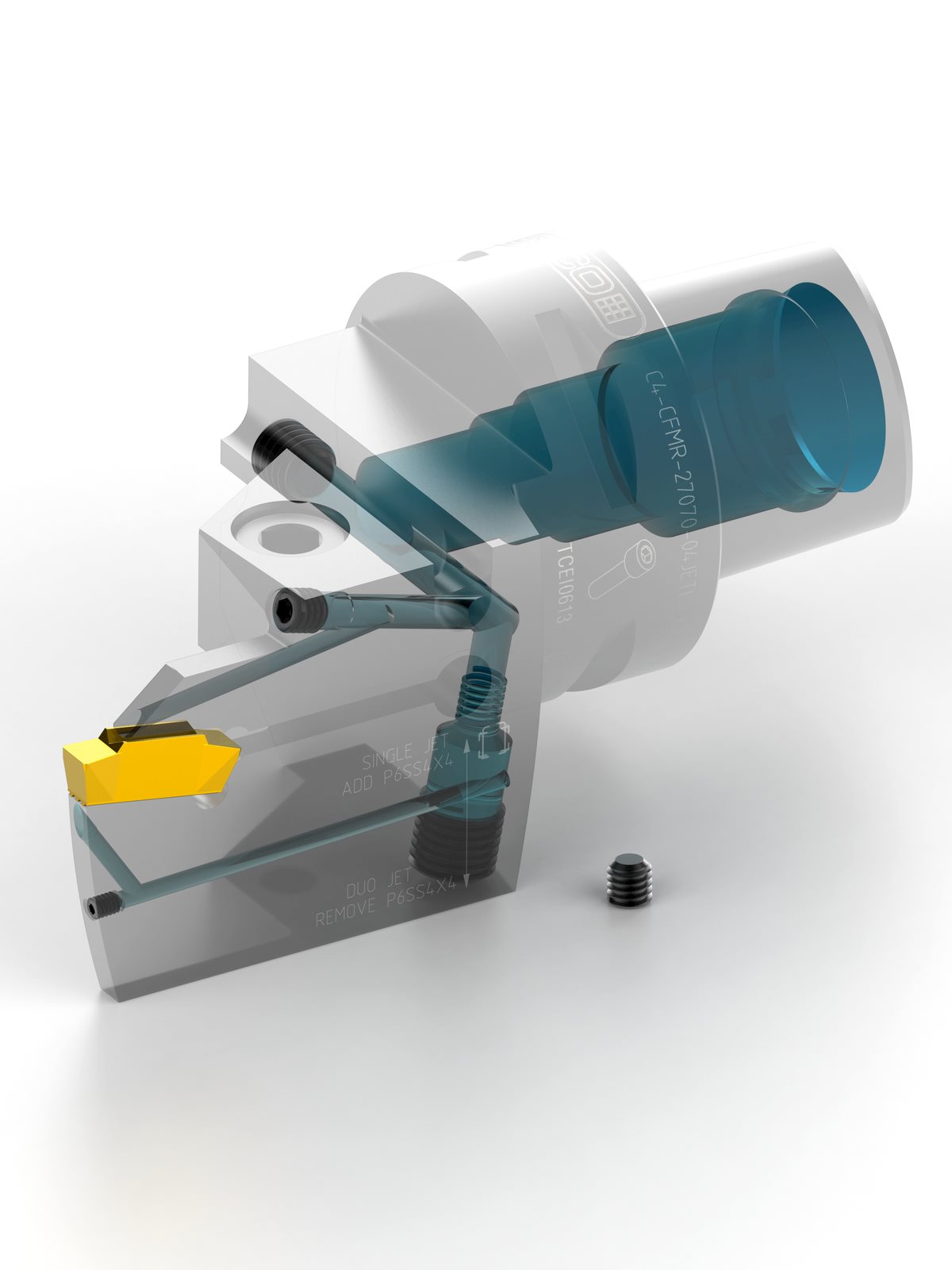

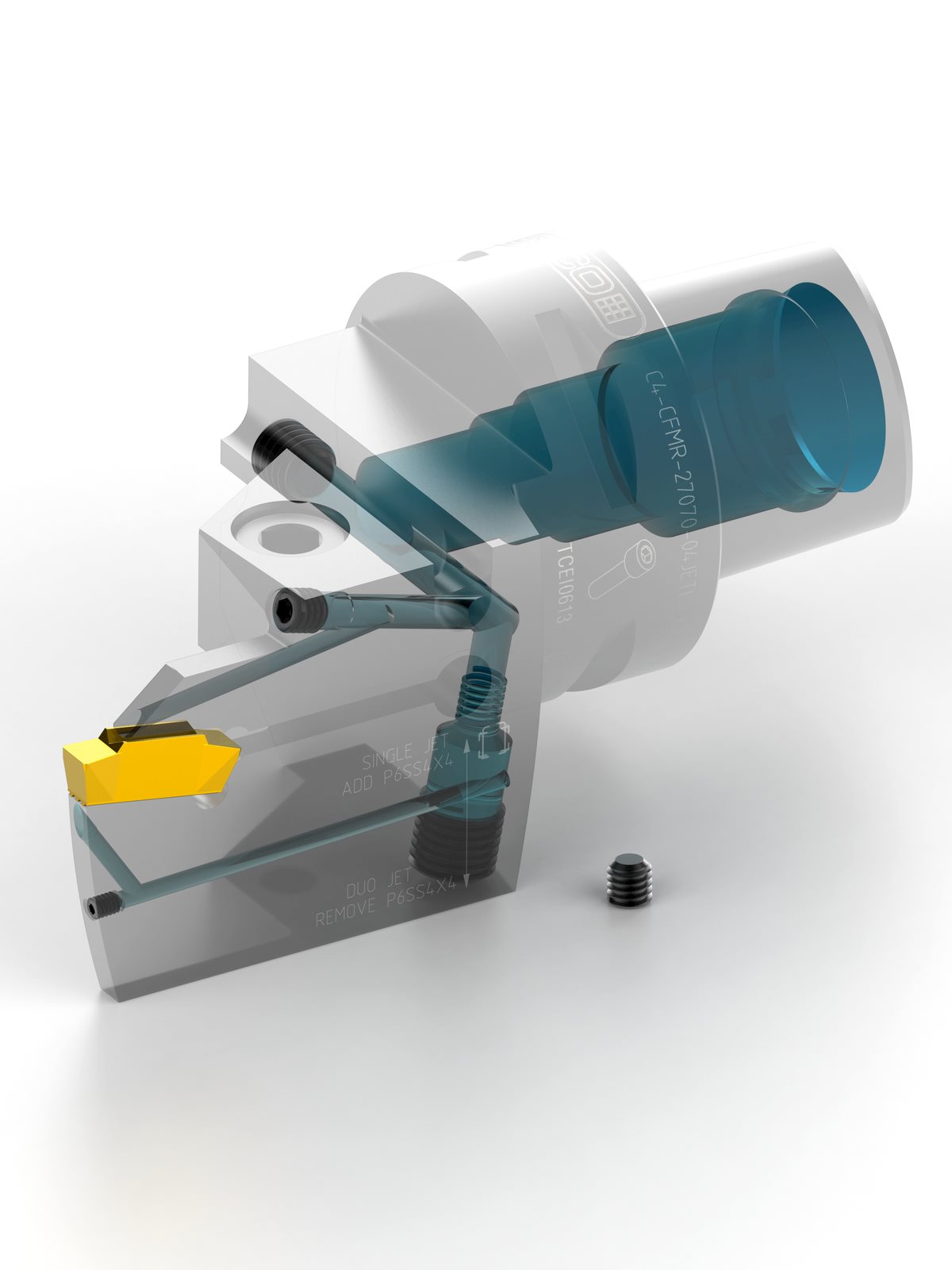

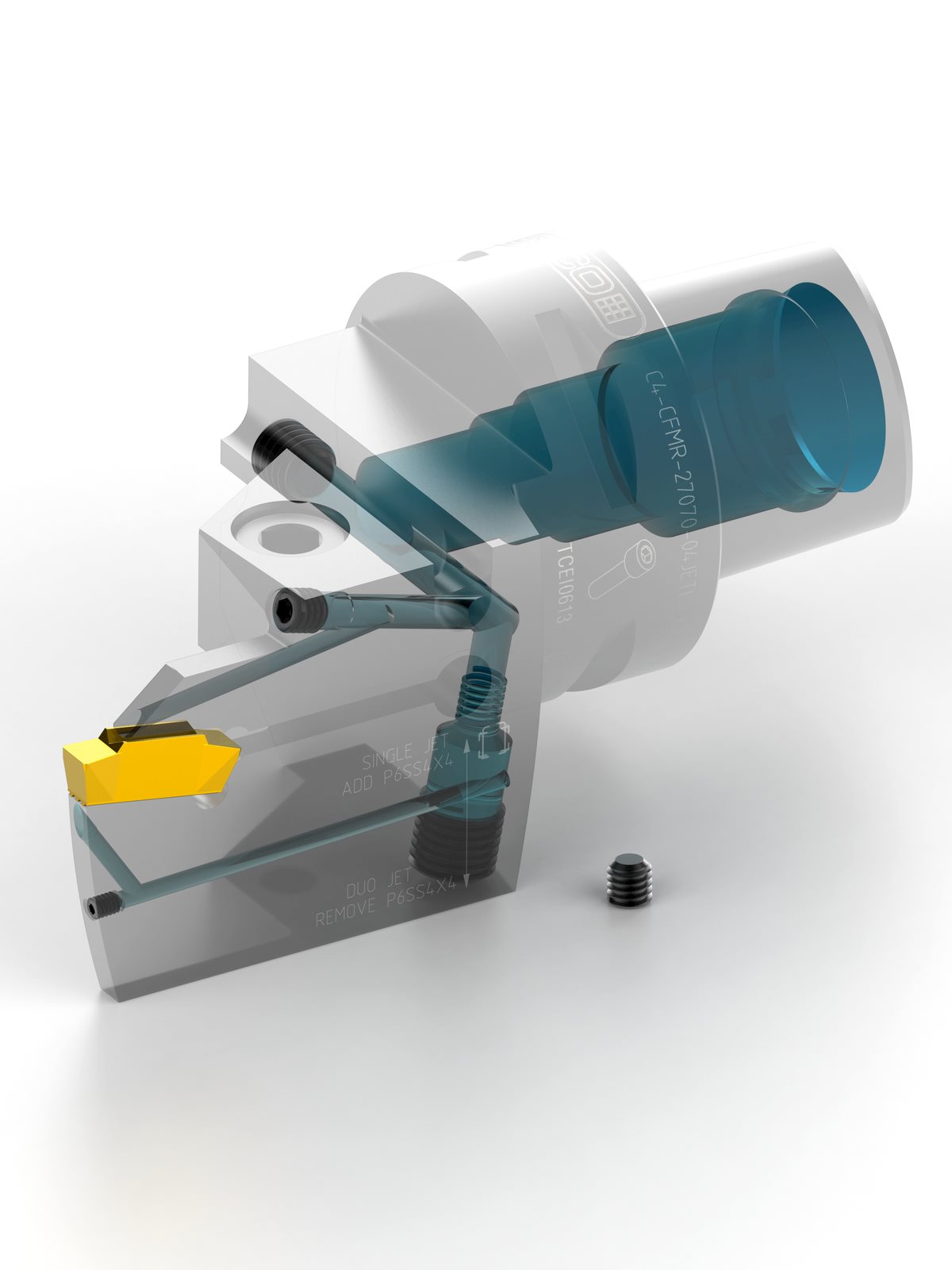

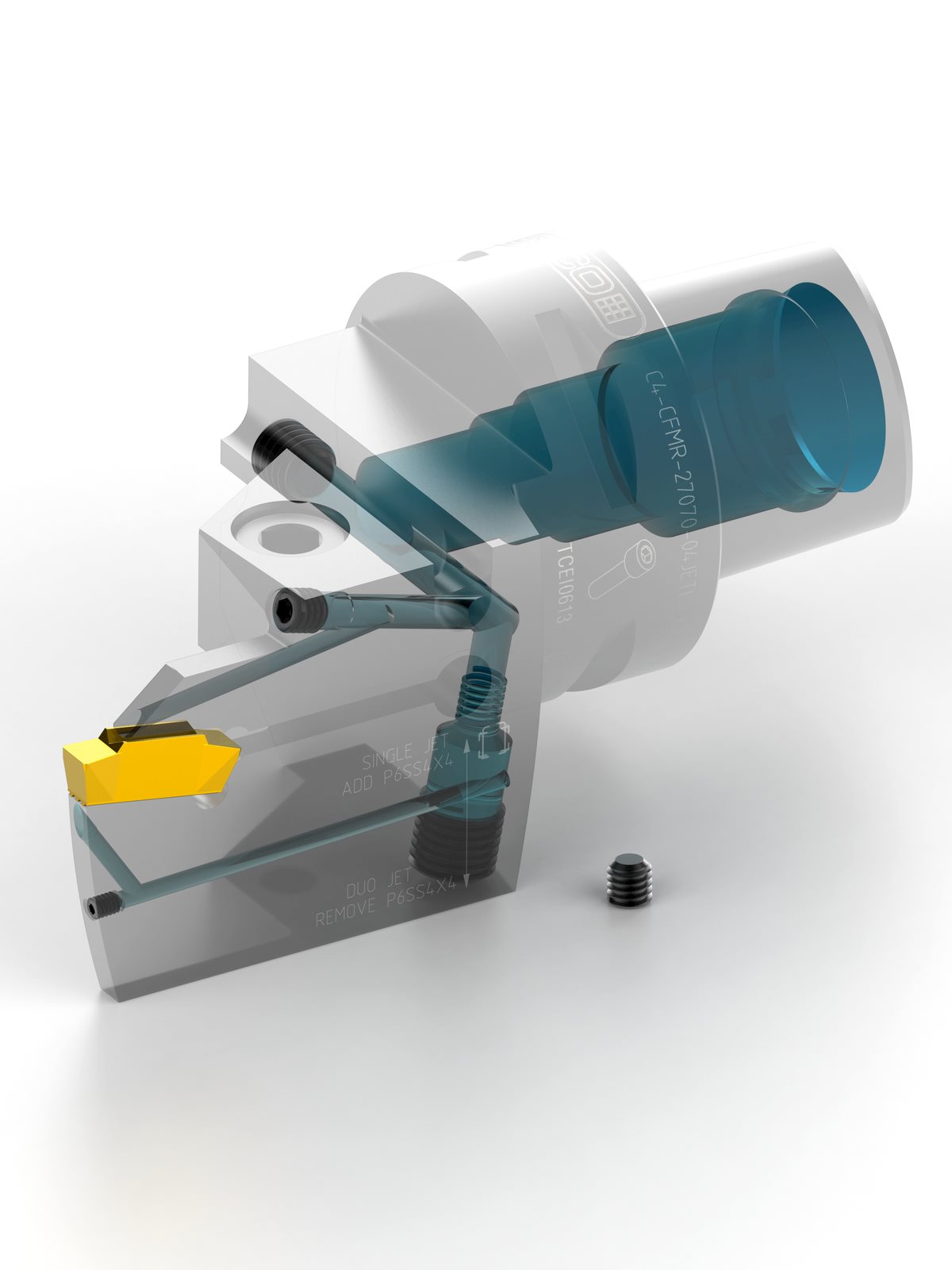

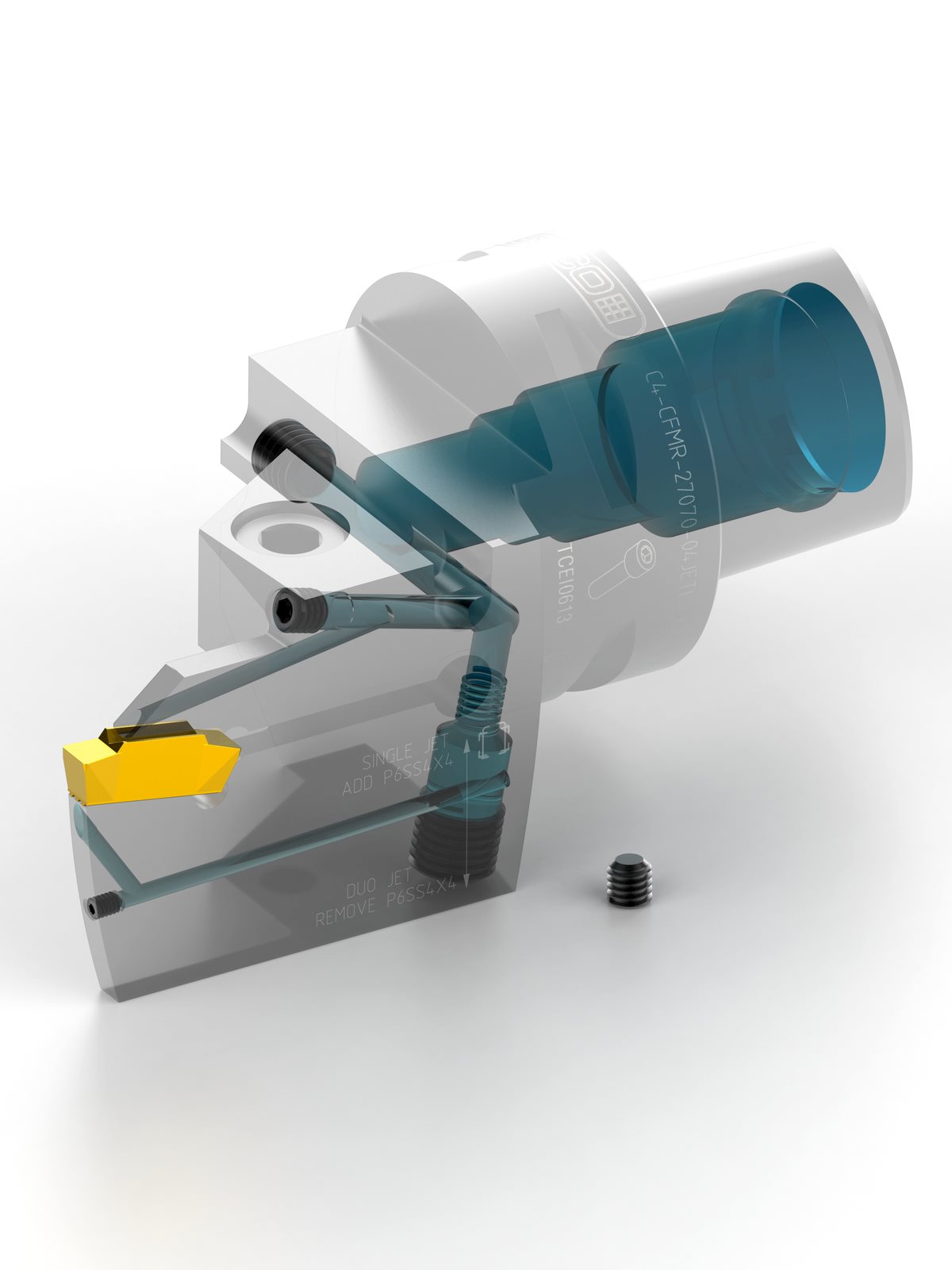

The Seco solution: Optimize processes and handle a wider range of machining conditions with toggleable Single/Duo Jet configurations on new JETI Capto holders for grooving and parting-off applications.

