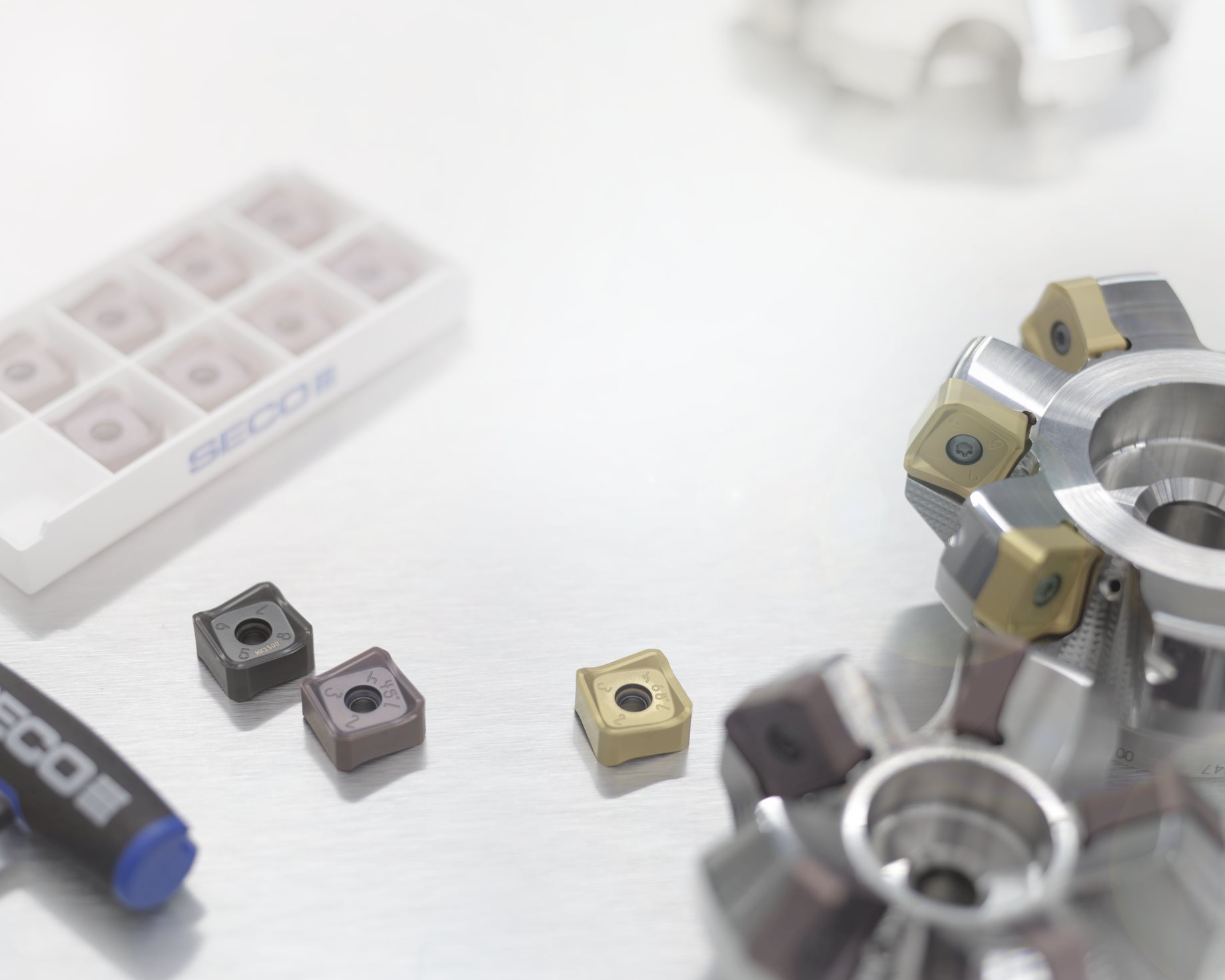

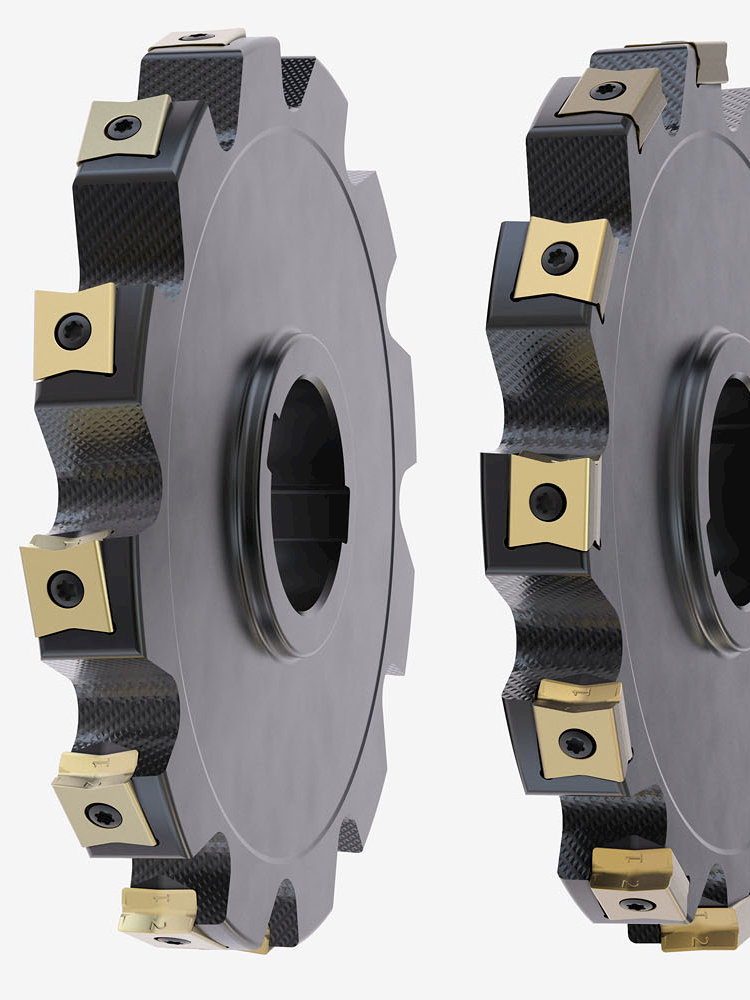

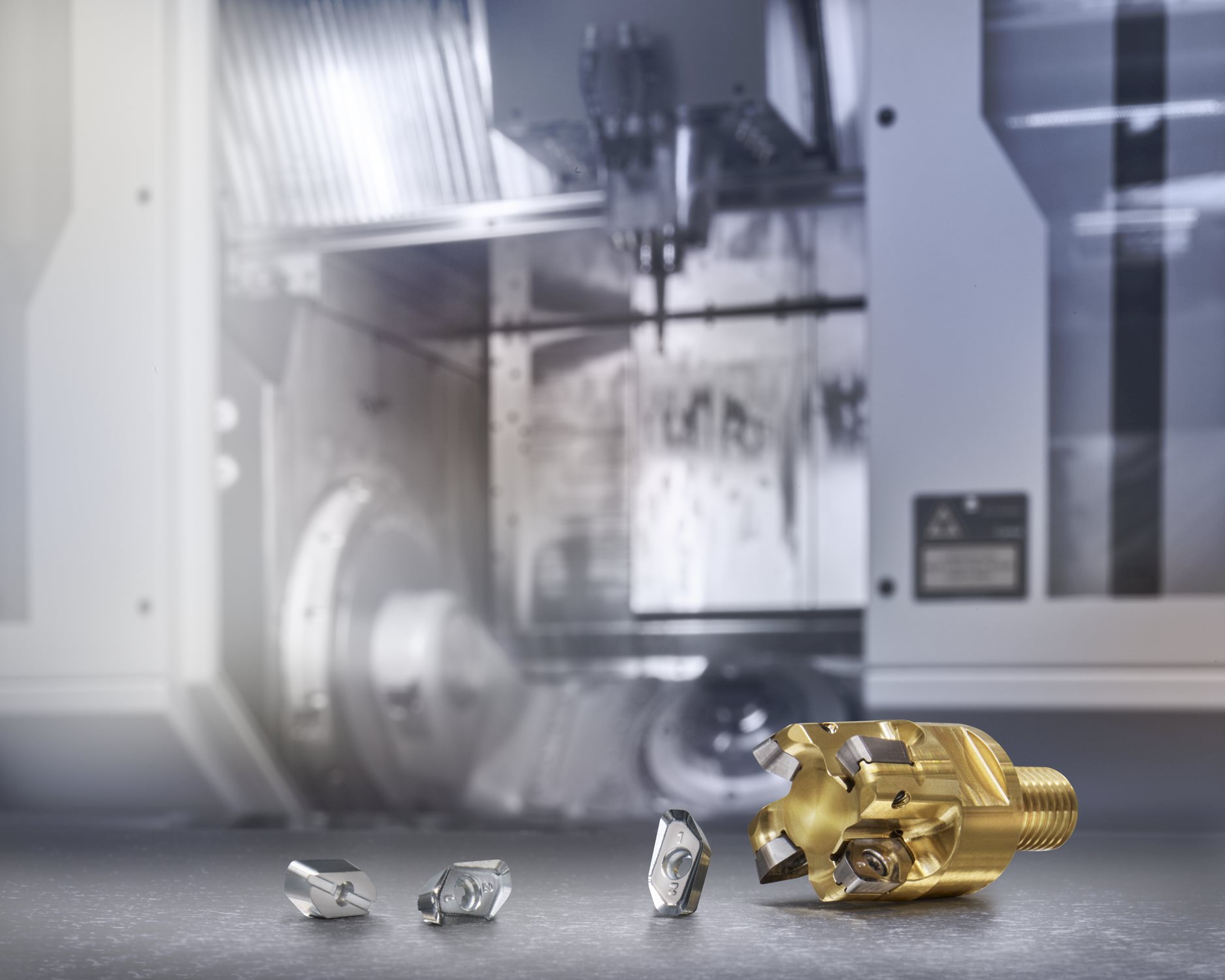

Overcome challenging part setups with Seco Octomill™ 06

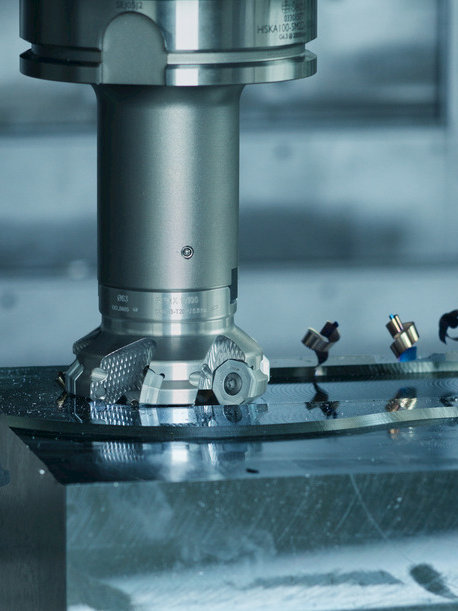

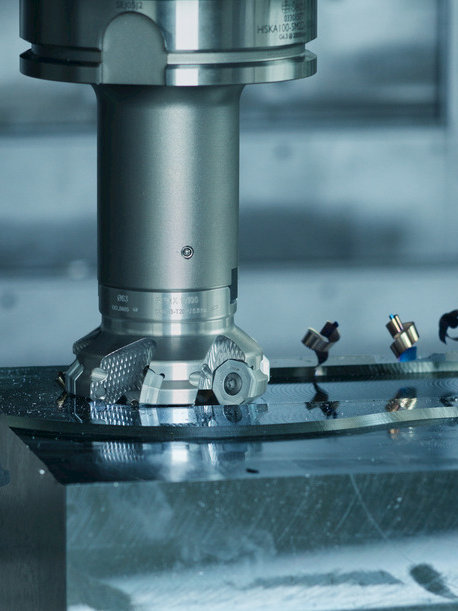

Seco Octomill™ 06 features easy-to-use self-centering inserts and provides machining stability, even in applications involving delicate part setups.

The design of Seco Octomill™ 06 makes it fast and easy to set up and index inserts while achieving high process stability and minimizing waste.

Your Challenge:

Are you facing challenges with time-consuming and insecure tool processing that negatively impacts your process stability and workpiece yield?

The Seco Solution:

