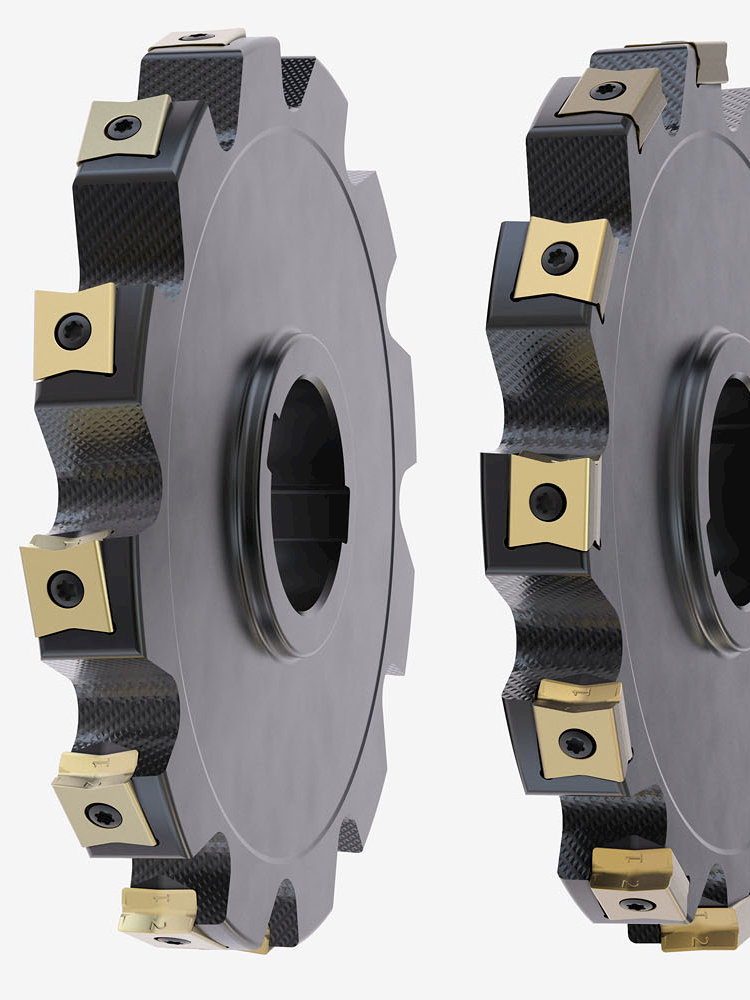

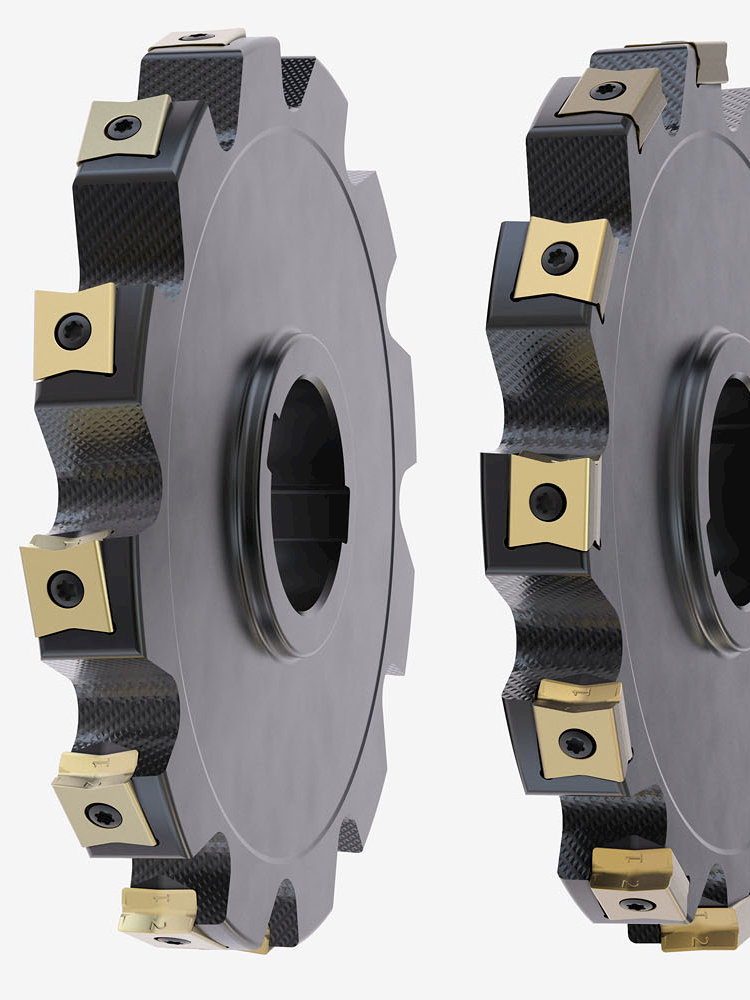

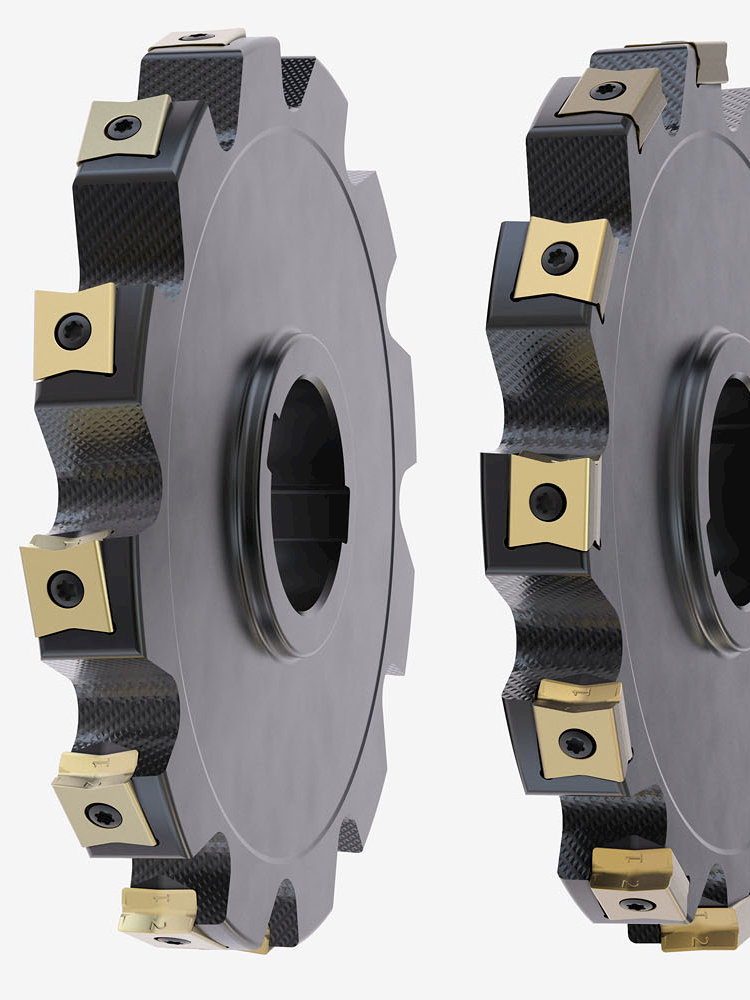

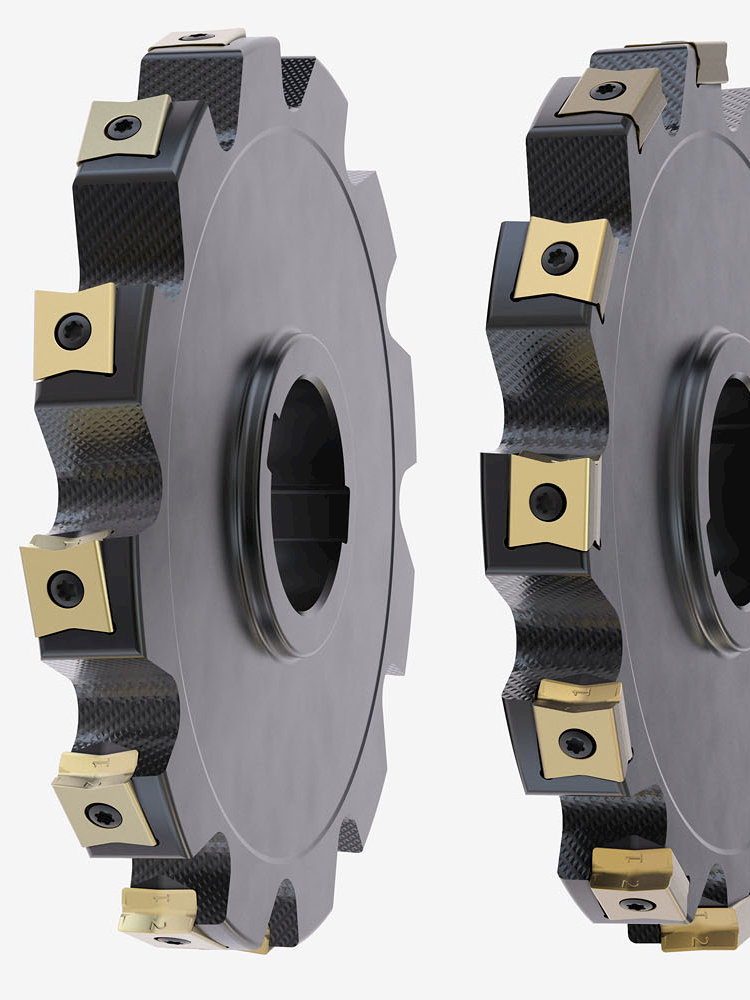

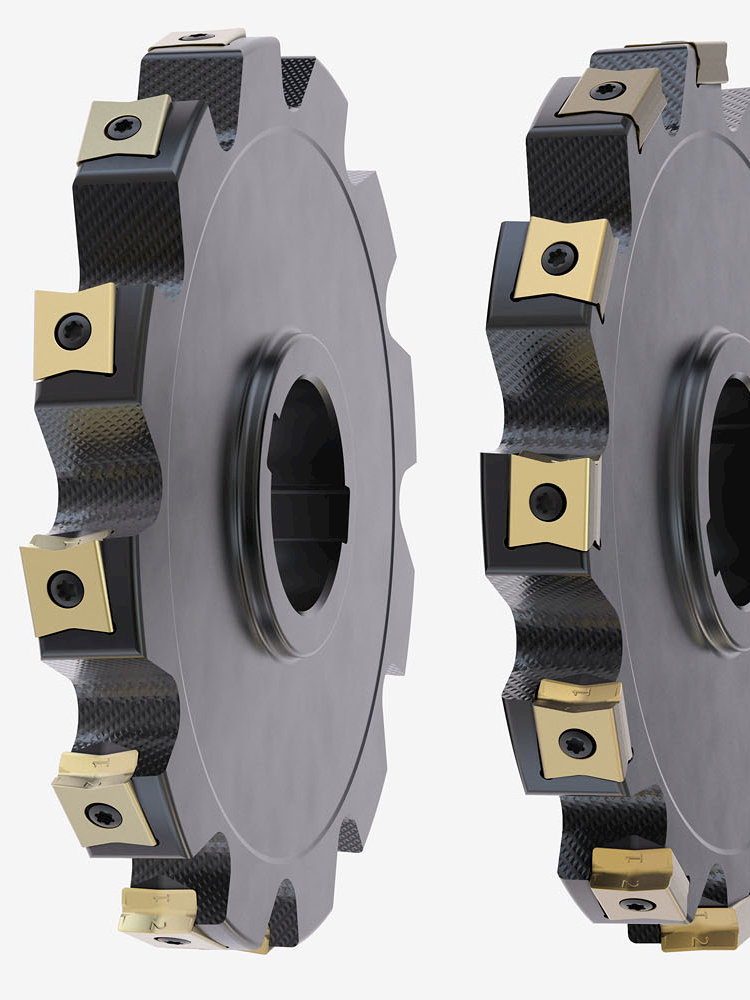

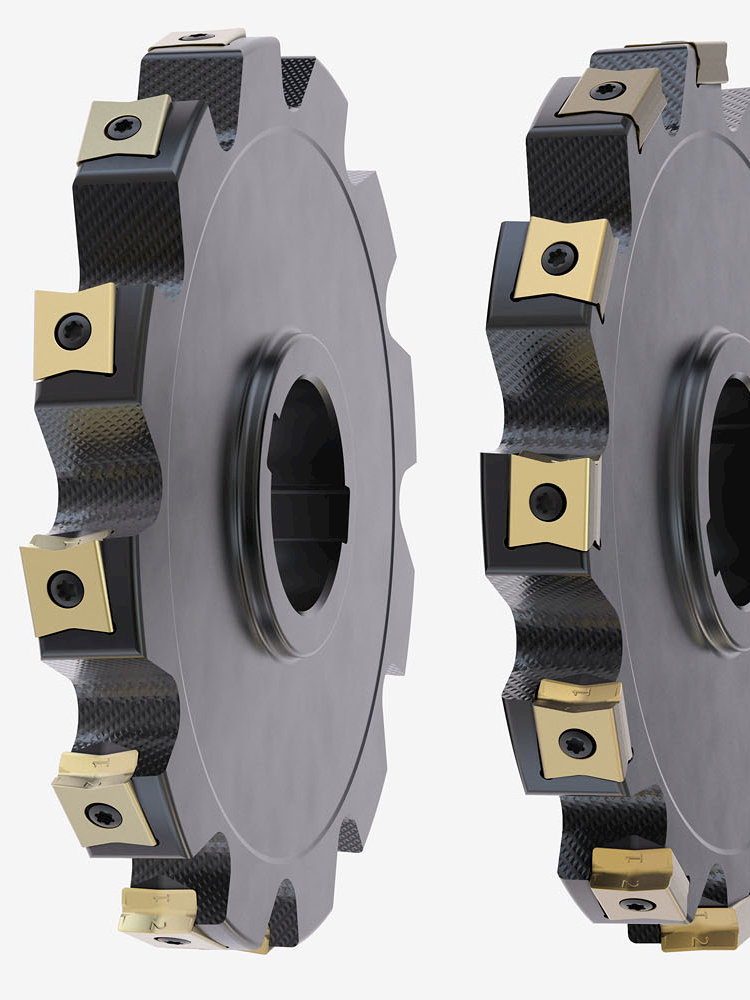

New Seco Disc Mills machine two sides of a part efficiently

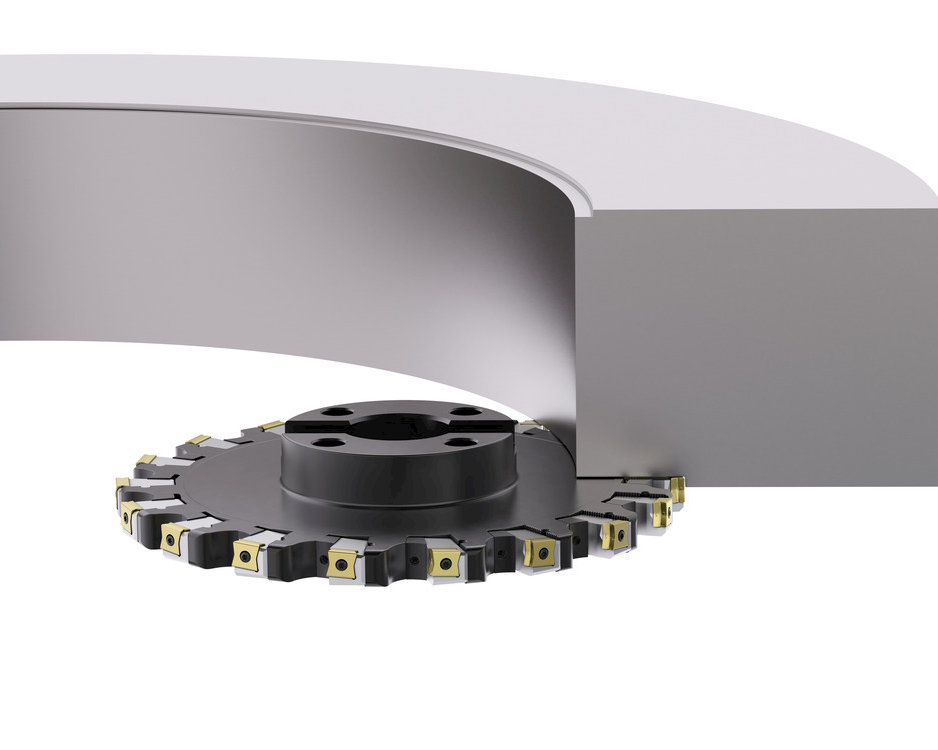

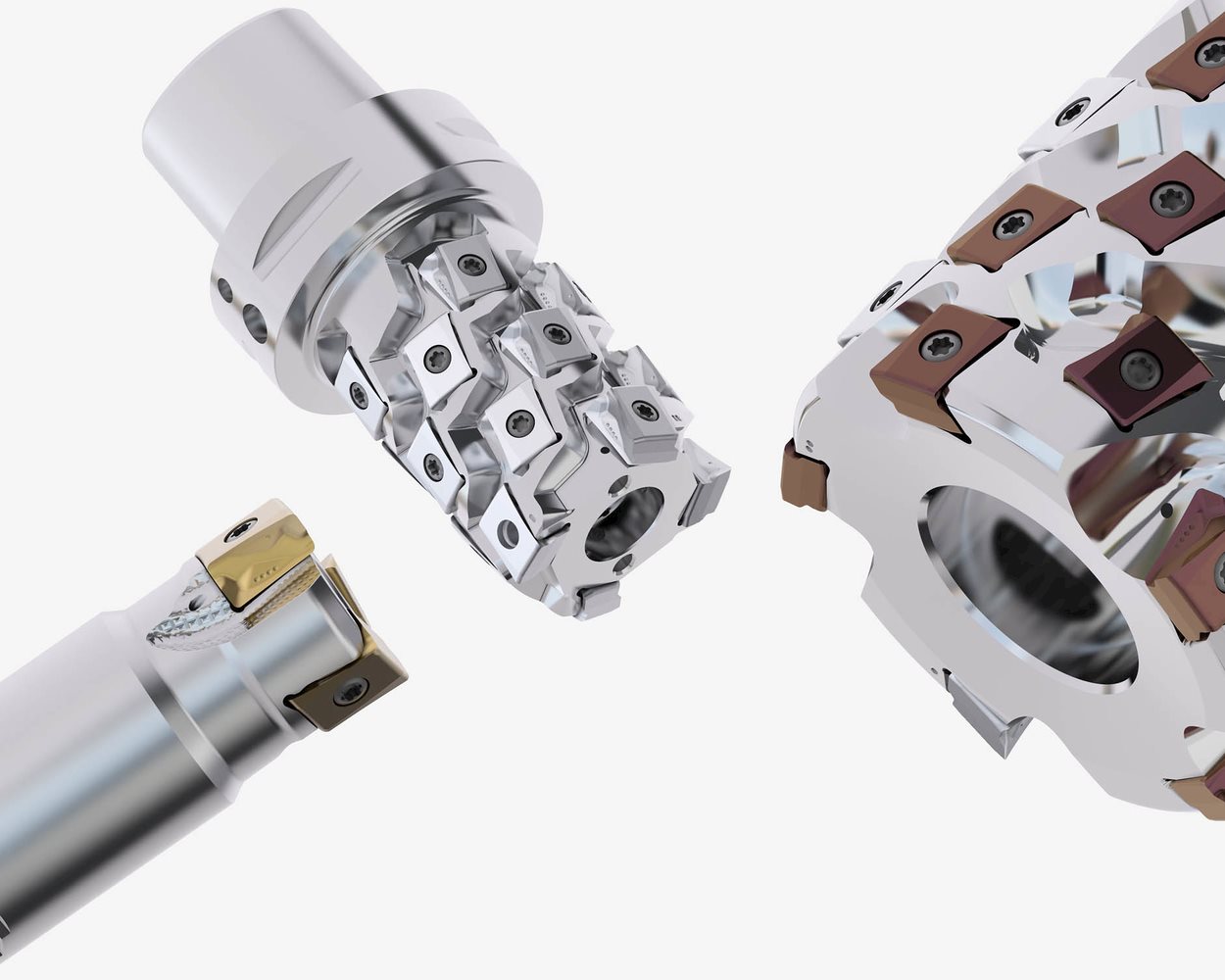

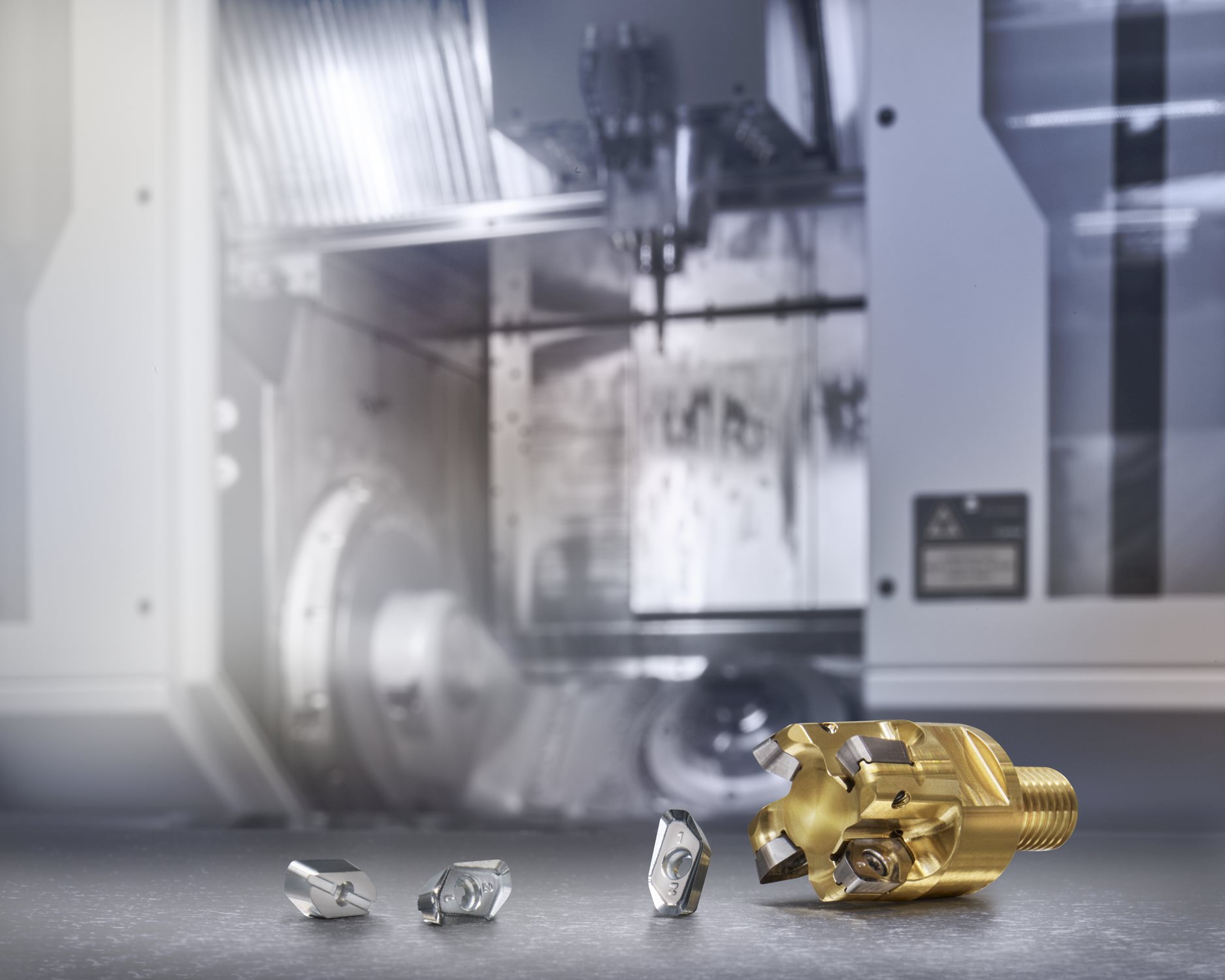