Improve your grooving and parting-off security and performance – and your tool life – while you avoid tool and shank deformation, with secure holders that incorporate an on/off switch to deliver high-pressure coolant only when you need it. This simple, easy-touse feature improves the flexibility of your Capto holders so you can carry less inventory. At the same time, you can rely on these holders to help you achieve ideal chip formation and management in a wide range of parting-off and grooving operations.

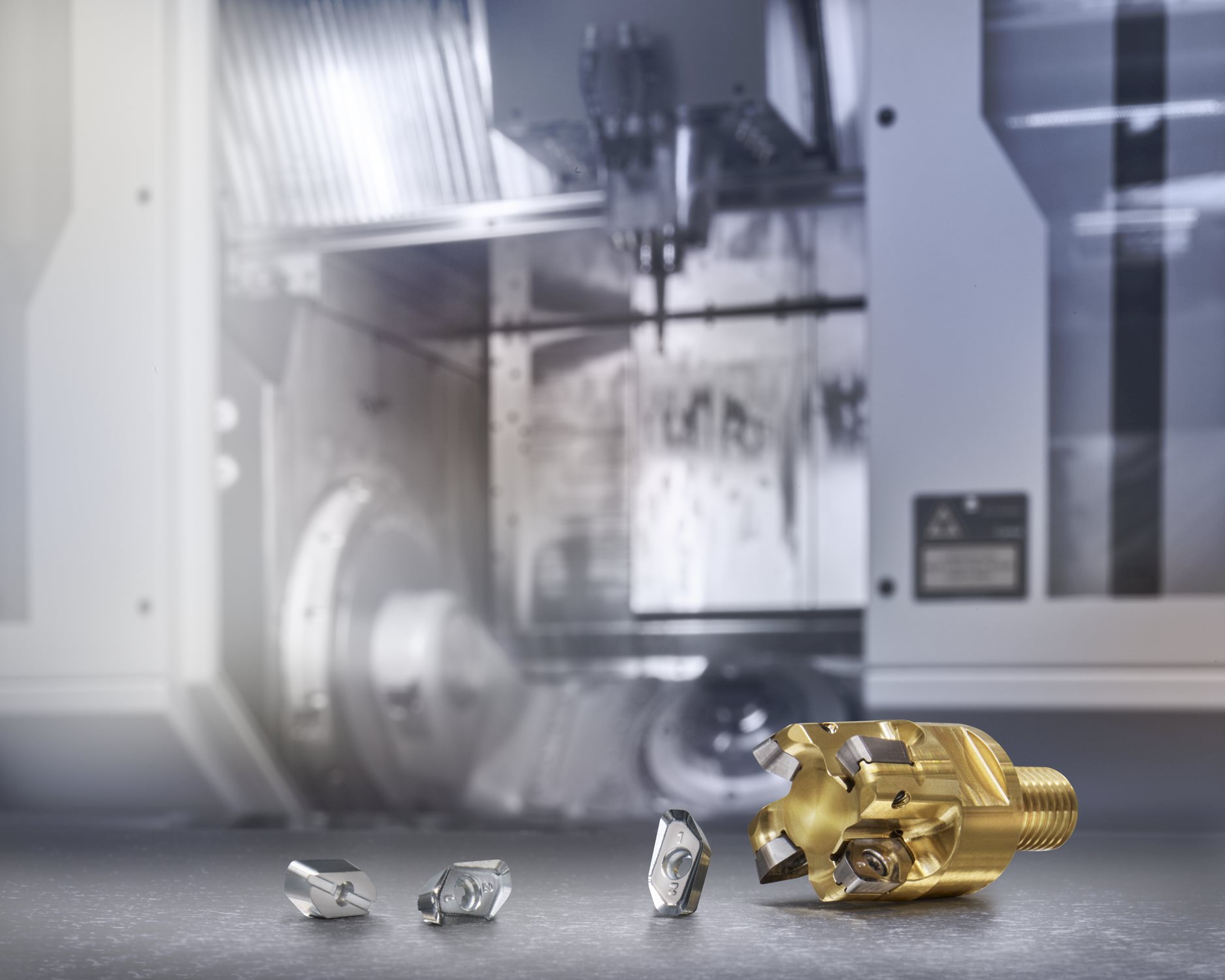

Your challenge: Long, stringy chips cause poor surface finishes, scrap workpieces or cause unplanned machine downtime.

The Seco solution: Create smaller, more easily controlled chips for better surfaces and more secure processes with precise coolant delivery.