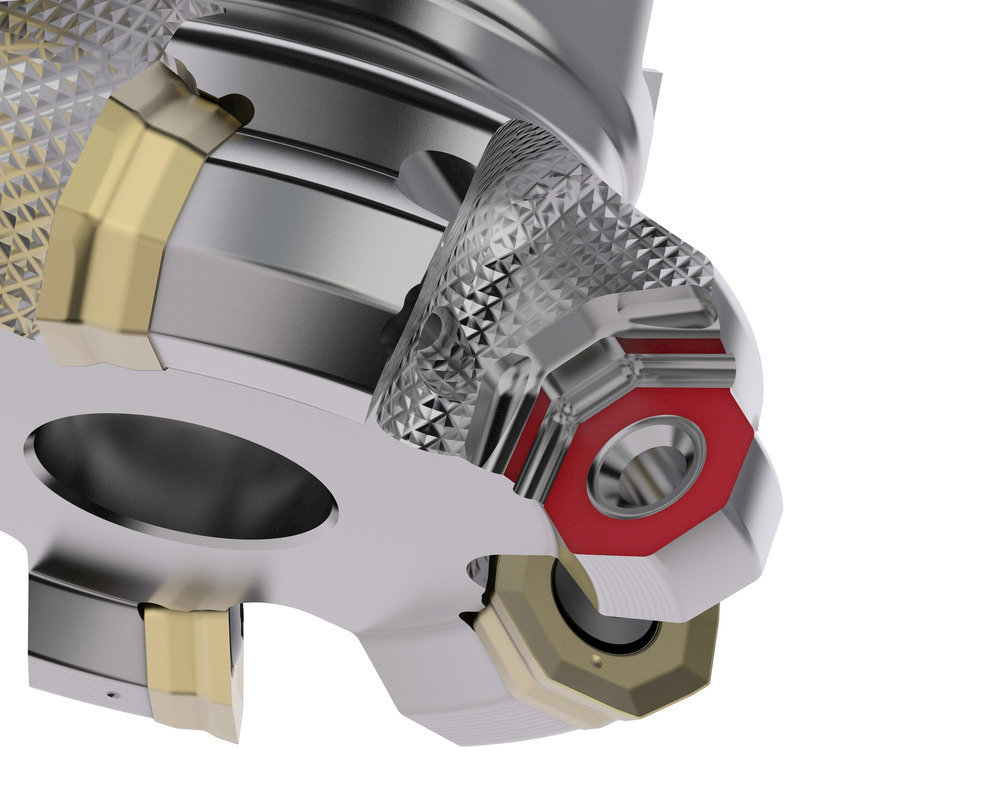

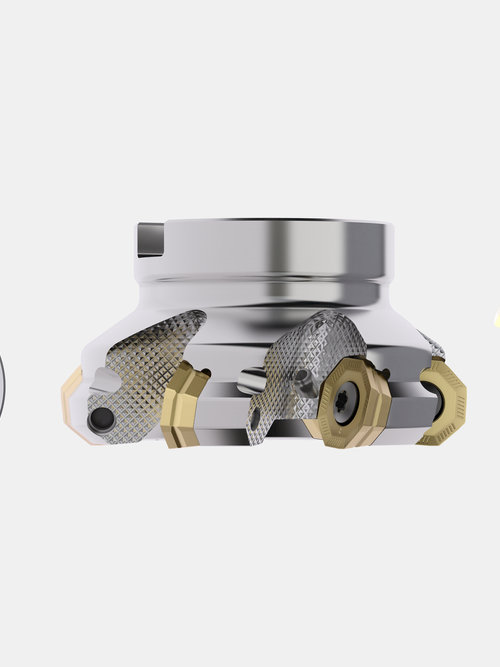

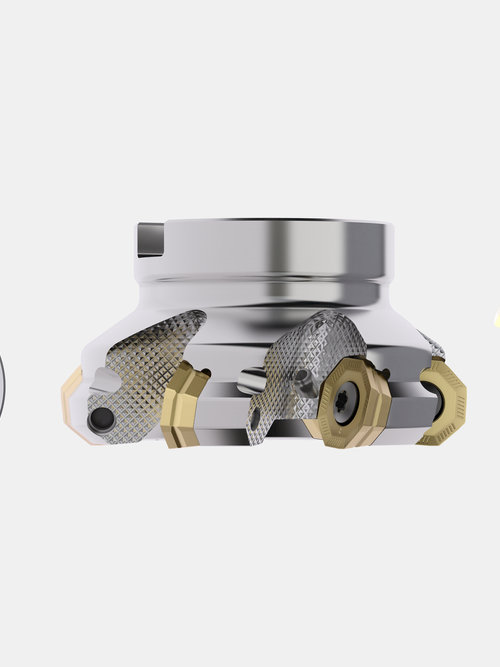

Seco Octomill™ 06 face mills offer improved insert self-centering with high repeatability of positioning for reliable, stable performance.

Your Challenge:

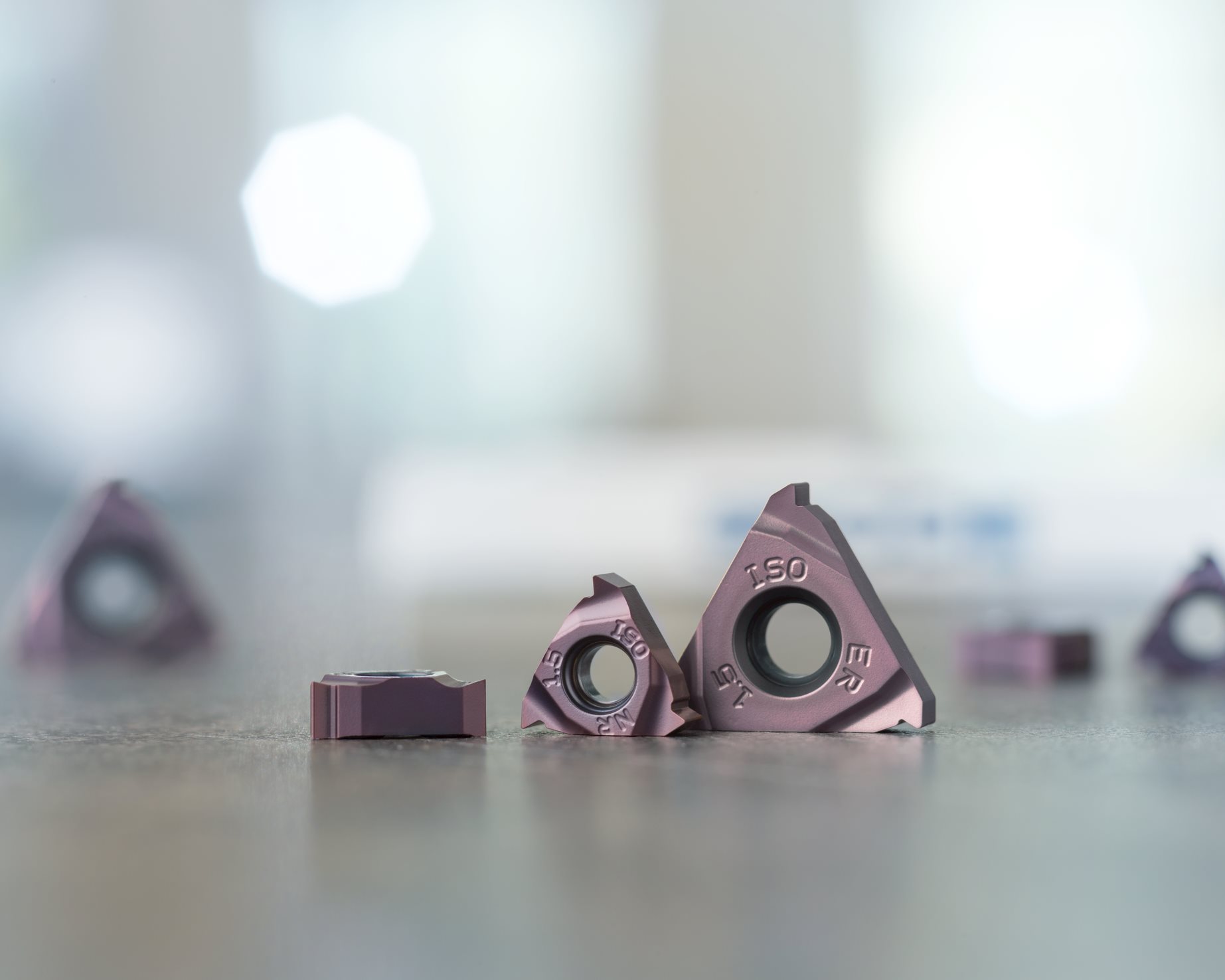

You need to eliminate insert waste.

The Seco Solution:

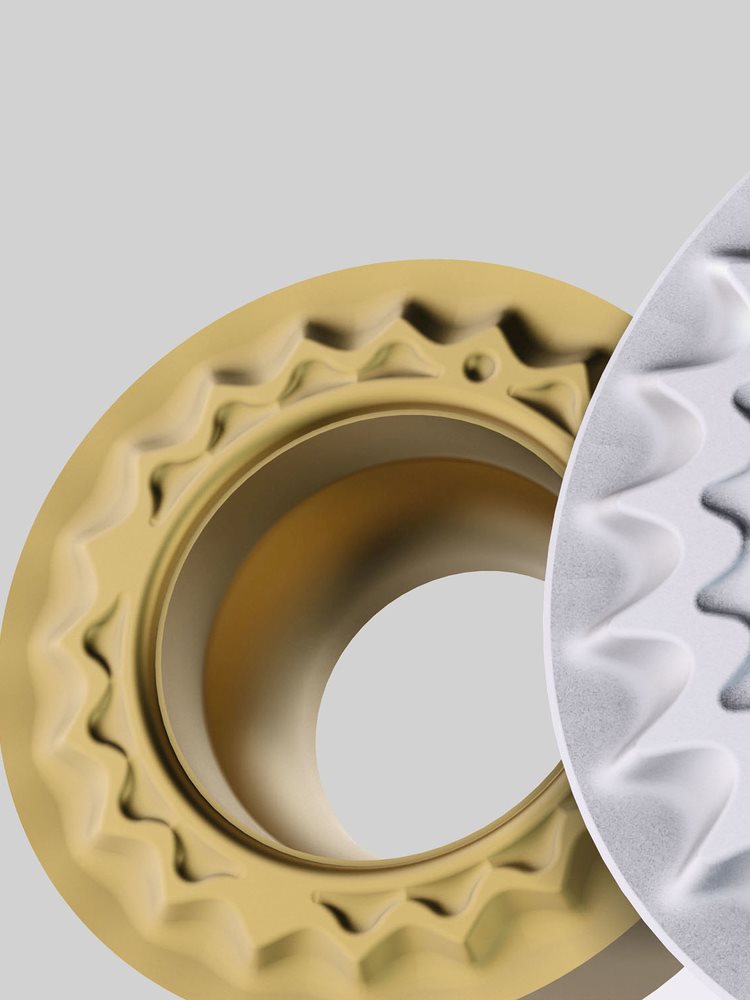

Seco Octomill™ 06 disconnects cutting edges from the cutter pockets’ support surfaces to prevent edge wear or breakage of a cutting edge from damaging unused insert edges.

