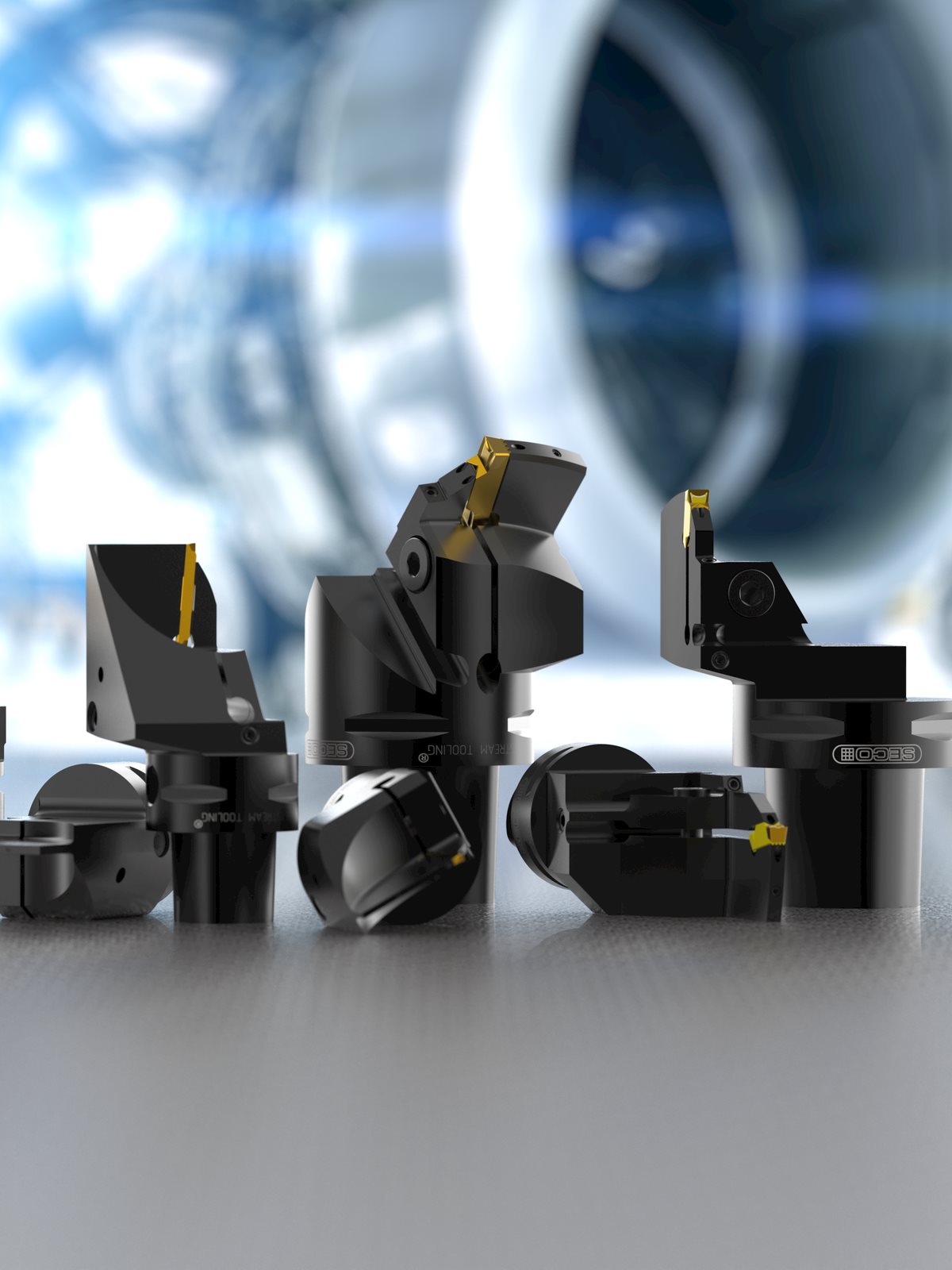

Jetstream Tooling® JETI tool holders pinpoint coolant for EFFICIENT chip control

Seco JETI and Jetstream Tooling® tool holders put coolant in the cut zone for chip control, longer tool life and process stabilityDiscover the product range