Discover the product range

Contact Us

Related content

Product details

Factsheet - JETstream Tooling Seco Capto Toolholders

JETSTREAM TOOLING® SECO CAPTO™ GENERAL ISO TURNING

Optimize Multi-Task Machining Coolant And Results

JETI Coolant Supply Alternatives

JETSTREAM TOOLING COOLANT PRESSURE COMPARISON

JETSTREAM TOOLING - TOURNAGE D'UN ARBRE

JETI CONVERSION GROOVING AND PARTING-OFF

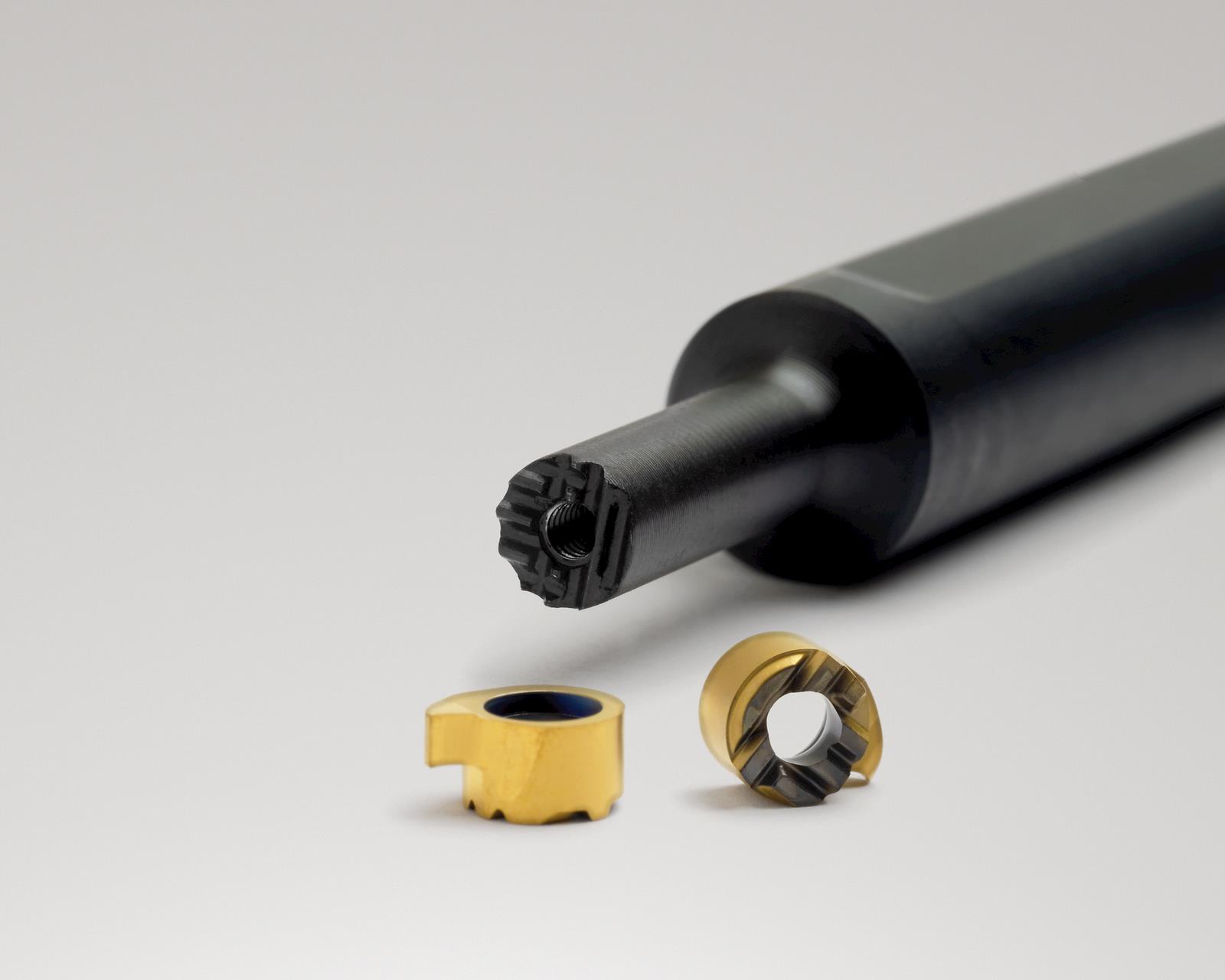

High-pressure coolant for round inserts enhances turning productivity

JETI Toolholder for RCMT/RCGT Turning Inserts

Video: Toolholder DUOJET with On-off switch

Grooving and Parting-off

JETSTREAM TOOLING DUO

Factsheet - Seco-Capto MTM Jeti Toolholders

Factsheet - JETI Toolholder for round turning Inserts

