Superb face milling system for finishing application

Achieve superior surface finishes with the new Seco Octomill™ 06 face milling system.Seco’s new generation Octomill™ size 06 features excellent runout accuracy and wiper flat alignment based on high quality and precision cutter bodies and inserts as well as the excellent self-centering and positioning effects of the cutter-insert interface. Essential for proper finishing processes with fixed pocket cutters. Additionally, the balanced cutting forces enhance finishing capabilities, particularly in challenging setups that tent to chatter and vibrations which has a negative impact on the surface finish in face milling operations. Back cutting affects as visual facets during entry and exit of the cutter as well as step over marks from path to path are also suppressed due to the cutting behavior of this system. This makes the new generation Octomill a valuable addition for demanding finishing applications, alongside Quattromill and Square 6.

The Octomill 06 achieves great numerical face milling surface finish values as Rz, Ra, Rmax as well as challenging waviness and flatness values. It also creates a nice and shiny looking surface finish appearance which is often a key request for visual accessible surfaces and a quality criteriaquality criterion for many components.

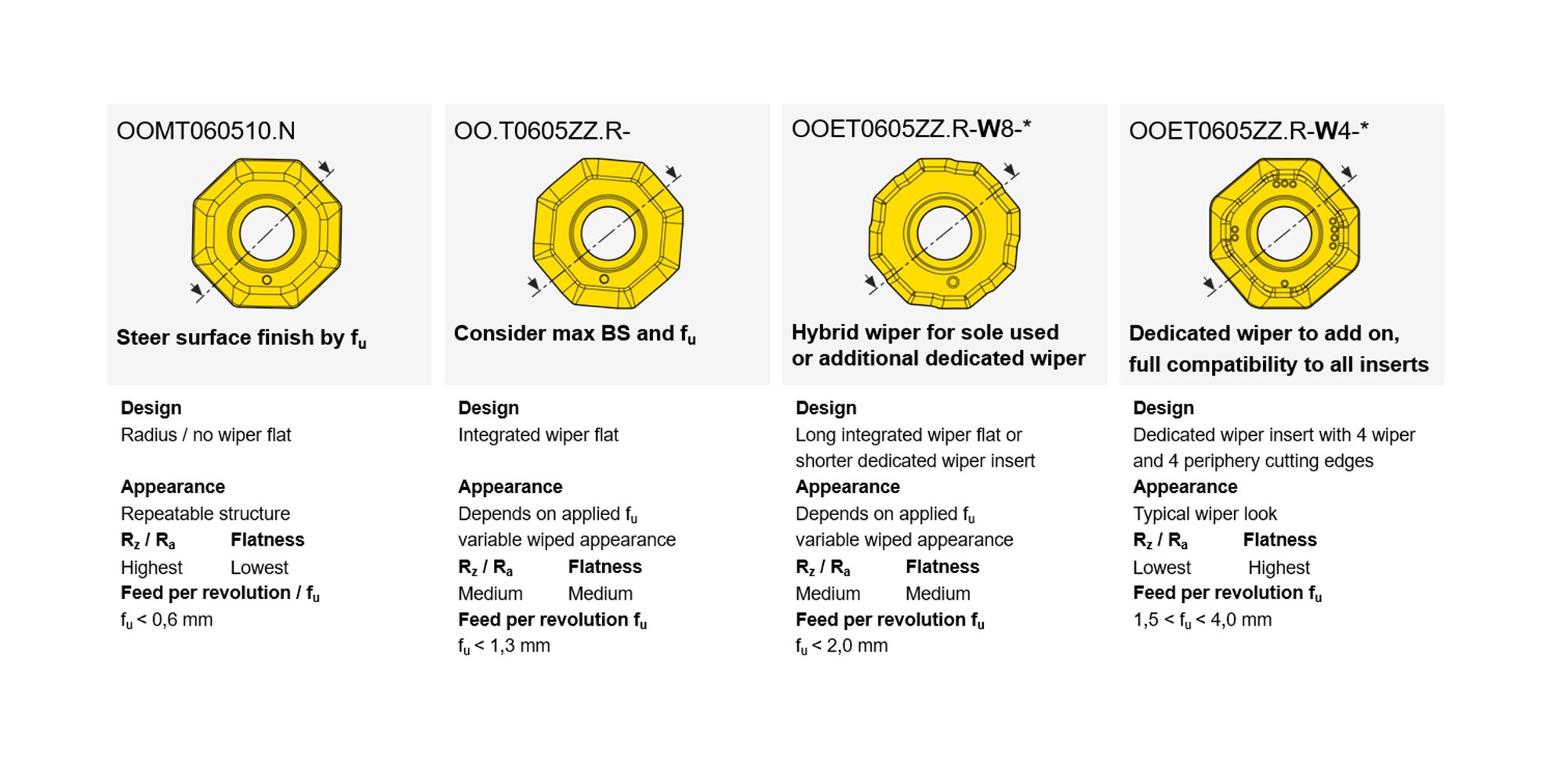

The insert portfolio offers suitable choices for all materials, including finishing applications. The regular inserts are fully compatible with the dedicated wiper inserts, marked with a "W" in the designation. Depending on the face milling surface finish requirements, the table below provides guidance on the most suitable insert choice.