Boost manufacturing efficiency with real-time machine monitoring

With Seco Machine Monitoring, remove machining bottlenecks and optimize machine uptime through real-time data visualization of equipment efficiency.

Contact Us

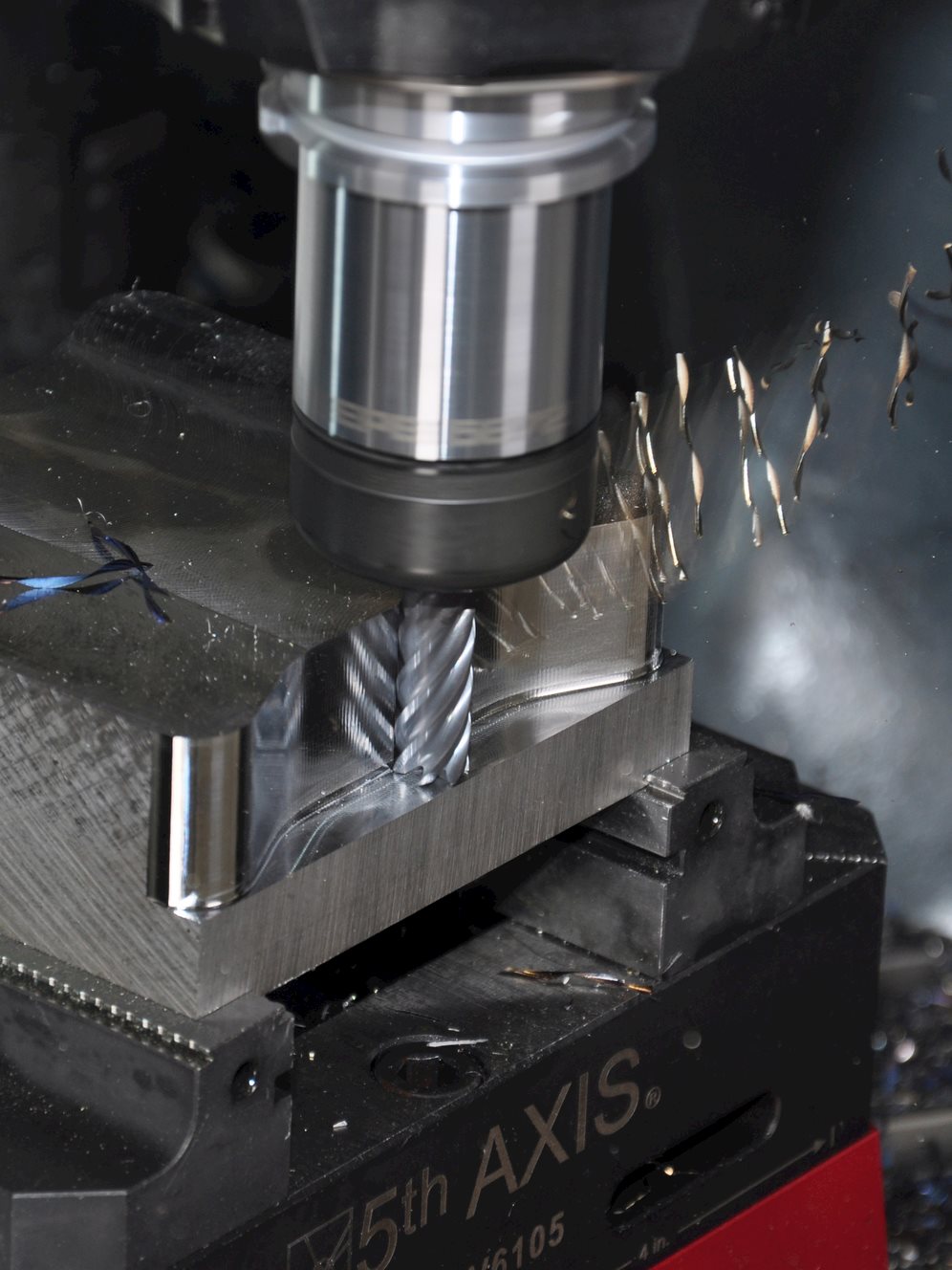

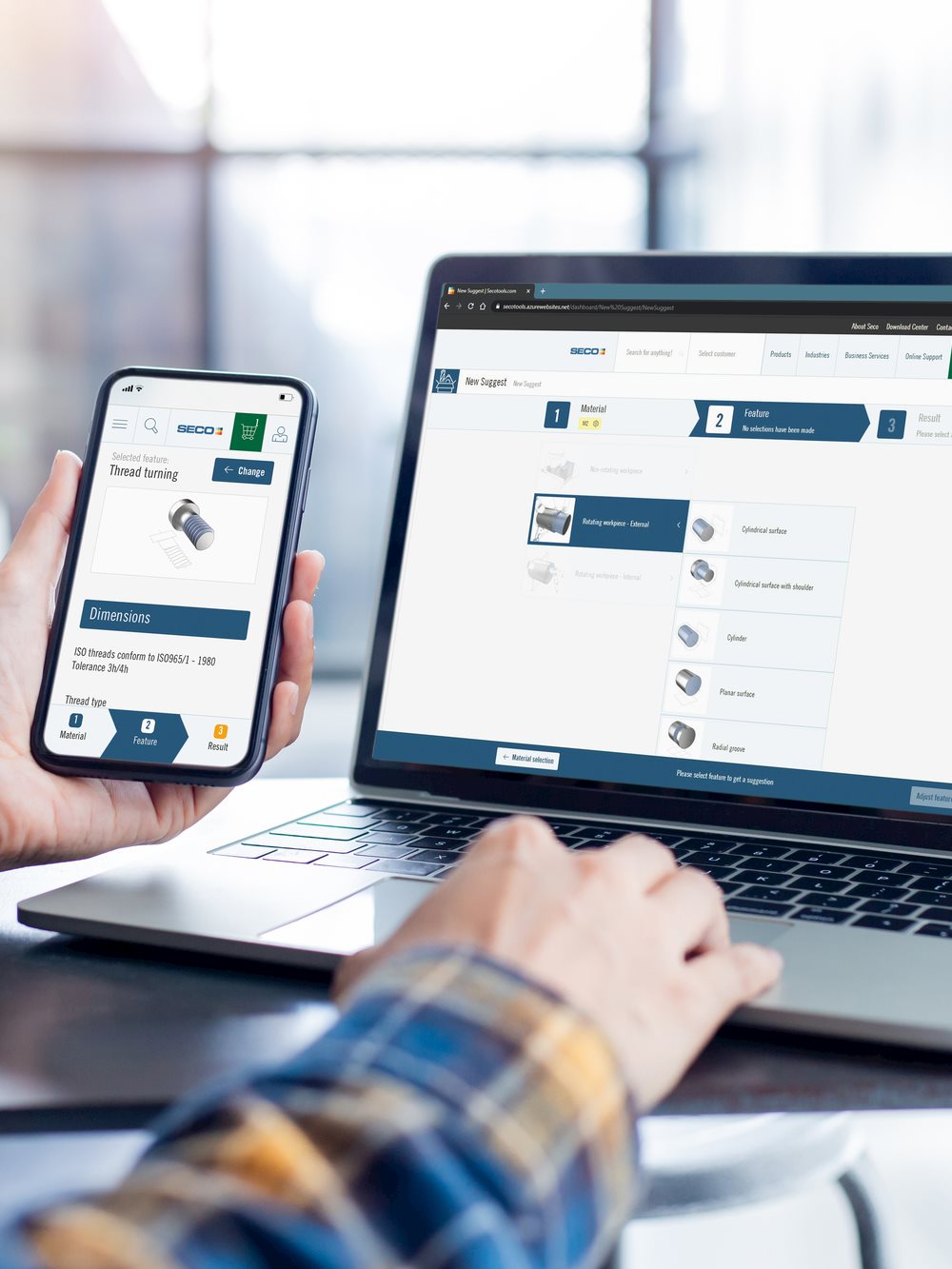

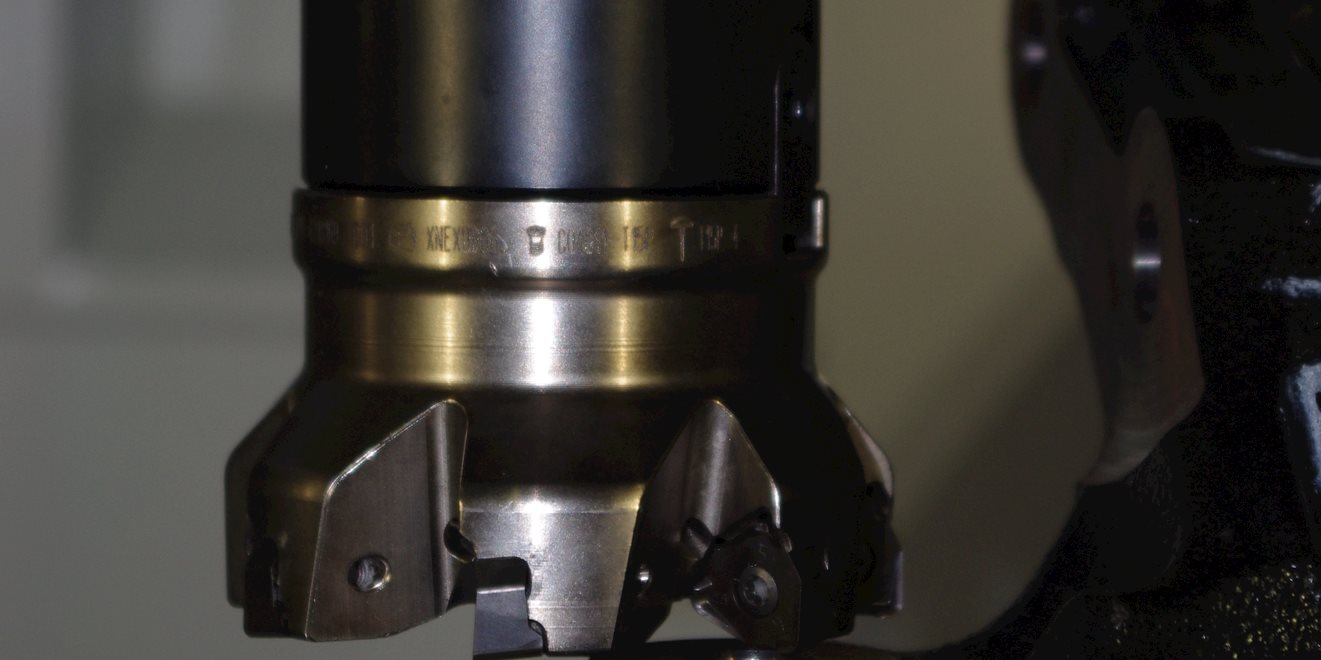

To optimize production performance for manufacturing transformation, manufacturers not only need answers to essential questions about what's holding back their efficiency. Before they can process the answers, they need to know which questions to ask. Production analysis that combines the value of OEE tracking with insights and real-time notifications from data visualization tools can show operators and managers where to find machining bottlenecks and how to eliminate them. With CNC machine tool monitoring through Seco Machine Monitoring, manufacturers can understand exactly what happens on the shop floor so they can maximize machine uptime for productivity.

Your challenge:

Limited access to real-time production data slows your response to individual applications, machines, cells and your overall production workflow.

The Seco solution:

Color-coded metrics on real-time dashboards give you the insights you need to improve efficiency.

Your challenge:

When production bottlenecks bog down your production line, a lack of insights into the causes of downtime makes it difficult to increase efficiency.