Advantages of Shorter Tooling for Multi-Tasking Machines - Seco Tools

Video: Tool Systems for Grooving and Parting-Off

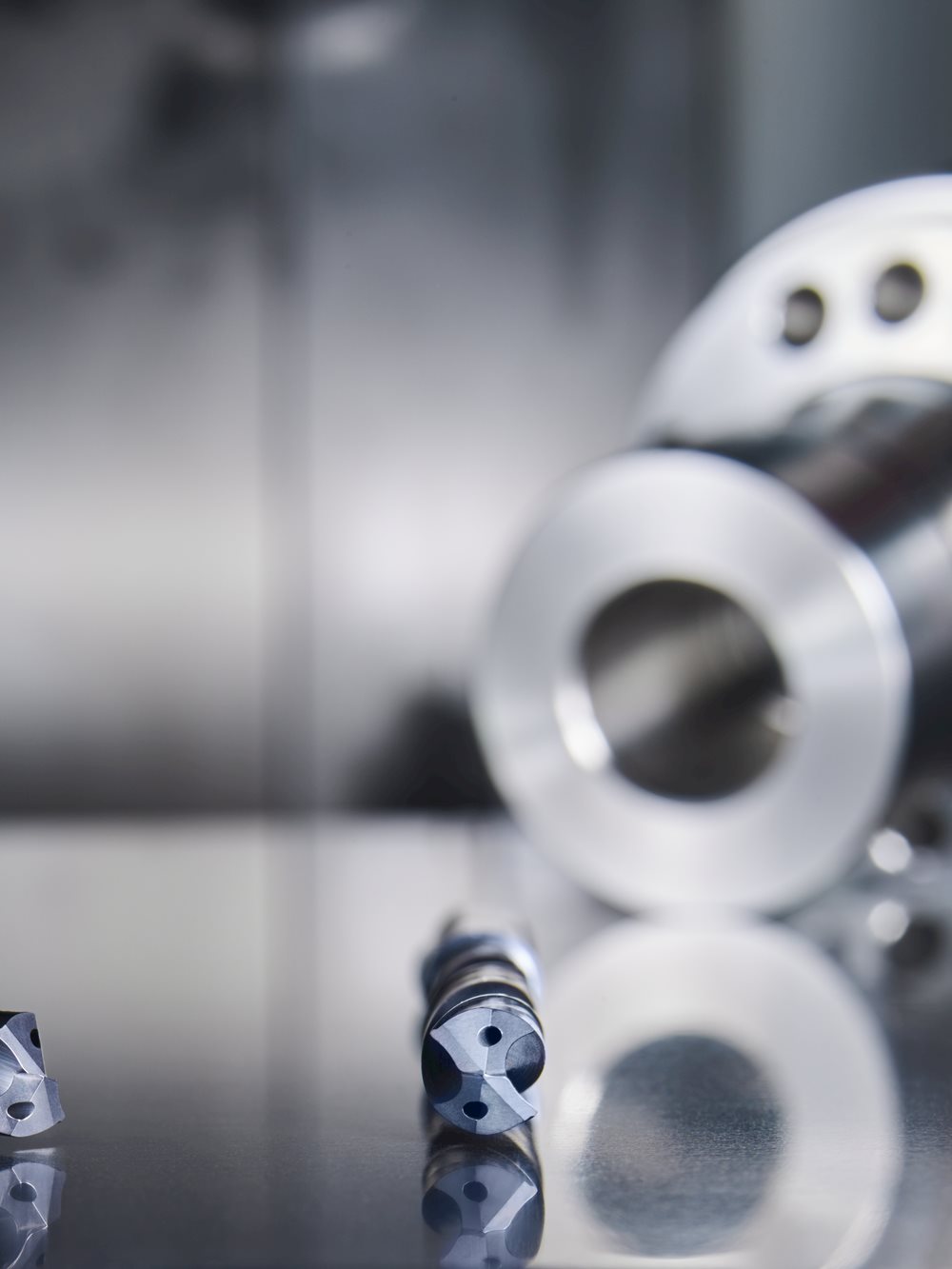

Seco Nanojet Reamers: reliable precision

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

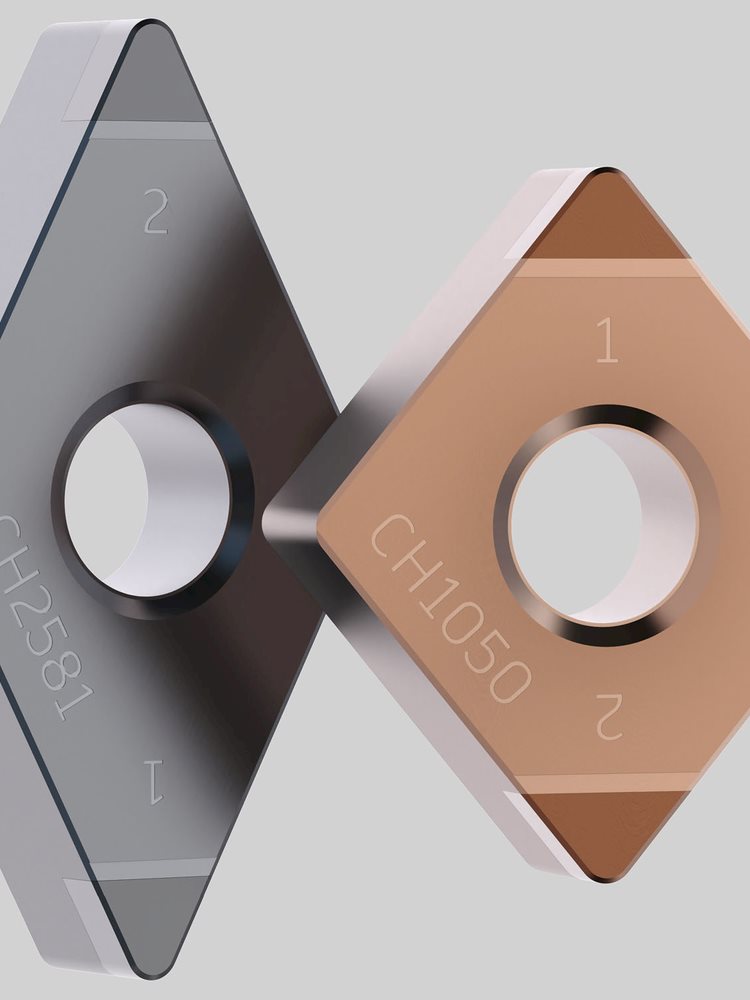

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

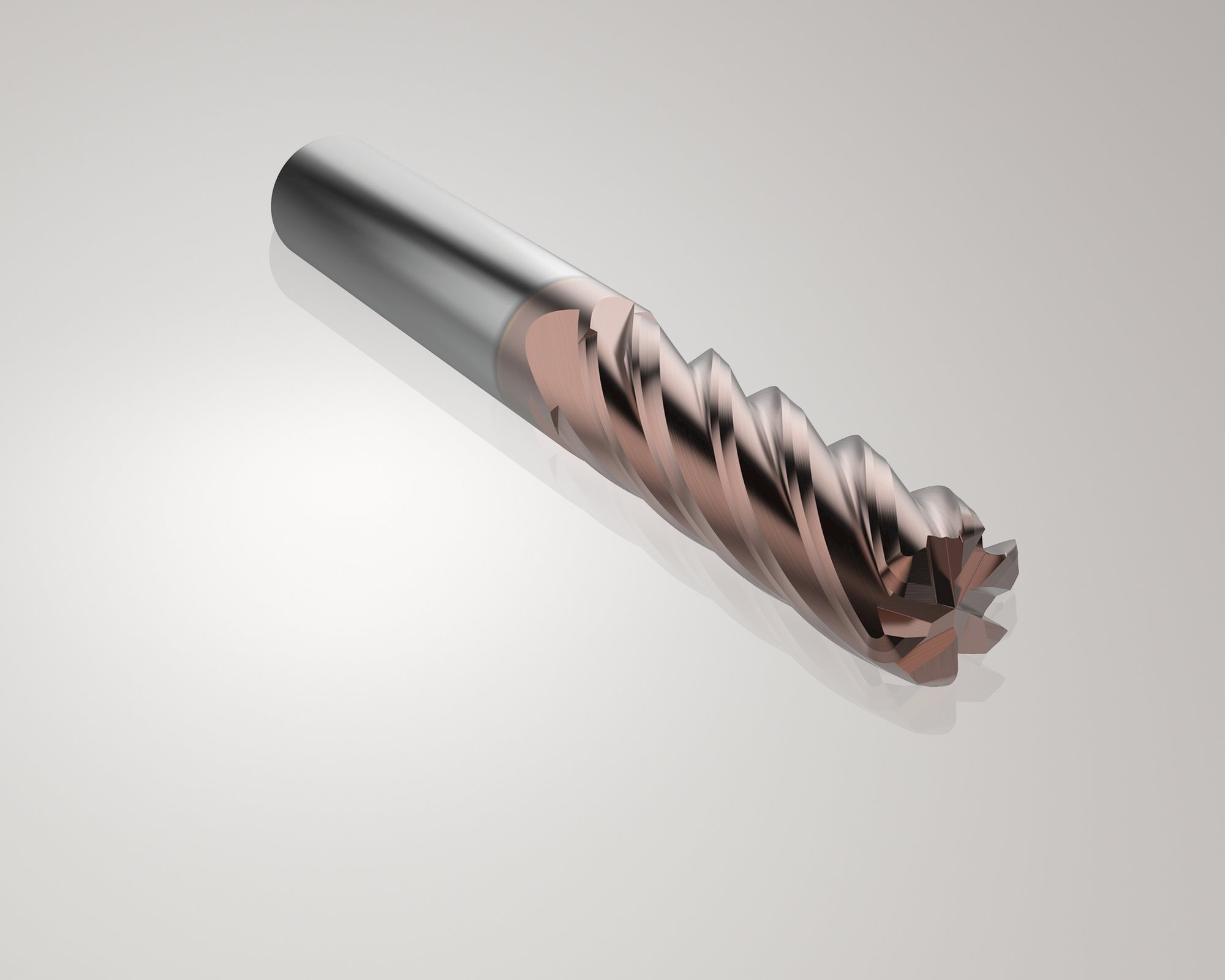

JS720 Solid End Mills addition

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

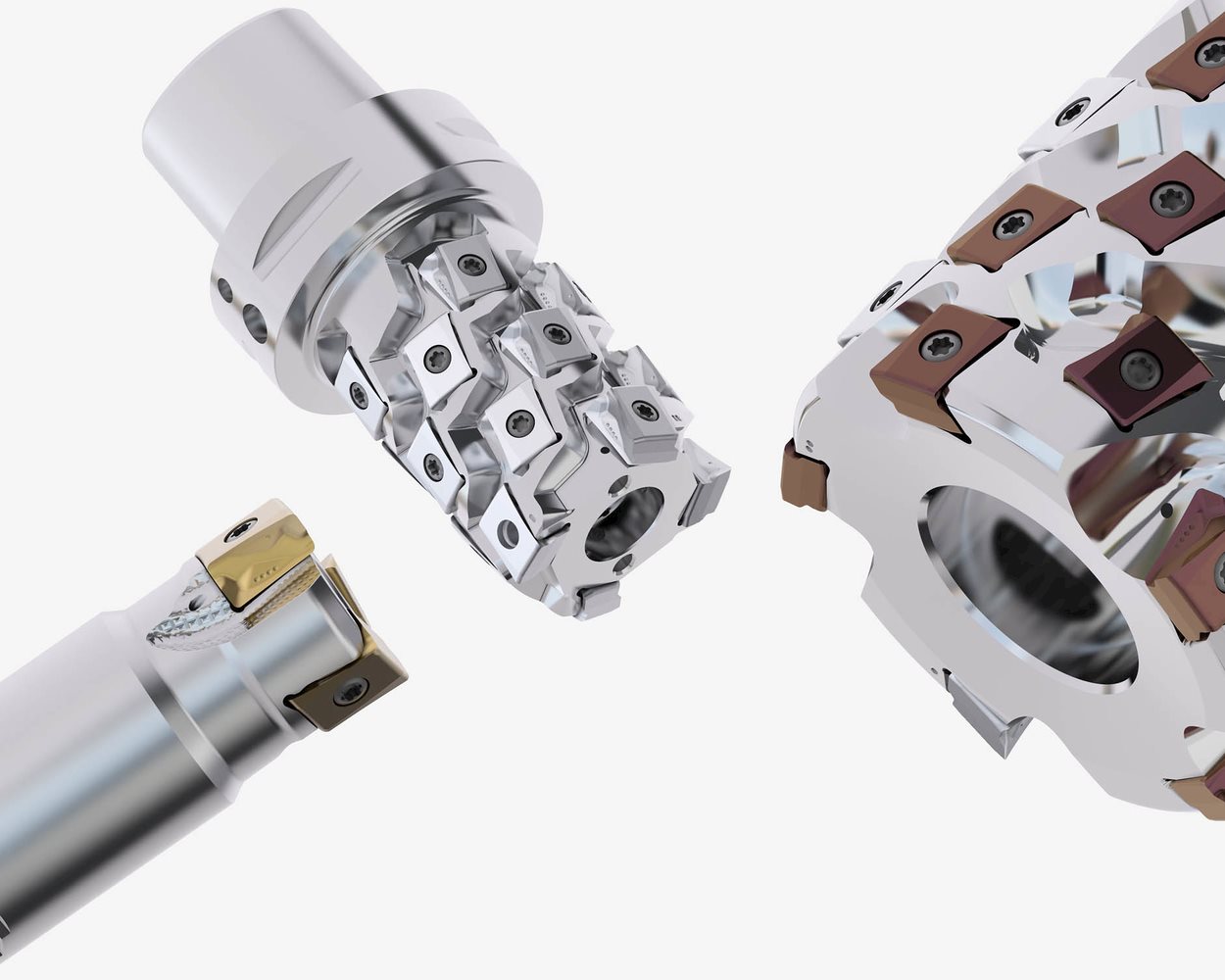

Square T4-12 Upgrades

Universal Drills

Seco JSE510 Solid End Mill series

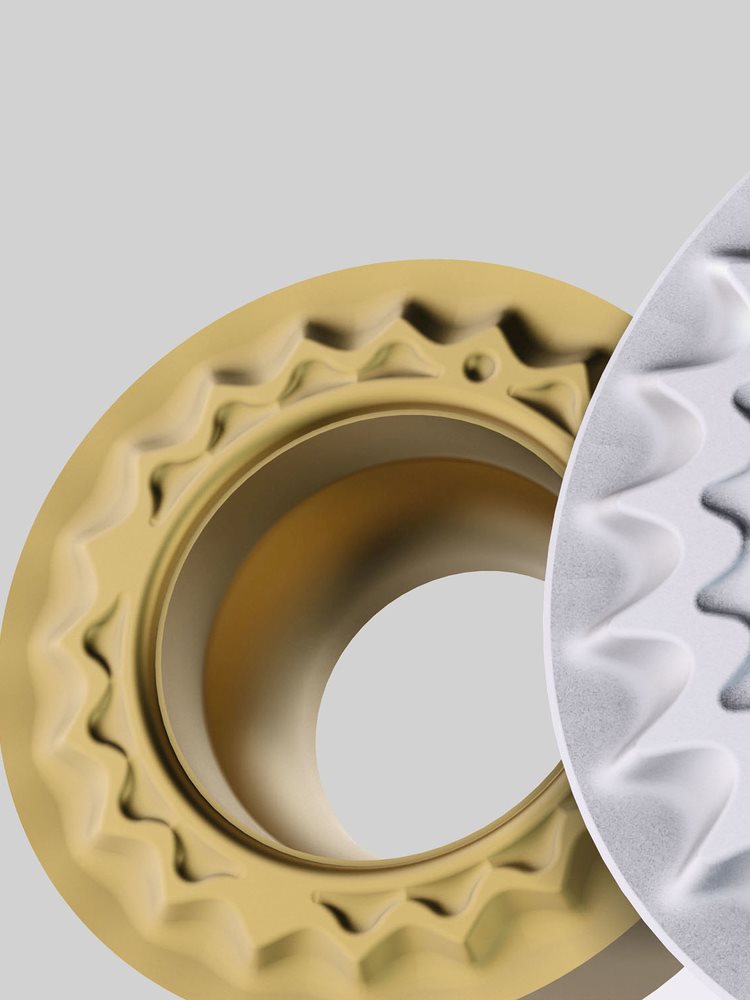

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Video: Optimize grooving and parting off with high-pressure coolant technology