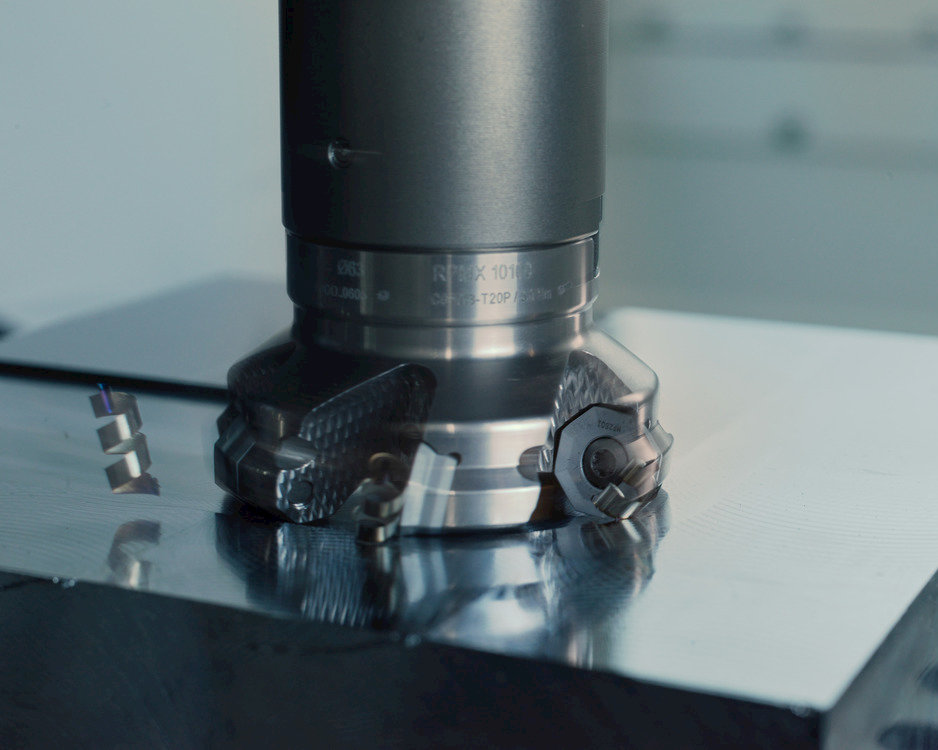

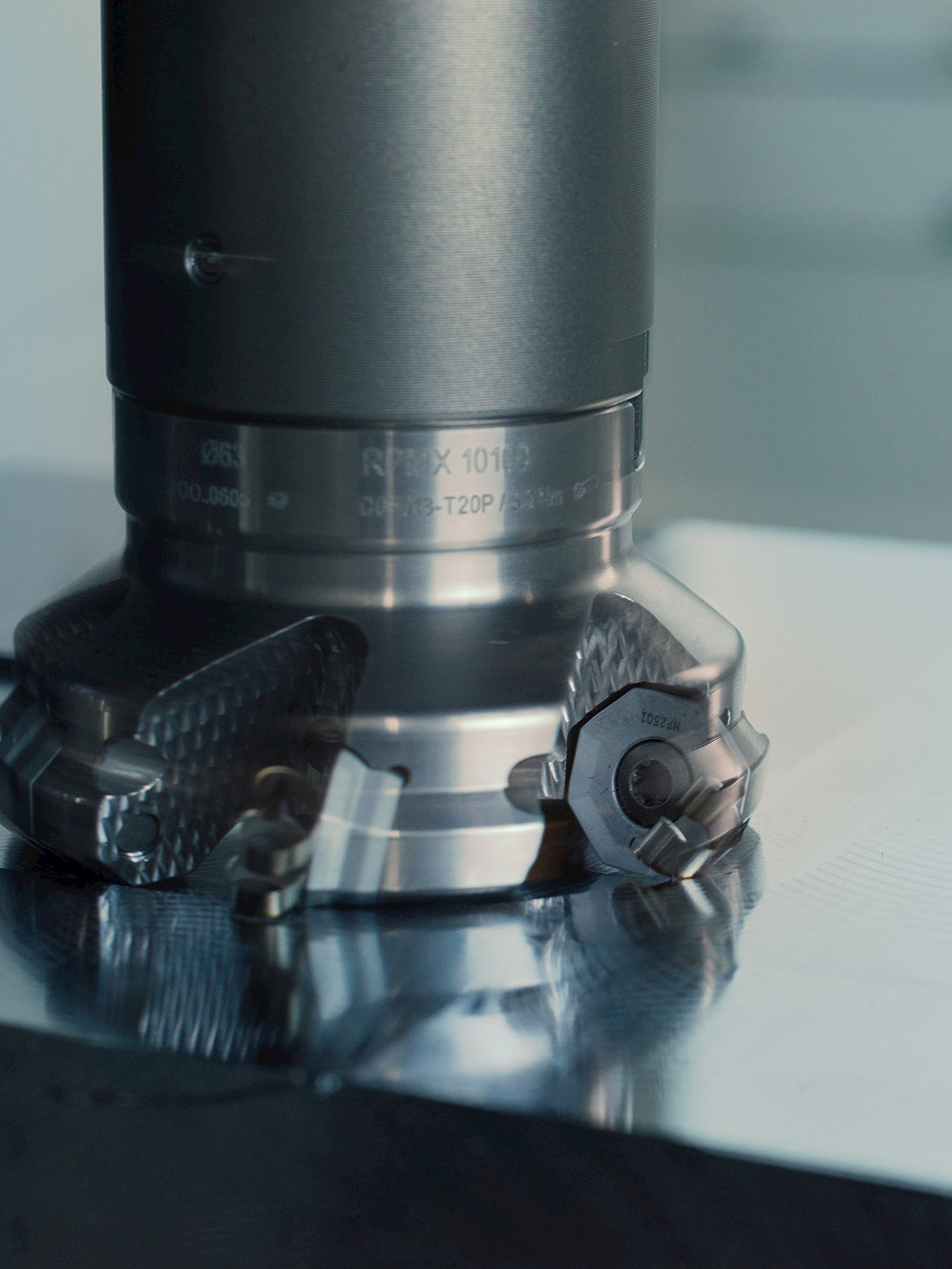

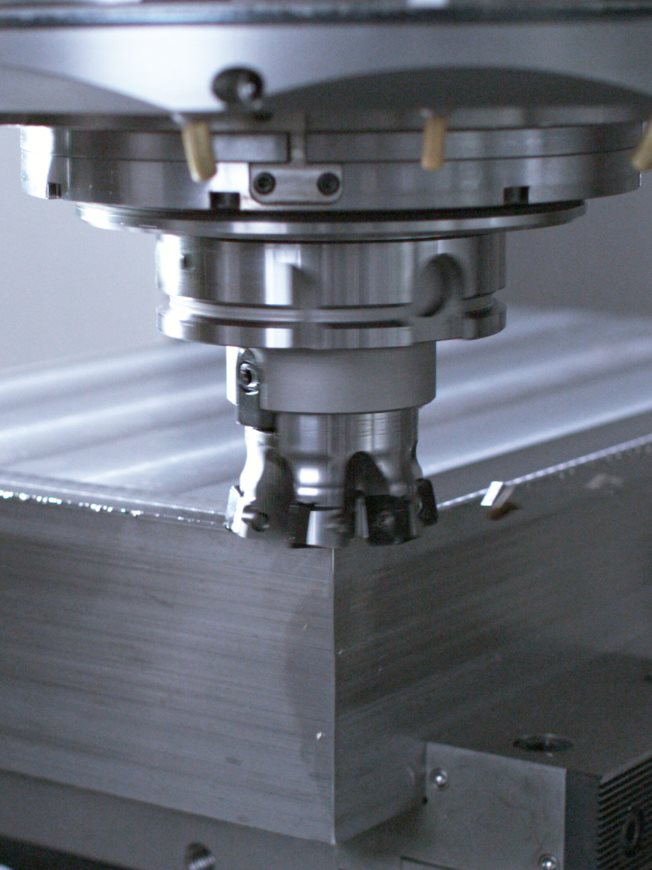

Seco Octomill™ 06 reduces axial forces to achieve high levels of part quality even for applications with long overhangs, unstable setups or thin part walls.

