STOP STRUGGLING WITH HIGH-PRESSURE COOLANT HOSES, PIPES AND FITTINGS WHEN GROOVING AND PARTING-OFF

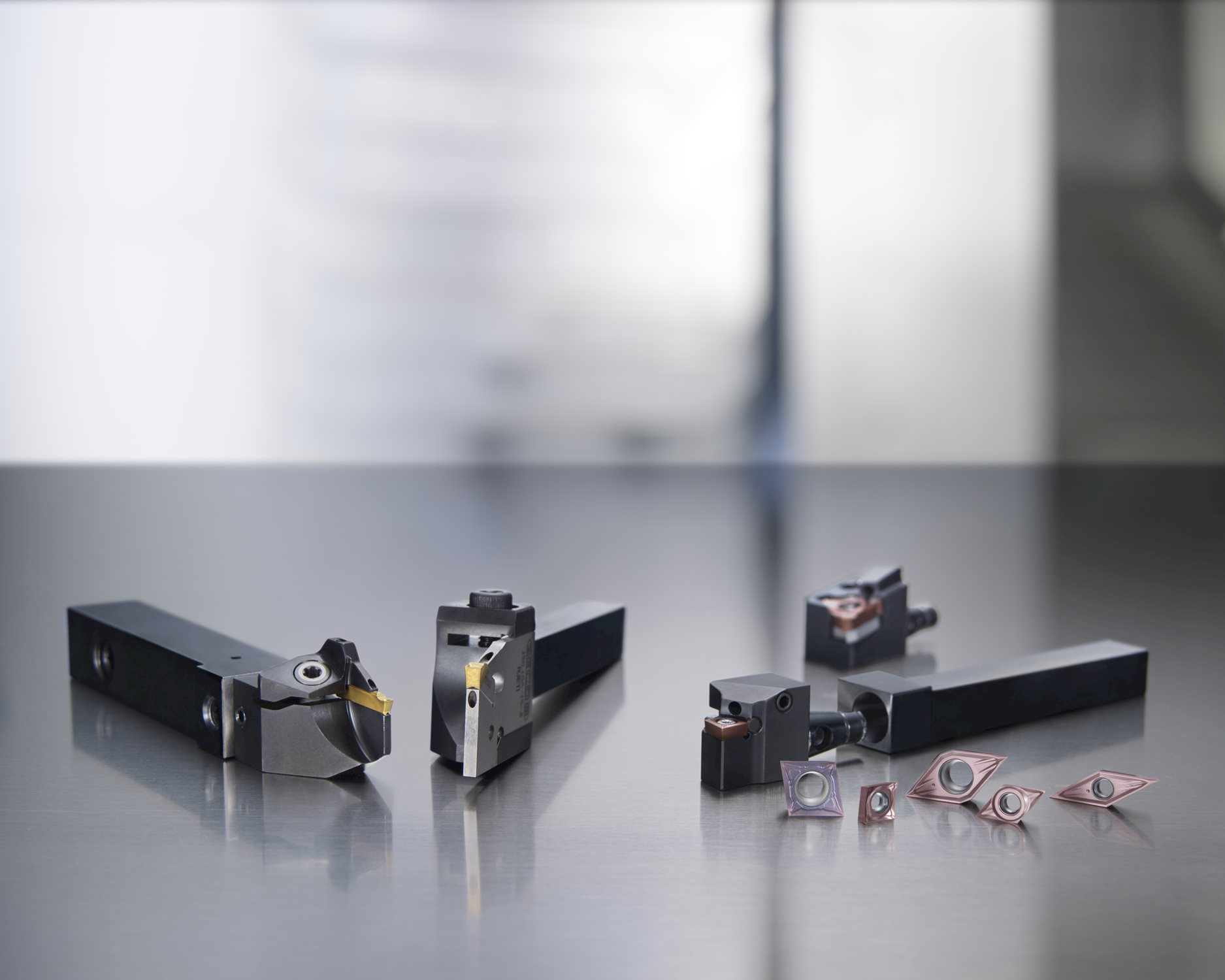

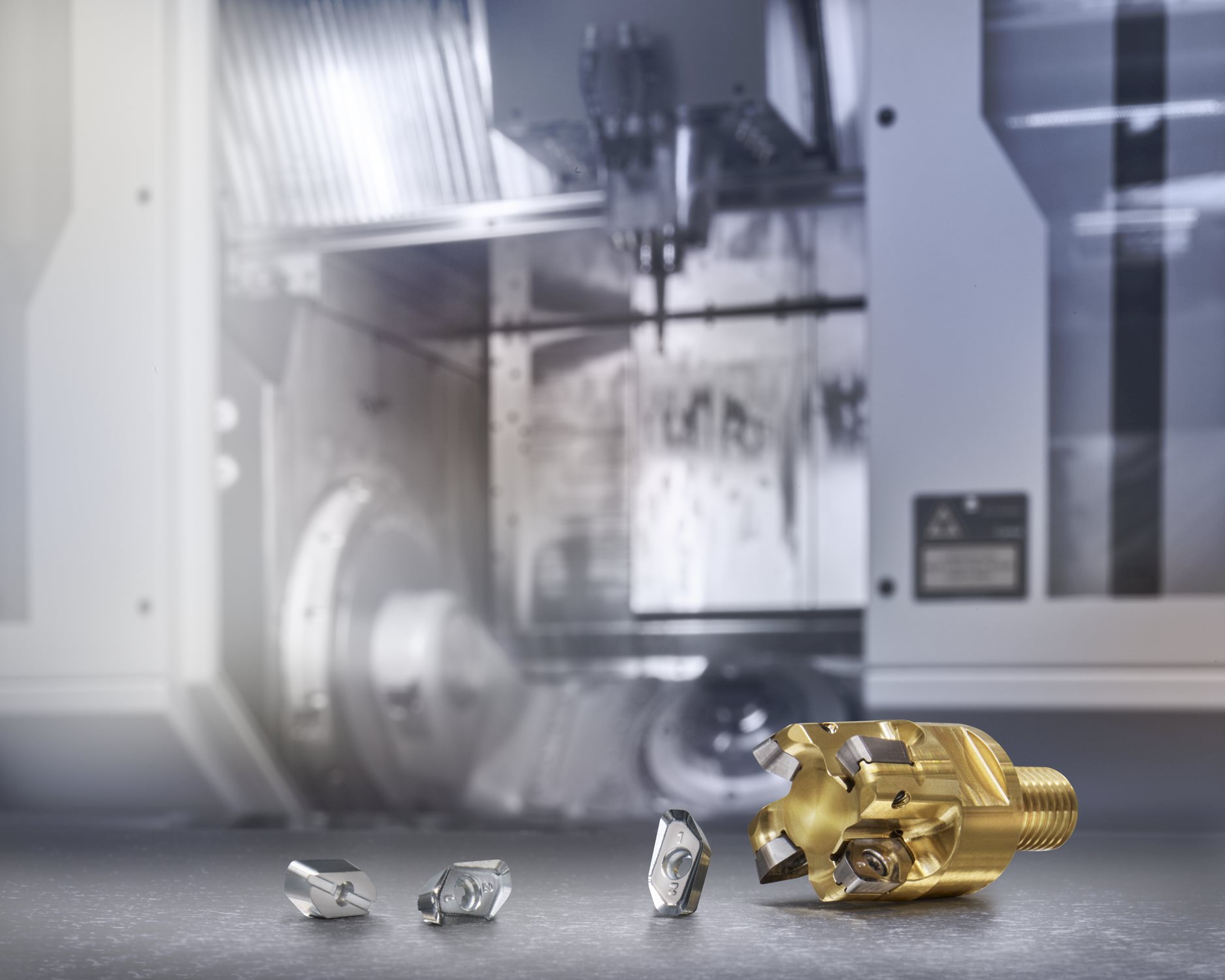

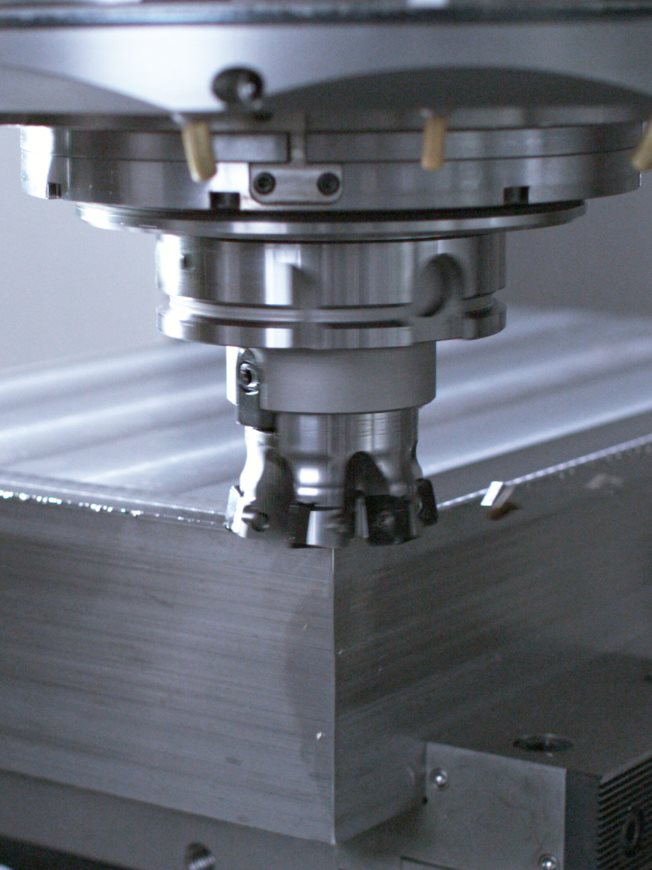

Do away with the components and connectors required for coolant-through tooling that can interfere with your grooving, parting-off and other turning operations when you incorporate Seco’s JETI (Jetstream Integrated) tooling. Achieve optimized machining, chip control and process reliability with Seco’s Jetstream Tooling®, which uses internal channels in the tool holder to aim high-pressure coolant directly into the cutting zone.YOUR BENEFITS

- Operational stability, reliability, improved tool life and surface finishes – all from Jetstream Tooling®

- Application flexibility with Duo JET coolant on or off functionality

- Elimination of hoses, fittings or spare parts increase both productivity and cost-effectiveness

| |

YOUR CHALLENGES: | | SECO´S SOLUTION: |

- External coolant components cause interference during machining

- Poor machining performance due to inaccurate, low-pressure coolant delivery

- Unreliable process due to bad chip formation

- Difficulty in efficiently processing certain parts and material that require either both upper and lower coolant delivery or only one of them

| | - JETI integrated coolant channels for interference-free, precise, high-pressure coolant delivery

- Jetstream Tooling® Duo on/off switch to achieve best performance, by optimizing coolant delivery depending on operation