Seco X2 System for Small Part Machining

Machining Navigator / Catalog Turning

Grooving & Parting-Off, MDT - Machining demonstration

High Feed square cut size 14 insert

ISO K THREADING TAPS

Video: Grooving & Parting-Off, MDT

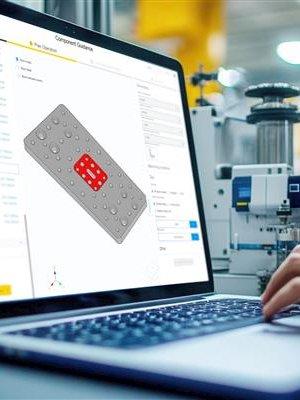

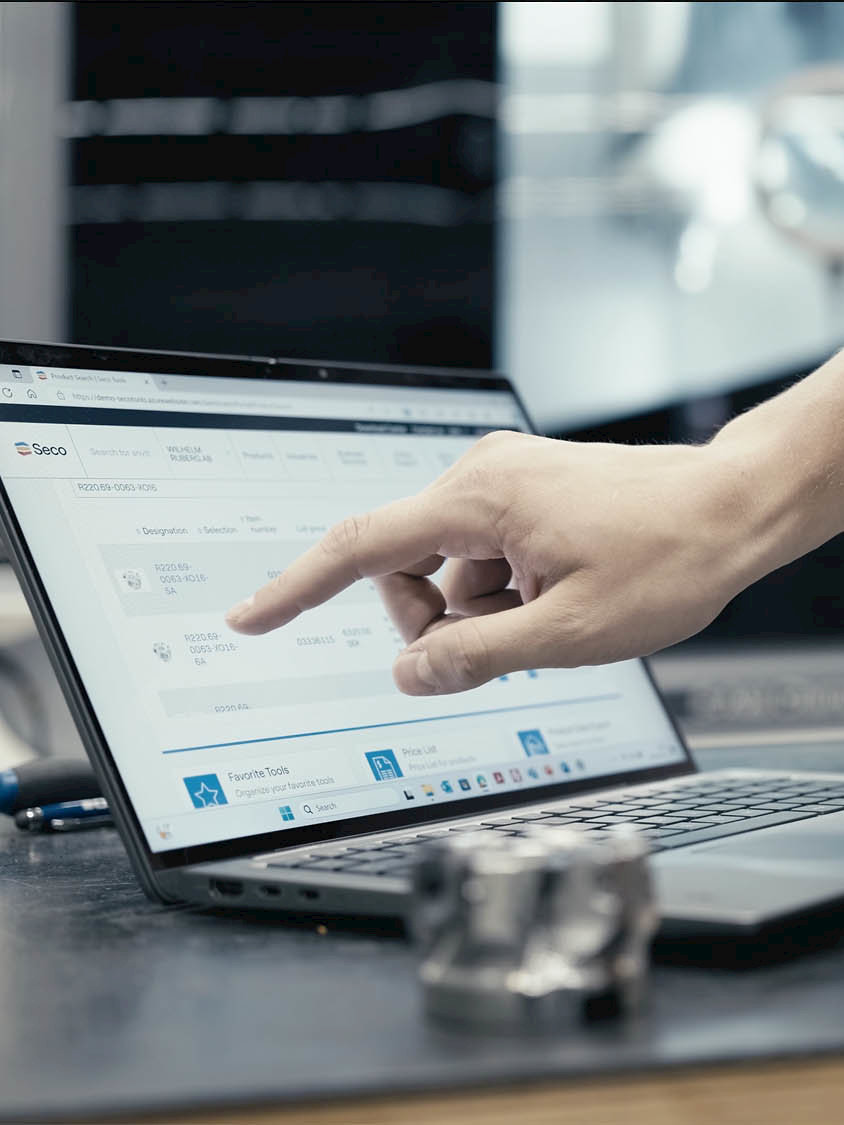

Seco Component Guidance

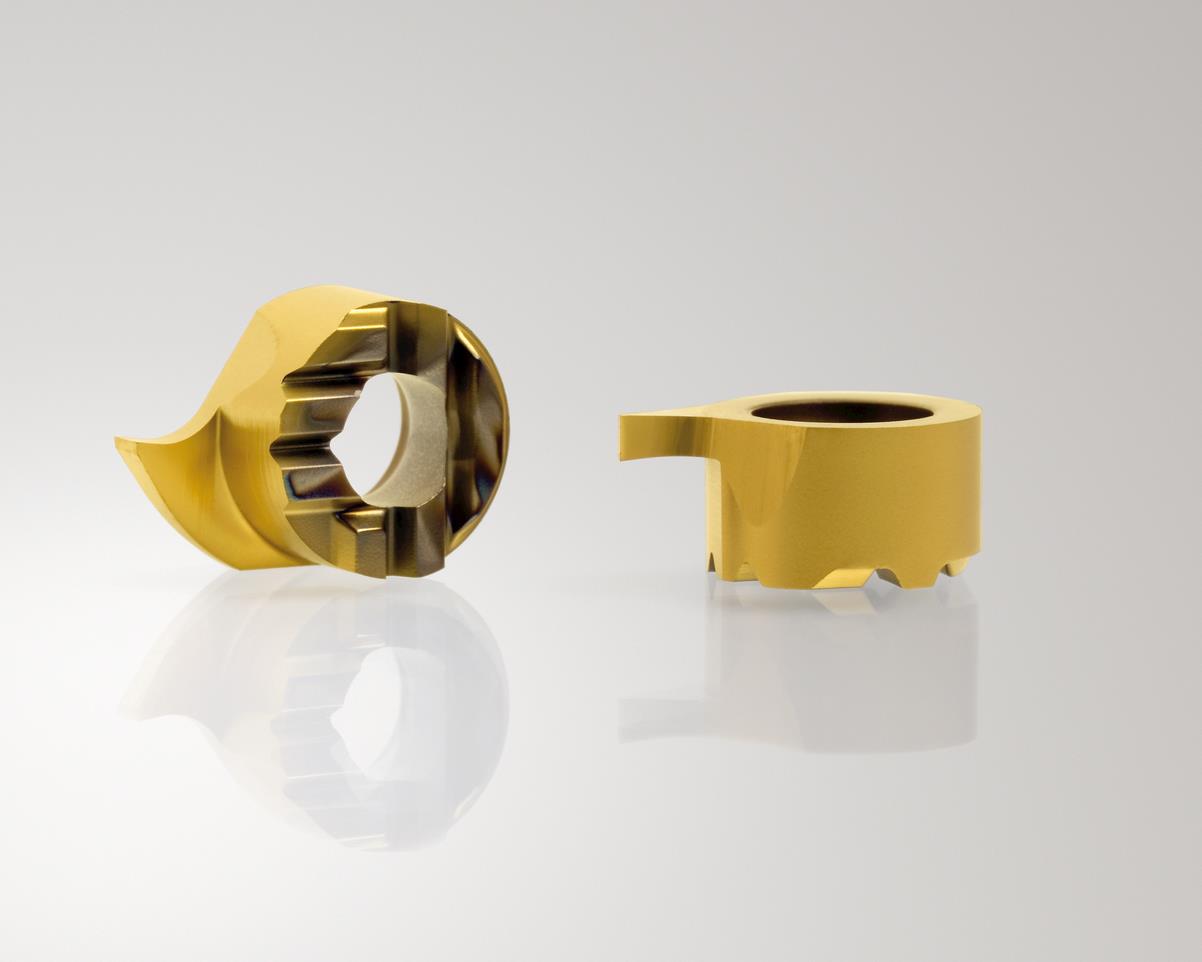

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

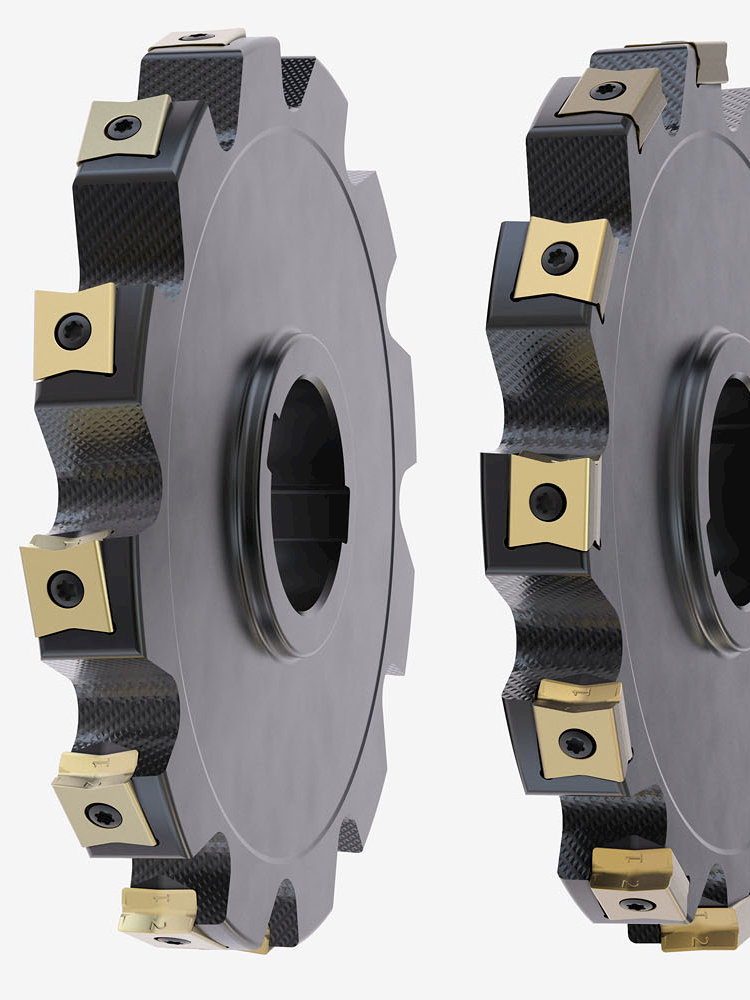

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Seco T35 Taps: match Tooling to Materials