Seco Octomill™ 06 reduces axial forces to achieve high levels of part quality even for applications with long overhangs, unstable setups or thin part walls.

Your Challenge:

Are you struggling with productive roughing and finishing of parts that have unstable setups or thin walls?

The Seco Solution:

Featuring a right-handed design with a straight cutting edge, Seco Octomill™ 06 face mills incorporate a high axial angle of +12° to reduce radial and axial forces and enable high-quality production with unstable setups or thin-walled parts. This results in lighter cutting than SD or OD style solutions with a more stable cutting edge than SE or OF style solutions.

Your Challenge:

How to optimize chip formation.

The Seco Solution:

A controlled, consistent and reliable chip formation is supported by a right-handed and straight cutting edge design as well as the high helix angle.

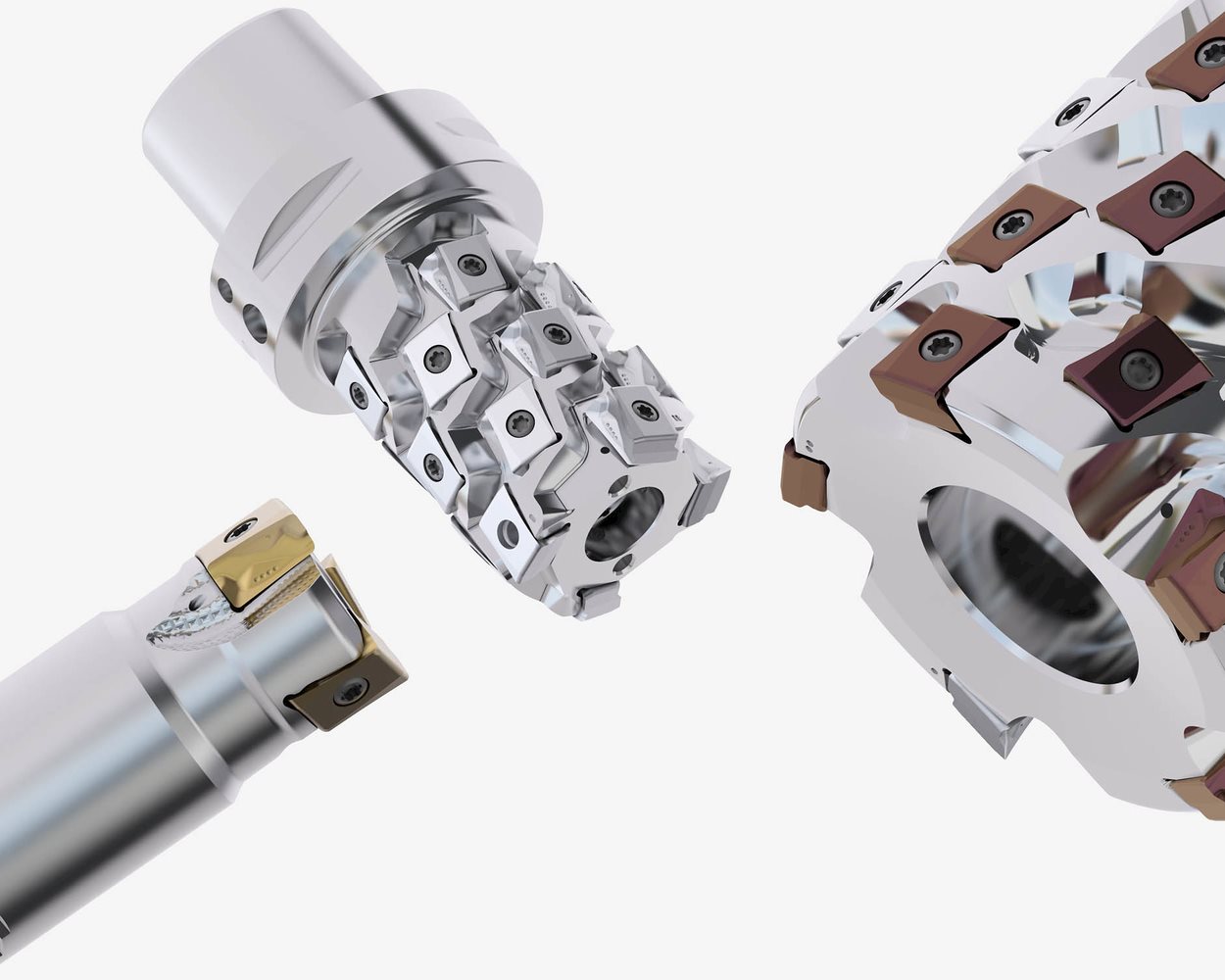

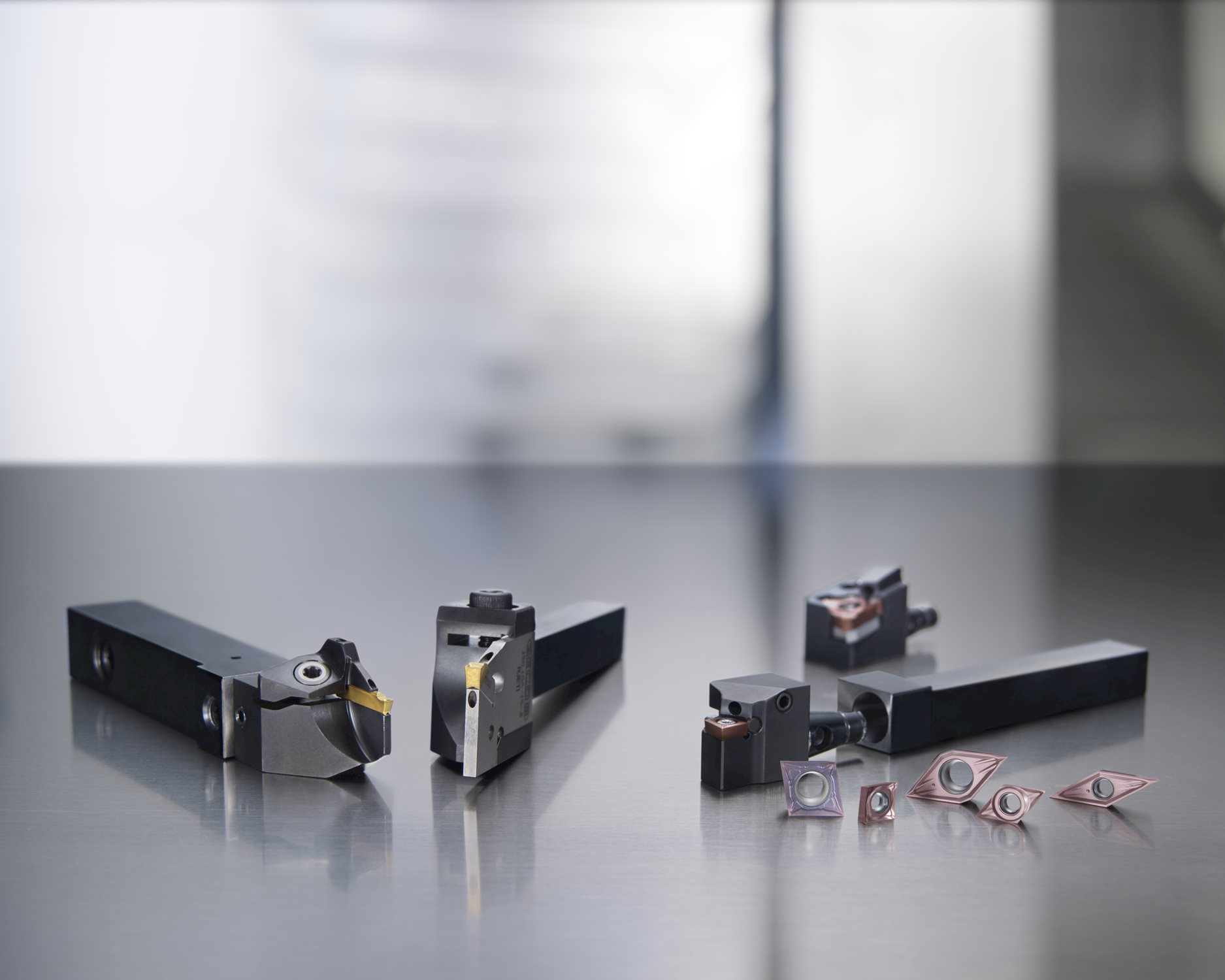

The multi-insert pocket design of Seco Octomill™ 06 enables one cutter body to achieve excellent results in a variety of applications, including face milling, ramping, helical interpolation and profiling.