The Seco solution:

Real-time data access and notifications give operators and managers the information they need to make informed decisions about production problems.

High scrap rates, poor job planning, irregular maintenance, lack of communication and low awareness of how to optimize machine tool efficiency can impair productivity on the manufacturing line. All these challenges point back to a lack of information about equipment efficiency, machining bottlenecks and production performance. Data-driven Seco Machine Monitoring gives manufacturers a full picture of overall equipment effectiveness so they can adjust their planning and resources for maximum performance.

Your challenge:

Without a realistic picture of machine output and utilization, manufacturers can't increase efficiency and optimize production levels.

The Seco solution:

Detailed insights into machining operations on all attended and unattended shifts make it easy to track Overall Equipment Effectiveness (OEE) and make continuous improvements to operations for better planning, scheduling and communication.

Your challenge:

High scrap rates, poor understanding of shop productivity and too many unknown production conditions complicate the process of enhancing productivity.

The Seco solution:

Data-driven insights reveal the real root causes of production problems so manufacturers can optimize their workflows.

When manufacturers list the essentials that contribute to their overall productivity, they typically point to equipment and programming. But as successful shops can attest, communication holds just as vital a role as any tooling or inventory. Without clear communication between operators and among all levels of a manufacturing organization, machining bottlenecks can remain hidden in information that no one shares. With data visualization through Seco Machine Monitoring and production analytics, manufacturers can receive real-time notifications about critical problems with manufacturing efficiency so they can understand the full picture of their operations and make informed decisions about how to optimize them.

Your challenge:

If operators, managers and shop ownership do not communicate about problems, concerns and bottlenecks can hinder production.

The Seco solution:

Data-driven communication and notifications give personnel at all levels the information they need to raise concerns and take action for greater productivity.

Your challenge:

A lack of input from the shop floor can hinder attempts to categorize down time and capture insights that enhance productivity.

The Seco solution:

Real-time capture of production data plus notes and information from operators can combine to identify workflow problems and resolve them.