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

X2 - Grooving And Parting-Off

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

JETSTREAM TOOLING®

Seco Innovates Jetstream Tooling® for ISO Turning Operations

150.10 - Parting-Off

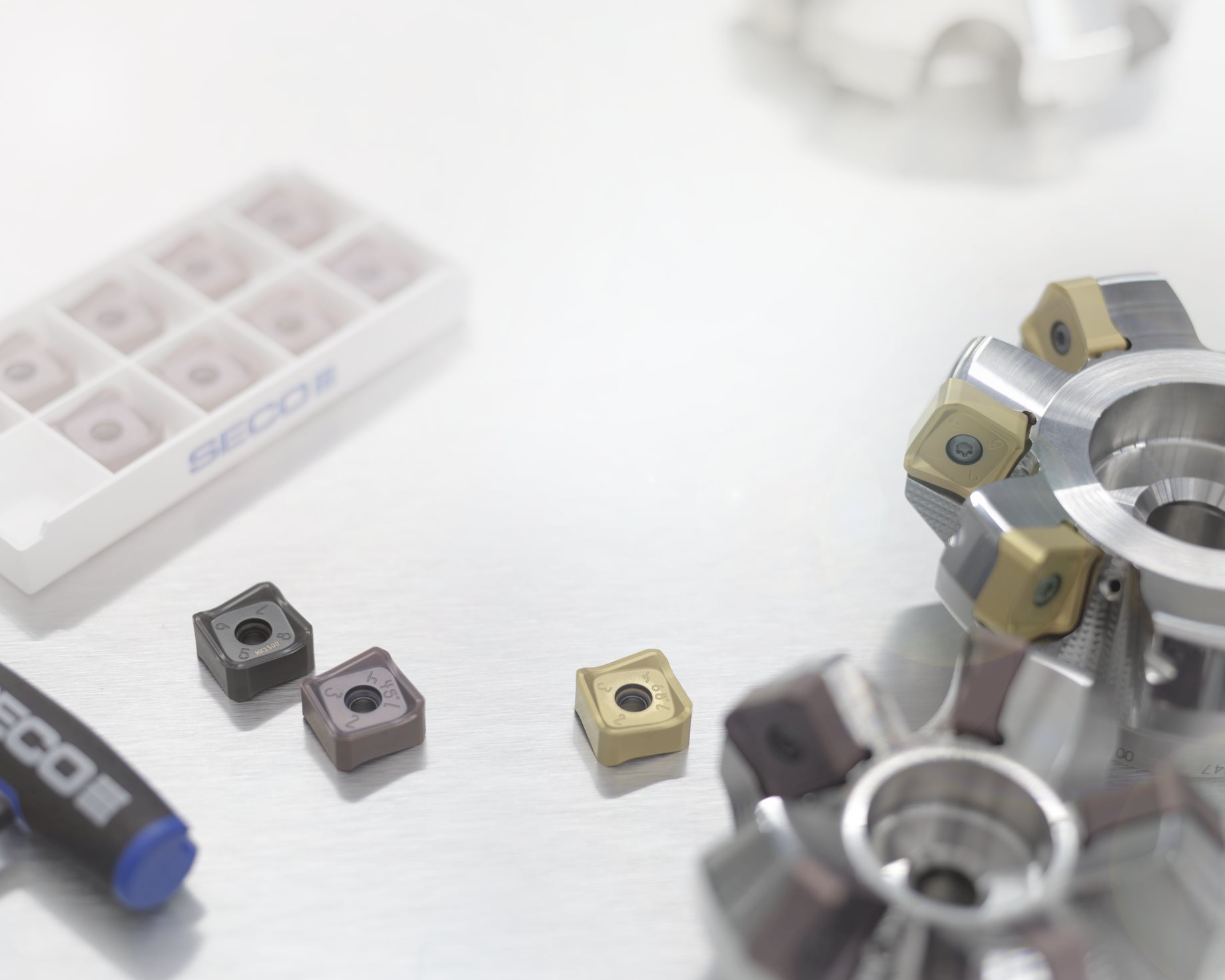

New MP Milling Grades

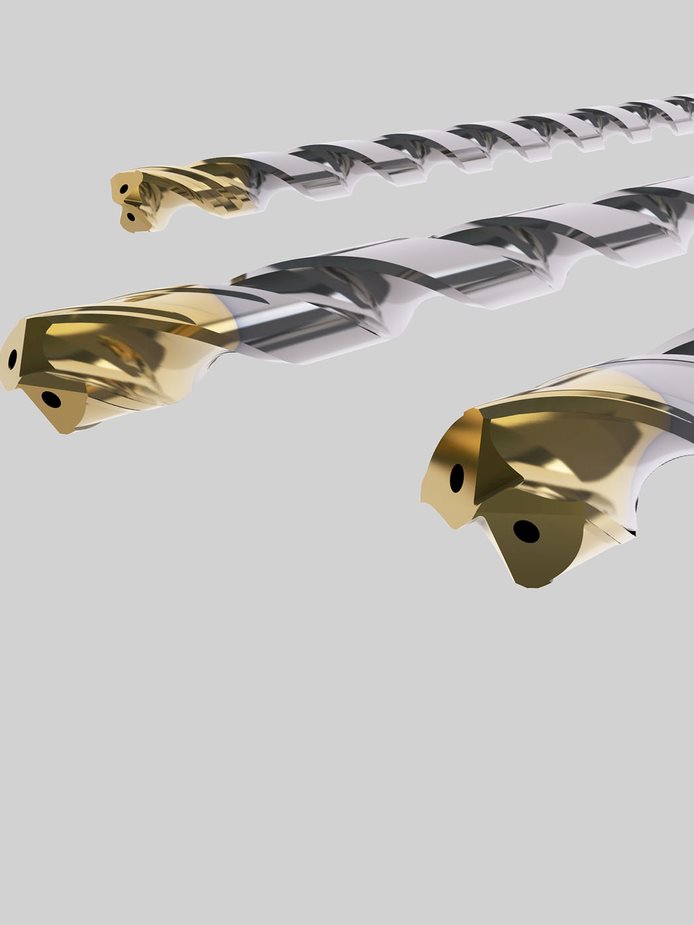

Unleash your drilling potential

Seco Tools Expands Range of Jetstream Tooling® Holders for General ISO Turning

COOLANT CLAMP IS SECO’S FIRST AM PRODUCT IN THE MARKET

JETI ISO Toolholder range extension

EXCLUSIVE EXCHANGEABLE HEAD GEAR SHAPER

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

MDT - Multi-Directional Turning and Grooving

Jetstream Tooling®

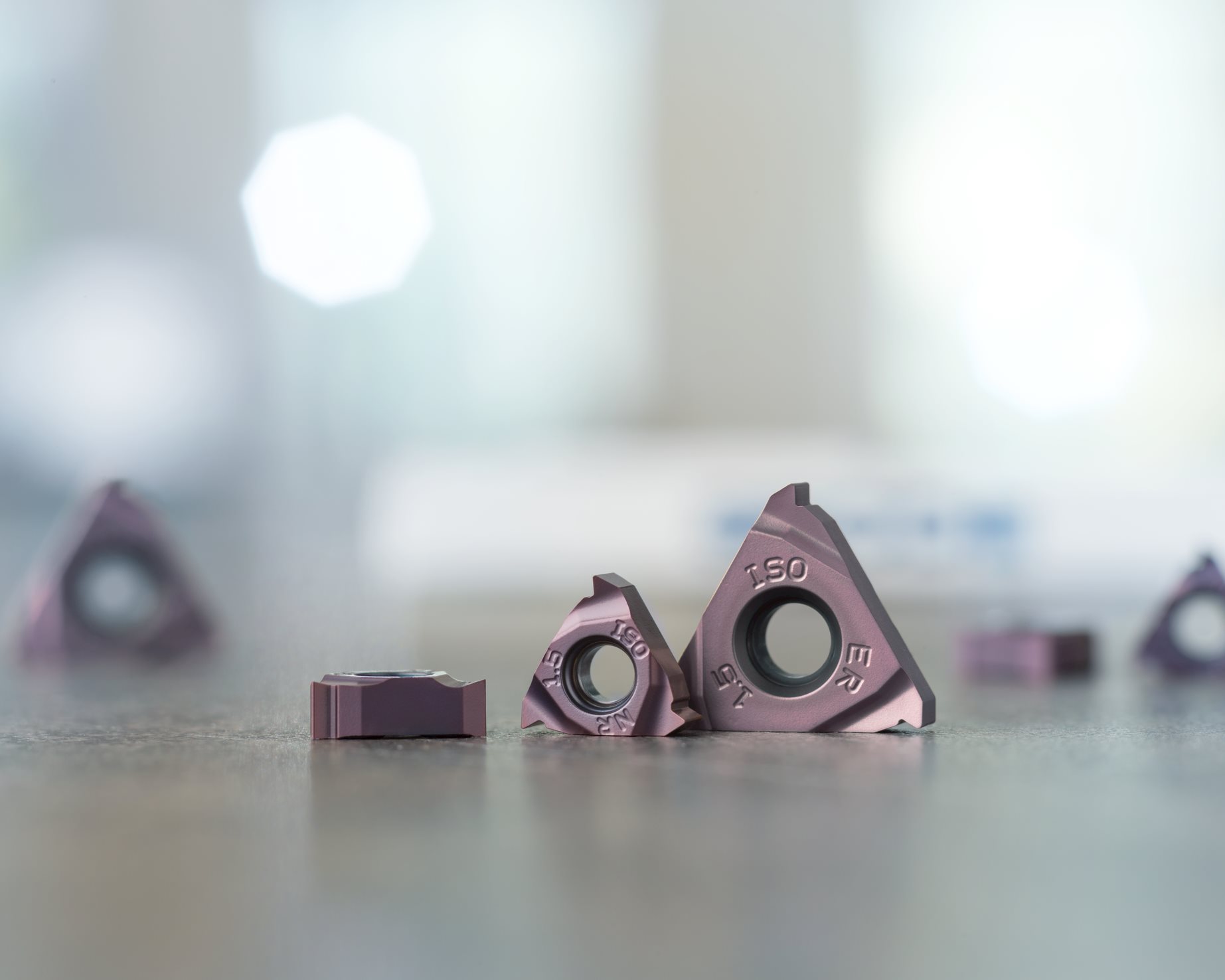