- Can still be used on machines with conventional coolant supply with connections from side and from the back

|

Related content

Product details

Video: Toolholder DUOJET with On-off switch

Seco Tools Expands Range of Jetstream Tooling® Holders for General ISO Turning

JETI conversion Grooving and Parting-off Capto

Seco News 2019.1

Machining Navigator / Catalog Turning

Seco Nanojet Reamers: reliable precision

Optimize Multi-Task Machining Coolant And Results

Seco X-Tra Long Solid Carbide Drills – 40xD-60xD

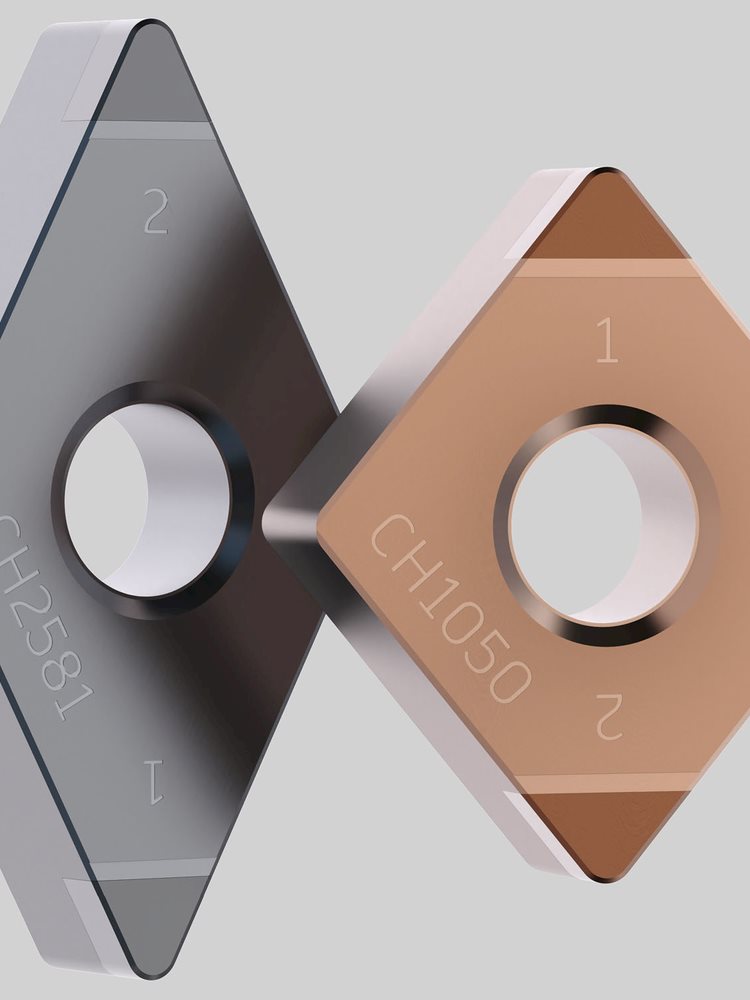

Seco CH1050/CH2581 PCBN Hard Part Turning Inserts

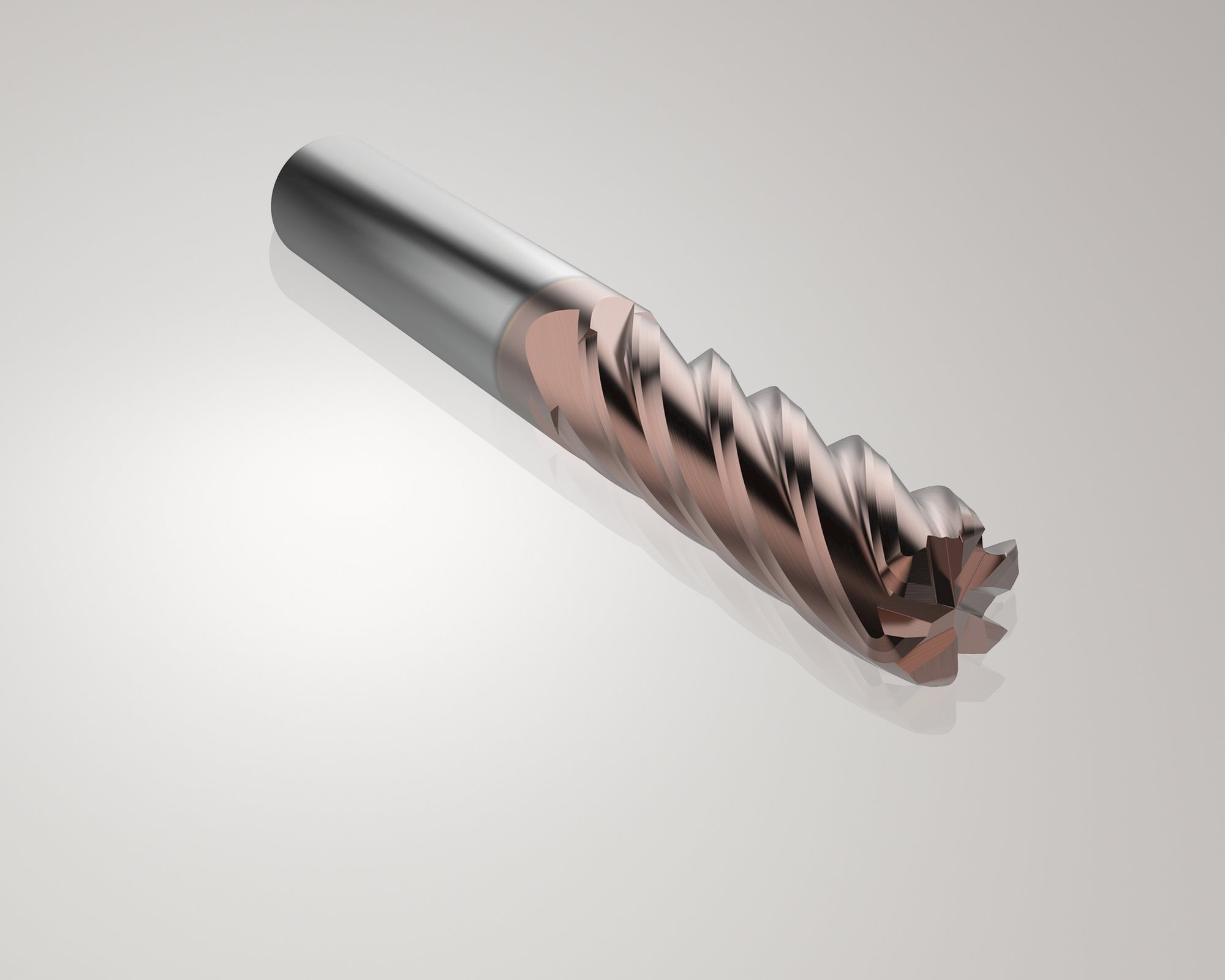

JS720 Solid End Mills addition

Seco Digital Tool Assembly: quick, accurate data

Easy setup with Seco Digital Axial Boring Heads

JH730 Solid End Mills addition

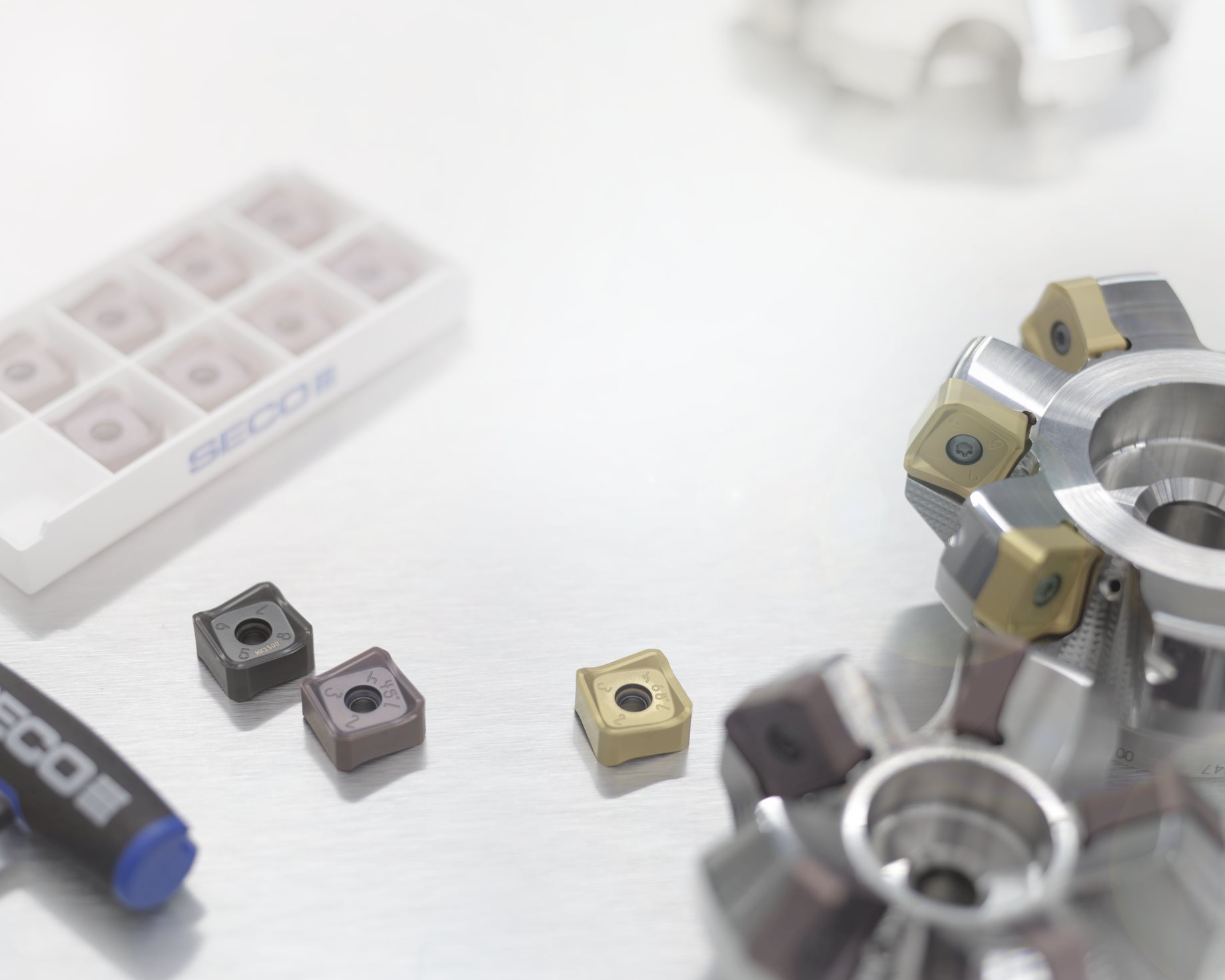

Square T4-12 Upgrades

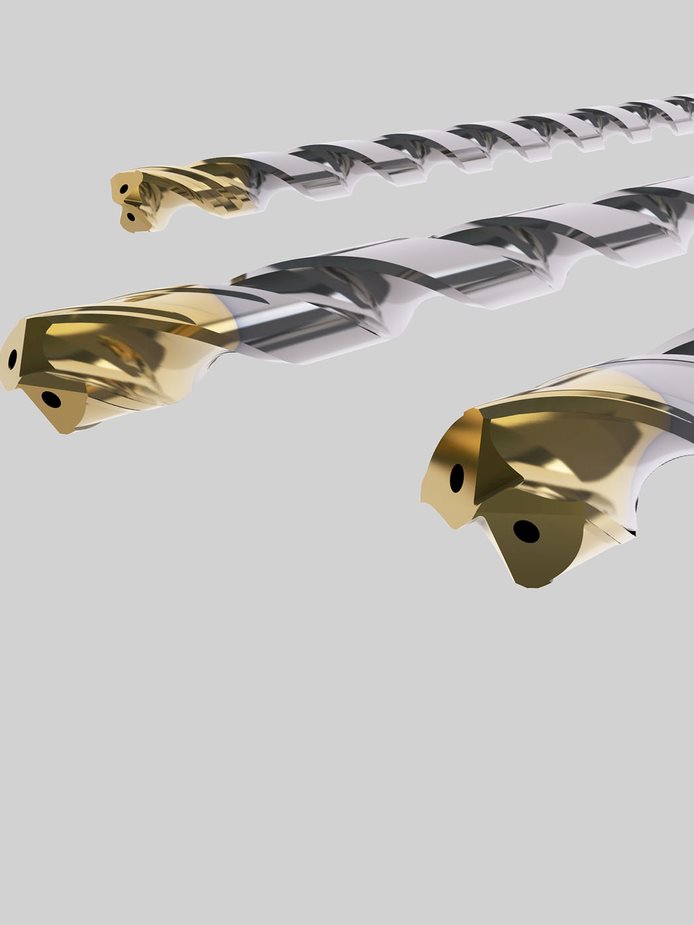

Universal Drills