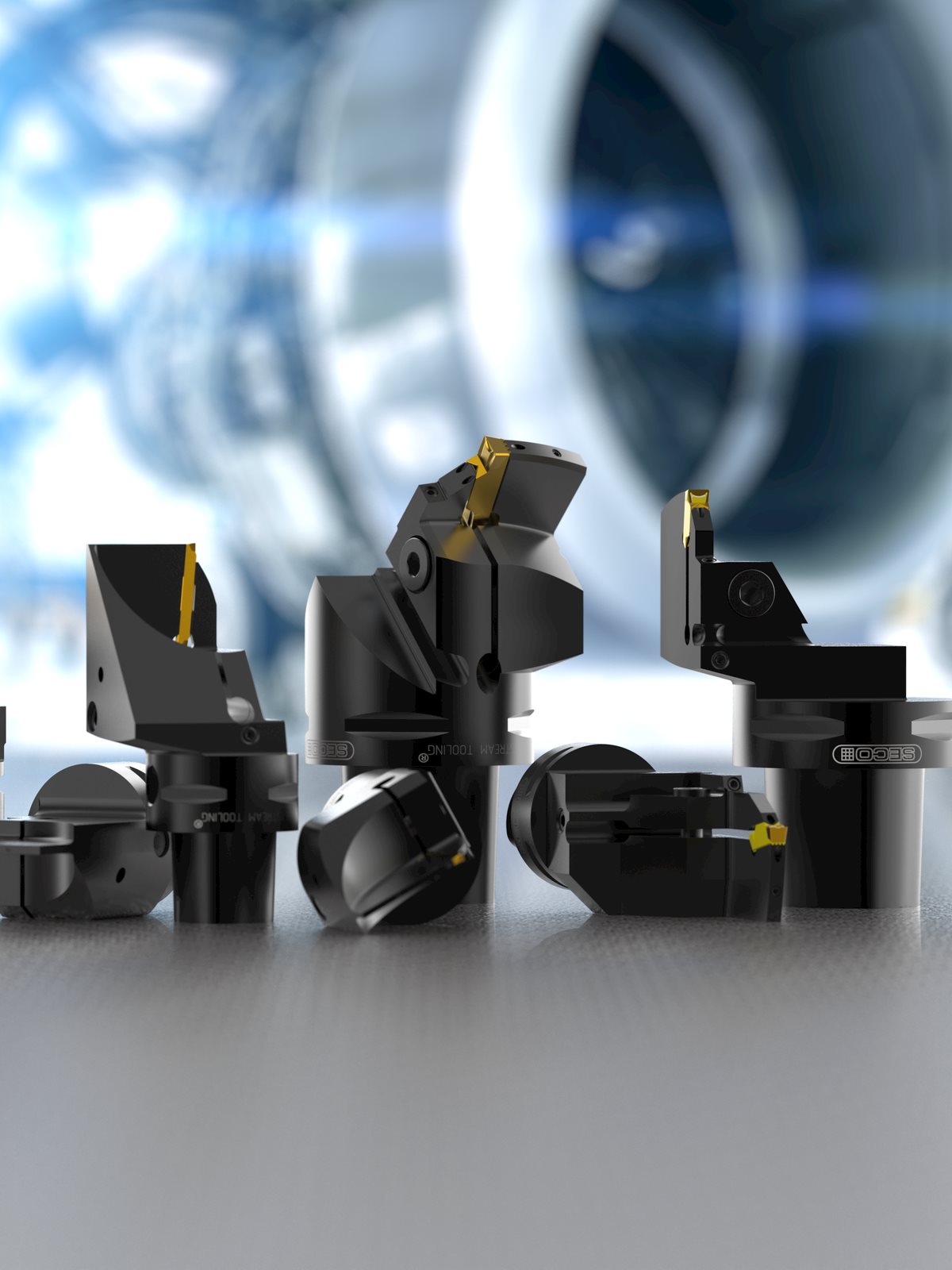

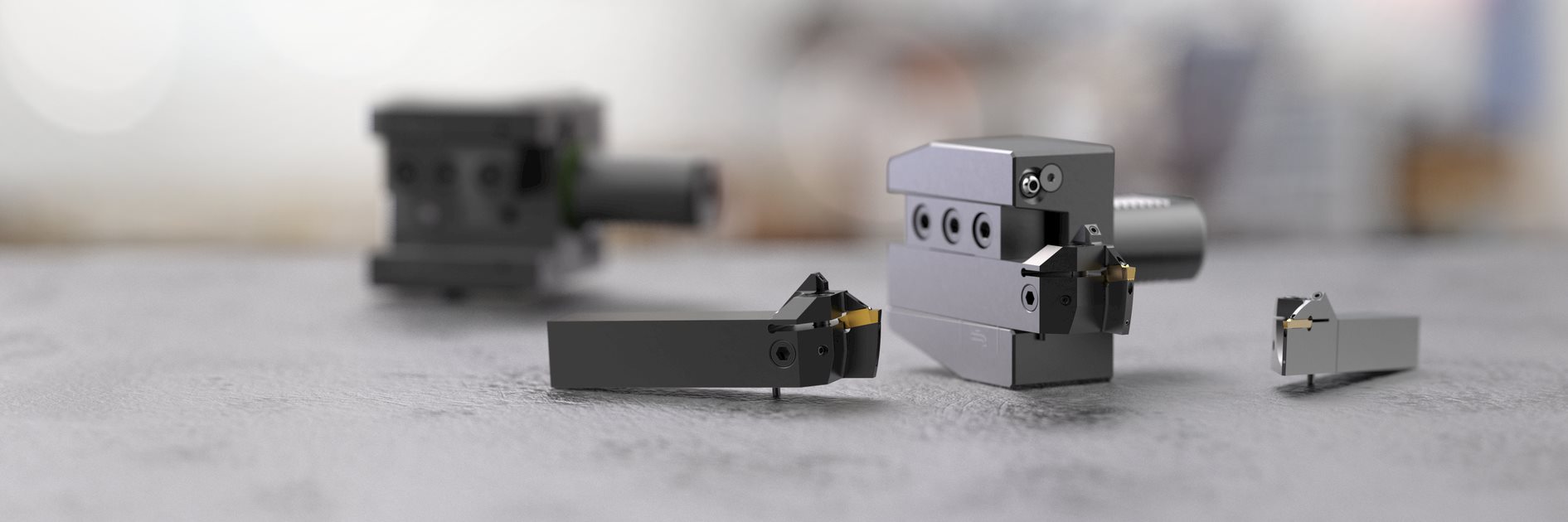

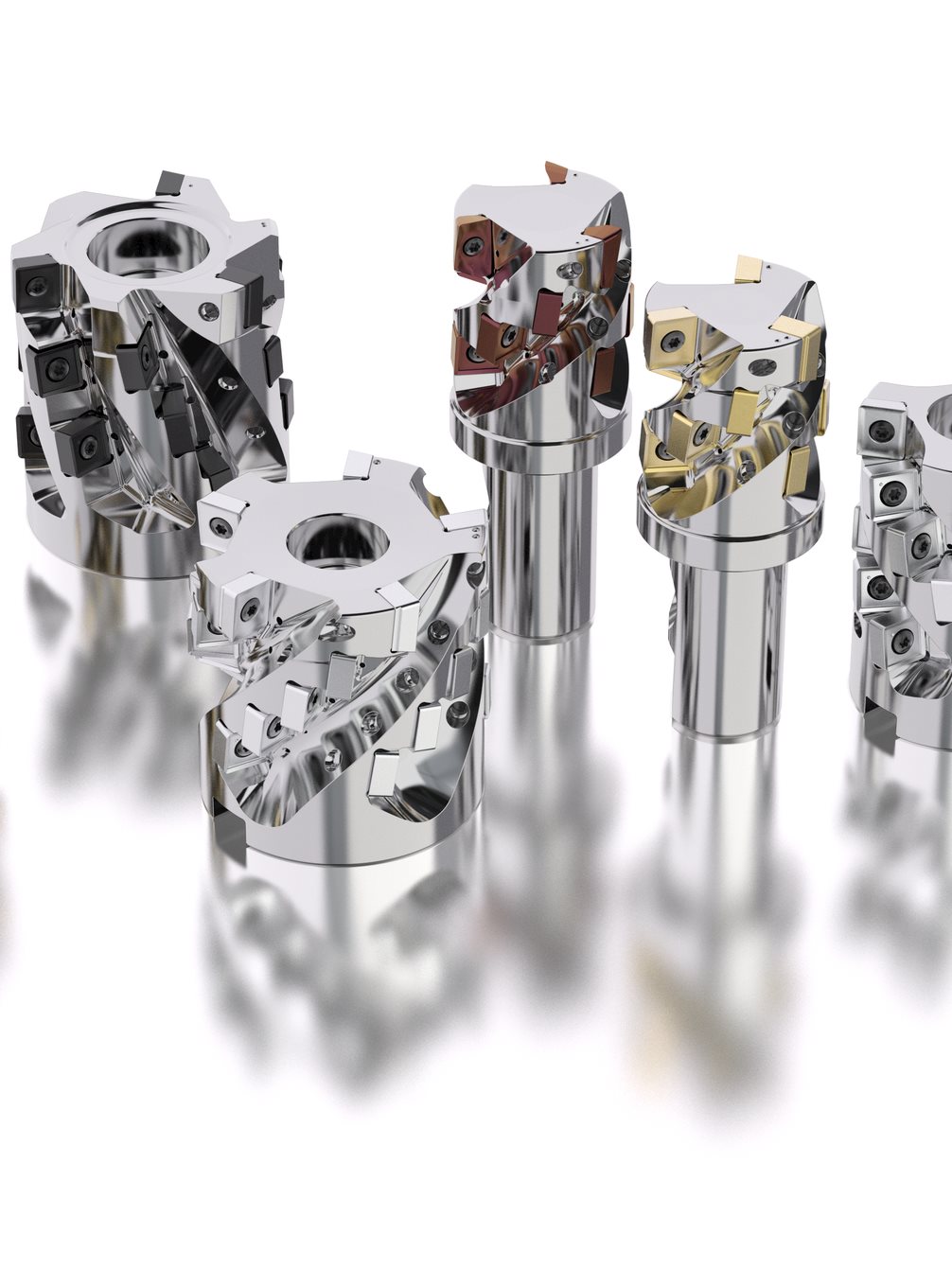

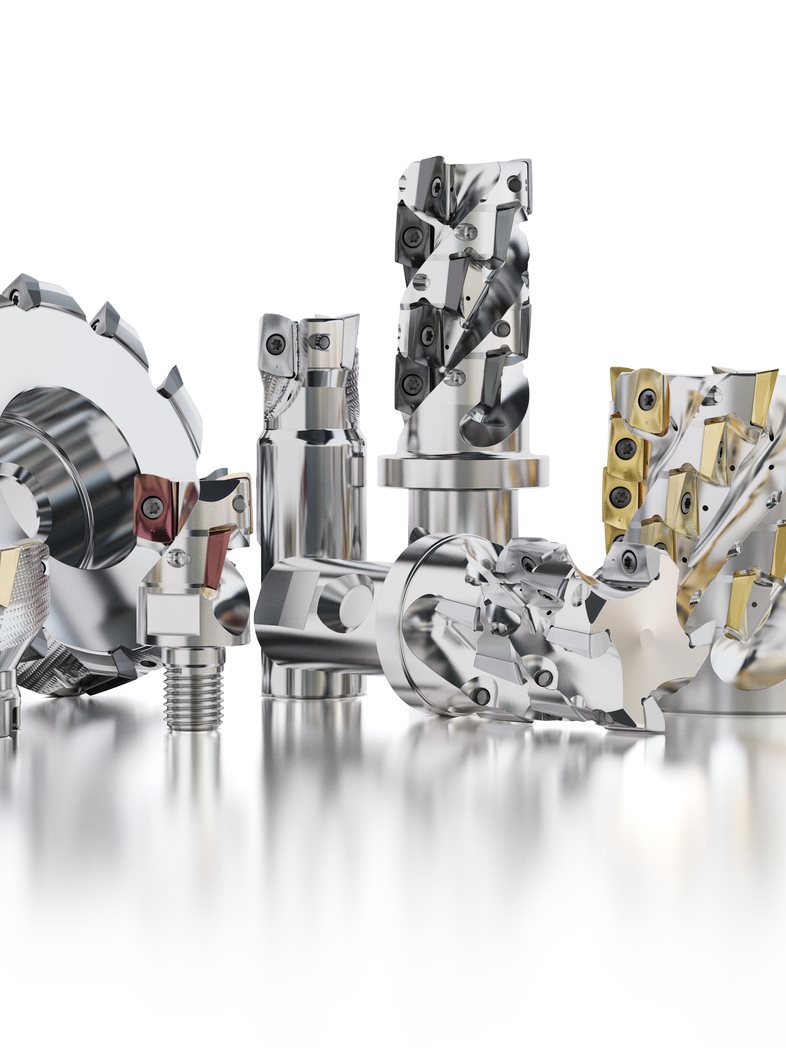

Manufacturers in every industry continue to face customer demands for shorter part turnaround times. To stay competitive, manufacturers must keep machine tools in the cut as much as possible and cannot waste huge amounts of time on toolholder setups or insert indexing. To keep machines cutting longer, Seco JETI and Jetstream Tooling® tool holders feature fewer components and special designs that make for faster setups and insert indexing, together with coolant delivery directly to the cutting zone to eliminate machine downtime due to chips.

Your challenge:

Time-consuming insert indexing slows down processes and setup time.

The Seco solution:

JETI and Jetstream Tooling® holders’ single-screw coolant clamp design makes insert indexing fast.

Your challenge:

Fast production cycles limit time for setup and indexing.

The Seco solution:

The special insert indexing design of JETI and Jetstream Tooling® holders’ saves valuable time.