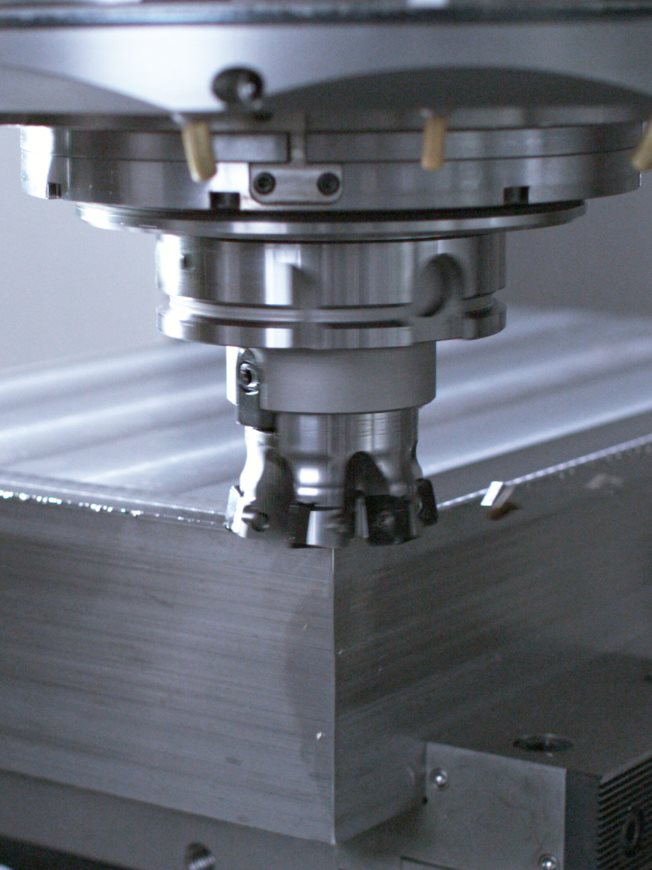

The Seco 335.98 disc milling cutter system boosts productivity with the ability to perform square shoulder milling operations on two sides of a part.

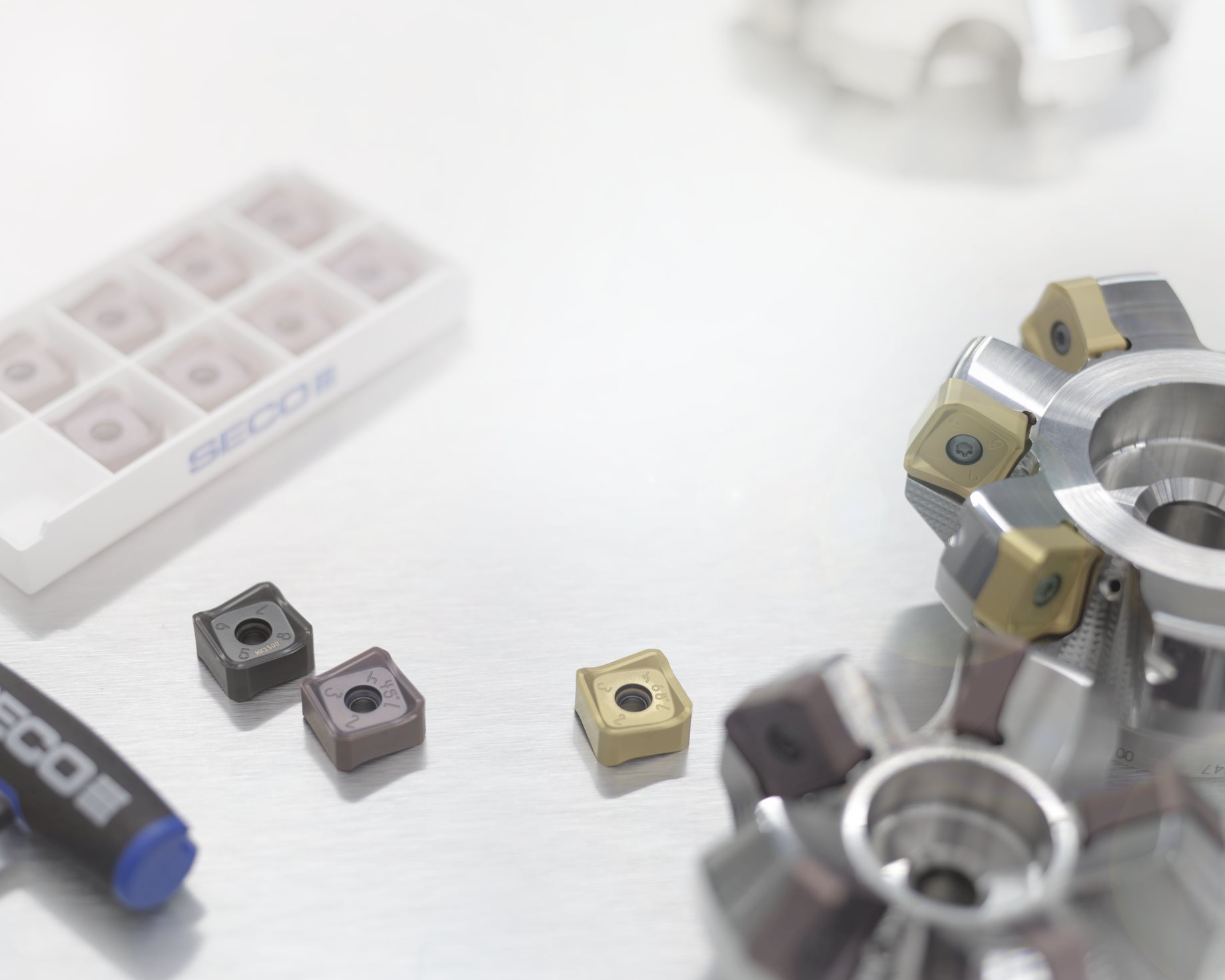

The new Seco 335.98 disc milling cutter system allows you to efficiently perform square shoulder operations on both sides of your workpiece. Each insert in the system provides eight usable cutting edges, enhancing insert life. The cutter bodies come with optional cassettes for added flexibility and easy maintenance. These innovative design features significantly increase the return on your tooling investment.

Your Challenge:

You want to reduce the cost per part for high-volume components.

The Seco Solution:

Seco 335.98 disc milling cutters achieve the lowest cost per part in half-side and face disc milling operations. The system uses dedicated inserts with eight usable cutting edges, pushing the boundaries of performance and innovation.

Your Challenge:

You’re aiming to reduce your tool costs in mass production.

The Seco Solution:

Seco 335.98 disc milling cutters minimize tooling costs with innovatively designed insert geometries that deliver up to 60% more cutting life in left-hand and right-hand side disc milling operations.

Your Challenge:

You need to control and reduce tool repair costs.