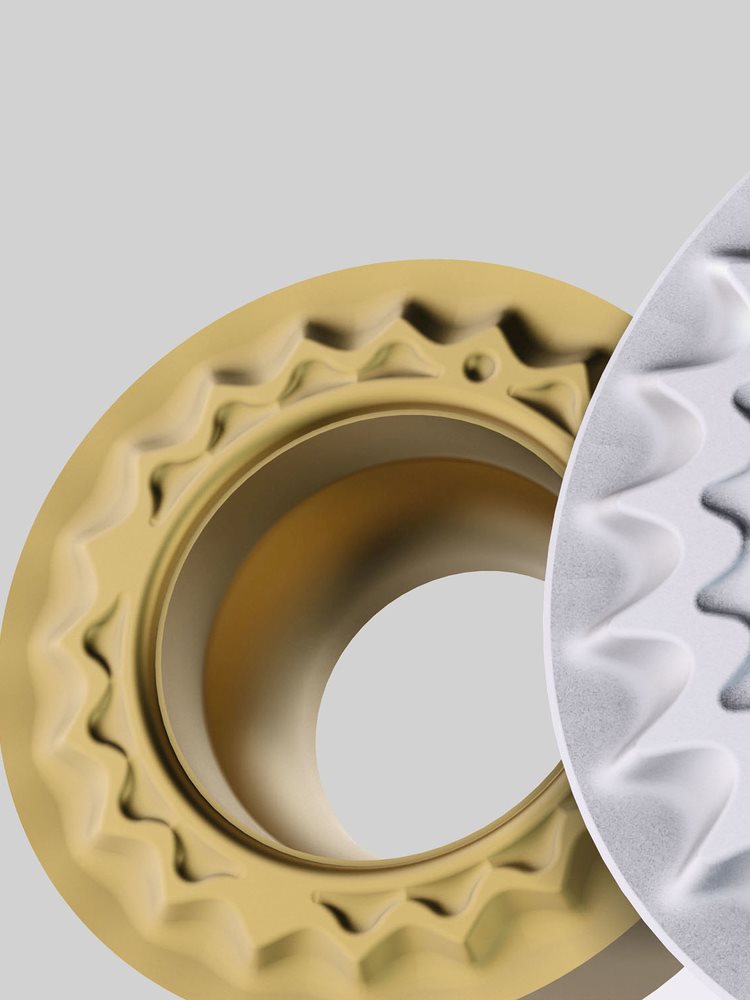

MF2 Chipbreaker on Round RCMT/RCGT Inserts

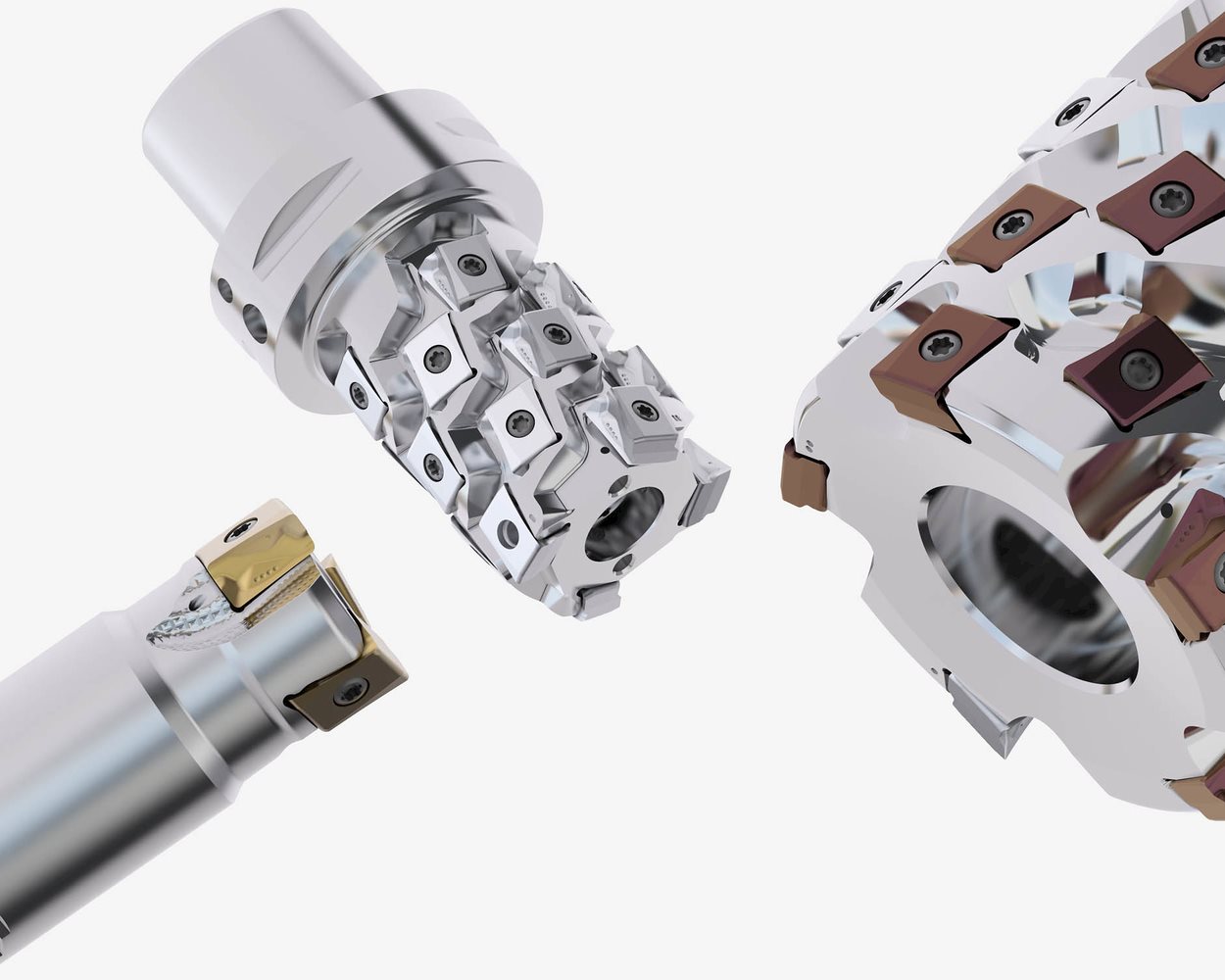

TURBO 16 SQUARE SHOULDER MILLING CUTTERS

Steadyline® ø25mm (1”) series

JM100 MINI END MILLS

TTP2050

DOUBLE QUATTROMILL™ 14

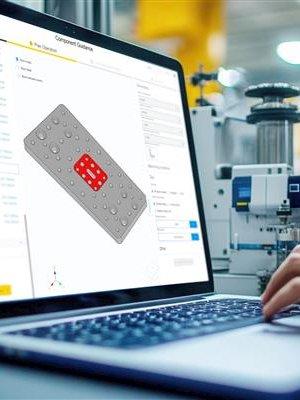

Seco Component Guidance

Versatile Round 20 Inserts Increase Tool Life

Seco Octomill™ 06: Flexible, Robust Tooling

Seco Stabilizer Series: Unmatched Metal Removal

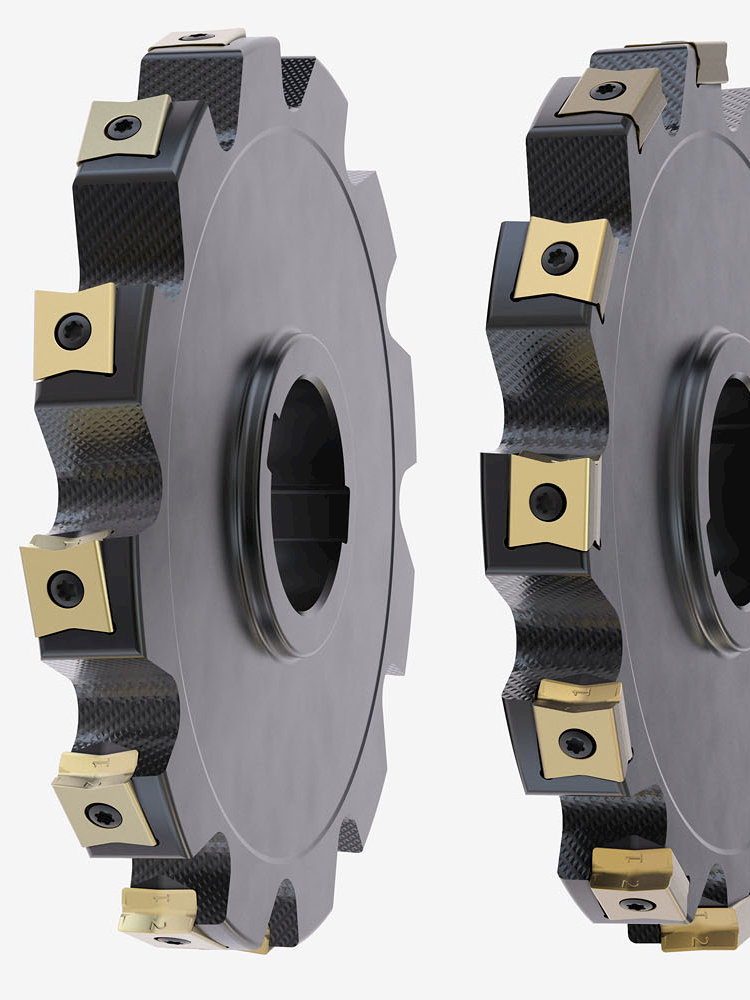