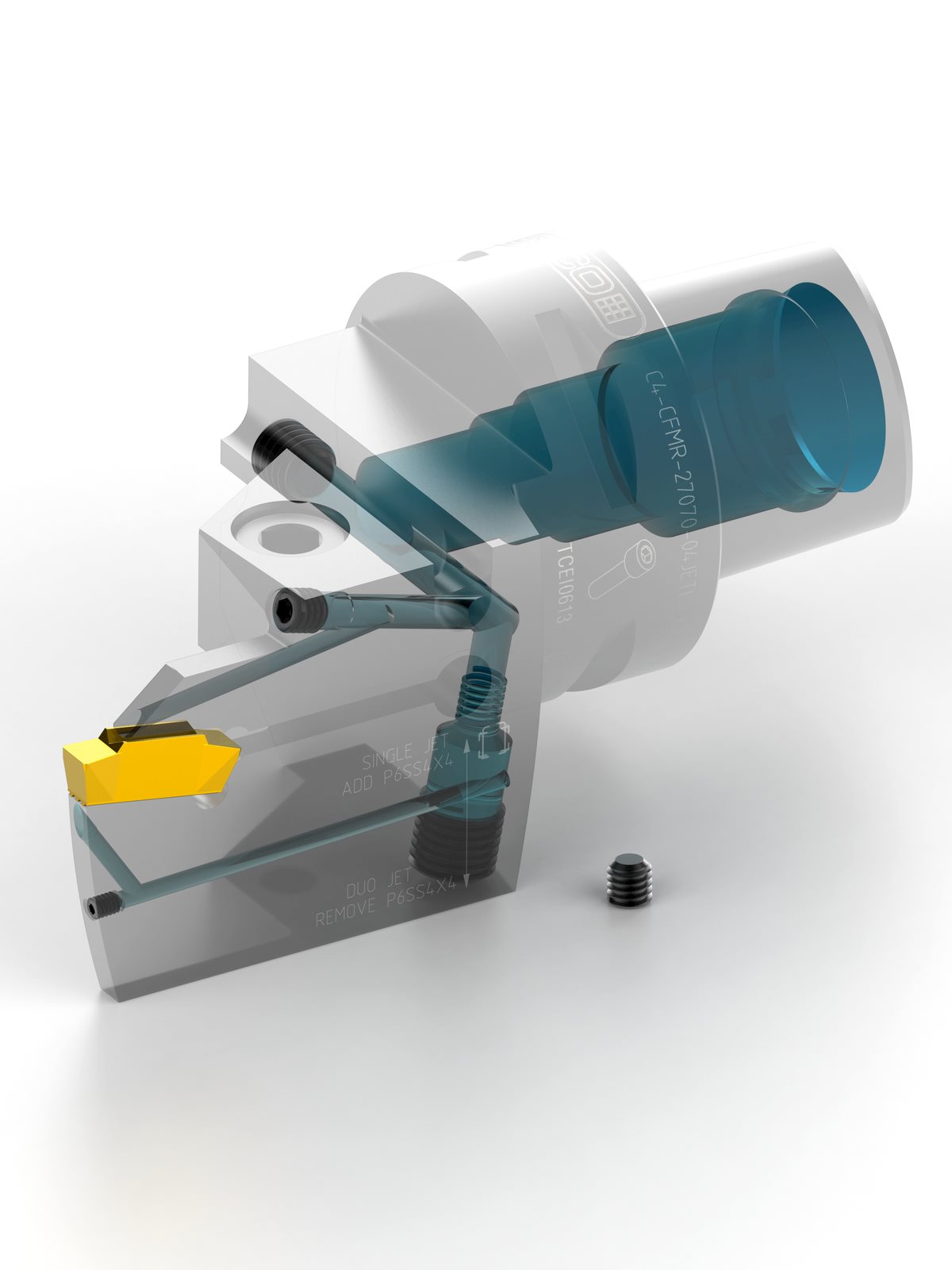

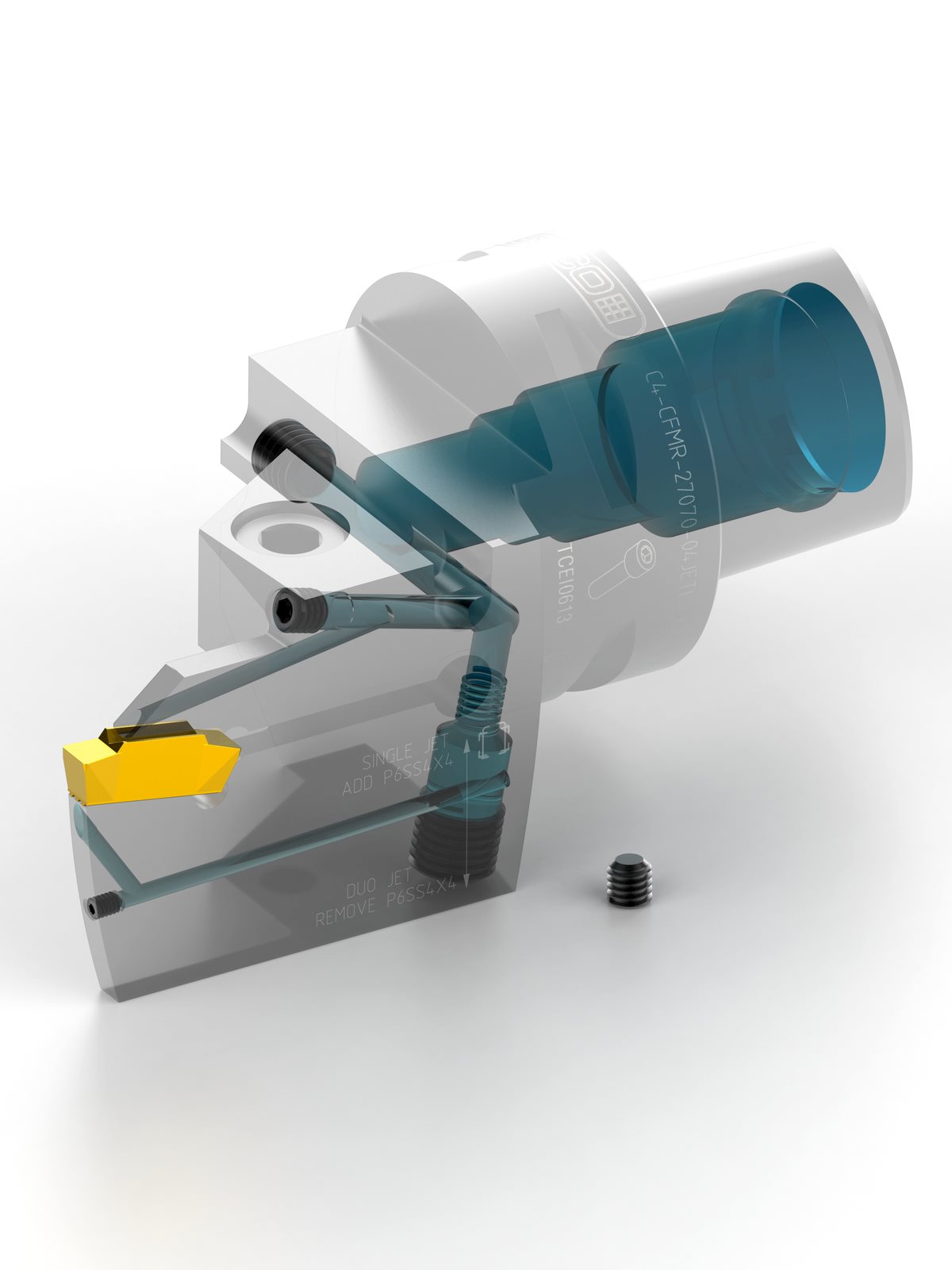

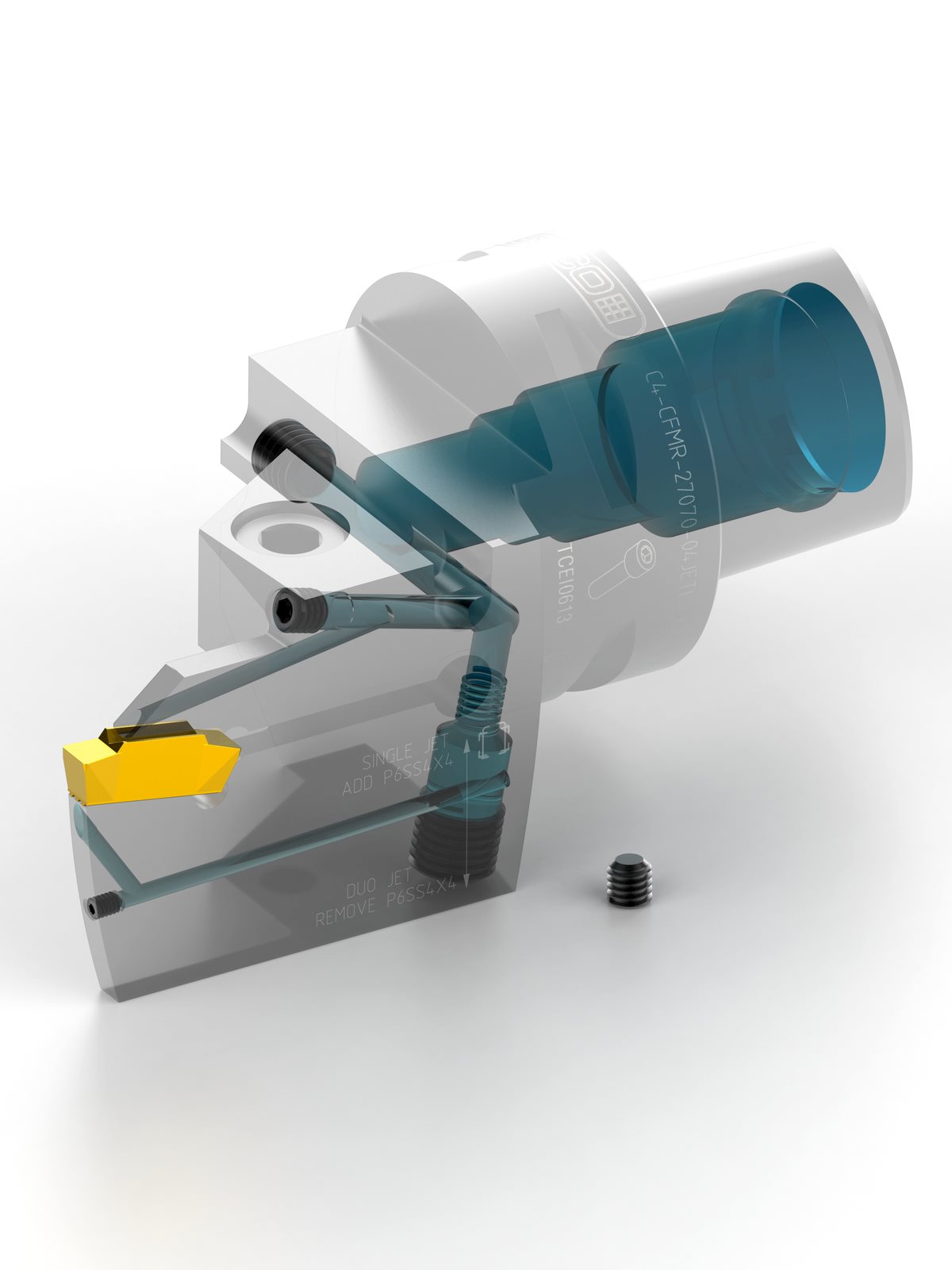

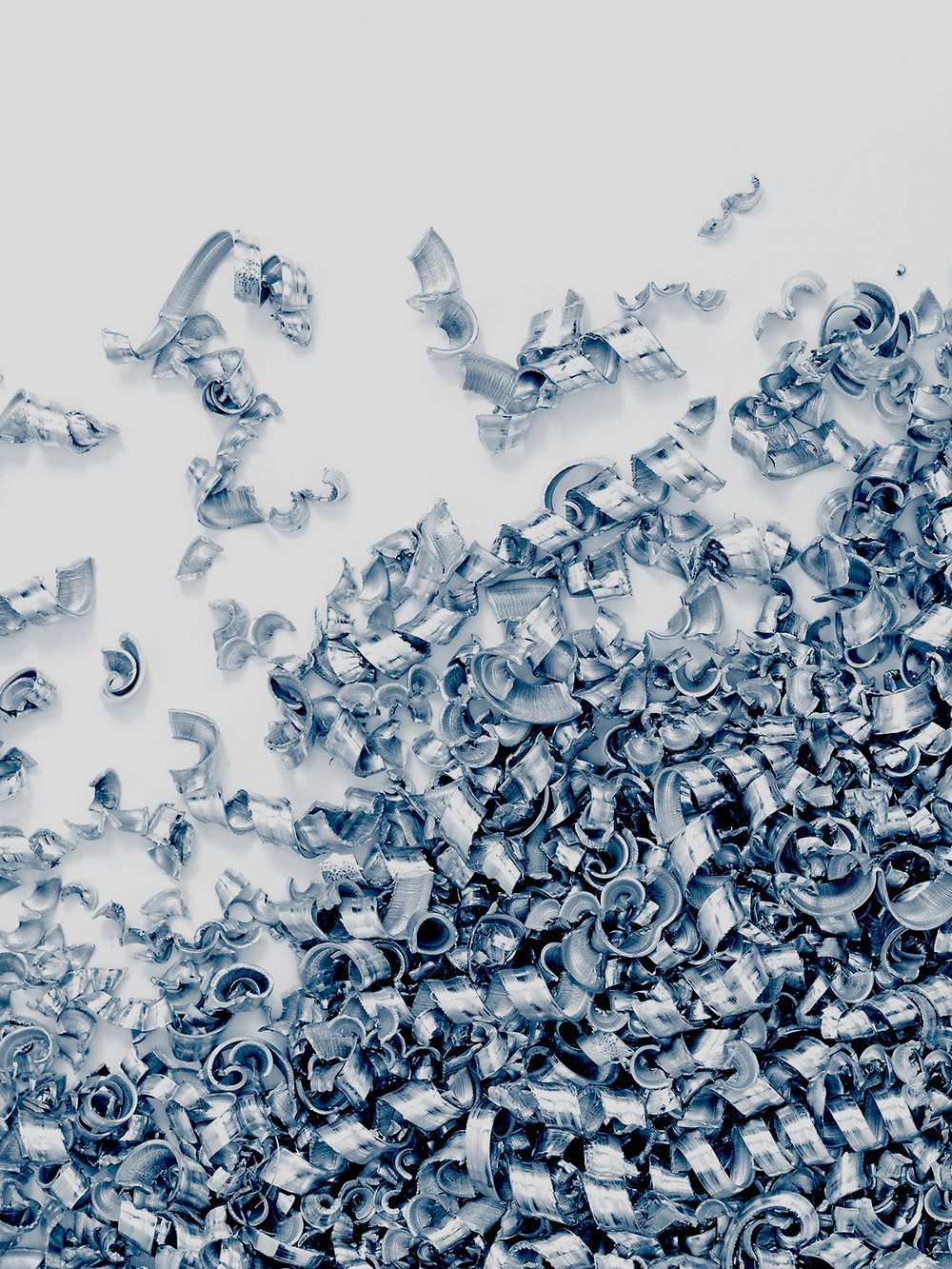

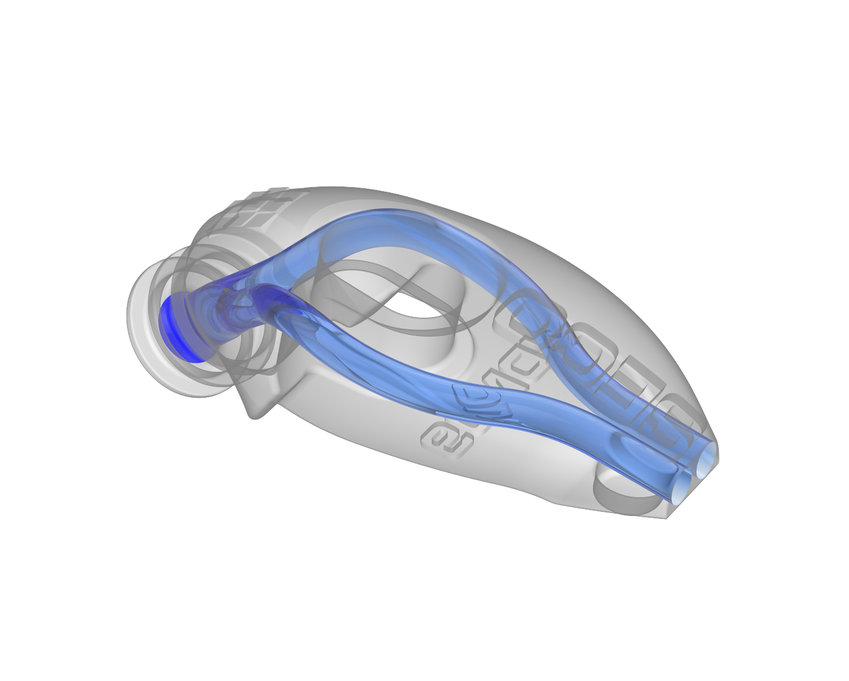

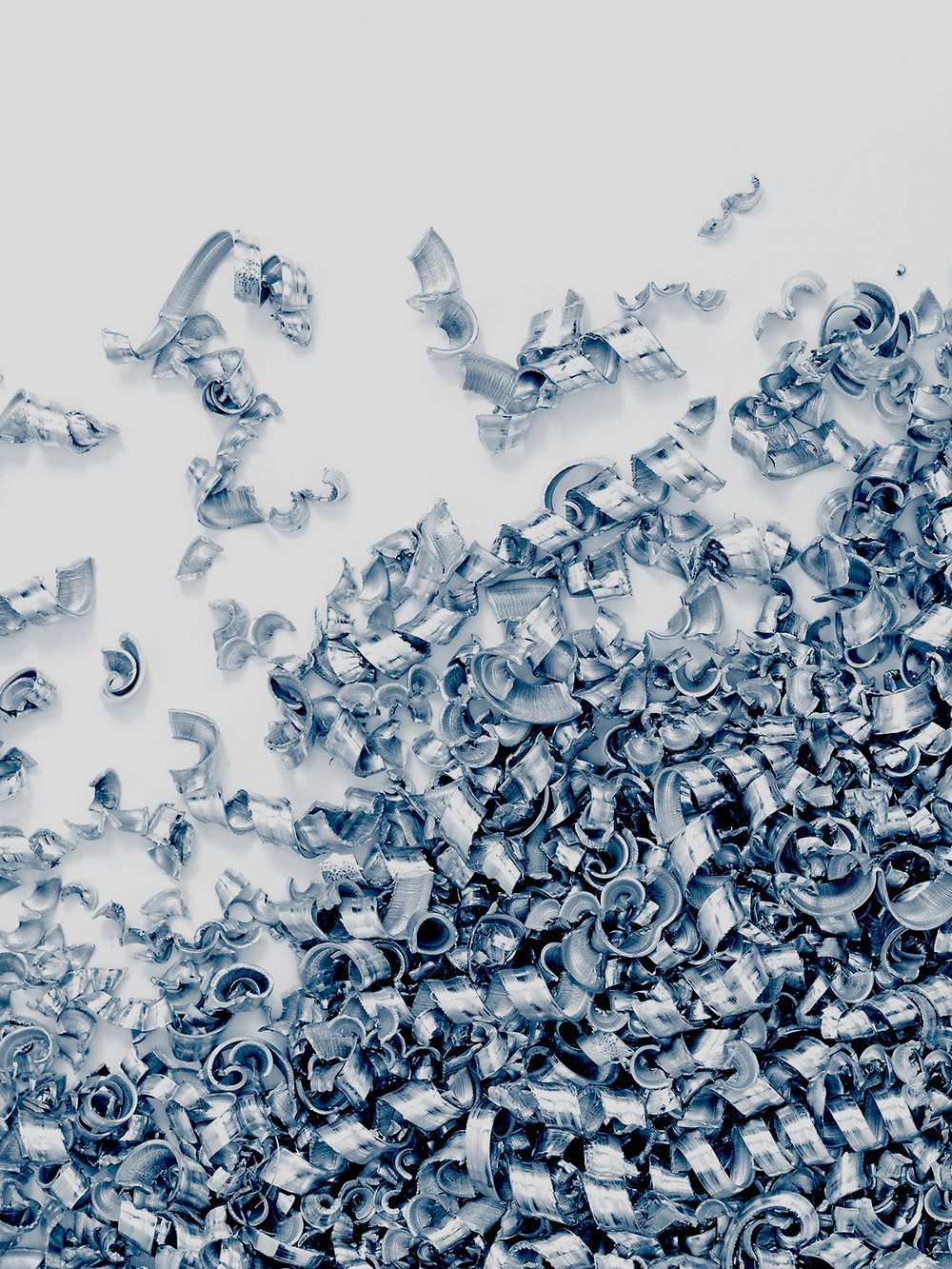

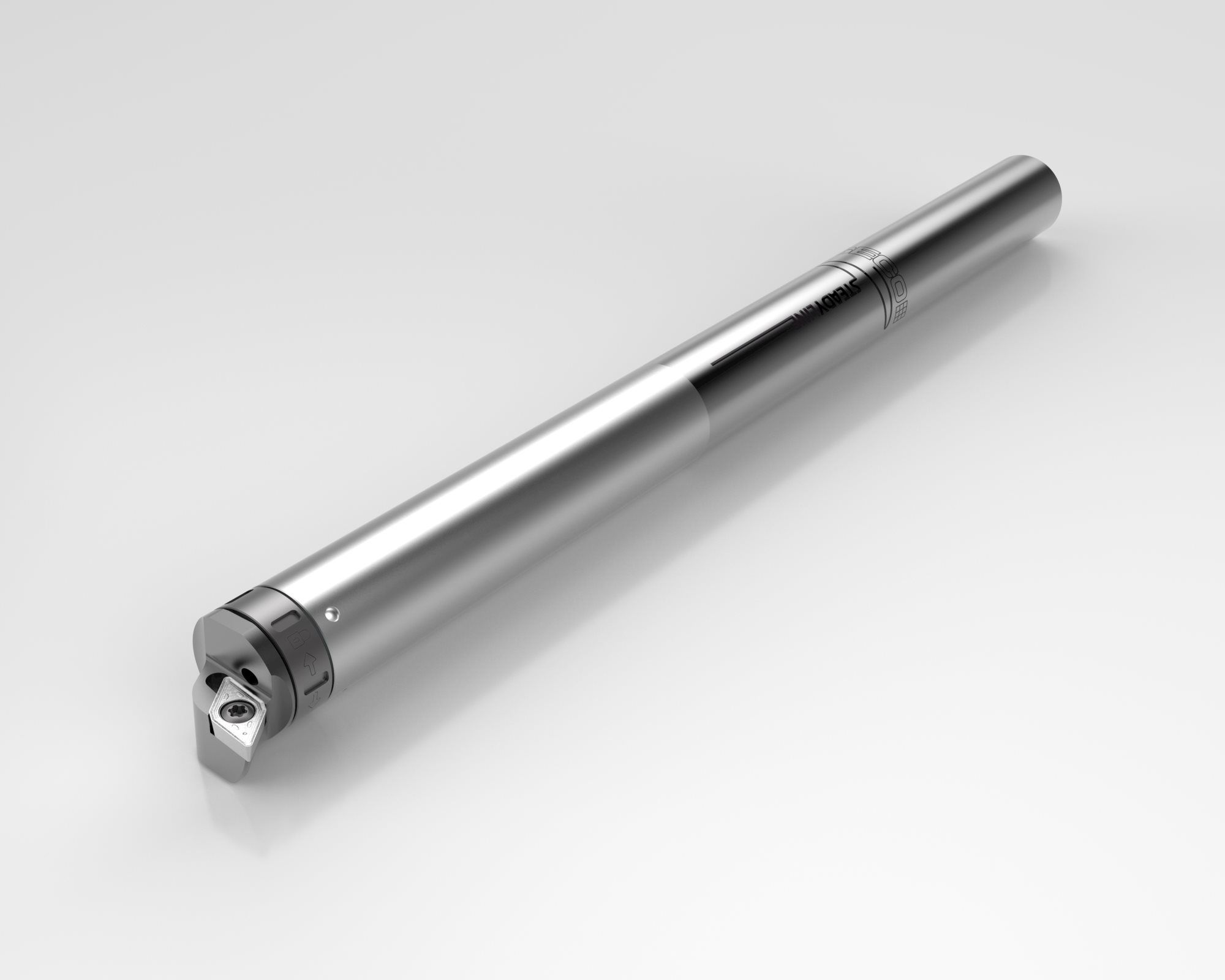

Uncontrolled chips are a manufacturer’s worst nightmare. The buildup of chips, especially during ISO turning operations, can prove hazardous not only to operators but also to your parts. Keep chips from scrapping workpieces and shortening your tool life with Seco Capto™ Duo JETI2 toolholders toolholders that pinpoint a high-pressure coolant flow