The Seco Solution:

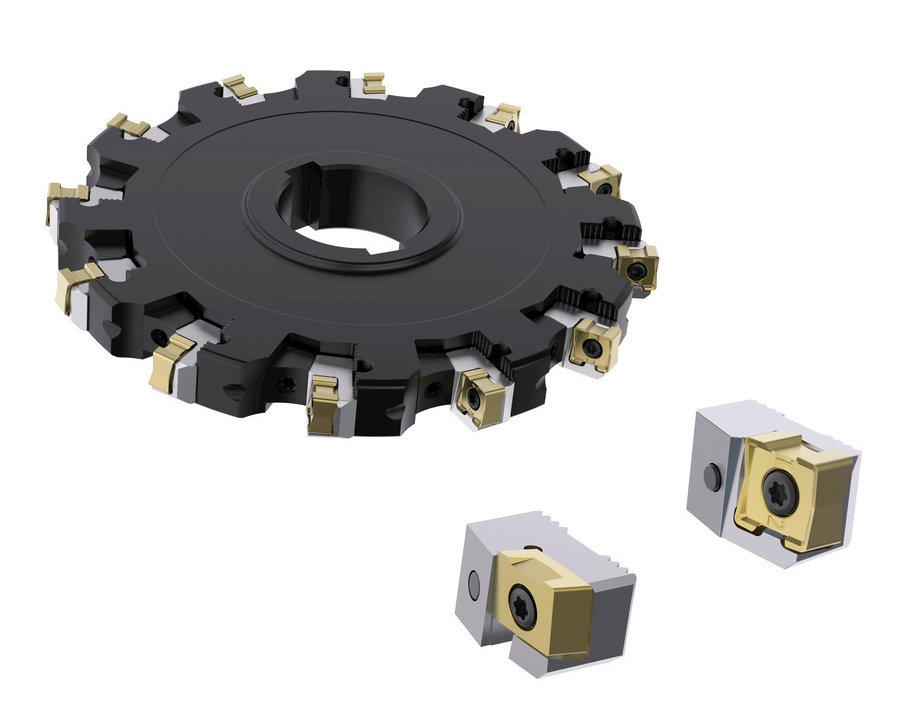

With Seco 335.98 disc milling cutters, users enjoy the convenience of replacing individual damaged insert cassettes instead of entire cutter bodies.

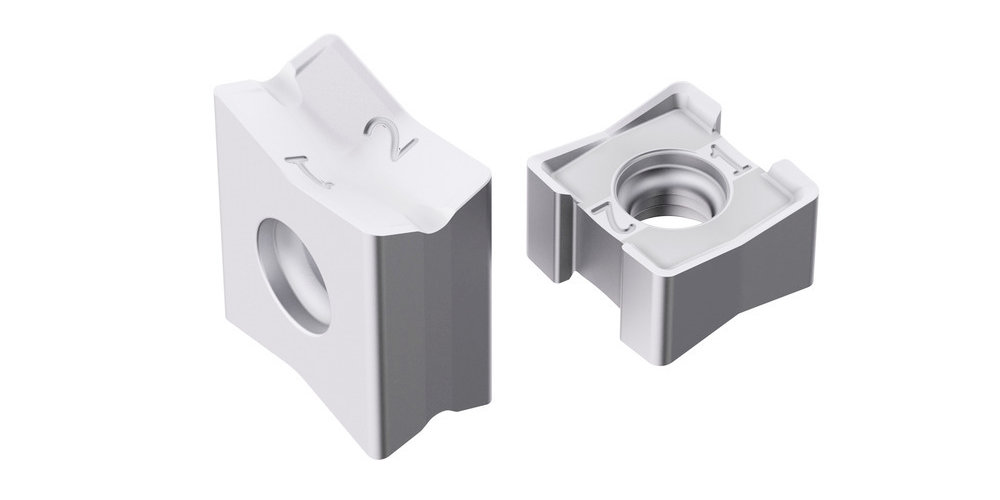

The Seco 335.98 disc milling cutter system features new insert interfaces that allow operators of all experience levels to change inserts easily, eliminating the risk of errors. These interfaces ensure a secure process, while the new insert geometries improve chip flow and reduce cutting forces. The result is enhanced process stability and predictability.

Your Challenge:

You need to ensure fast, reliable setups.

The Seco Solution:

The unique insert geometry of the Seco 335.98 disc milling cutter system prevents insert mounting mistakes and provides a robust, reliable interface between the cutter body and insert.

Your Challenge:

You want to minimize the risk of unplanned machining interruptions.

The Seco Solution:

The Seco 335.98 disc milling cutter system features inserts with a free cutting design that promotes chip flow and reduces the risk of chip jamming.

Your Challenge:

It’s nearly impossible to cut complex, difficult-to-clamp parts without vibration.

The Seco Solution:

Insert geometries of the Seco 335.98 disc milling cutters minimize cutting forces for vibration-free machining.

Optimize results for a specific high-volume application with the new Seco 335.98 disc milling cutter system. A comprehensive range of stocked standard inserts and spare parts - and an experienced custom products team - can adapt a disc milling cutter to match a specific operation efficiently.

Your Challenge:

How to optimize tool performance across various components.

The Seco Solution:

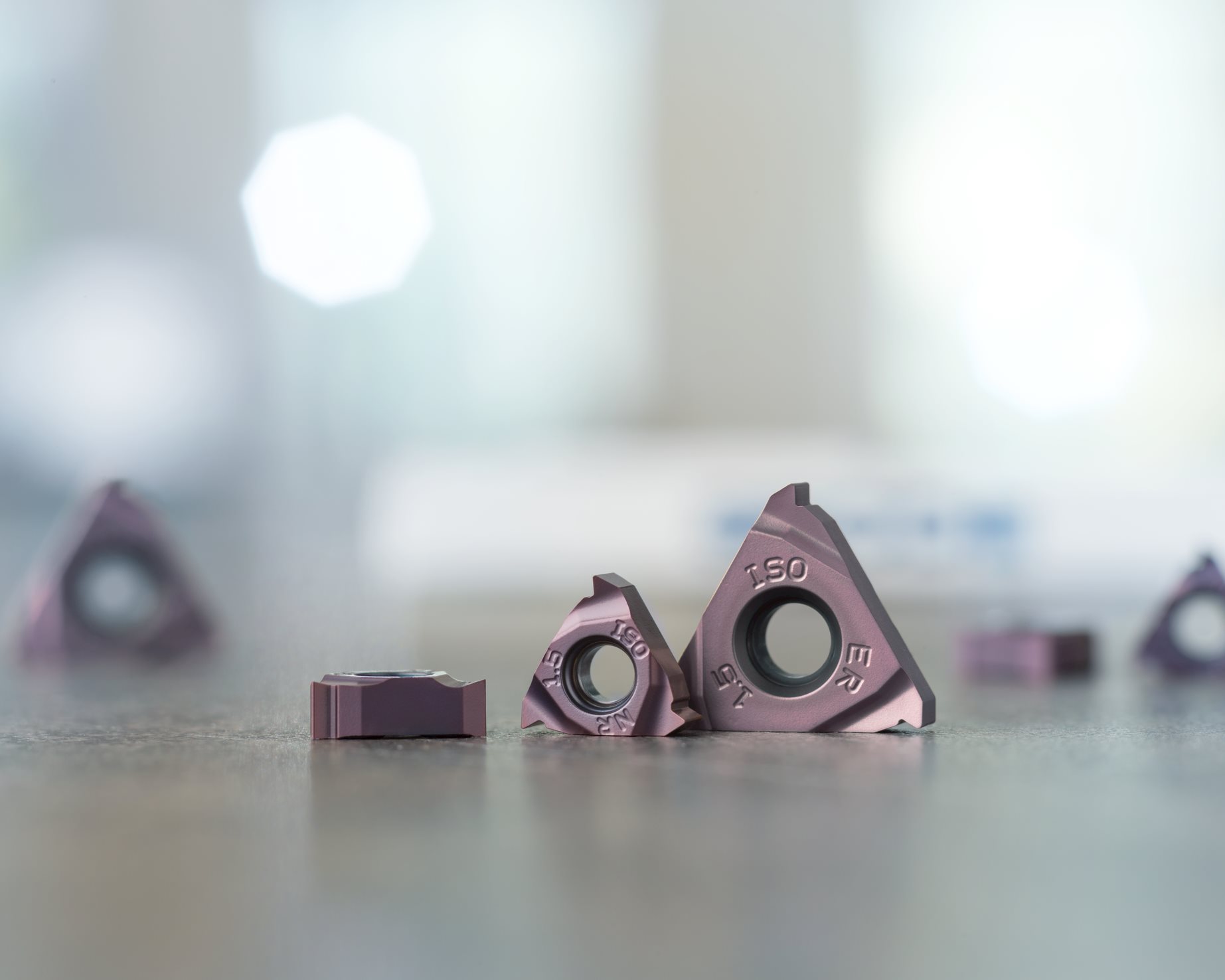

The Seco 335.98 disc milling cutter system offers two sizes of standard inserts in a broad range of grades, as well as corner radii options for optimal performance in various applications.