When manufacturers analyze production performance, their perspective may draw on a decade or a career's length of experience, but that viewpoint may not be broad enough to show them how to optimize their processes. Seco Machine Monitoring provides real-time notifications of production performance through data visualization tools that make it easy to see machining bottlenecks and optimize machine uptime. In addition, the Seco Manufacturing Transformation system includes numerous options to partner with customers for continuous improvement of everything from tool analysis to operator education. With 80 years of global expertise in all aspects of production performance, Seco can help manufacturers maximize every component of their productivity.

Your challenge:

Manufacturers lack insight into the sources of production problems and are unsure which questions to ask or answer.

The Seco solution:

With a robust portfolio of solutions and a commitment to continuous improvement, Seco offers manufacturers a holistic response to their desire for greater efficiency.

Your challenge:

Manufacturers try to address production problems without knowing their root causes or how to solve them.

The Seco solution:

Seco shares insights based on 80 years of manufacturing expertise and a full repertoire of solutions based on technology, research and experience.

Contact Us

Are you interested in Manufacturing Transformation solutions?

Discover all our solutions and content around it

Related content

Engineering Services

Inspiration through Innovation 2020 – Aerospace Manufacturing Best-Practice Virtual Event

Recycling

Video: Manufacturing Transformation - Let's take a look at what we can do for you I Seco Tools

Truck And Bus Applications

Thank You!

About Seco Tools

Standard Diamond Coated Drilling Solutions

Seco Profile Milling Solutions

Jetstream Tooling® with MDT

Threadmaster™ Thread Mills

Jetstream Tooling® with MDT

Seco Milling Solutions

Seco Feedmax™ Solid Carbide Drills

Secomax™ CBN170

Seco Jabro Solid Carbide

Seco Copy Milling Solutions

Plunge Milling Cutters

Seco Graflex Boring Tools

Seco Graflex Boring Tools

Seco Holemaking Solutions

Seco Holemaking Solutions

Ball Bearing Location

Face Milling with Double Octomill

Plunge Milling Cutters

Turbo Square Shoulder Mills

Seco Holemaking Solutions

Seco HFM Solutions

Helical Shoulder Milling with Turbo Mill

Custom-Made PCD Milling and Drilling Solutions

Seco Holemaking Solutions

Square Shoulder Helical Mills

Plunge Milling Cutters

Quattromill®

Seco Reaming Solutions

My Pages

Multi Flute Brochure Download

Access to Suggest

Standard Jabro Composites Range of Solid Carbide Tools

Standard PCD Milling And Drilling Solutions

SECO'S MASTERCLASS SPRING SERIES

Jetstream Tooling®

Seco Feedmax™ Solid Carbide Drills

Brake Caliper Fastening Holes

Lower Ball Joint Location

Steering Arm, Tie Rod Location

ABS/ ABR Sensor Location

Strut Mount

Seco Feedmax N-Geometry Solid Carbide Drills

Jabro JH421 End Mills for Aluminum Machining

Jabro™ JHP490

Jabro-Solid2 JS522 Long Flute Finishing Tool

Jabro-Solid2 JS522 Long Flute Finishing Tool

Jabro-Solid2 JS522 Long Flute Finishing Tool

Mechanical Edge Profiling Cutters

Jabro-Solid2 JS522 Long Flute Finishing Tool

Mechanical Edge Profiling Cutters

Mechanical Edge Profiling Cutters

Aeromaster

Broaching Tools

Turbo Square Shoulder Mills

Jabro™ Solid Carbide Fir Tree and Dovetail Tools

Helical Profile Milling with Turbo Mill

Graflex Boring Tools

Seco Holemaking Solutions

Graflex Boring® Tools

Jabro™ Solid Carbide Tools

Seco Feedmax™ Solid Carbide Drills

Plunge Milling Cutters

Jabro™ Solid Carbide End Mills

Jetstream Tooling with MDT

Tool Reconditioning

Making the move towards complete digital transformation

Inventory Management

Video: Manufacturing Transformation - solutions and services to support your production I Seco Tools

Electronic Data Interchange (EDI)

Manufacturing Transformation

Tool Deterioration Analysis

Engineering Services

Seco Tools Expands Digital Services with Strategic Partnerships

Manufacturing Evaluation

Data sparks the fourth Industrial Revolution

What's trending in Tool Management Systems?

When and How to add machinery

How Productive is your shop?

Seco Innovation Hubs

Inspiration Through Innovation

Knowledge & Education

Custom Products

Documented Cost Reductions (DCR)

Component Engineered Tooling

Seco Taps T32 - T33 - T34

Seco JH724-JH726 Medical barrel Solid End Mills

How to deal with "difficult-to-machine' materials

GTDA: The path to efficiency

The role of average chip thickness in Milling operations

Seco Hydraulic Chucks

Seco End Mills for Plug-and-Play Dental Milling

Seco Helical SN8-13

You asked - We answer

Seco High Feed SP