Your Challenge:

You want to minimize your tooling inventory through increased tool flexibility.

The Seco Solution:

Seco Octomill™ 06 reduces tooling inventory with a multi-insert pocket design and large variety of grade and geometry combinations that enable one cutter body to handle face milling, round and moderate high feed inserts for various applications.

Inline Content - Sugar Form

Sugar Form url - https://info.secotools.com/acton/media/45194/octomill

Frame height - 550 px

Related content

Octomill .43 - OO..0605

Extended Factsheet - Octomill™06 face milling cutter

Factsheet - Octomill™06 face milling cutter

Octomill OO.T06 / OF..05/07 – 8 edges – KAPR 40°/43°

Seco Octomill 06

Versatile and flexible

Superb surface finish

Roughing in unstable set ups

Easy and fast handling

Seco Octomill 06

Face Milling Range

Seco News 2025.1 - Product Summary

Seco news launch 2025.1

New Seco Face Milling Cutter offers high flexibility and ease of use

Octomill 06 - contact us

Octomill 06: Explanation and comparison of the system design

Octomill 06: Insert Handling

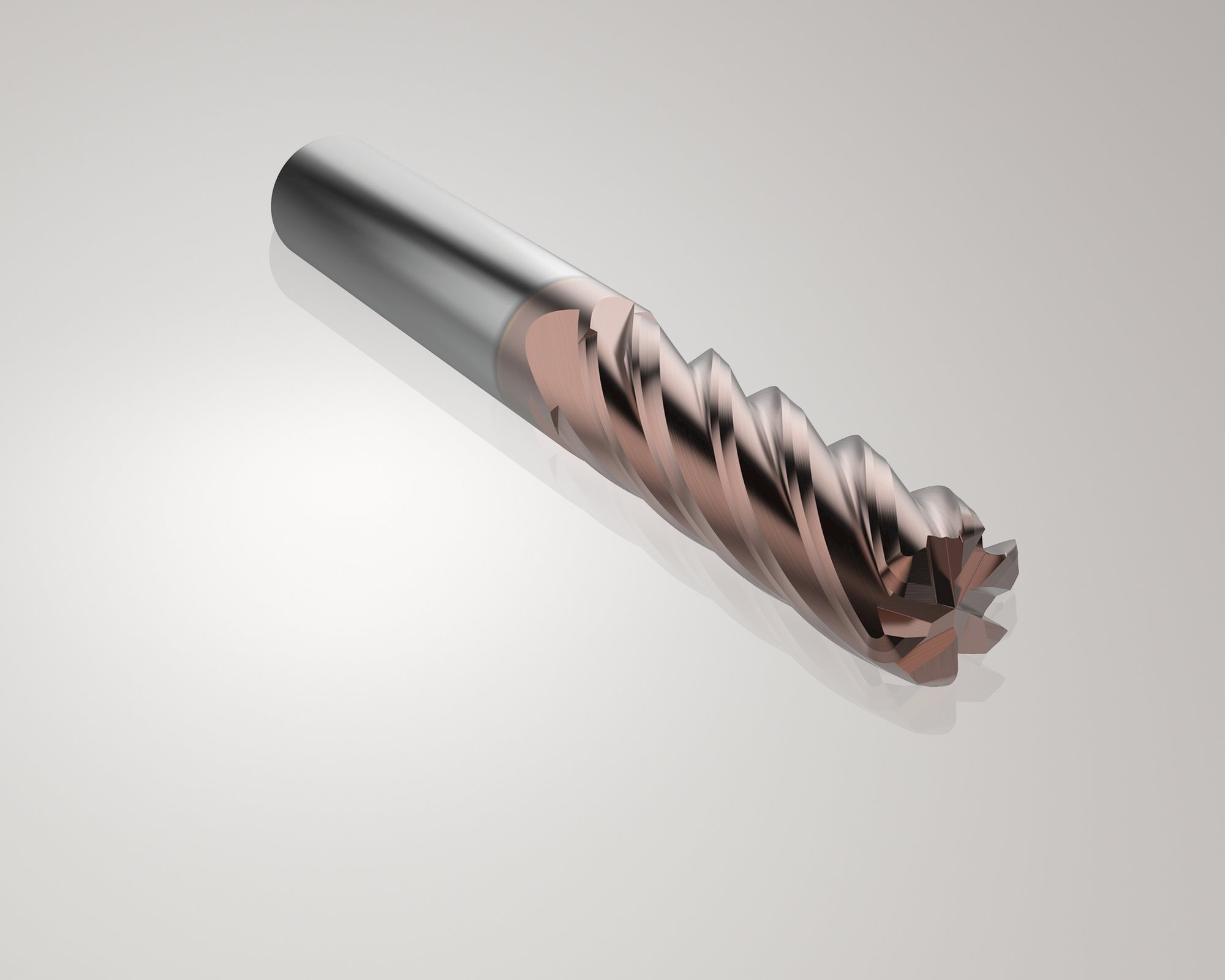

Seco Stabilizer Series: Unmatched Metal Removal

Seco T35 Taps: match Tooling to Materials

Versatile Round 20 Inserts Increase Tool Life

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Octomill .43 - OF..05T3

Seco Double Octomill™ Cassette Cutter achieves near zero axial runout

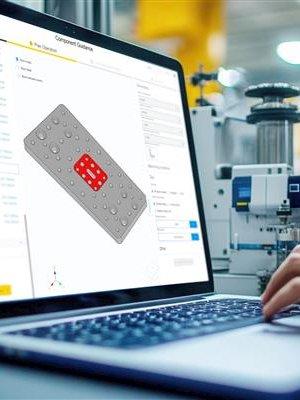

Seco Component Guidance

Octomill .43 - OF..0704

Seco My Design: Design custom tools

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

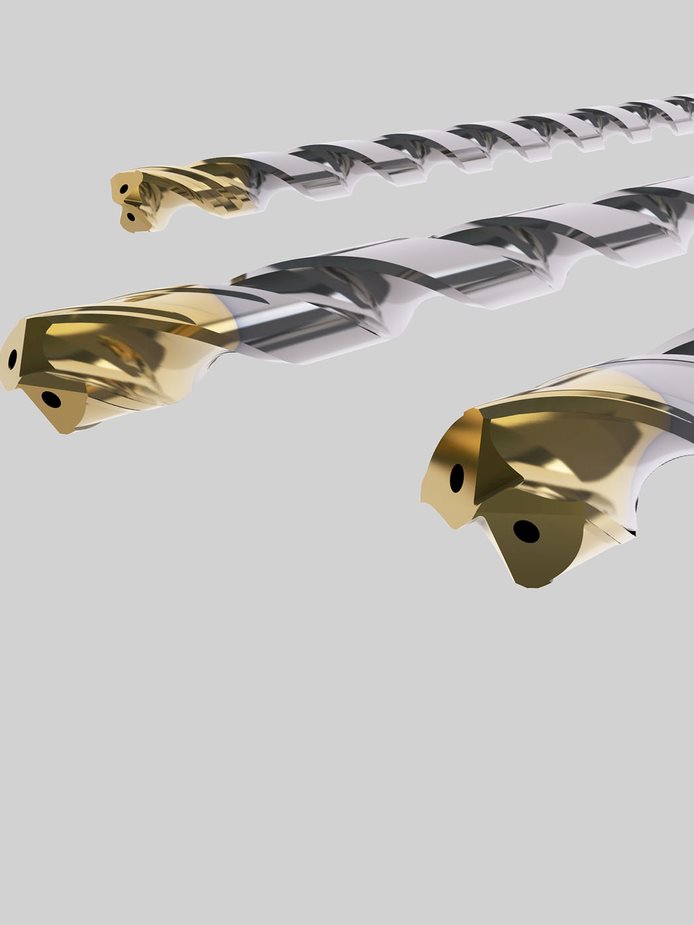

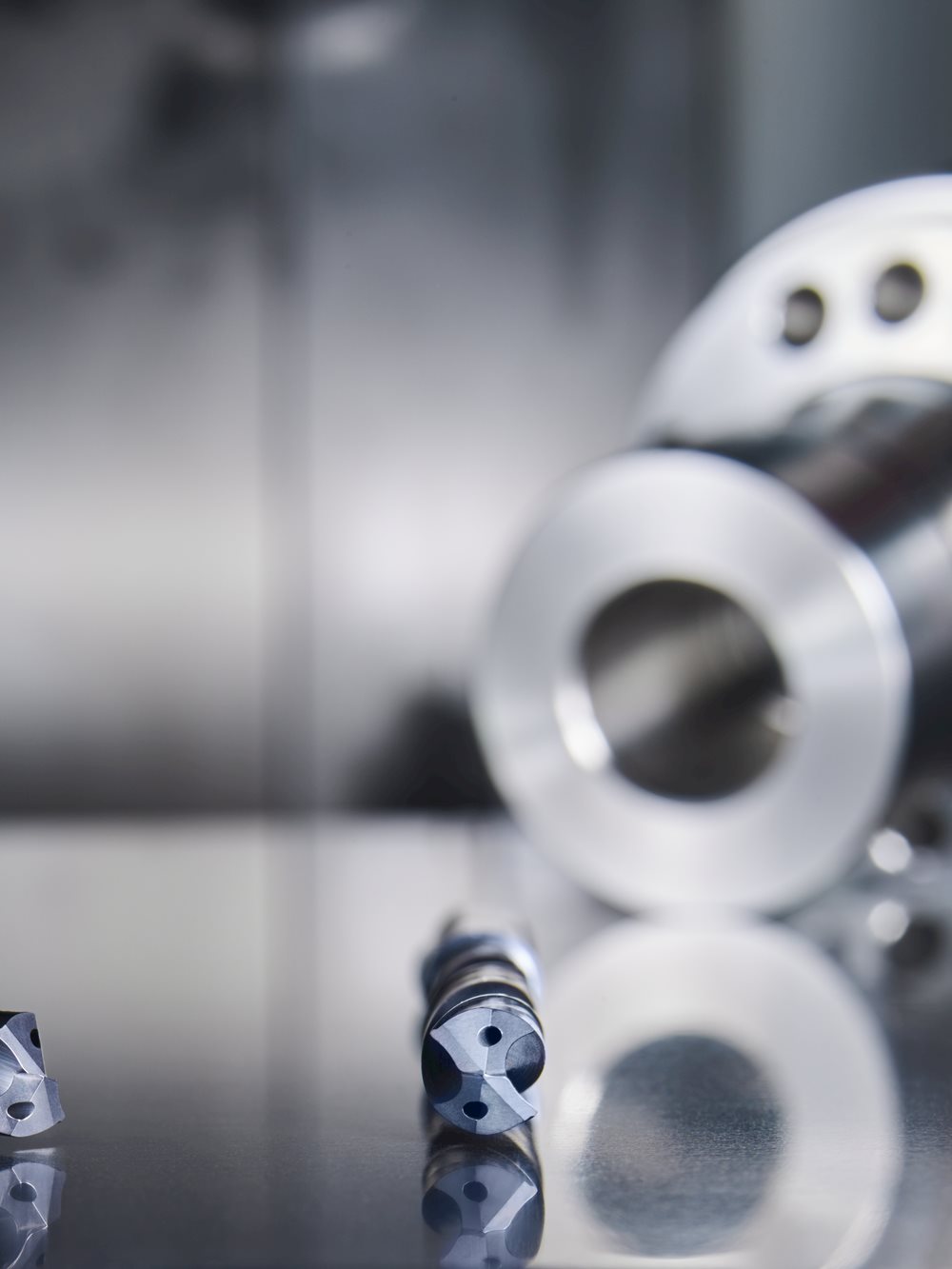

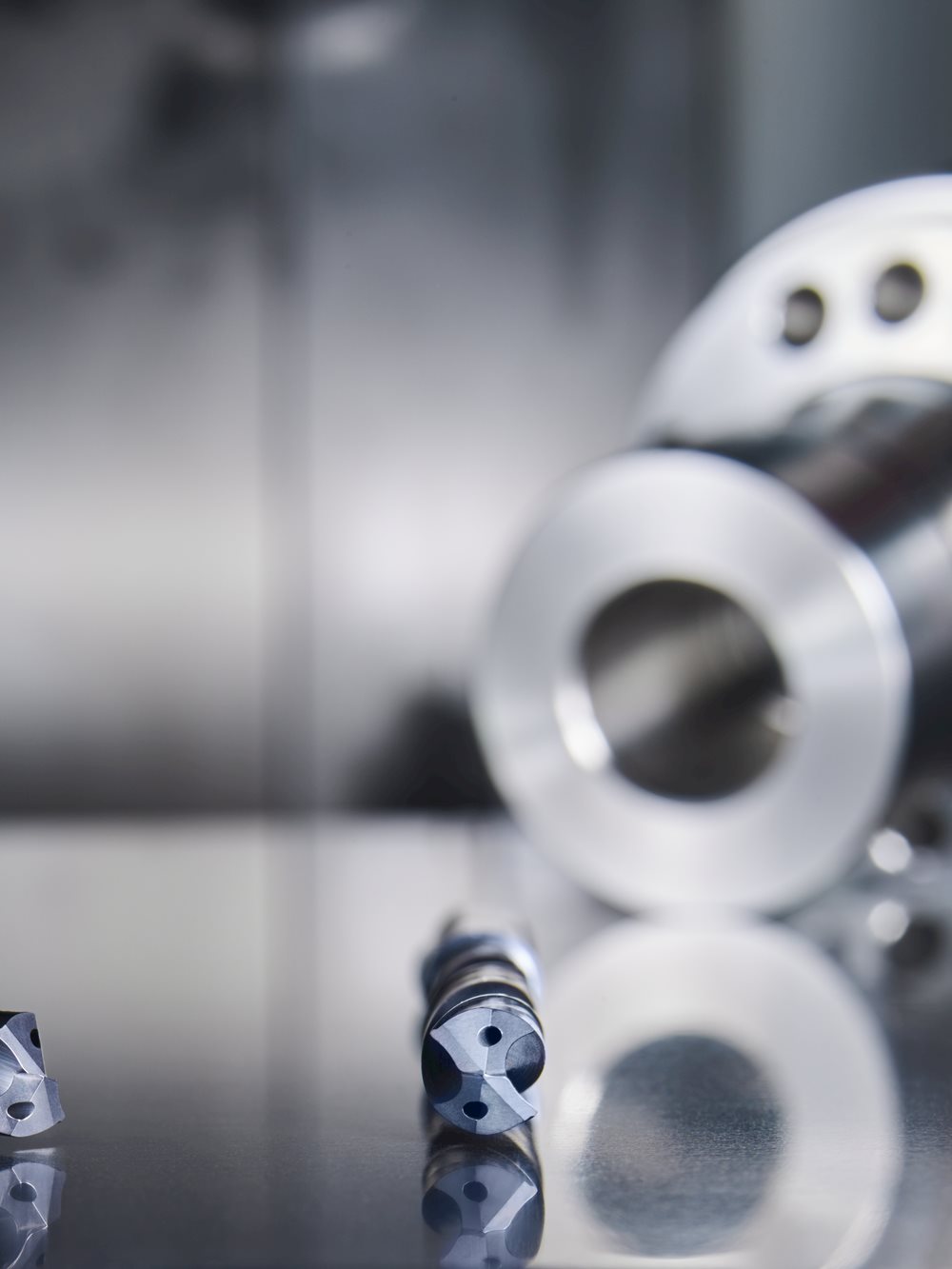

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

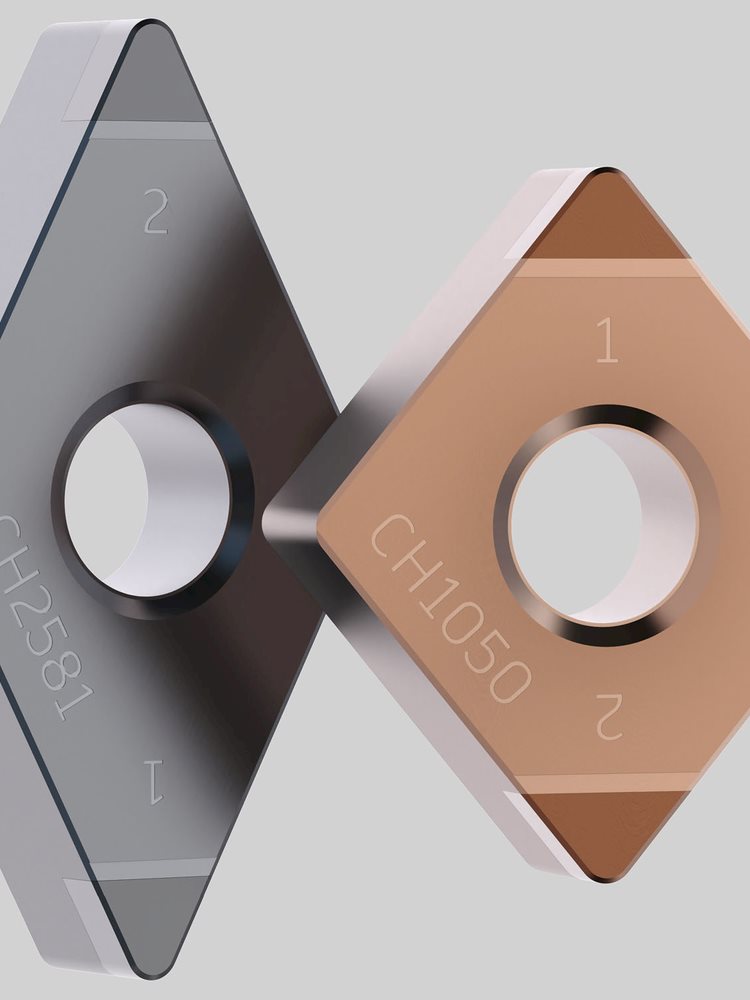

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