Your Challenge:

Reaching an optimal cutter performance over a range of applications.

The Seco Solution:

Seco 335.98 disc milling cutters offer customizable options on demand, ensuring part specifications are met at the most cost-effective price.

Your Challenge:

You want to increase tooling flexibility.

The Seco Solution:

The Seco 335.98 disc milling cutter system offers interchangeable insert cassettes, making cutter maintenance easier and enabling upgrades.

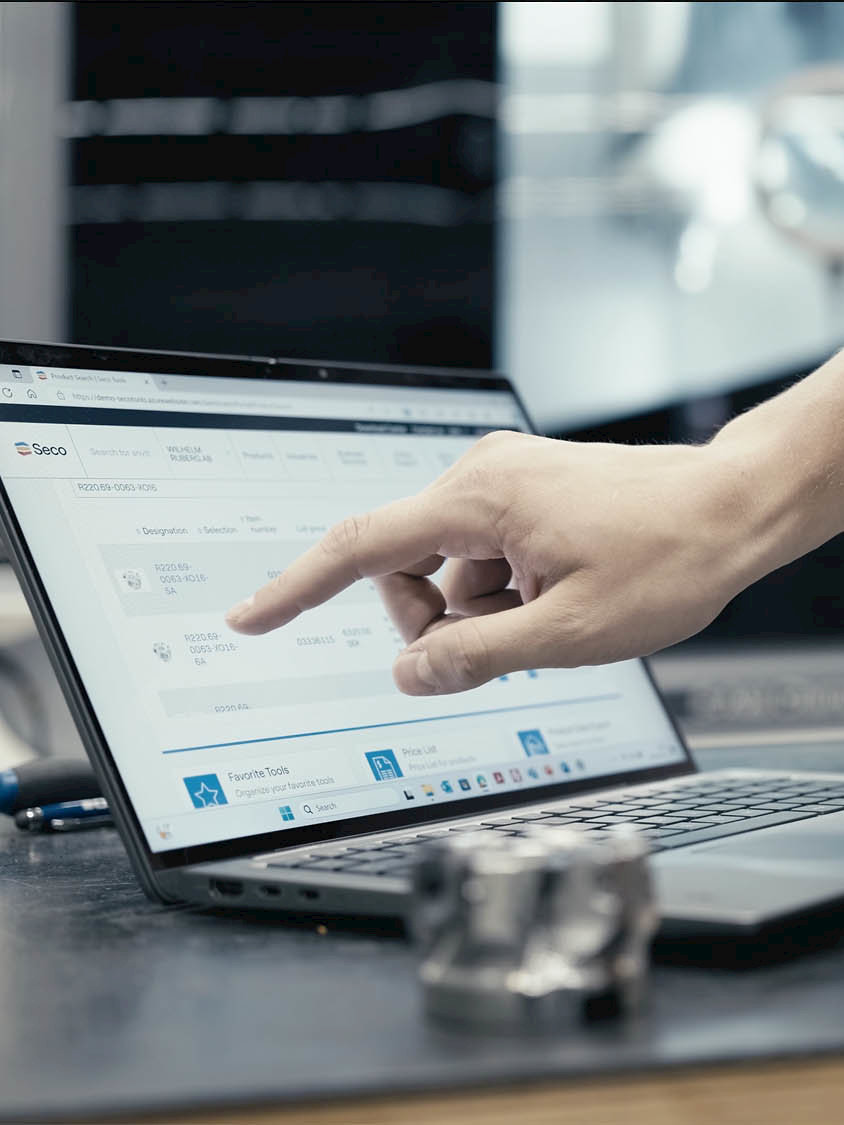

Discover the 335.98 Disc Mills product range

Inline Content - Sugar Form

Sugar Form url - https://info.secotools.com/acton/media/45194/335-98-disc-mill

Frame height - 550 px

Related content

Seco News 2025.1 - Product Summary

335.98 - Fixed pockets - XN inserts

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

Seco T35 Taps: match Tooling to Materials

Versatile Round 20 Inserts Increase Tool Life

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Factsheet - Seco® 335.98 Disc milling cutter system

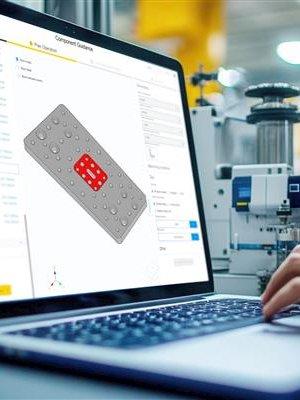

Seco Component Guidance

Machine two sides of a part securely with Seco disc milling cutter system | Seco Tools