335.14 Disc Milling Cutter extension

Seco T30 Taps: a versatile universal geometry

Seco 335.98 Disc Milling Cutter system

Seco My Design: Design custom tools

Seco Machine Library

Seco T35 Taps: match Tooling to Materials

Seco X-Head Exchangeable End Mill System

Seco Helical LN4-11 Milling Cutter

Guillaume Bourderon appointed Sales Unit Market Manager France

Seco X2 System for Small Part Machining

JETI Toolholder for RCMT/RCGT Turning Inserts

Seco S43/S45/S46 Solid End Mills for Aluminum

Turbo 12 & 18 Chip Splitter Inserts

Seco C-Series General Purpose End Mills

Machining Navigator / Catalog Holemaking

Machining Navigator / Catalog Threading

Machining Navigator / Catalog Solid End Mills

New MP Milling Grades

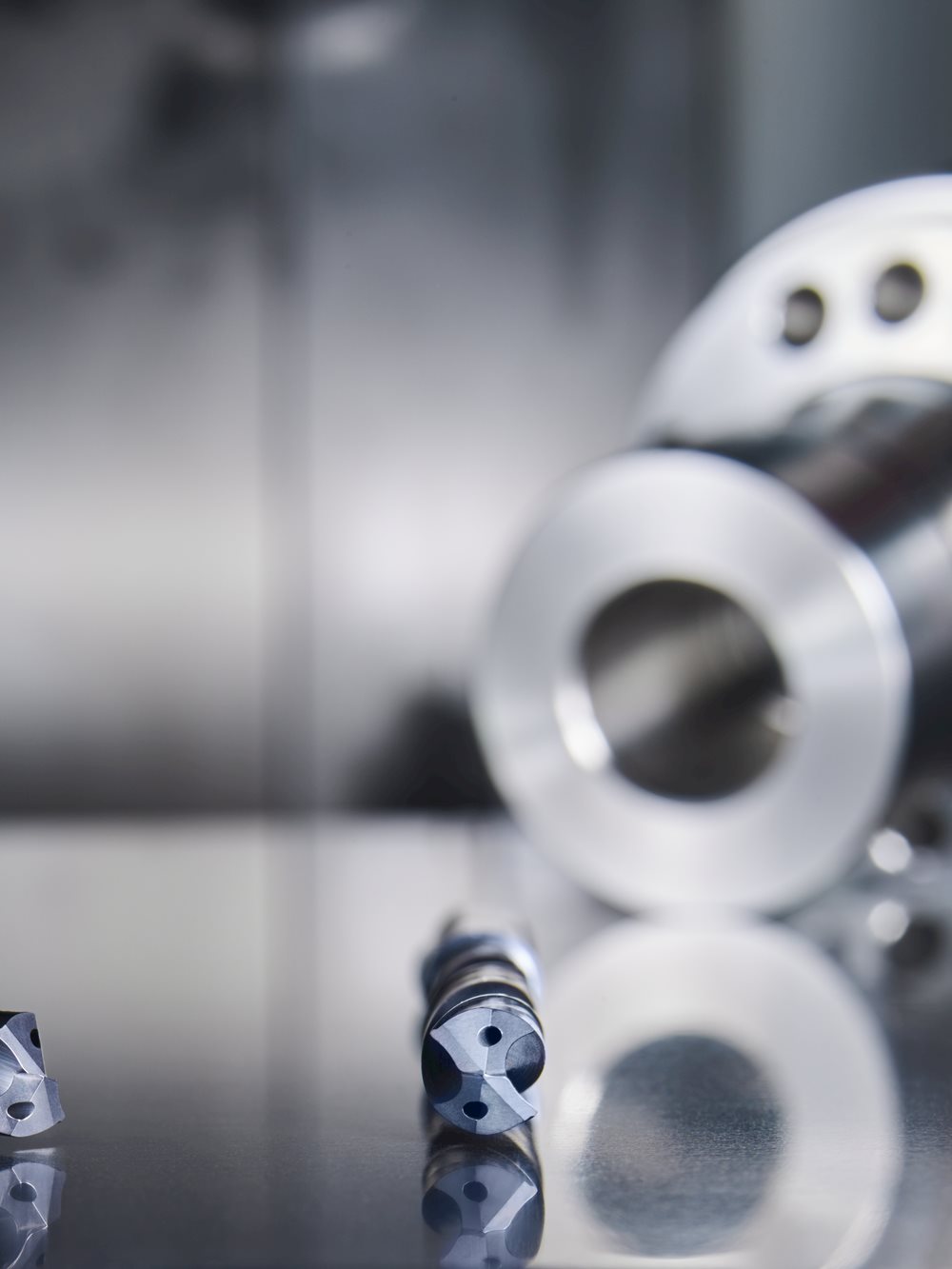

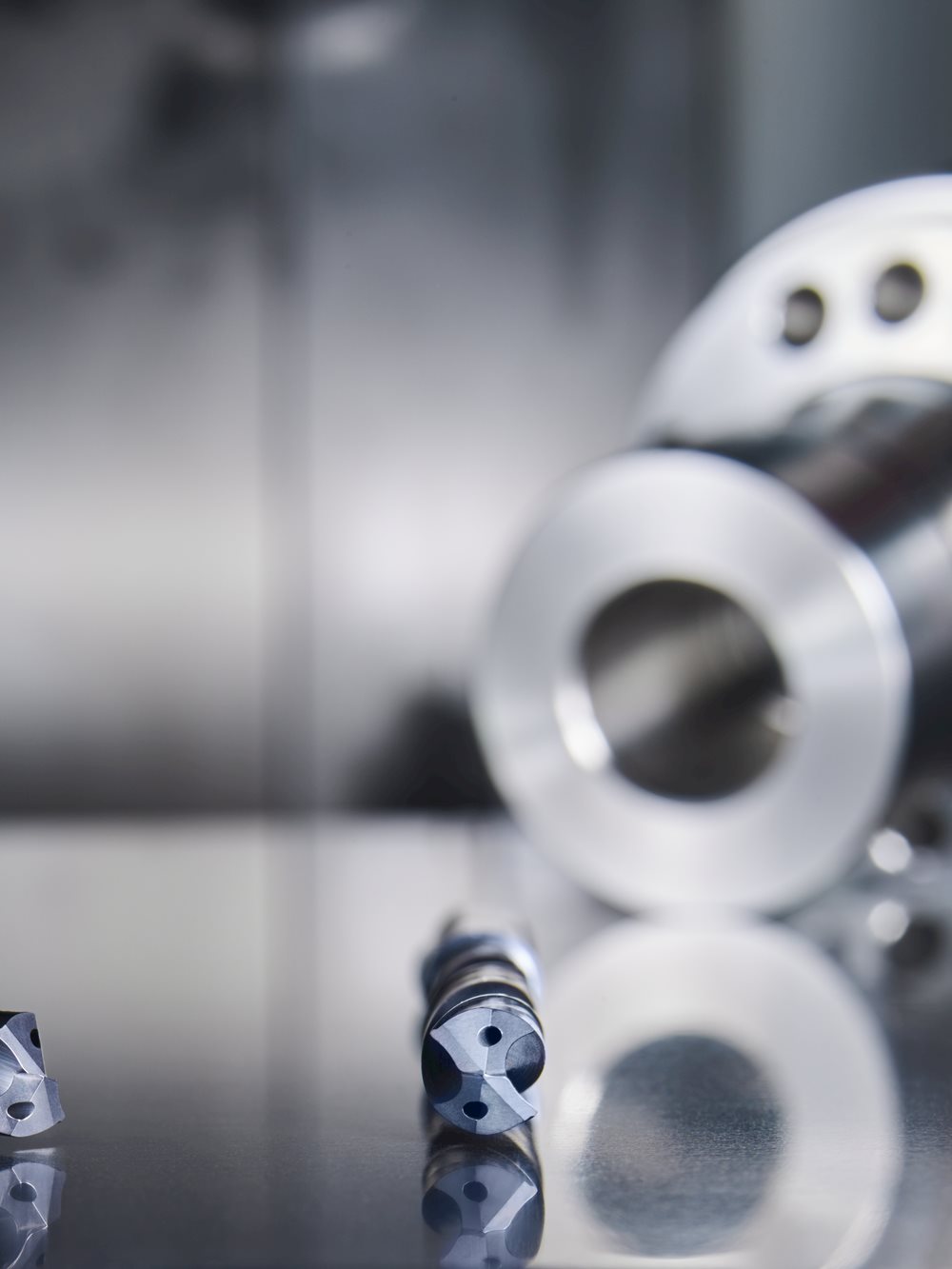

Unleash your drilling potential

JETI ISO Toolholder range extension

Modular QC (quick-change) toolholder for small part machining