JS720 Solid End Mills addition

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

Square T4-12 Upgrades

Universal Drills

MF2 Chipbreaker on Round RCMT/RCGT Inserts

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Seco Machine Library

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

JETI CONVERSION GROOVING AND PARTING-OFF

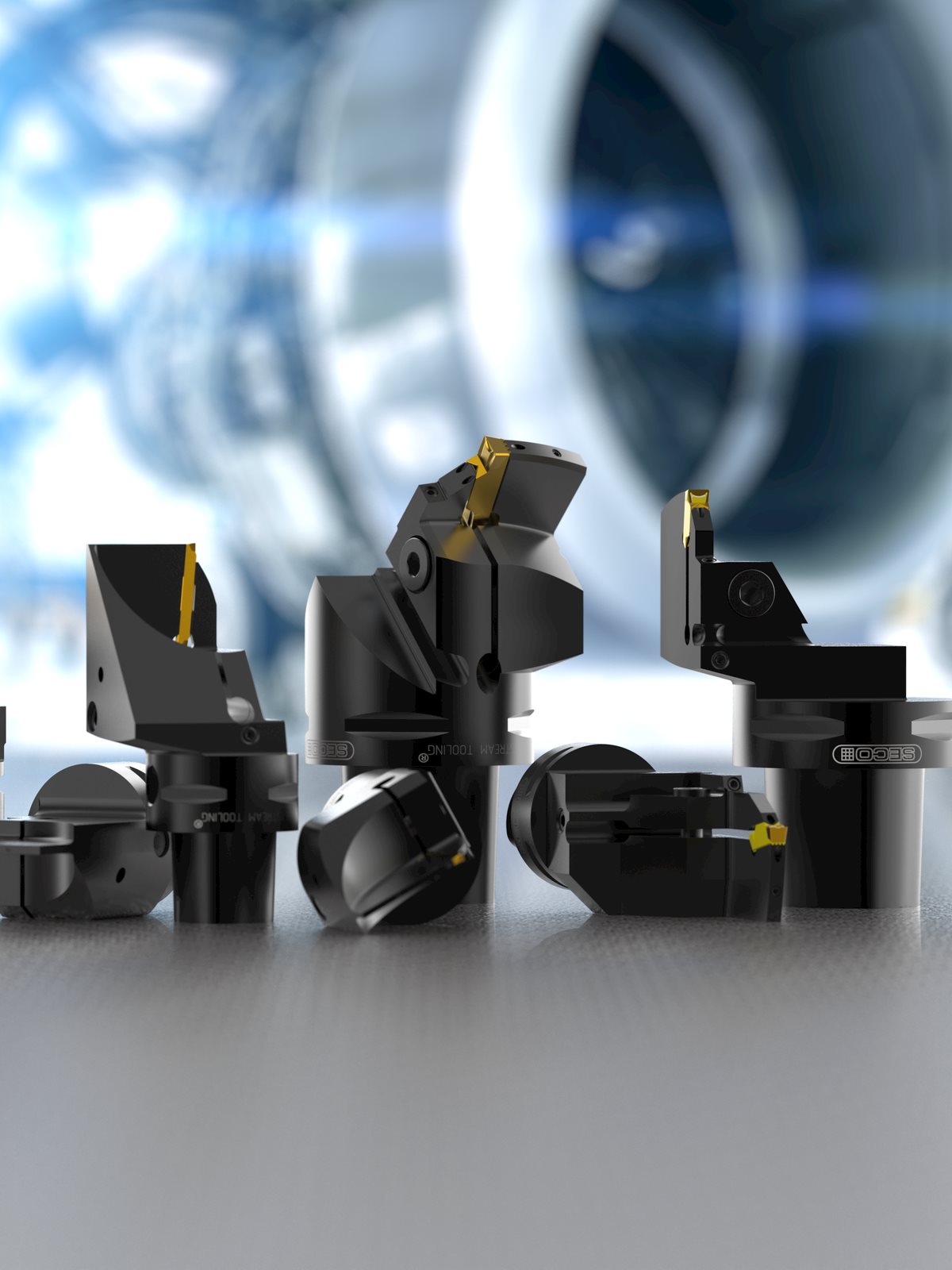

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Steadyline® ø25mm (1”) series

New MP Milling Grades

Unleash your drilling potential

JETI ISO Toolholder range extension

JETI conversion Grooving and Parting-off Capto

JM100 MINI END MILLS

Modular QC (quick-change) toolholder for small part machining

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

Video: 16 Edges for Maximum Face Milling Economy with Double Octomill

R220.88 WITH SNMU INSERTS

TTP2050

DOUBLE QUATTROMILL™ 14

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22