Seco My Design: Design custom tools

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

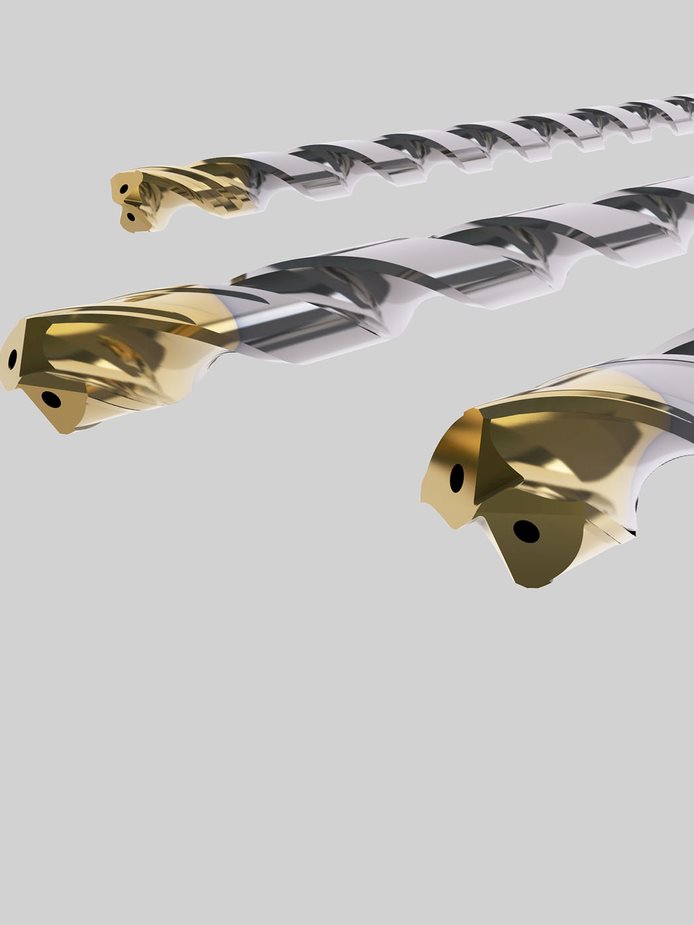

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

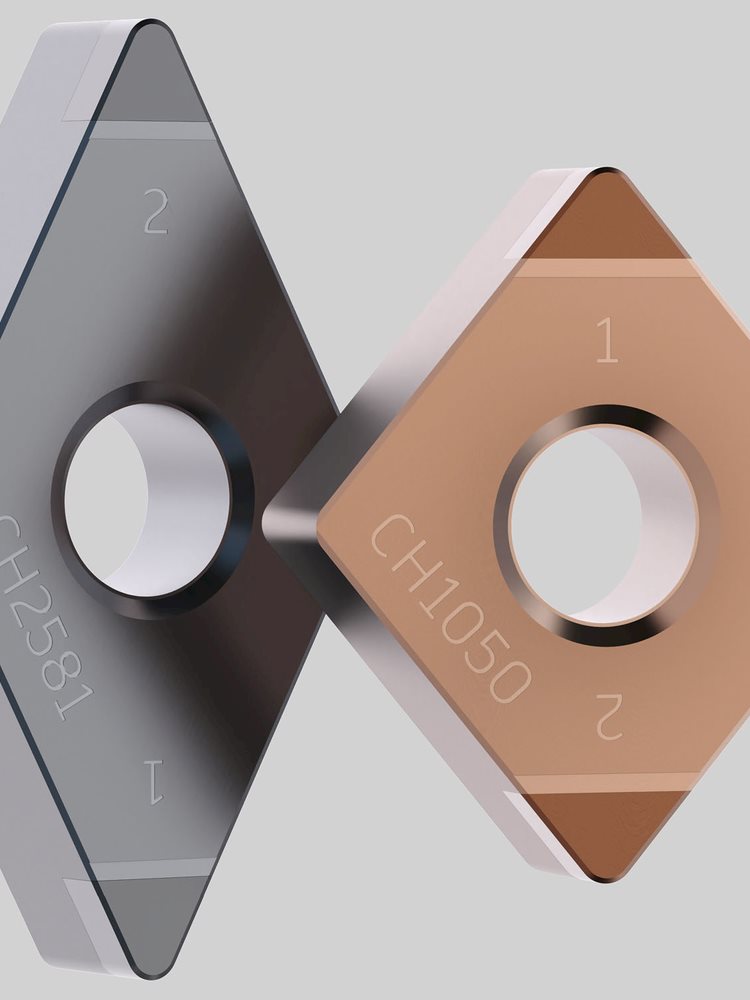

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

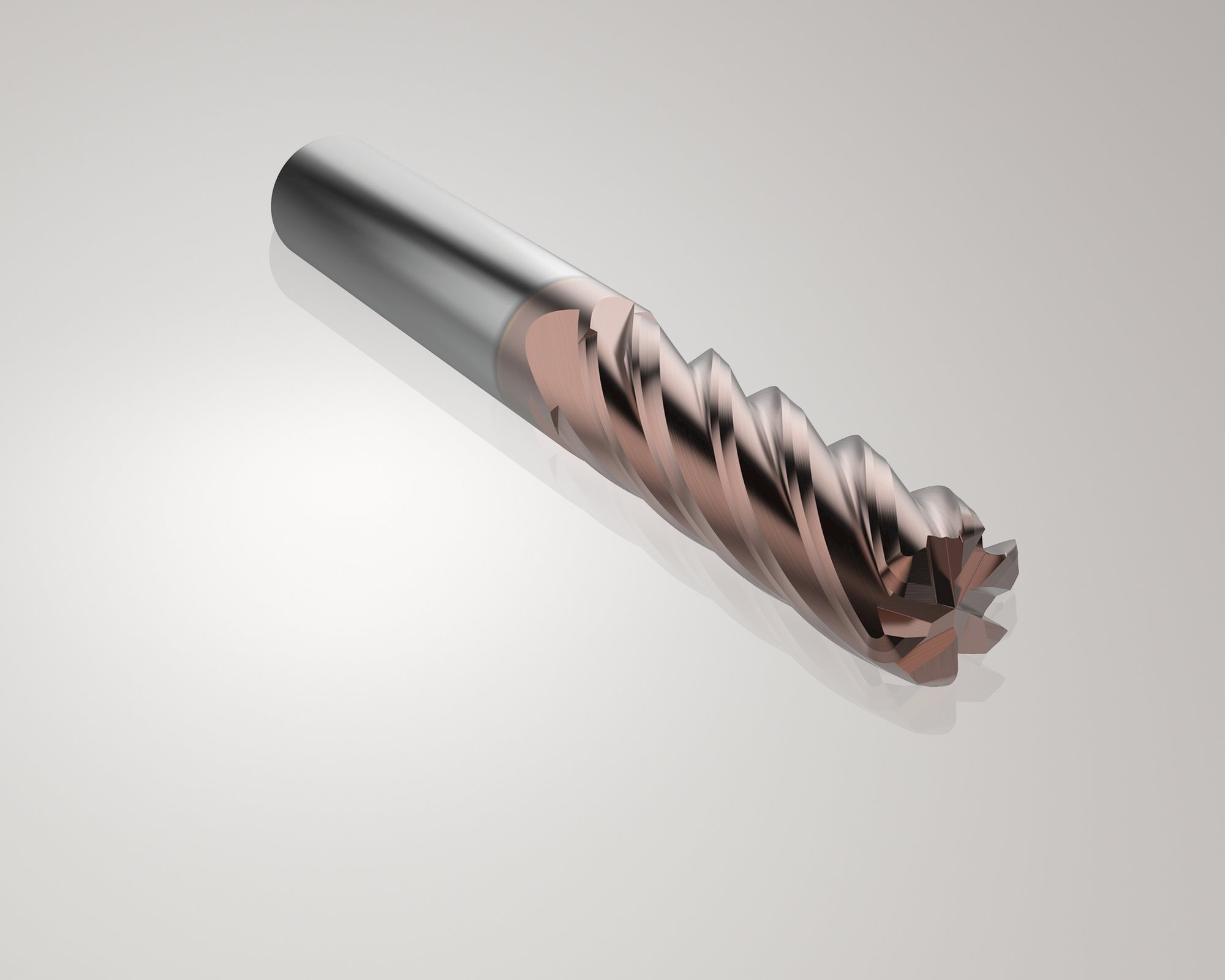

JS720 Solid End Mills addition

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

Square T4-12 Upgrades

Universal Drills

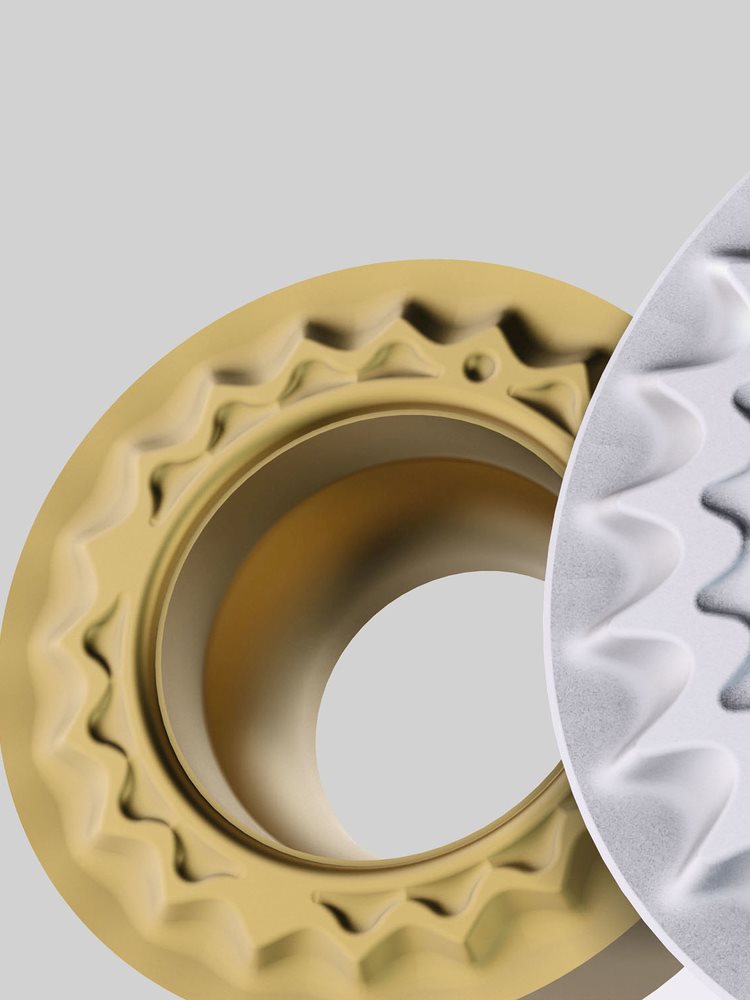

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