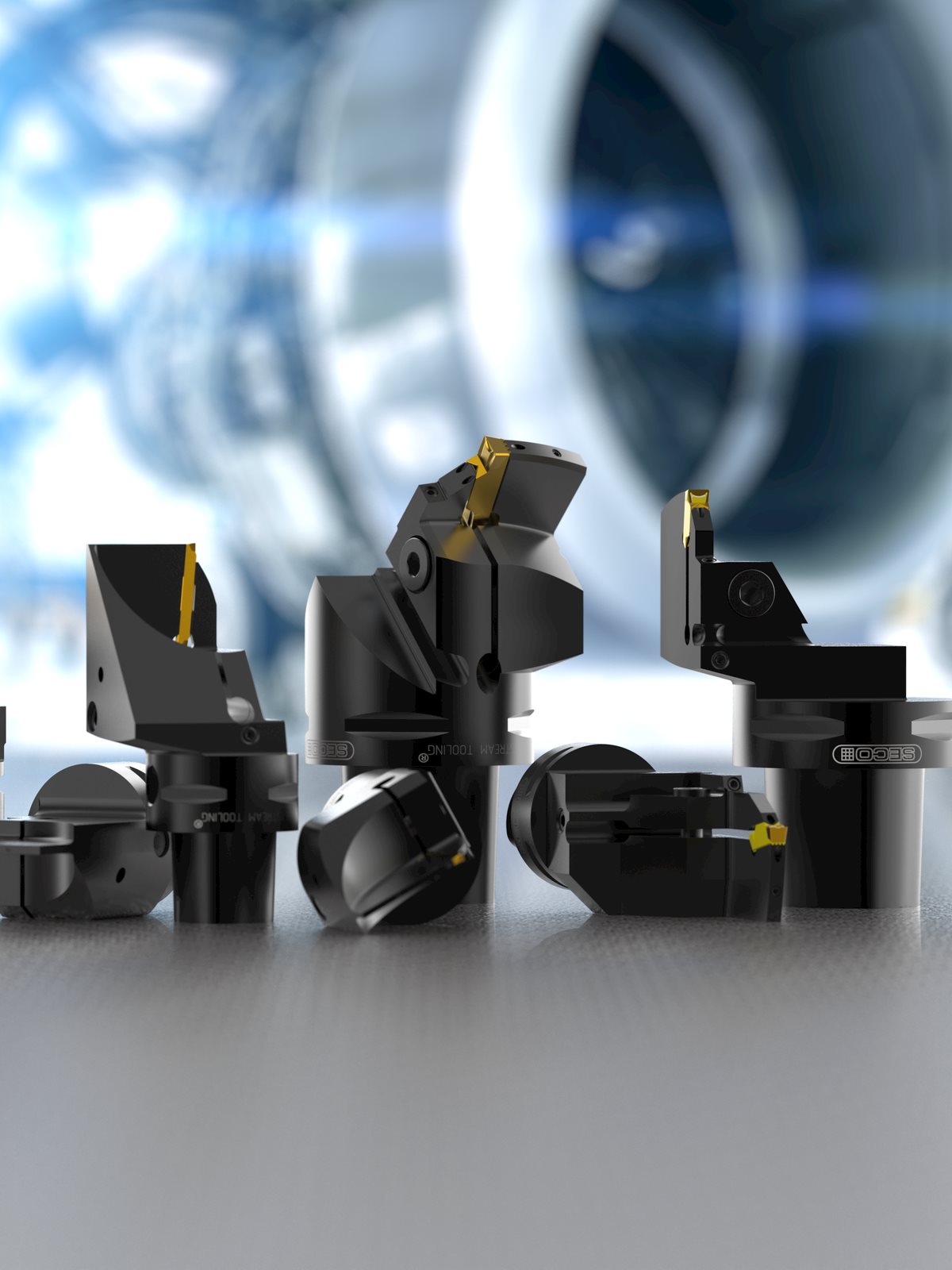

SECO-CAPTO TOOLHOLDERS & CASSETTES FOR ADVANCED MATERIAL

XP08 ALUMINIUM ROUTER

RANGE EXTENSION OF SHELL MILL HOLDERS, SMALL FACE & SIDE LOCK HOLDERS IMPROVEMENTS

COMBIMASTER™ M20

EASYSHRINK EVO

UNIVERSAL DRILLS 8XD AND 12XD

SECO ROUND 10 AND 16 COPY MILLING INSERTS

DOUBLE TURBO 16

High Feed square cut size 14 insert

ISO K THREADING TAPS

R220.88 WITH SNMU INSERTS

DOUBLE OCTOMILL™

DOUBLE QUATTROMILL™ 22