directly at the cutting zone to blast chips away and ensure reliable, uninterrupted turning with better surface finishes and longer tool life.

Your challenge:

Maintain chip control and process security in turning applications, especially in ISO-S, ISO-M and ISO-P materials.

The Seco solution:

Guide chips away from the cut with JETI and Jetstream Tooling® holders that deliver high-pressure coolant directly to the cutting zone where it is most effective.

Your challenge:

ISO-S, ISO-M and ISO-P materials can generate hazardous accumulations of chips that stall turning operation productivity.

The Seco solution:

JETI and Jetstream Tooling® holders guide chips away from the cut with high-pressure coolant directed at the cutting zone.

When you can perform multiple turning operations with the same tooling setup, you lower tooling costs and inventory. But most importantly, the fewer tool changes you have to make, the shorter overall part cycle times, which in turn increases machine output. Thanks to their clearance radius design, Seco JETI and Jetstream Tooling® holders provide ample clearance to perform both external and internal turning operations while directing high-pressure coolant precisely to the cutting zone for chip management and extended cutter life.

Your challenge:

Switching through-coolant holders when transitioning from OD to ID processes lengthens production time.

The Seco solution:

JETI and Jetstream Tooling® tool holders eliminate tool changes for shorter machining cycle times and increased part accuracy because they allow for both external and internal turning applications.

Your challenge:

Maintaining separate toolholder inventory for OD and ID processes increases costs.

The Seco solution:

JETI and Jetstream Tooling® holders eliminate tool changes and enable manufacturers to reduce toolholder inventory.

Discover the product range

Contact Us

Are you interested in Jetstream solution?