New Seco disc milling cutter system reduces costs while improving security

Seco Machine Library

335.98 Disc Mill - contact us

335 98 Knuckle application | Seco Tools

XNHQ07 insert: How to use the 8 edges | Seco Tools

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

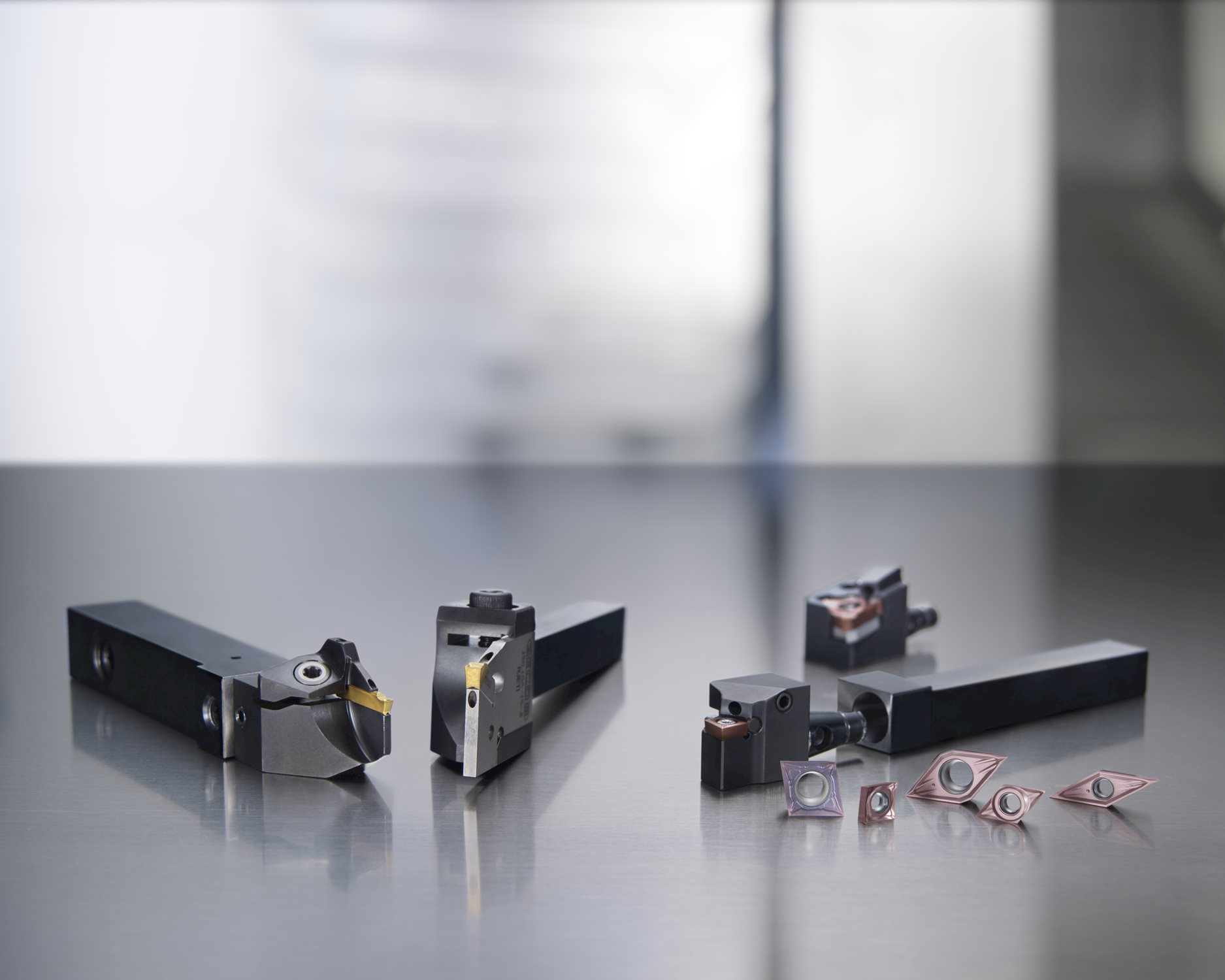

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

New MP Milling Grades

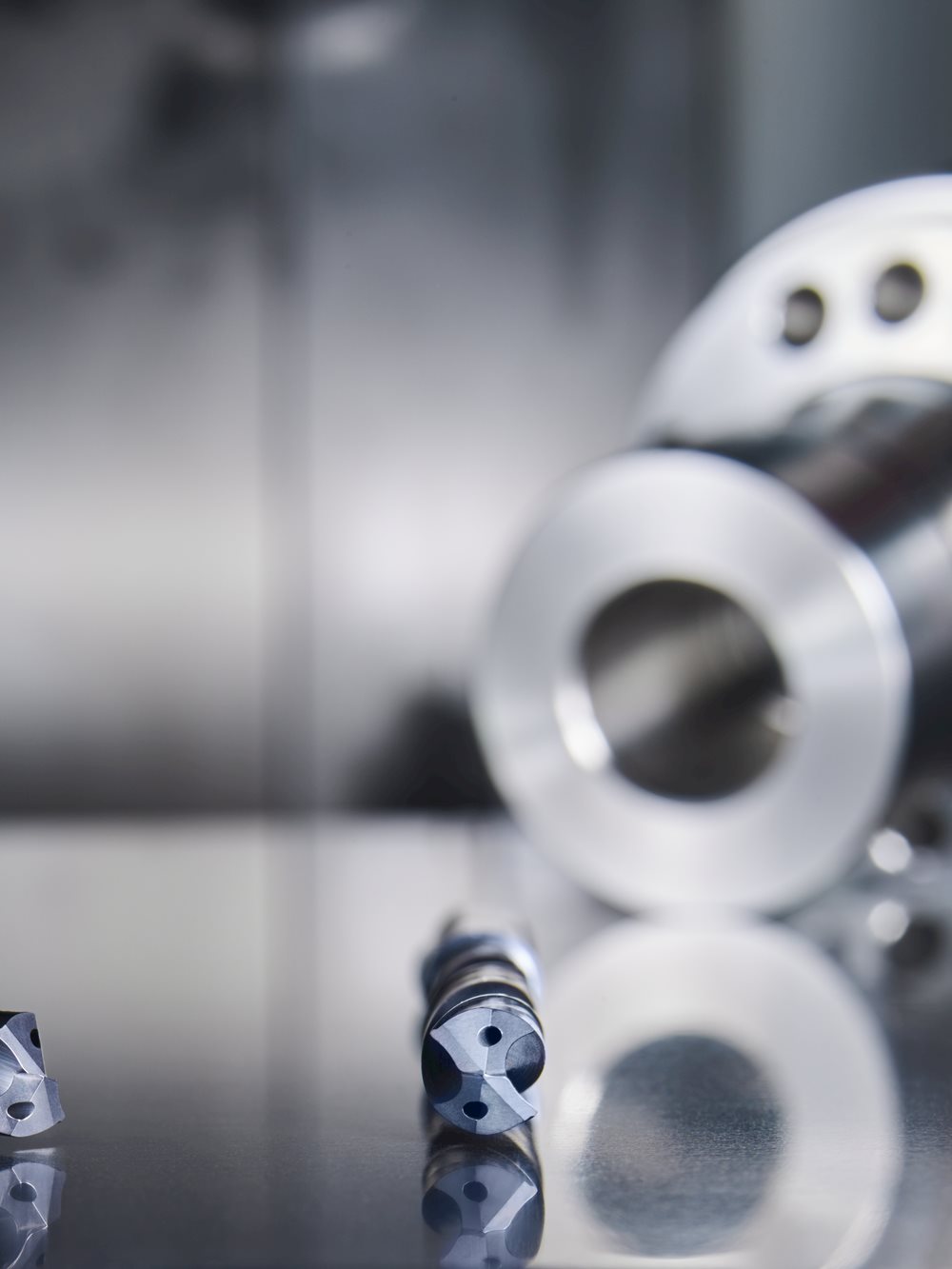

Unleash your drilling potential

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22