Video: Single-Point Threading Jetstream Introduction

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22

Small Diameter Internal - Mini-Shaft Inserts

Multidirectional Turning - MDT Inserts

Parting Off - 150.10 Inserts

Holders for Ceramic Inserts

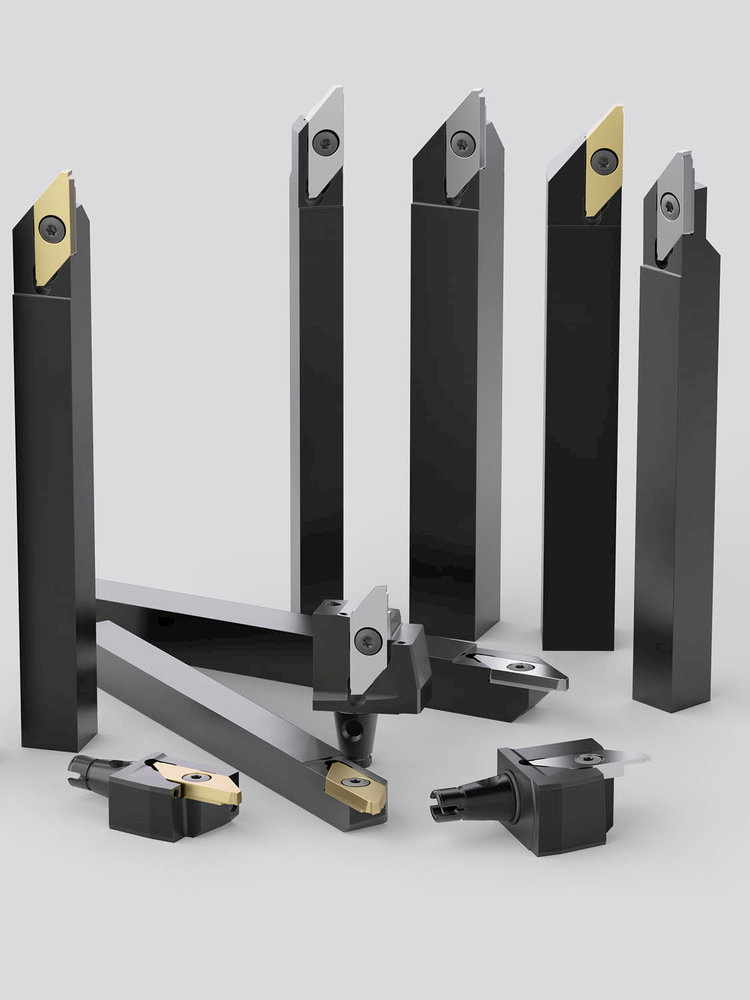

External

Toolholders for Grooving and Parting Off - Internal

X4 - Shallow Grooves And Parting-Off

Mini-Shaft - Small Diameter Internal Grooving

K-Style - Precision Grooves

Video: X4 Introduction

Video: Jetstream Tooling® Duo - Usage

Video: Grooving & Parting-Off, 150.10

Video: Grooving & Parting-Off, X4

Video: Grooving & Parting-Off, X4 - Machining Demonstration 1

Video: Grooving & Parting-Off, X4 - Machining Demonstration 2