Discover our solutions and content

Related content

JETI conversion Grooving and Parting-off Capto

Factsheet - JETstream Tooling Seco Capto Toolholders

Optimize Multi-Task Machining Coolant And Results

JETI Coolant Supply Alternatives

JETSTREAM TOOLING COOLANT PRESSURE COMPARISON

JETSTREAM TOOLING - TOURNAGE D'UN ARBRE

What you need to know about chip formation

JETSTREAM TOOLING DUO

High-pressure coolant for round inserts enhances turning productivity

Advantages of Shorter Tooling for Multi-Tasking Machines - Seco Tools

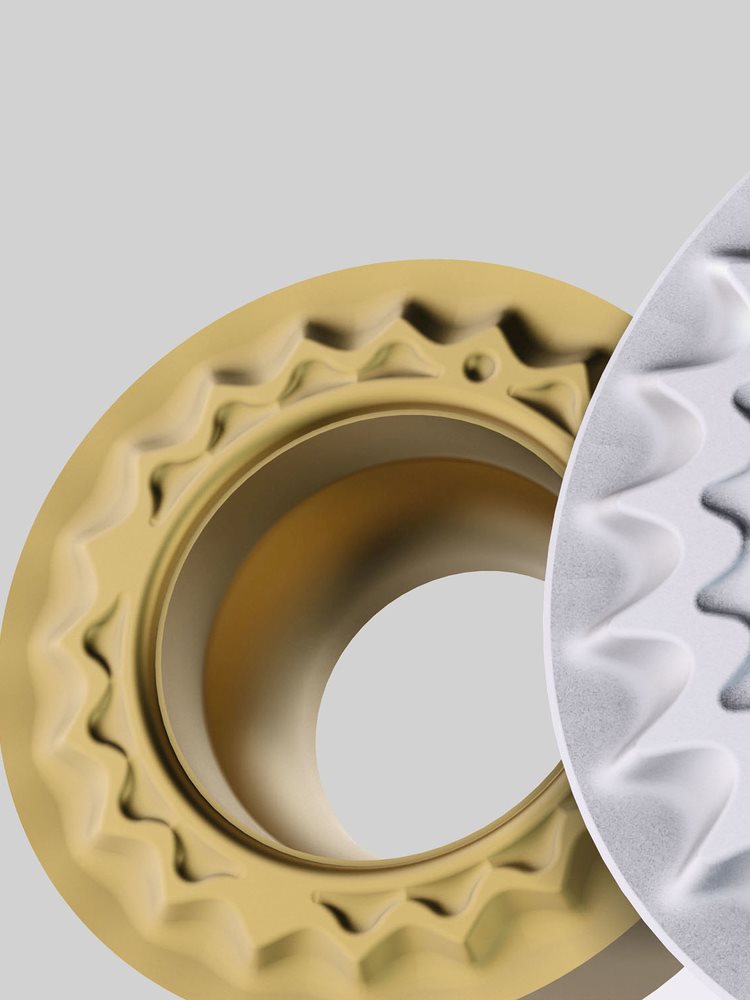

JETI Toolholder for RCMT/RCGT Turning Inserts

Factsheet - Seco-Capto MTM Jeti Toolholders

Factsheet - JETI Toolholder for round turning Inserts

JETSTREAM TOOLING®

Is average chip thickness an outdated concept?

COOLANT CLAMP IS SECO’S FIRST AM PRODUCT IN THE MARKET

The Importance of Cutting Fluids in Metal Cutting

Toolholders Pinpoint Coolant and Eliminate Turning Operation Interference

Seco Taps T32 - T33 - T34

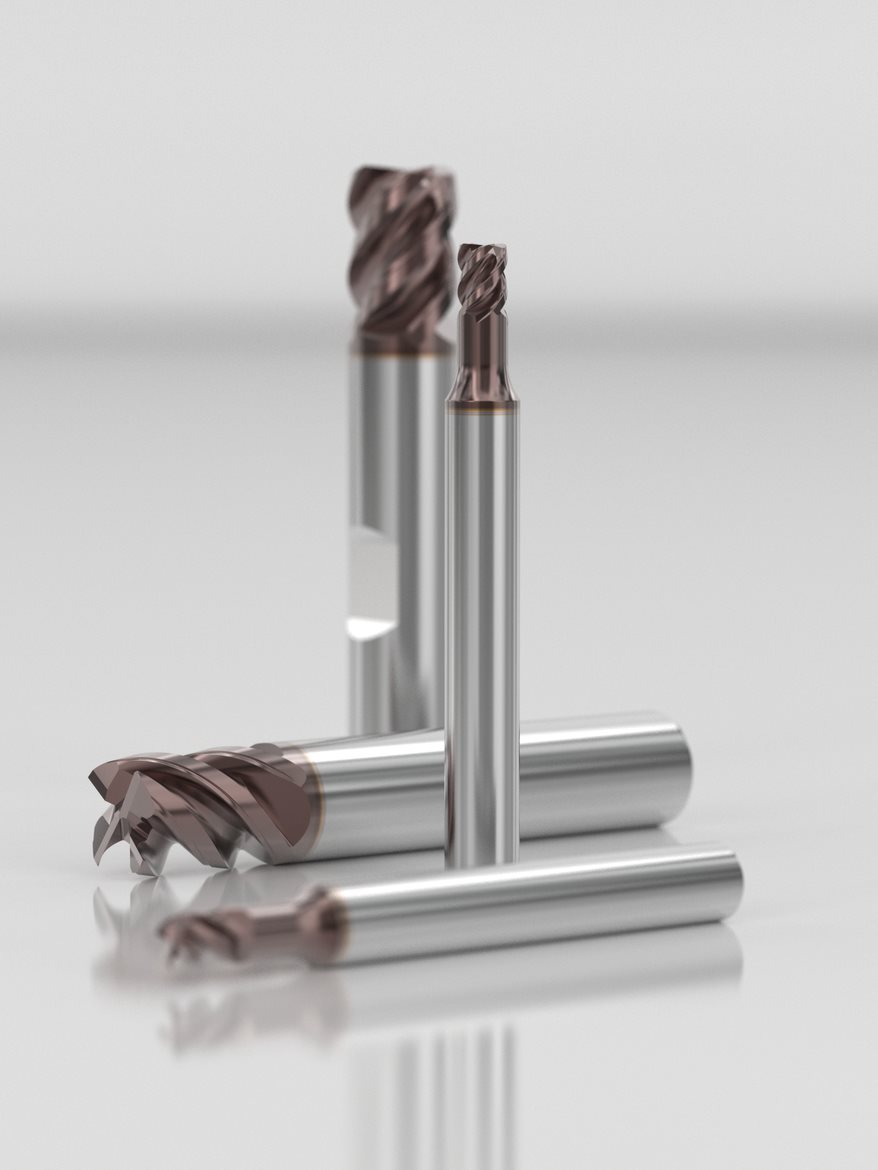

Seco JH724-JH726 Medical barrel Solid End Mills

The role of average chip thickness in Milling operations

Seco Hydraulic Chucks

Seco End Mills for Plug-and-Play Dental Milling

Holders

Seco Helical SN8-13

Video: Jetstream Tooling® JETI Shank Adapter

Video: Jetstream Tooling® for Steadyline® Turning Heads

Video: Simple Jetstream Tooling Threading Assembly

Seco Innovates Jetstream Tooling® for ISO Turning Operations

Seco High Feed SP

Seco News Summary 2022.2

Helical Interpolate Like A Pro

Seco Tools to partner with Fusion Coolant Systems to drive forward corporate environmental sustainability efforts

MF2 Chipbreaker on Round RCMT/RCGT Inserts

How to overcome chip challenges?

Seco helps customers reduce their carbon footprint

Seco JS754 Stub Series End Mills

Video: Getting Technical - Is average chip thickness an outdated concept?

Brochure - Product Highlights

Turning - Wear Analysis and Chip Control

New Seco MDT heads deliver turning interchangeability and vibration control

Getting Technical - Best chip formation for productivity and economy in machining

Internal Coolant Turbo 16 Square Shoulder Milling Cutter

Jetstream Tooling®

Video: Single-Point Threading Jetstream Introduction

Video: JETSTREAM TOOLING®: Goodbye to long, tangled thread turning chips